An investigation into the applications of composite materials focusing on how they have either replaced traditional materials or allowed innovations to be realised from a performance perspective. Through use of a survey and interview, the author assessed consumer and expert opinion that composites have moved from being a highly performing technical material, reserved for the most extreme applications, to an aesthetic material appreciated for its cosmetic values. The research also looks into where the future may lie with the development of new processes and materials.

From automotive and military applications to furniture and fashion accessories, composite materials have become a significant material choice for a vast range of industries. The substantial advantages that composite materials can provide means that, they have become a reliant resource in endless applications. The lightweight properties and strength capabilities are far superior to other materials and, this has led to innovations that otherwise simply would not be possible. What exactly is a composite material? By definition, composite means, 'Made up of several parts or elements' (Collins,1984) so in the case of a composite material, they are made up of 2 or more constituents. Typically, it is a reinforcing substrate or substrates suspended in a bonding matrix to distribute load between the reinforcing fibres. The overall aim of combining these materials is to optimize properties, so that the finished product performs better than the individual materials would on their own.

This research aims to look into the changes and innovative developments that composite materials have undergone and with the aim of exploring how they have been implemented by designers into a plethora of applications. Combining information from a varied range of sources, the author aims to gain an in depth understanding of the history and development of composites as a material for design and what their future may hold.

The aim of this study is to investigate the use of composites as a design material and what direction they might take in the near future. Also, gaining insights into how they have become a more popular and desirable choice of material in everyday products as well as specific applications.

Q1- How do composites directly compare to more traditional materials in terms of strength, stiffness, weight and other key areas ?

Q2- Have composites allowed developments that would not be possible without their advanced performance ?

Q1- Are composites becoming more of a fashion accessory rather than a dedicated functional material and what has helped to cause this change in application?

Q1 - In terms of materials what is currently being investigated and what might the future hold?

Q2 - How have processes developed to cater for the ever changing demand in performance and cost?

Advanced composite materials such as the prepreg carbon fibre matting, that is used in the likes of high end applications such as Formula 1, are relatively young materials. Rudimental composite materials have been discovered to date back to 1500 BC when Egyptian builders would use straw mixed with mud to create a stronger more durable material to build with. The straw will be acting as long thin fibres adding additional strength to the mud, which acts as a glue, holding it all together (Johnson, 2015). A few thousand years later, around the time of Genghis Khan in around 1200 AD, the Mongols used a combination of natural materials, bamboo, bone, cattle tendons and silk, all bonded together with natural pine resin (Figure 1). The bows were small, but due to their unique construction, they were extremely powerful and lightweight compared to anything that had been seen before. So much so, that the composite Mongol bow was the most deadly ranged weapon until the widespread use of gunpowder firearms in the 14th century (Mar-Bal Incorporated, 2015).

Figure 1. Mongolian Composite Bow (Wolfe, n.d.)

The idea of modern composite materials was initiated with the invention of plastic materials starting with Bakelite in 1909 (Bucquoye, 2002). Shortly after, more plastics like vinyl, polystyrene, phenolic and polyester were created. As these new synthetic materials were outperforming their natural resin counterparts, they quickly became hugely popular and the plastics industry was born. The 1930's were where composite materials were first conceived in their most wellknown format. In 1935, Owens Coming launched his fibre reinforced polymer, a series of glass fibres suspended in matrix of unsaturated polyester resin.

As the industry grew, and more development and research was undertaken, the hugely beneficial properties of composite materials were realised. With this, new techniques for optimising the characteristics of the material were put to use. In 1950's, automated manufacturing methods such as pultrusion, filament winding and vacuum bag molding were established as key processes in the composite material industry (Mar-Bal Incorporated, 2015). The space race and other engineering challenges that were being tackled in the late 50’s and 60’s demanded materials that were stronger and lighter than what was available. Being able to withstand the ferocious temperatures associated with re-entering the earth's atmosphere, scientists looked into various solutions like adding asbestos fibres into a phenolic resin, another route considered was metal matrix composites to try and solve their issues. These consist of an inorganic or ceramic fibre which adds heat resistance to lightweight metals, thus reducing the coefficient of thermal expansion, allowing the materials to perform better under extreme temperatures. This investigation with new materials led to a very important discovery. In 1964, a new polymer based material was developed at DuPont industries by Stephanie Kwolek. This new fibre with tensile properties five times that of steel, was created, and goes by the trade name ‘Kevlar’. This had a massive impact on the way that composite materials were used, the possibility of a lightweight material stronger than steel allowed designers to develop products that simply weren't practical beforehand. New super tough helmets were lighter and provided more protection and also the development of bulletproof vests was made possible by the invention of the Kevlar aramid fibre (Palucka Bensaude- Vincent, of N/A, 2015).

As the requirements of composite structures have become more specific and more demanding, the ways that the materials are used has also changed. Rather than using multiple layers of fibre matting for increasing the weight of the component, a sandwich construction is used. These typically require a stiff foam core or some form of honeycomb structure, that is made up largely of air, therefore has little mass, this is then surrounded by a resin infused matting, to provide the strength. These sandwich components have a very good strength to weight ratio and are incredibly stiff (Hu & He, 2006). One of the drawbacks to these components is that, due to the thinner layers of matting and resin, it is possible to puncture the outer skin and expose the foam core. This type of construction is commonly found in high spec racing kayaks.

The idea of automating a very labour intensive process is a good way to increase production output, turnover and ultimately profit. Traditionally, hand layup was the only way to produce the intricate shapes that composite materials are capable of being transformed into. An operator is required to apply all of the various layers by hand into the mould, ensuring that all of the matting is sufficiently wet out with resin. A solution to this was the introduction of the spray up process, replacing the long woven fibres of matting, spray up uses a spray nozzle to spray out the resin similarly to that of a paint spray gun. Into this resin, short fibres are added and become randomly orientated as they are sprayed onto the mould. This method allows for a very even thickness and uniform properties throughout. Its a very desirable feature as inconsistencies can lead to stress concentration and failure (Edmondson, 2013).

Although intended as a highly advanced engineering material developed for structural advantages and weight saving capabilities, composite materials (predominantly carbon fibre) have become somewhat of a fashion accessory. Carbon fibre which was once reserved as an expensive commodity set aside for high end applications can now be found on pens, knife handles, mobile phone cases, sunglasses and various other everyday items. To some, it may seem unnecessary and wasteful that composite materials are used in such applications.

'Worse, once you've had a few, you might inadvertently tell people that your car is made of carbon fibre, and then they'll think you're a big chump (May, 2007).

The idea of carbon fibre representing quality, cost, and high precision has gone so far that people are willing to use vinyl wraps that imitate the effect of a carbon fibre panel with clear gel coat. It is of some people's opinion that this goes against the pretext that composite materials are predominantly a weight reducing performance material, and adding the weight of a graphic that provides no additional performance properties is highly contradictory. However, due to the growing number of everyday items made from carbon fibre that are available to buy, it would appear that there are others who would disagree.

One of the main reasons that composite materials are chosen by designers is that, the characteristics and performance can be far greater than traditionally used materials. In some cases, this has gone so far that it simply would not be possible to manufacture components out of any other sort of material whilst still getting worthwhile performance.

One clear advantage that composite constructions have over more traditional materials is, the stiffness to weight ratio. The combination of properties in the materials provide a very rigid substrate that is also very light. Figure 2 shows the relationship between density and stiffness for a range of materials, composites, their constituents and also some comparable materials such as high carbon steel, titanium and aluminum.

Figure 2. Young’s Modulus vs Density (CES 2015) (CES EduPack 2014, 2014)

Figure 2 clearly shows that, for a similar value of stiffness the synthetic reinforcing materials are far, far lighter than materials like titanium and high carbon steel. The graph also shows how much stiffer carbon fibres are compared to the rest of the selection. This incredible rigidity in relation to lightness means that carbon fibres are used heavily in high performance applications. A good example of this is the aerospace industry, sending material into the sky is very fuel intensive, therefore every kilogram that can be avoided in the construction of the aircraft will have big savings later on in its lifetime. In an airliner, the use of carbon fibres can make a huge difference to the weight of the aircraft, typically 20% less than aluminum and 50% less than steel, this makes a massive difference to the fuel economy and weight carrying capacity (Verhelle, 2002). Additional stiffness can be achieved by laminating a layer of closed cell foam in between two layers of surface material. The finished product is incredibly light due to the low density of the foam, and incredibly stiff due to the separation of the surface skins. However, the risk of buckling and localised crushing does increase with these materials, which can have a detrimental effect on the overall performance (Gay & Hoa, 2007).

One major downside to carbon fibre and all composites in general is that, it is expensive in comparison to more traditional material choices. Using the same materials as Figure 2 for comparison, Figure 3 shows the relative material cost in relation to its young's modulus. Due to the energy intensive production methods, the synthetic fibres are considerably more expensive than their steel and aluminum counterparts (Zoltex, 2014).

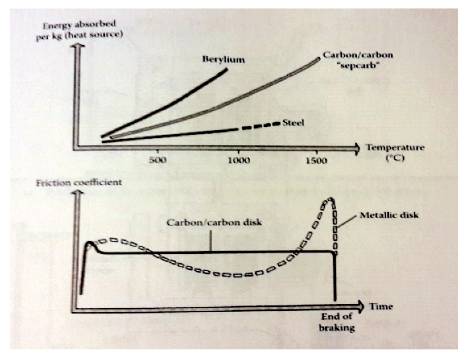

Thanks to their superior performance, composite materials are being used to replace traditional materials in order to improve the capabilities of the component. One example of this is carbon brakes, a traditional steel brake disk which is essentially a heavy lump of metal. As seen above, carbon is a significantly lighter material and where, lightness is a key which can add up to a significant saving. A good example of this is in aviation, where the weight saving can be over 400 kg for a large airliner. To put this into perspective, it has been estimated that just 1kg reduction in weight can save up to 2999L of fuel per year. Carbon also has higher energy absorption capabilities than steel and is more resistant to thermal expansion, retaining its mechanical properties well at high temperatures. Another advantage of using carbon as a break disk is its frictional stability, as the temperature rises as seen in Figure 4, the coefficient of friction for steel fluctuates considerably under the braking process, while carbon is much more consistent (Verpoest & Bucquoye, (2002), Gay & Hoa, (2007), Boeing, (2009) and Soutis, (2005)).

Figure 4. Comparison of Friction Coefficient and Energy Absorption for Steel and Carbon (Gay & Hoa, 2007)

Composite materials have heavily influenced the sporting industry and designers are constantly coming up with new and innovative ways to make use of their advanced properties. One relatively new example of this is apparent in the latest racing boats for Canoe Slalom built by Galasport. Not only are their boats are made entirely from composite materials, they also use them in interesting and slightly unconventional ways. Working with another company “COMPOTECH” which is specialized in the manufacture of composite beams, tubes and dampers, they have come up with an interesting design solution.

Although the advanced composites that go into theses, high spec racing boats allow them to be extremely rigid and lightweight (down to 6.8kg for a 3.5m k1), they do have a downside. Due to the nature of the sport, it is not uncommon that, these boats will come under enormous and instantaneous impact forces. Paddling on extremely powerful white water is technically challenging and a slightest mistake from the athlete can have disastrous consequences for the boat. With the force of the water pushing the boat about in all sorts of directions, rocks and other obstacles including, the river bed itself can become real hazards. The super lightweight construction required means that, these boats are nearly always a sandwich construction of three major layers. The top and bottom layers are made from various mattings depending on paddler choice and requirements, while the middle layer is made from a core material. Most commonly with canoe manufacturers, this comes in the form of a closed cell PVC (Polyvinyl Chloride) foam (Vajda Group, 2014). The use of a foam core reduces the weight of the construction, while still keeping its desired rigidity, however it does have its drawbacks. Due to the addition of the core layer, the risk of buckling increases, they also have no effect on the dampening of impacts (Gay & Hoa, 2007).

One of the common incidents that occur is that, the athlete will lose control of the boat in one of the hydraulic features on the river, where the water is actually moving down towards the bottom of the river bed. Due to the speed and power of the water and lack of compressive strength, there is a real risk of fracture to the outer skin of the boat and permanent deformation to the foam core. This can be devastating to the structure of the boat, not only is there the possibility that the boat will start to sink, there is also the likelihood of long term damage to the structure. If there is fracture of any sort, there is a high chance that, water will start to ingress between the layers where it will start to wick and gradually spread over a large area. Not only does this add weight to the boat, but it can also cause delamination of the layers, significantly reducing its strength (Figures 5 & 6).

Figure 5. Closed Cell Foam Pillar in the Tail End of a Boat

Figure 6. Glasports Innovative Carbon Kevlar Rings

In order to help counteract this and remove some of the forces away from the deck and hull sections, manufacturers have previously used a foam rib placed longitudinally along the boat in the bow and tail sections. This column is adhered to the top and bottom of the boat and helps to add strength in compression by absorbing the energy, if the impact. The problem with closed cell foam as a strengthening material is that under compression, the individual cells fail and collapse (Linul, et al., 2013). The resultant plastic deformation means that, the foam support can only really do its job once before it becomes redundant. Glalasports innovative solution is to replace the rigid foam rib with a series of composite rings.

Made from a carbon Kevlar matting, these rings take the place of the rigid foam rib. Not only are they lighter than the foam counterpart, due to their ability to elastically deform and return to their original shape, they are considerably more effective at absorbing energy over a continuous period of time. Figure 7 shows the position of the rings and how they help prevent the boat from fracturing under a strenuous situation.

Figure 7. Explanation of the Ring Technology (Galasport, 2012)

Composite materials also allow for feats of engineering that simply wouldn't be possible using alternative construction materials. Aircraft design is one industry that has made best use of these advantages, producing components that just wouldn't be possible with metal fabrication techniques. Composite materials combined with modern mould tooling allow for incredibly complex designs, variable camber twisted wings can provide enhanced aerodynamic efficiency in flight. The Boeing 777x has an ingenious wing design, which allows it to flex upwards during flight, this improves airflow, reduces drag and ultimately saves fuel, technological feats such as this would not be possible without the application of composite materials. Aerospace manufacturers are also coming up with inventive ways of modifying existing processes to cater for their needs, for the B787 Boeing manufactured a fuselage section using a filament winding technique on an enormous scale. The tensile hoop strength properties of the fibres when orientated in such a way are critical in sustaining the difference in internal and external pressures. By optimising the properties of the material and the associated manufacturing processes, the part can be made as one piece, due to the slightly ovular profile of the fuselages cross-section, this would be highly unfeasible using aluminium (Soutis, (2005), Marsh, (2005)).

It is clear that, composites (especially carbon fibres) have an aesthetical application as well as a functional one. Carbon fibre is left with its fibres exposed under a clear gelcoat in a number of applications, where it would be just as easy to apply a colored pigment. There could be a number of reasons for this, do people actually like the effect or is it simply because people want to show off the fact that they are using high performance carbon fibre as a material?

Throughout the author's initial research into the general area of composites, it was apparent that, not everyone has the same opinions about their use as an aesthetic material. A quote from a car enthusiast James May featured in an earlier section of this research suggests that, there are those with the opinion that carbon fibre is a bit gimmicky, and not really worth all the hype that surrounds it. He is not alone with his views, a quick internet search using phrases including 'opinion on carbon fibre', 'carbon fibre aesthetics' and various other searches bring up a variety of blog posts with critics and die hard enthusiasts arguing over the aesthetic values of carbon fibre. A common theme goes something along the lines of 'How will a carbon interior look in my car?' and then proceeds the argument.

There are a range of posts posing the questions to the current relevance of carbon fibre, in particular, one found on the Tesla forum questions is, if anyone still likes the look of Carbon Fibre. Another blog style webpage give examples of '18 stupid uses of carbon fibre', while another questions its longevity as an aesthetic application, comparing it to ‘vinyl wood trim’ (Danej, (2013), Liszewski, (2012), rex8499, (2014)).

There are definitely arguments for the use of Carbon fibre in aesthetic applications, in 2007, Apple filed a patent for a forming process to 'improve' the aesthetics of Carbon Fibre stating that, the current material and processes can lead to non-uniformity and other cosmetic imperfection, also the limited range of surface finishes can lead to a tired look (Foresman, 2009).

Wood, flax, hemp, wool are just a few of the naturally occurring fibres that can be used as a reinforcement for a composite structure. Since the late 1990's, the composite industry has had a renewed interest in the development of natural fibres. The ever growing pressure on industries to reduce the consumption of fossil fuels and the planets limited resources means that, the use of natural fibres has become a very important area for investigation. Although they initially show significantly poorer mechanical and chemical properties than the synthetic fibres more commonly used, extensive research is being conducted to try and improve their integration with existing and new matrix materials (Hodzic & Shanks, 2014). Another issue with natural fibres is that, there are massive inconsistencies with the material. It can vary hugely between plants, crops and even the conditions in which they were grown. This however can be solved with a developed selection system similar to that used in the textiles industry (Crosky & Soatthiyanon, 2014). The two main areas that needs to be addressed is the resin compatibility and the absorption of moisture (Westman, et al., 2010). On the positive side, natural fibres have significant cost advantages than synthetic fibres. They require far less processing to get them to a useful stage, not to mention the advantage of biode gradability, which gives them an important advantage when it comes to environmental concerns (Ticoalu, et al., 2010) .

It's widely known that, the material from which the spiders make their silk has many useful properties and is regarded as one of the strongest natural materials known to man. Over millions of years, these fibres have evolved to overcome two major restrictions, the strength to absorb energy of an impact from an insect or other flying creature. They also need to have an incredibly small diameter in order to avoid detection. It's this impressive strength to weight ratio that has warranted it so much attention (Turner & Karatzas, 2004). When comparing the tensile strength of spiders’ silk to even some of the most advanced synthetic materials like Kevlar, the values are remarkably similar, however spiders silk is lighter and less dense meaning it could have massive implications for a wide range of applications (Hsia, et al., 2012).

Recently a study was undertaken to investigate the tensile properties of limpet teeth, which are used by the creature to cling onto rock during feeding. The study shows that the material that these teeth are made from has the highest recorded tensile strength of any biological material outperforming spider silk, previously thought to be the strongest natural material. Combining this material as a short fibre reinforcement with a suitable matrix could lead to an exceptionally high performing material (Barber, et al., 2015).

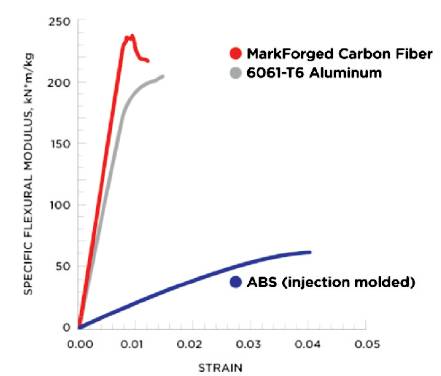

The capabilities of 3D filament printers have progressed rapidly in recent years with the range of possibilities ever increasing. Also the price has fallen drastically to, making them more accessible to more people. One of the main drawbacks to 3D printing is the strength of the finished part, due to the way that the parts are made in layers they do have internet weakness (Figure 8). Composite materials can go a long way in improving the strength of the finished part in exactly the same way that they are used to reinforce a matrix material in any form of composite material. In the case of a filament 3D printer, the fibre is simply co extruded with the molten polymer and laid out in the same fashion. The result is a complex 3D printed part that has higher strength to weight than aluminum (MarkForged, 2015) .

Figure 8. Flexural Modulus vs Strain for 3D Printed Carbon Composite Compared with Aluminium and Acrylonitrile Butadiene Styrene (ABS), (MarkForged, 2015)

In order to get a better idea of the consumers' opinions on carbon fibre as an aesthetic finish and how they view it as a fashion material in everyday products, the author conducted a survey to gain further insight. The main aim is to understand their thoughts on the use of the material in applications that are not necessarily structural, and see how they feel about the additional costs that can come with carbon fibres as an aesthetic finish. There is also a brief section on the environmental aspect of using a material that is difficult to recycle, purely as a cosmetic feature. The survey allows for a clear understanding of people's actual ideas to be collected and assessed, by tailoring questions carefully. A survey can extract the most important information in a relatively clean way. Multiple choice questions give the participants a degree of choice, but not so much that it becomes difficult to actually obtain and understand what is their thinking.

Interviewing an industry expert allows for an interesting perception and opinion that is otherwise inaccessible. By questioning an individual, who has spent considerable amount of time working with the material, there is a vast wealth of knowledge to be accessed. Not only is the information relevant and up to date, but a calculated estimate can be given as to which way the industry may develop based on experience. This is being based on current developments and arising issues. It is also possible to build upon and question answers to gain further information and ask why certain opinions are so. The only issue is that, these interviews provide the opinion of a single individual biased towards the industry, therefore care has to be taken when analysing the results.

The survey results are presented in Table 1.

A summary of the main points from an interview with the author and an industry expert Paul Statham from Easy Composites are presented below.

What have been the developments since you've been involved with composites?

Has CAD/CAM been able to influence the industry in any way?

What is the newest material that you're working with?

You mentioned the use of thermoset resins and recycling with natural fibres, how do you dismantle the fibres form the matrix?

What direction do you see composites going in the near future?

There's been a recent hype about limpets' teeth being classed as the strongest material known to man, do you ever see things like this and maybe spiders silk being used as a reinforcement material?

Are there any consistent issues that you have to manage on a daily basis that you would like to see solved or improved?

Obviously as someone in the industry you are constantly surrounded by the material, but how do you see carbon fibre as a fashion material and what is your opinion on that?

The overall consensus from the survey was that, people generally like the aesthetics of carbon fibre, with the vast majority of participants showing an actual appreciation for their aesthetics. Of the 40 responses, 28 said that, they either liked or strongly like seeing the material with only 4 actively showing distaste. The results were perhaps not as expected due to the general opinion that came from the blog posts, that the author had viewed prior to conducting the survey. It was believed that, a larger majority of participants would take the view similar to that of the question posted on Tesla forum (rex8499, 2014). However, from the interview that the author had with the expert, the survey results do reflect what was said about the percentage of sales that go towards aesthetic purposes. He estimated that 50% of their total sales is down to the fact that, carbon fibre has an aesthetic appeal, proving the large interest in cosmetic appearance.

The participants were also questioned on why they feel the way that they do about carbon fibres use in everyday products. The positive feedback was generally based around the lightness that the material can bring to a product, the sleekness and complexity of the forms that can be achieved, was also appreciated. The shininess of the surface and the way that the light interacts with the fibres appears to be a highly attractive characteristic of the material. Another feature that was noted by the participants was the high tech, elitist element, that carbon fibre can bring to a product, giving the effect that it is better than its competitors in some way. The author believes that some of the appeal comes from that fact that, people always want better or newer things, its why there is always a rush for the newest technology when it's released. This same attitude can be related to the use of carbon fibre, the fact that, it has been used in such high end applications can make a product seem better than it actually is. This perceived value makes people believe that, if carbon fibre has been included, a product must be superior in some way.

Contrasting to the positive views discussed above, the participants also provided responses for why they disliked the use of carbon fibre for these applications, a reoccurring theme was the cost of the material. There was also the concern that, the addition of fake carbon fibre (possibly in the form of a vinyl) can actually devaluate the product if done badly. The author believes that, there is a possibility that this sort of thing has effected the overall opinion of the use of composites in everyday applications. Another reoccurring concern that was conveyed is the idea of unnecessarily over engineering everyday products, purely in order to incorporate a composite to use as a selling point. On a similar theme, one participant stated that, they felt composites were designed for functional purposes and are being misused in the case of 'nonstructural' application and this has helped lead to misconceptions regarding the material and its properties. There was also concern shown for the fact that these materials are very difficult to recycle and perhaps designers should be more reserved when thinking of using composites for a purely aesthetic application. These views reciprocate what the author discovered on the online blog posts giving the impression that people see the material as a bit pointless and gimmicky unless used as a structural component.

The participants were also asked as a percentage, how much more money would they be willing to spend on a product containing carbon fibre purely for aesthetic purposes. Nearly 75% of responses were in the range of 0, and 20% showing that, generally people are not willing to pay an additional cost for carbon fibre as a purely cosmetic feature. Nearly half of that 75% (14 participants) were not willing to pay extra for the aesthetic use of carbon fibre. Interestingly, when questioned on whether they thought the increased cost was worth the aesthetic properties, the responses were split very evenly between across the board with a slight inclination towards disagreeing.

From other research, the author came across the idea that, there is perhaps a view that, people would rather the material stayed as an engineering material, this point also came across in the survey responses. The participants were given a choice of answers to show, which point of view fitted their ideas most accurately. Strangely although only 4 people had said that, they disliked seeing the material as a purely aesthetic material, 45% of respondents selected the option that they feel that these materials should be reserved for technical structural applications. The author believes that, this shows there is still a mindset that this is a technical material and although it has aesthetic merits, the most important characteristic of the material is its functionality.

It has also been apparent that consumers have some issue over the recyclability of the material. To find out how much this is considered, the point of purchase, a question was posed to see if there was any thought given to the environmental implications and see, if any consideration was given to other alternatives. 41% of responses were from consumers who didn't give any thought to the environmental considerations when making a purchase. With 35.9% saying that, the environmental issues were of a concern, but they would still make the purchase anyway.

Although the actual materials haven't changed an awful lot in the past 15 years or so, processes have developed in order to optimise performance, vac bagging, resin infusion and pre pregs, mean that the consistency of the material has improved considerably. Manufacturing using thermoplastic matrix has come a long way into bringing mass production to composite materials, reducing the time it takes to manufacture a part from many hours to several seconds. Although they have limitations in their mechanical application, they are still lighter and perform better than a standard moulding without reinforcement.

Another possibility for the future is that, the use of natural fibres will take off in a big way, although they do have drawbacks, their environmental credentials could mean that they become a necessity in some applications. The use of these fibres can achieve significant cost savings and they are by far better for the environment, there is concern over realistically relying on these materials. They absorb moisture in the air and degrade at a much quicker rate than their synthetic counterparts. A combination of this and a poorer adhesion to the matrix materials can cause severe delamination in the structure of the composite, forming bubbles and areas of localised weakness (Ticoalu, et al., 2010). This can cause the lifespan of a component to be reduced significantly, the repercussions of which can offset the environmental advantages as a part may need to be replaced. To try and combat this, there has been numerous attempts to deal with the water abortion by treating the fibres with a organosilane, which had the effect of decreasing moisture ingress by up to 30%, the process however is expensive and deemed uneconomical to sustain (Newman, 2008). Another significant issue is the current lack of consistency with the fibres, which can vary from crop to crop depending on a whole host of variables. This means that, it is extremely difficult to predict the strength of the end material. This lack of consistency in the reinforcement means that, the components have to be manufactured with a greater safety factor in order to compensate for potential weaker areas. This generally means adding more weight and material to the part, which is not ideal when one of the main advantages of using composites is to reduce weight. There is hope however, through the development and use of hierarchical structures developers to increase the mechanical properties of the fibres and vastly improve their mechanical potential. There is also ongoing work on the ways to improve adhesion to the matrix using a nanocellulose coating (Lee & Bismarck, 2014).

In order to address the environmental issue further, there are some much more biodegradable options. Using the starch based thermoplastic PLA (Polylactic Acid) as a matrix, combined with a natural fibre, leads essentially to a material that is 100% biodegradable. Although not particularly strong in its current forms, if the hierarchical structures that are being investigated, it significantly improve the fibres performance, then there may be a possibility of it becoming more widely accepted.

Another area of development for the high performance materials is the out of autoclave pre pregs. Although these still require a hot cure, they can be done in an unpressurised oven at much lower temperatures. Thus, reducing the initial outlay and energy consumption reduces the cost of the overall part. Although not quite as high performing, the cost difference may be a key in pushing development. In this, the need for an autoclave is eliminated, therefore opening the market to a wider range of consumers.

Composites are a range of very impressive materials. They have a huge variety of applications and uses, both functional and aesthetic. As a constructional material, they consistently outperform traditional counterparts in a range of areas. As a generalisation, current composites are lighter, stiffer and stronger than the steels and aluminiums that are used in the same applications. Their only significant downfall is their cost, which, although falling still is considerably more expensive. Due to their ability to outclass traditional equivalents, composite materials have paved the way for innovations, that may not have been economically feasible or even physically possible without their use. Boeing for instance is a prime example, it is unlikely that, without the weight saving benefits that composites can provide, some of their larger planes would be efficient enough to be viable as a commercial venture, even if they were physically possible and not too heavy to get off the ground.

It's safe to say that, carbon fibre is certainly appreciated for its aesthetic properties as well as, its functional capabilities. Brought to the attention of the masses by their high profile use as a performance enhancing material, the composites industry has been benefitted by the interest. People always want something better than other people, so being able to have a mobile phone case made from a super high performance material is going to help add the perceived value that people desire.

As a demand for the higher performance materials, which has increased the ability to supply a solution has had to develop, more advanced techniques have become the norm for high specification applications.

However, higher the performance, more complex the procedure and more expensive the overall part. Thanks to the fully automated mechanical productions lines, which are starting to become a realistic way of producing large quantities of units, it's likely that the prices will fall as the intensive labour time is reduced. Meaning that for less complex designs, the properties will still improve as the prices falls. Development in both process and materials is, and will be an ongoing process, that will continue to discover new and innovative solutions. With the ever growing need for answers to the planets reducing natural resources, the need to improve vehicle efficiency will continuously demand improvement from the world of composites, as designers strive for even lighter energy saving materials. In terms of the material composition, natural fibre composites will continue to be developed and improved as the need for green credentials becomes more important. Both thermoplastic and thermoset polymers will have to adapt to cater for the environmental demands and reduction in carbon footprint. Whether this is achieved by becoming more biodegradable, or effectively producing a high performance over a longer lifespan in order to simply reduce the need for replacement and the amount of resources used.