The fossil fuel reserves are decreasing due to increase in consumption of diesel, hence there is a need to develop alternative fuel. Hydrogen is considered as one of the best alternative fuels for internal combustion engines because of unique combustion properties. For Compression Ignition (CI) engines, it is impossible to get hydrogen to its auto-ignition temperature by compression alone. Hence, an attempt is made using hydrogen as an air enriched medium with diesel as main fuel. Experiments are conducted to study the effect of piston geometry on the emission characteristics of diesel engine enriched with hydrogen at different flow rates such as 2 litres per minute ( lpm), 4 lpm and 6 lpm on four stroke single cylinder diesel engine at constant speed of 1500 rpm for different loads. Knocking tendency is observed for flow rates above 6 lpm at all loads due to raise in temperature and peak pressures with addition of hydrogen. The emissions for diesel engine enriched with hydrogen are reduced to 27.1%, 37.5% and 18.8% of Unburnt Hydro Carbons (UHC), Carbon Monoxide (CO) and smoke density respectively. However, there is 14.9% increase in Oxides of Nitrogen (NOx) emission due to high combustion temperatures by hydrogen induction. Further, the experiments are conducted with toroidal piston bowl geometry for different flow rates of hydrogen without change in compression ratio. The effect of this change on emission parameters is further reduced to 6.9%, 13.6%, 11.6% and 3% in UHC, CO, smoke density and NOx respectively.

Compression ignition engines play a dominant role in transportation and agricultural sectors all over the world because of their durability and superior thermal efficiencies. In view of rapidly decreasing the availability of diesel against the increased consumption, a need to develop alternative fuel is essential. By conducting investigations using experimentation and simulation models, it was proved that the performance and emission parameters of the CI engine are improved with dual fuel mode operation [1]. By many researchers, hydrogen is considered as an alternative fuel for internal combustion engines because of less pollution, non-toxic, odourless and wide range flammability. The properties of hydrogen comparing with diesel are shown in Table 1. Less carbon content is the remarkable property of hydrogen fuel. Some of the desirable properties like high flame velocity, high diffusivity, high calorific value etc., motivates to use hydrogen as an alternative fuel. On combustion of hydrogen, higher flame speed can achieve higher thermal efficiency. With hydrogen directly injected into the combustion chamber in a compression ignition engine, the output power would be doubled that of same engine. Problems associated with inlet air manifold back fire and power de-rating will not occur when using direct injection [2]. As auto ignition temperature is high (about 585 C), it is impossible to get hydrogen to its auto ignition temperature by compression only in case of CI engines [3, 4]. So, ignition triggering devices are used in the combustion chamber.

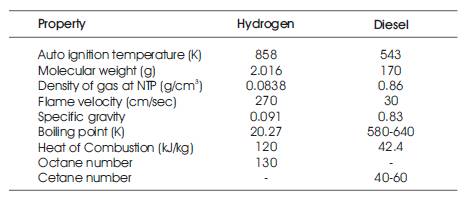

Table 1. Properties of Hydrogen in Comparison with Diesel

The unique combustion properties of hydrogen makes an ideal choice for its use in compression ignition engine [5]. The hydrogen air mixture burning velocities ranges from 153 to 232 cm/sec which results in more isochoric, thus thermodynamically more favourable combustion duly spread the temperature and pressure rise over several degrees of crank travel [6]. Hydrogen as an air enrichment medium with diesel as an ignition source in a stationary diesel engine system will improve the performance and reduce emissions [7, 11]. As the hydrogen fraction increases above certain extent, abnormal combustion such as pre-ignition, knock and backfire occurs. Hence the amount of hydrogen being added should be optimised [8]. Hydrogen addition results in improving engine combustion and emission performance is remarkable at low load conditions than at high load conditions [9].

The in-cylinder air motion in diesel engines are generally characterised by swirl, squish and turbulence as these have major impact on air-fuel mixing. Swirl motion of air is commonly generated by design of intake port to improve the combustion [10]. To provide a powerful squish which imparts to air movement similar to that smoke ring, toroidal combustion chambers can be used with cone angle of spray of 1500. The effect of piston bowl geometries on performance and emission of diesel engine is studied for better performance and reduced particulates of emission.

The main objective of this work is:

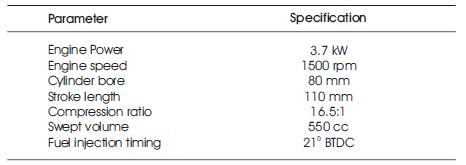

The experiments are conducted on a single cylinder, four stroke, water cooled diesel engine. The specifications of the engine are shown in Table 2 and schematic diagram for experimental setup is shown in Figure 1.

Table 2. Specifications of the Engine

Hydrogen operation has a good overall safety measure shown in Figure 2, as it associates with Hindenburg or Challenger disasters in its operation. To suppress the explosion inside the hydrogen cylinder, a flame arrester is used. The flame arrester consists of a partly filled water tank with fine mesh to prevent the flame propagation beyond the wire mesh. In case of backfire, the flame gets quenched as it reaches the water surface. Also to prevent the reverse flow of hydrogen into the system, a non-return valve is provided. To visualise the flow of hydrogen during the engine operations, a flow indicator is used.

Figure 2. Image of Actual Setup of Inducting Hydrogen Indicating safety measures

Initially, the diesel engine with standard piston of hemispherical piston bowl geometry is fired on no load and it is let to run until reached to a steady-state condition, denoted by constant cooling water outlet temperature. To measure the emission particulates, AVL Di Gas Analyzer and AVL Smoke Meter are used. Then the engine running on diesel is taken on load in steps by means of Eddy current dynamometer at constant rated speed and emission readings are recorded. This procedure is repeated for 20%, 40%, 60%, 80% and 100% loads. By inducting hydrogen along with air at constant flow rates of 2 lpm, 4 lpm and 6 lpm, the experiments are conducted at different loads. For flow rates above 6 lpm of hydrogen, it is an observed tendency of knocking, this may be due to high combustion temperatures with high burning velocities. This is because of hotter walls of combustion chamber and more heat is being lost through cooling water and hence results in reduction of efficiency.

Again, the standard piston is replaced with modified piston with toroidal bowl geometry. And ensured the same volume for the modified bowl of the piston in order to maintain the same compression ratio. The engine is again allowed to run with diesel fuel alone at no load to attain steady state. Then by repeating the same procedure, emission particulates are measured for diesel fuel alone. Again experimentation are conducted by inducting hydrogen along with air at constant flow rates and finally compares the emission parameters for all cases.

In this experiment, emission parameters such as UHC, CO, NOx emissions and Smoke Density are measured at different loads for standard and modified piston bowl geometry with hydrogen enrichment at different flow rates.

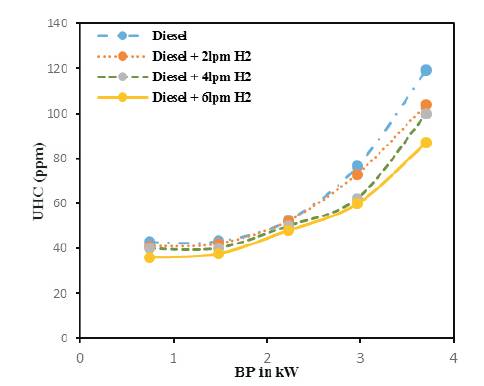

The variations of unburnt hydrocarbon emissions with load for five steps with hydrogen induction at different flow rates are shown in Figure 3. The amount of UHC emissions will be increasing with the increase of load. There is reduction in UHC emission with increase of flow rate of hydrogen when compared to diesel fuel alone. When a flow rate of 6 lpm hydrogen is inducted into the combustion process, resulting in 87 ppm at rated load condition as against 119.4 ppm with diesel alone under same conditions. It is observed that, there is reduction of 27.1% UHC emissions at rated load. This is due to increased cylinder gas temperature during combustion process as hydrogen has no carbon in its molecule, complete burning of the fuel eventually that led to reduction in UHC emissions.

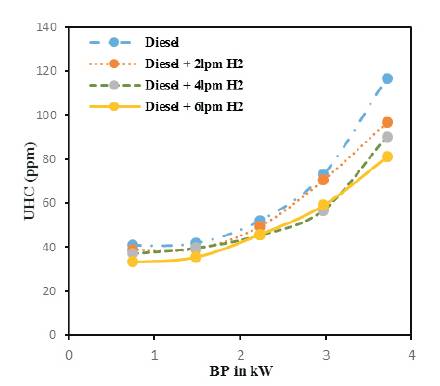

Further observed from Figure 4, the particulates of UHC are further reduced by changing the piston bowl geometry for different flow rates of hydrogen. At 6 lpm hydrogen flow rate, it is observed UHC particulates are 81ppm for modified piston and for diesel alone with modified piston is 116.8 ppm at rated load. UHC particulates at rated load with 6 lpm flow rate of hydrogen with modified piston are reduced by 6.9% when compared with standard piston. This is because of improved combustion with better mixture formation due to improved swirl motion of air.

Figure 3. Variation of Unburnt HydroCarbons with Brake Power for Standard Piston

Figure 4. Variation of Unburnt HydroCarbons with Brake Power for Modified Piston

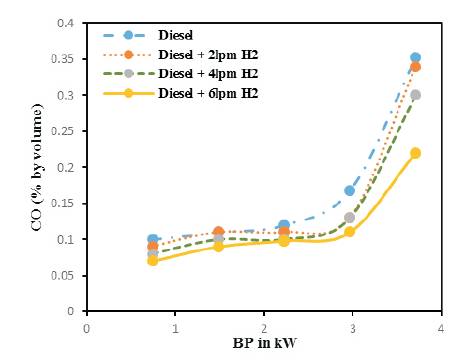

The variations of Carbon Monoxide emissions at different rated loads with hydrogen induction at different flow rates are shown in Figure 5. The volume of CO emissions will be increasing with increase of load in all cases. There is reduction in CO emission with increase of flow rate of hydrogen when compared to diesel fuel alone. Further it is noticed that, at higher loads the percentage of reduction in CO emission is more compared to part loads. At rated load, a flow rate of 6 lpm hydrogen is inducted into the combustion process, resulting in 0.22% by volume as against 0.352% with diesel alone under same conditions. It is observed that, there is reduction of 37.5% CO emissions at rated load. This is because of reduction in carbon content with addition of hydrogen and assists the combustion process by increasing the cylinder temperature.

Figure 5. Variation of CO Emissions with Brake Power for Standard Piston

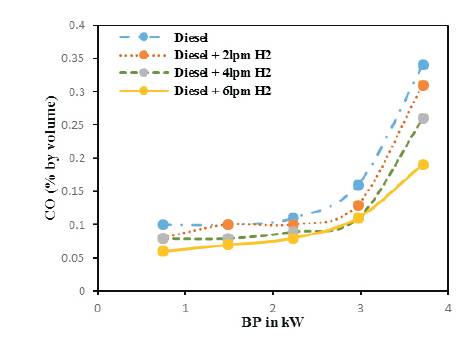

It is noticed from Figure 6, the volumes of CO emission are further reduced by changing the piston bowl geometry for different flow rates of hydrogen. At 100% load with 6 lpm hydrogen flow rate, it is observed that CO emissions are 0.34% by volume and 0.19% for only diesel with modified piston. The CO emissions at rated load with 6 lpm flow rate of hydrogen with modified piston are reduced by 13.6% when compared with standard piston. This is because of higher air movement and hence improved combustion with better mixture formation.

Figure 6. Variation of CO emissions with Brake Power for Modified Piston

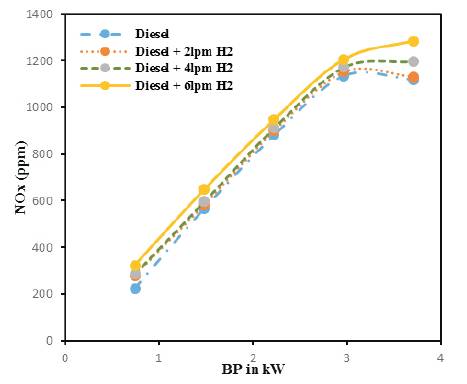

The variations of oxides of nitrogen emissions are shown in Figure 7 for five different rated loads with hydrogen induction at different flow rates along with air. The amount of NOx emissions will be increasing with increase of load and also with increase of hydrogen flow rate. When a flow rate of 6 lpm hydrogen is inducted into the combustion process, resulting in 1285 ppm at rated load condition as against 1118 ppm with only diesel under same conditions. It is observed that, there is increase of14.9% NOx emissions at rated load. This is due to increased combustion temperature and maximum rate of pressure rise caused by hydrogen addition. However, by adopting exhaust gas recirculation and by using suitable catalytic converters NOx emissions can be controlled [11, 12].

Figure 7. Variation of NOx Emission with Brake Power for Standard Piston

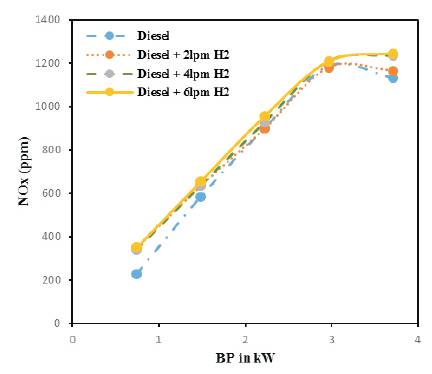

It is observed from Figure 8 the particulates of NOx are slightly reduced by changing the piston bowl geometry for different flow rates of hydrogen. At 6 lpm hydrogen flow rate, it is observed NOx particulates are 1246 ppm for modified piston and for only diesel with modified piston is 1131 ppm at rated load. NOx particulates at rated load with 6 lpm flow rate of hydrogen with modified piston are reduced by 3% when compared with standard piston. This is because of effective utilization of temperatures for burning the fuel with improved swirl motion of air.

Figure 8. Variation of NOx Emissions with Brake Power for Modified Piston

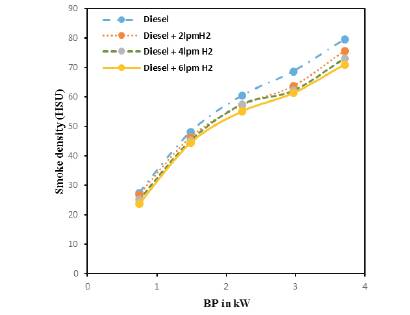

The variations of smoke density in HSU for different rated loads with hydrogen induction at different flow rates are shown in Figure 9. The smoke density will be increasing with increase of load for all cases of experimentation. There is reduction in smoke density with 6 lpm hydrogen is inducted into the combustion process, resulting in 71 HSU at rated load condition as against 79.6 HSU with only Diesel operation under same conditions. It is observed that, there is reduction of 10.8% at rated load. This is due to reduced quantity of fuel injected with addition of hydrogen and in the absence of carbon in hydrogen fuel.

Figure 9. Variation of Smoke Density with Brake Power for Standard Piston

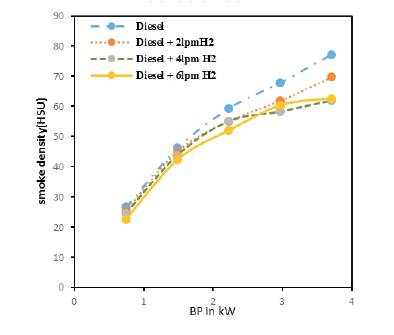

Further it is observed from Figure 10, the particulates of smoke are further reduced by changing the piston bowl geometry for different flow rates of hydrogen. For modified piston at 6 lpm hydrogen flow rate, it is observed that the smoke particulates are 62.7 HSU and for diesel alone it is 77.2 HSU at rated load. Smoke Density at rated load with 6 lpm flow rate of hydrogen with modified piston is reduced by 11.6% as compared with standard piston. This is because of improved combustion with better air fuel mixing in presence of Hydrogen enrichment.

Figure 10. Variation of Smoke Density with Brake Power for Modified Piston

This paper reports the role of hydrogen induction at different flow rates in existing diesel engine by modifying the piston bowl geometry in analysing the emission characteristics with the objective of improving the engine exhaust characteristics at different loads. The main conclusions of the present study are summarized and tabulated in Table 3 as follows:

The emergence of hydrogen as a sustainable fuel for the future is well established with the above analysis. Its suitability to internal combustion engines must be considered for the better driving units of the immediate future dictates the exploration of hydrogen as strategic sustainable energy barrier. In view of this, the present study offers a pilot study to extend the operational benefits of using hydrogen in CI engines by varying design and operational parameters.