The Indian vehicle manufacturing industry along with child part and raw material industries are basking a healthy and increasing growth, in the last two decades. This shoot up has been noticed since the economic liberalization happened in early 1990's. Indian automotive market has grown from 5 million vehicles (2002) to 23.4 million vehicles (FY 2014-2015). India is already on the 2nd place in two-wheeler (2W) segment and on 4th place in Commercial Vehicles (CV). India is now poised to rank amongst the top three global automotive markets in all vehicles, by the year 2020. Observing such volatility in the present and future of the Indian auto market, it calls for an analysis of challenges and complexities of Supply Chain Management (SCM) practices that are catering to the industry, so that the trends will shape the futuristic supply chain management practices which can be given a try to predict and understand. This paper seeks to analyse the Indian auto market future trends and presents the status as well as futuristic view of complexities and challenges that affects the SCM practices. It is the best hope that this study will provide an understanding which will help in adopting good SCM practices in auto industry and lead to various competitive advantages.

Automotive Industry is what can be accepted as one of the major drivers of a country or it is not wrong to say as the global economy; When an auto industry is going to establish or would be setting up in any area of the country then it automatically calls thousands of Tier 1, Tier 2 and hence so many small level vendors to get established either in its vicinity or in other nearby areas. A huge demand of raw material and ready to feed child parts are now being generated as an Original Equipment Manufacturer (O.E.M) works, calling in a pool of employment side by side; thus it can be imagined that how it mobilizes the economy of any area or of a country. The automobile has been called as a “product as well as a function” because it involves engineering services as a function and hence it gives a fine product in the end, from automotive supply chain (Thomas K., 2013). It would not be wrong to call Automotive Industry as the “head of all Industries”, as it uses the products and services of a number of other Industries. It supports industries like mining, steel, rubber, plastic, Information Technology (IT), banking and insurance etc. According to Ernst & Young's India Attractiveness Survey (2012), India is rapidly emerging as a favourite location for various manufacturing Industries (Ernst & Young, 2012). Industries move across the countries in order to grow and expand and this is known as globalization, which has occurred in the areas of Finance, Investment and Production. Globalization in the automotive sector calls in competitiveness. This globalization has opened a large potential market in India also like any other emerging economy, as has been shown (Rajshekhar Javalgi & Gross, 2011). So in order to survive in such a competitive environment, automotive Industry needs to in-corporate efficient and productive systems, and also the way of working in all the departments like Finance, Purchasing, Engineering, Production, Design and Development as well as in Supply Chain Management. Supply Chain Management plays a vital role in order to sustain in growing market where conditions are so volatile and competitive.

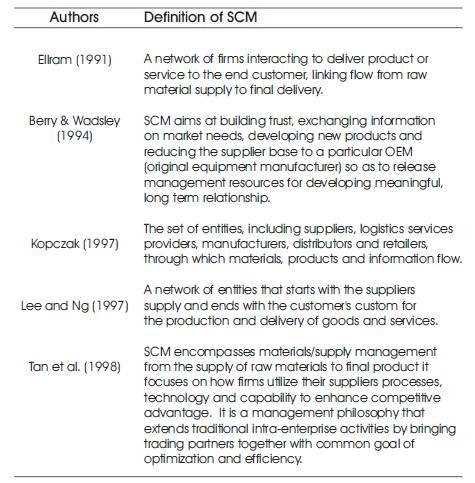

Supply chain is a network of firms to deliver product or service to the final customer, linking flow from raw material supply to final delivery, as has been shown (Bhardwaj & Jawalkar, 2015). Supply Chain Management can be understand as a network of organisations (Small, medium and OEMs) connected in a hierarchy allowing exchange or flow of materials, information and money. These all kinds of flow or exchange may be facilitated with some real time information systems. SCM definitions by various researchers and scholars are shown in Table 1.

Table 1. SCM Definitions by Various Researchers and Scholars.

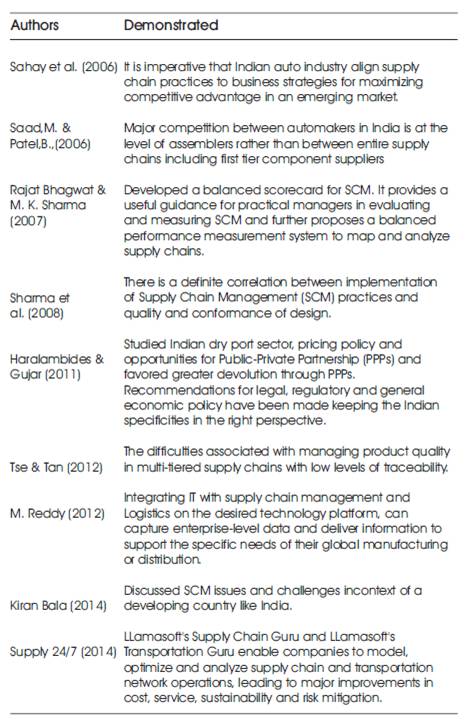

With aid of the various management systems in the end, some product or service can be assumed to get delivered to the end customer. The Supply Chain Management includes new product development, marketing, operation, distribution, finance, customer service and other function that related to serving customer request, as has been shown (Chopra & Meindl, 2007). The effective Supply Chain Management is very necessary to cope up with day-to-day obstacles which keep on dragging back the supply and demand processes. In Table 2, the author demonstrate the SCM challenges in the Automobile Industry.

Table 2. SCM and Automobiles

In this study, there are two sections, Section-1 emphasis on the trends of Growth and Future of Indian Automotive market. Section 2 will try to analyse the complexities and challenges of the Supply Chain Management services those are facilitating Indian automotive market. In the end some conclusions are drawn based on the study that will help to cope up the challenges in SCM and to adapt sustainability in the tough phase of competition.

Although Indian Automotive Industry started its journey in 1940's, but a tremendous growth has been recorded since the Economic Liberalization in early 1990's. The Government of India encourages foreign investment in the automobile sector and allows 100 percent FDI under the automatic route as has been shown (http://www.ibef.org/). The Indian government has laid out the goals of company in two documents- 'Auto Policy 2002' and Auto Mission Plan 2006-2016 (Automotive mission plan, 2006-2016). Recently Indian Government has initiated a very effective Strategic plan named “MAKE IN INDIA”, provokes all global Manufacturers as well as Indian Manufacturers to setup their facility in India. This action taken by the Government has bore fruits, which could be felt from the growth of the Automotive Sector. Rushing of various automotive giants into the Indian market has become possible due to large pool of cheap labour and other resources. The industry comprises various segments like group assemblers, multinational child part assemblers and various SMEs (Small and Medium Enterprises) from economic performance of Indian automobile industry (Ray S., 2012) .

The journey of evolution of the Indian Automotive market is observed in Figure 1.

From 1982-1992, since the market was not open to globe and also the buying power was not up to the level, the sales figure was low (Venkata Ramana Reddy, 2012). After liberalization, the sales started pumping up along with the buying power as shown in the Figure 1.

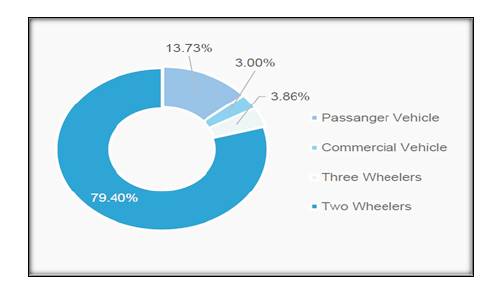

The market share by volume is indicated in Figure 2 for the financial year 2015.

Figure 2. Volume Wise Market Share of Auto Segments for 2015 in Indian Scenario

Source: Society of Indian Automobile Manufacturers (SIAM), TechSci Research.

Figure 2 shows the volume percentage of market captured by various segments of automobiles. It shows that Indian auto market is mainly dominated be two wheelers, the passenger vehicles.

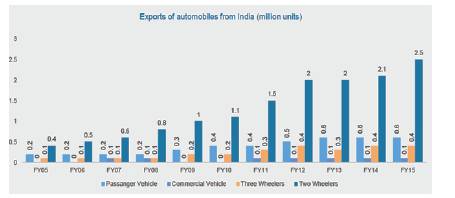

Figure 3 indicates the trends of growth in the export of automobiles from India.

Figure 3. Exports of Automobiles from India since 2005 upto 2015

Source: Society of Indian Automobile Manufacturers (SIAM), TechSci Research.

Graph shows the growth trends in the export market. Two wheelers segment has achieved an appreciable growth as compared to other sectors. Hence there is huge scope for the improvements and growth in other sectors.

A very brighter and dynamic future is expected to be faced by the Indian Automotive market in the coming era, which would be possible as the grounds set by the Indian Government for taking positive steps towards making India as the manufacturing hub. In the same path, Governmentof India (GOI) has setup its new policies.

Source: Automotive Mission Plan (2006–2020), Make in India.

The domestic vehicle growth predicts are given in Figure 4. Source: A.T Kearney Analysis

Figure 4 shows that domestic vehicle production is expected to grow by 10% in terms of unit sale and that of domestic auto component market is expected to rise by 16%, which are really significant numbers.

Another Growth Scenario as per the analysis done by TechSci Research, is shown in Figure 5 .

Source: SIAM, (National Electric Mobility Mission Plan) NEMMP 2020, TechSci Research; Note- E-Estimate, CAGRCompound annual growth rate.

Observing the ups and downs of the growing Indian Automotive market which would be faced in the coming era. It can be said that Indian SCM should be prepared in advance for the coming challenges and complexities in order to cope up and to meet the demand and supply. Since Indian SCM is not upto the mark from infrastructure point of view; but now GOI is also making moves towards improving the same, so there is a need to understand these complexities and to prepare an action plan.

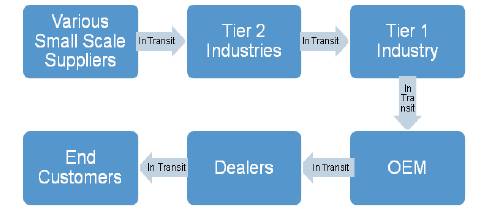

Indian SCM faces complexity generally in Logistics and Inventory management. The industries in India spend approximately 14% of GDP on logistics as compared to 10- 11% that in Europe and 9% in United States of America as has been shown (Souresh Bhattacharya et al., 2014). This much of expense is a result of complexities, a wide network of supply chain and last but not least the availability of infrastructure to co-ordinate between various supply chains present from small scale industries to that which are operated on medium scale industries and OEMs. Figure 6 shows the presentation of SCM complex structure and network diagram. SCM activities are involved from small scale suppliers to end customers.

Figure 6. SCM Complex Structure and Layout

Figure 6 shows the complex layout or the chain of SCM. Since the chain or channel is so long, definitely the complexities and challenges involved would be of the same level. The complexity of the automotive supply chain may be gauged from the fact that a typical vehicle comprises approximately 20,000 components with about 1000 subassemblies or modules as shown by Schwarz, M. (2008).

SCM practices in India faces a lot of challenges. These challenges affect SCM as a whole but particularly Inventory management. The top five challenges to SCM in India are- visibility, cost involvement, risk involvement and its management, increasing customer base and finally the globalization (IBM, 2009). Some specific challenges are for suppliers in developing countries as they rely on a low cost strategy as has been shown (Alain Chong & Chan, 2011). Various studies and analysis have been conducted so far and the overall challenges can be represented as shown in Figure 7.

Source: A.T Kearney Analysis.

After observing and understanding the above analysis and study, it might not be wrong to say that the Indian Automotive market is already very volatile and seeing the growth forecast in future, furthermore it is expected to be more and more volatile, lack of demand and supply meet and hence the operating environment conditions for the SCM would not become user-friendly to operate. Also India is suffering from lack of infrastructure which will take time to improve. The Indian industries yet to achieve the level of working similar to that of the developed countries has been shown (Chang & Klenow, 2009). A good potential is present for the national level SCM integration (Park D et al., 2012). The Indian auto industry should try to adapt or improve the under mentioned steps in order to get set ready for the existing and coming challenge.