Study on Mechanical Properties of Textile Reinforced Concrete

Abstract

This study deals with the experimental investigations on the effects in Textile Reinforced Concrete (TRC) as reinforcing material and conventional concrete. In this study, M25 grade concrete is used for nominal mix design. High strength high modulus polyester filament yarns are used to study its effects in reinforcing concrete mixes and to obtain basic strength. For the concrete to achieve its maximum strength and longevity, curing must be carried out for a suitable period of time. In this study, the curing is done by preventing excessive loss of moisture from the concrete either by leaving formwork in place, covering the concrete with impermeable membrane after the formwork has been removed by the application of suitable chemical curing agent (water based), or by combination of such methods. Curing by continuously wetting the exposed surface prevents the loss of moisture from it. The compressive, flexural strength tests were performed by placing the textile in the form of layers 1, 2 and 3. As a result, it had been found that the use of polyester textile material considerably increases the flexural strengths. It is also observed that there is a sudden decrease in flexural strength and compressive strength when textile is placed in 3 layers. The maximum flexural and compression strength is obtained by placing the textile in the form of 2 layers and found to be economical. Eventually it has been observed that, there have been an increase in flexural strength for about 48%.

Keywords :

- Compressive Strength,

- Flexural Strength,

- Membrane Curing,

- Textile Reinforced Concrete.

Introduction

Concrete is one of the most flexible and has been a leading building material. It can be casted to fit any structural shape (Shetty, 2006). It is readily available at an affordable price in urban areas. Concrete is strong under compression but is really weak under tension (Raju & Parnesh, 2018). High compressive strength, good fire resistance, high water resistance, low maintenance and long service life are the advantages of using concrete (Shetty, 2006). The drawbacks of using concrete include low tensile strength, practice of moisture curing for about 28 days after casting, and necessity for formwork during casting. Concrete when reinforced could be practically used in the construction of many structural elements including footings, columns, beams and slabs (Dheerendra Babu, 2016).

There are various materials capable of reinforcing the concrete to add the tensile strength to it. Few of them arementioned here.

- Reinforcing using basalt fibers and rebars (Abed & Alhafiz, 2019; High et al., 2015).

- Reinforcing by bamboo (Sutharsan et al., 2020).

- Reinforcing using steel like HYSD bars (Rahman et al., 2019).

- Reinforcing using steel fibers (Ghaffar et al., 2014).

- Reinforcing using fibers (Rai, & Joshi, 2014).

- Reinforcing using timber (Caldová et al., 2014).

- Reinforcing using domestic waste plastic as fibers (Kandasamy & Murugesan, 2011).

- Reinforcing by inducing prestress (Hegger & Voss, 2008; Henry et al., 2007).

- Reinforcing using textile reinforcement (Butler et al., 2010; Colombo et al., 2013).

This study primarily aims to manufacture the designed M25 grade concrete by reinforcing it with textile reinforcement.

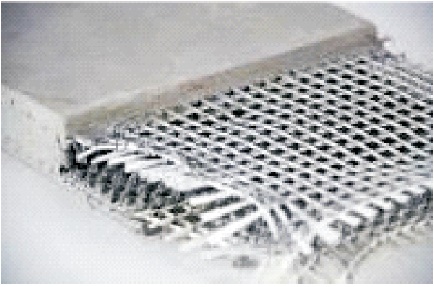

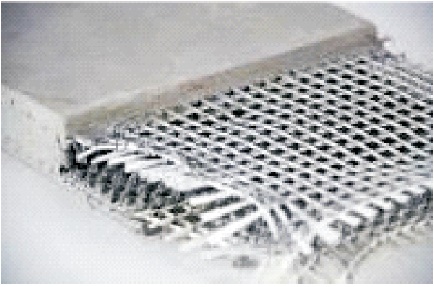

Textile Reinforced Concrete (TRC) is concrete containing materials with high tensile strengths and with negligible elongation properties that are reinforced with woven or nonwoven fabrics. The fibers used to make the fabric are very tenacious, such as jute, glass fiber, kevlar, polypropylene, polyamides (nylon) etc. These fibers are capable of acting as alternatives to the reinforcing materials like HYSD bars (Arunakanthi & Kumar, 2016; Gopinath et al., 2016). The character of textile reinforced concrete also changes with different concretes, fiber materials, geometries, distribution, orientation, and densities. The Figure 1 shows the image of textile reinforced concrete.

Figure 1. Textile Reinforced Concrete

On the other hand, curing is one of the important processes that should be executed for a considerable period of time. This process not only influences the strength of the concrete, but also the durability and reduces the heat of hydration (Bureau of Indian Standards, 2016). The concrete really demands high amount of water to get cured. To overcome this, based on the previous works done by us, it has been found that Membrane Curing is extremely effective on-site, and yields best results in terms of strength and demands very low scale of water and other resources, when compared to other methods of curing (Gowsika et al., 2017; Reddy, 2013). The Figure 2 showcases the application of membrane curing in concrete.

Figure 2. Application of Membrane Curing for Concrete

This study also aims to cure the manufactured textile reinforced concrete using membrane curing.

1. Literature Review

Gayathri et al. (2018) have made a study on mechanical behaviour of textile reinforced concrete and have stated that, in textile reinforced concrete a fabric cage is used for tensile strengthening. The woven fabrics with high tensile capacities and elongation properties are mixed into the concrete. Jute, glass fiber, kevlar, polypropylene, polyamides (nylon) etc. are the most widely used fibers for producing fabrics. The fabric weaving is done in a coil fashion or a layer. As a result, the reinforced concrete with synthetic fibers is flexible from the inside along with the highresistance outer materials.

Gopinath et al. (2016) have made a research on the investigations on textile reinforced concrete as cover for RC beams and reported that experimental investigations were conducted to determine the flexural behaviour of reinforced concrete beams under monotonic and lowcycle fatigue load with basalt textile reinforced concrete. Reinforced concrete beams with textile reinforced concrete basalt were tested using four-point bending test. It is observed that the ultimate charge increases when the reinforced beams are subjected to monotonic loading.

Volkova et al. (2016) have made a technical assessment on flexural behaviour of textile reinforced concrete by developing two samples of TRC using high strength reinforcing fabrics made from glass and carbon rovings. Three-point bending test was performed to examine the samples developed flexural performance. In addition, it analysed the deformation behaviour of reinforced concrete. The benefit is the higher residual load-bearing capacity which enables the structure to be preserved in its integrity.

Williams Portal et al. (2015) have presented a paper on sustainable potential of textile reinforced concrete and indicated that a novel construction material, such as textile reinforced concrete (TRC) could be used to fulfill this demand. Textile reinforced concrete is a combination of fine-grained concrete and multi-axial textile fabrics have been researched in the last decade. This article provides a qualitative and quantitative evaluation of the TRC's sustainable potential and prospective development, particularly reinforced by alkali-resistant (AR) glass, carbon or basalt. Based on the results of this evaluation, carbon textile fibers were found to maintain optimum potential mechanical behaviour.

2. Objectives

- To introduce geotextile material into the concrete as a reinforcing material.

- To observe the influence of the same material at different layers in the concrete, on the strength of concrete.

- To observe the comparison of the strength parameters in nominal and reinforced concretes with respect to compressive and flexural strengths.

- To reduce the usage of reinforcement in Reinforced cement concrete (RCC).

- To eliminate the use of water used for curing of concrete, and use pigmented emulsions of linseed oil as a curing agent.

3. Materials Used

3.1 Cement

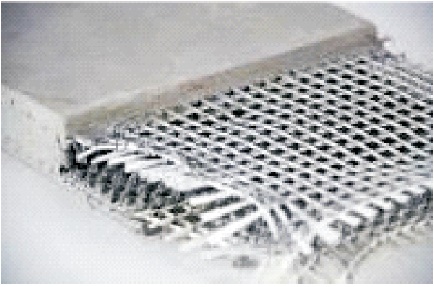

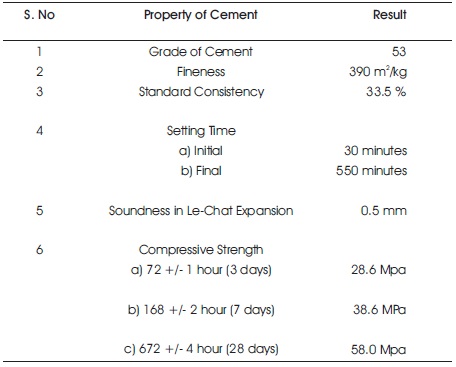

Cement is one of the basic construction material that will be generally in powdered form and hardens upon the addition of water to it. It can serve as a binding material to the aggregates to obtain strength. It possesses cohesive and adhesive properties. The cement used for this study is Portland Pozzolana Cement of 53 Grade (BIS, 1988). The Cement is tested for various properties (BIS, 2013) and is present in Table 1.

Table 1. Properties of Cement Used

3.2 Fine Aggregate

The aggregate passing through 4.75 mm sieve could be called as fine aggregate (BIS, 2016). Generally, fine aggregate is a filling material for the concrete. The fine aggregate used for this study is river sand collected from local RMC plant. The specific gravity of the fine aggregate used for this study is found to be 2.65 (BIS, 1963).

3.3 Coarse Aggregate

The aggregates passing through 20 mm sieve and retained on 4.75 mm sieve could be called as coarse aggregate (BIS, 2016). Generally, coarse aggregate is a material that enhances the strength and stability for the concrete. The coarse aggregate used for this study is collected from Miyapur quarry. The specific gravity of coarse aggregate used for this study is found to be 2.83 (BIS, 1963).

3.4 Water

Water is the main ingredient used to mix all the contents. Potable water is used, as usage of other water may contain salts and cause decrease in strength of concrete.

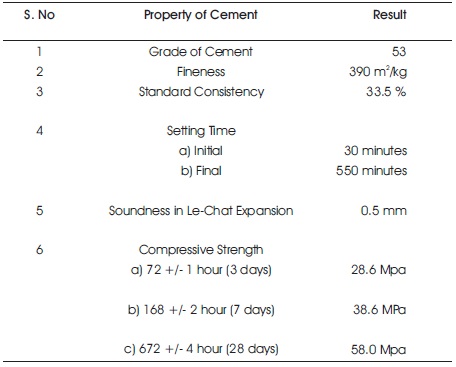

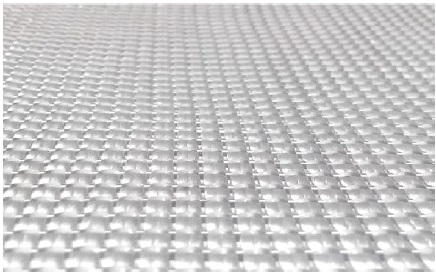

3.5 Geotextile

Geotextile is one of the types of Geosynthetic materials, which is basically biodegradable in the nature. In the weaving process, woven geotextiles are created by interlacing two sets of yarns at right angles. In the warp and weft directions, woven geotextiles have high strengths and modulus, and low rupture elongations. This material is used as a reinforcing material to strengthen the concrete in this study.

This is a specialized heavy duty fabric with superior strength modulus and other physical properties. HTSF-Q-W-3020-A satisfies AASHTO M-288-96 Class I requirement for reinforcement in erosion control along highway embankment use providing cost effective alternative to multilayer aggregates filter. HTSF-Q-W-6398 satisfies AASHTO M-288-96 Class I and II requirement for separation in slop protection of embankment. The tensile strength of this material, when tested under ASTM D 4595 (ASTM International, 2005) under machine direction and cross direction conditions are found to be >200 kN/m and >60 kN/m respectively.

The Figure 3 shows the geotextile material used for this study.

Figure 3. Geotextile Material

3.6 Curing Compound

In this study, for the purpose of membrane curing, we have adopted the chemical which is a pigmented emulsions of linseed oil. After its application and drying, it attains a bonded white colored appearance. It is not affected by natural weathering (Reddy, 2013; Rhodes & Evans, 1949). The visual appearance of this chemical is presented in Figure 4.

Figure 4. Curing Compound used for this Study

4. Methodology

- Initially, all the materials required for this study are collected and are subjected to various testing processes to attain their specifications, and check whether they are fit to be used.

- As this study aims to manufacture textile reinforced concrete, the concrete is casted with M25 standard grade of nominal proportion 1:1:2 (BIS, 2000). The water cement ratio is selected as 0.5. The concrete is manufactured with normal grade and also the geotextile has been placed at 1, 2, 3 layers respectively. The curing is done for a period of 7, 14, 28 days.

- The testing is done for compression and flexural strength of a total of 36 cubes (size 150 x 150 x 150 mm) and 36 beams (size 500 x 100 x 100 mm) specimens casted.

- Then the process of casting of concrete is started, in which the mixing of concrete is done by adopting hand mixing as shown in Figure 5.

Figure 5. Mixing of Concrete

- After the concrete is mixed, the geotextile material is cut into pieces in such a way that it is equal to the dimensions of the cube and beam as shown in Figure 6. The geotextile material is placed in the form of layers (say 1,2,3). For the single layer the geotextile is placed at bottom of the cubes and beams. For two layers, the geotextile is placed at top and bottom. For three layers, the geotextile material is placed at top, bottom and center of beams and cubes. The Figure 7 presents the casting of textile reinforced concrete.

Figure 6. Placing of Geotextile in the Concrete Cube and Beam Mould

Figure 7. Placing of Concrete in the Beam Mould

- Then the process of compaction would be commenced. The compaction is done by table vibrator for every layer. It is to be kept in mind that no manual compaction should be done, as it may distort the geotextile material and placement. The vibration should be given properly and uniformly, as shown in Figure 8.

Figure 8. Compaction of Concrete Mould on Table Vibrator

- Later, the concrete is allowed to harden for a period of 24 hours. The Figure 9 presents the unmoulding of hardened concrete specimens.

Figure 9. Unmoulding of Hardened Concrete

- Then the process of curing is done by applying a layer of pigmented emulsions of linseed oil to achieve membrane curing as shown in Figure 10.

Figure 10. Application of Curing Compound for Hardened Concrete

- After the specimens are done with curing process, they are subjected to testing process.

5. Results and Discussions

After the concrete specimens are done with the curing period, they are subjected to compression and flexural testes (BIS, 1959) and the testing process, results and analysis is explained.

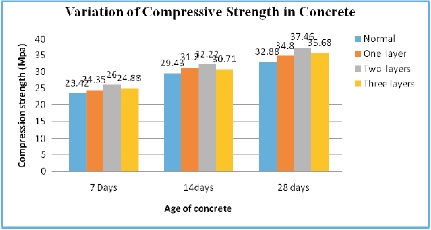

5.1 Compression Test Results

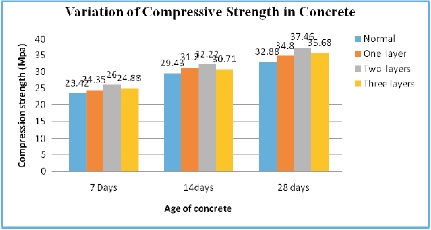

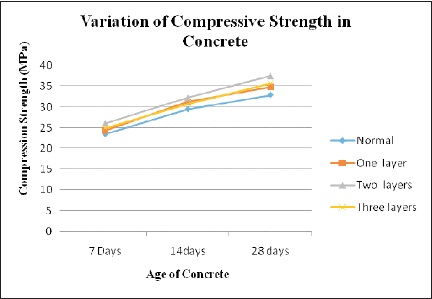

This test is done by introducing the cured concrete cube specimen in the compression testing machine. The ultimate load (kN) carried by the specimen is noted and is proceeded for further calculations. Figure 11, 13 and 14, and Table 2 shows the compression testing of concrete specimen, its results and analysis.

Figure 11. Compression Testing of Cube Specimen

Figure 12. Cube Specimen after Failure by Compression

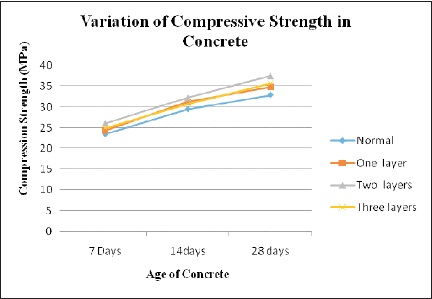

Figure 13 and 14 shows the bar chart and line chart of the compression testing results obtained respectively. Figure 12 showcases the cube specimen after failure by compression.

Figure 13. Bar Chart Showing Variation

Figure 14. Line Chart Showing Variation of Compressive Strength in Concrete

The compressive strength of the specimen is expressed in N/mm2.

5.2 Discussions on Compression Test Results

From the Figure 13 and 14 it is evident that,

- After 7 days of curing, the normal concrete is found to have a compressive strength of 22.42 N/mm2 whereas after 14 days of curing period, this strength has enhanced to 29.43 N/mm2. It has been noted that the strength reached to 32.88 N/mm2 after 28 days.

- At the age of 7 days, one layer textile reinforced concrete is observed with a compressive strength of 24.35 N/mm2. After 14 days it has been improved to 31.2 N/mm2. Finally, the compressive strength has been observed to be 34.8 N/mm2 after 28 days.

- In the two layers of textile reinforced concrete, after 7 days of curing, the compressive strength is found to be 26.00 N/mm², whereas after 14 days it is increased to 32.22 N/mm2. Finally, the compressive strength is observed to be 37.46 N/mm2 after 28 days.

- In three layers textile reinforced concrete, the compressive strength of 24.88 N/mm² is obtained by the end of 7 days. After 14 days the strength has got enhanced to 30.71 N/mm2. Finally, the compressive strength is observed to be 35.68 N/mm2 after 28 days.

- The compression strength of normal concrete is less than one layer, two layer and three layer as shown in Figure 13 and 14.

- The compression strength of one layer textile reinforced concrete is less than two layer and three layer, and greater than nominal concrete as shown.

- The compression strength of two layer textile reinforced concrete is greater than nominal concrete, one layer and three layers.

- The compression strength of three layers textile reinforced concrete is greater than nominal concrete, and less than one layer and two layers as shown in Figure 13 and 14.

- The maximum compressive strength is obtained in two layer textile reinforced concrete and hence it is adoptable.

5.3 Flexural Test Results

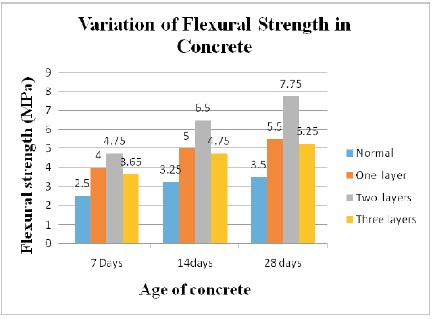

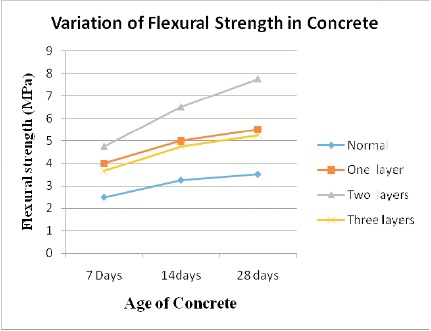

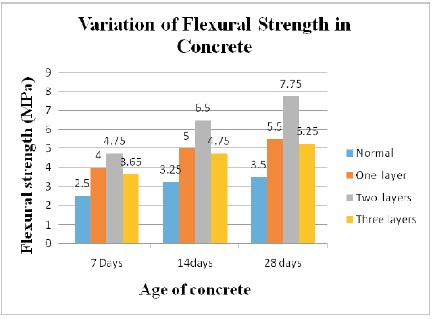

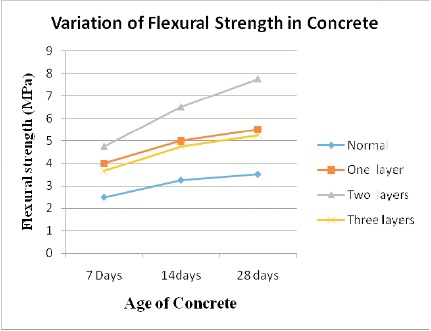

This test is done by introducing the cured concrete beam specimen in the flexural testing machine. The ultimate load (kN) carried by the specimen, under two-point loading, is noted and is proceeded for further calculations. The Figure 15, 17 and 18, and Table 3 shows the flexural testing of concrete specimens, its results and analysis. The Figure 16 presents the beam specimen after failure due to flexural test loading. Figure 15 and 16 shows the bar chart and line chart variation in flexural strength respectively.

Figure 15. Flexure Testing of Beam Specimen

Figure 16. Beam Specimen after Failure due to Flexure Test Loading

The flexure strength of the specimen is expressed in N/mm2.

5.4 Discussions on Flexural Test Results

From the results it is evident that,

- The flexural strength of nominal concrete is less than one layer, two layer and three layer as shown in the Figure 17 and 18.

Figure 17. Bar Chart Variation of Flexural Strength in Concrete

Figure 18. Line Chart Variation of Flexural Strength in Concrete

- The flexural strength of one layer textile reinforced concrete is less than two layers and greater than nominal concrete and three layers as shown.

- The flexural strength of two layer textile reinforced concrete is greater than nominal concrete, one layer and three layers.

- The flexural strength of three layer textile reinforced concrete is greater than nominal concrete, and less than one layer and two layers as shown in the Figure 17 and 18.

- The maximum flexural strength is observed in two layers textile reinforced concrete, and hence it is adoptable.

6. Achievements of Objectives

As stated in the objectives primarily,

- The geotextile material is introduced as a reinforcing material in the concrete and examined.

- The influence of the geotextile material is used at different layers in the concrete, and is explained.

- A comparison is made between normal and reinforced concrete with respect to compressive and flexural strengths.

- There has been ultimate reduction in the water quantity for curing by adapting membrane curing.

Conclusion

- Adaption of geotextile is capable of reducing the cost of manufacture when compared to steel reinforcement.

- It is also observed that there is no much variation of compressive strength in both normal and reinforced concretes.

- Whereas, in terms of flexural strength, there has been surprising and significant increase in the strength from normal to reinforced concretes which satisfies the main objective. Also, observing the flexural variation, there is about 48% more flexural strength than nominal concrete.

- In the concrete with 2 layered geotextile, the strength parameters are observed to be really high, acceptable and satisfactory compared to normal concrete.

- The membrane curing process fetched on-site results without application of single drop of water.

Recommendations and Scope for Further Studies

- Further studies could be made on this concrete, by different concrete grades and adopting different mix designs with respect to BIS (2012).

- Addition of admixtures, and other material replacements could influence the strength parameters of concrete.

- Various tests like modulus of elasticity, bond strength etc., could be done for further detailing.

- Geosynthetic materials like geogrid, geomembrane etc., could be tested for capability of concrete reinforcement.

Acknowledgement

We, Gourishetty Ruthvik and Challa Datta Karthik, would like to take this opportunity to thank our Project Guide Mr. G. Siva Vignan for helping us throughout this study. We would also like to thank our Department of Civil Engineering, St.Martin's Engineering College, Hyderabad, Telangana, India for supporting us. We also like to thank our parents for imposing so much of faith and love on us.

References

[1]. Abed, F., & Alhafiz, A. R. (2019). Effect of basalt fibers on the flexural behavior of concrete beams reinforced with BFRP bars. Composite Structures, 215, 23-34. https://doi. org/10.1016/j.compstruct.2019.02.050

[2]. Arunakanthi, E., & Kumar, J. C. (2016). Experimental studies on Fiber Reinforced Concrete (FRC). International Journal of Civil Engineering and Technology, 7(5), 329-336.

[3]. ASTM International. (2005). Standard test method for tensile properties of geotextiles by the wide-width strip method (Standard No. ASTM D4595-05). Retrieved from http://www.astm.org/cgi-bin/resolver.cgi?D4595

[4]. BIS. (1959). Methods for test of strength of concrete (Standard No.IS516). Retrieved from http://www.iitk.ac.in/ce/test/IS-codes/is.516.1959.pdf

[5]. BIS. (1963). Methods of test for aggregates for concrete - Mechanical Properties (Standard No. IS 2386- IV). Retrieved from http://www.iitk.ac.in/ce/test/IScodes/ is.2386.4.1963.pdf

[6]. BIS. (1988). Methods of physical test for hydraullic cements (Standard No: IS 4031). Retrieved from https://www.iitk.ac.in/ce/test/IS-codes/is.4031.6.1988.pdf

[7]. BIS. (2000). Plain and reinforced concrete - Code of practice (Standard No. IS 456). Retrieved from http://www.iitk.ac.in/ce/test/IS-codes/is.456.2000.pdf

[8]. BIS. (2009). Concrete mix proportioning - Guidelines (Standard No:IS10262). Retrieved from https://law.resource.org/pub/in/bis/S03/is. 10262.2009.pdf

[9]. BIS. (2013). Ordinary portland cement, 53 grade specification - Code of practice (Standard No. IS 12269). Retrieved from http://www.iitk. ac.in/ce/test/IS - codes/is.12269.2013.pdf

[10]. BIS. (2016). Coarse and fine aggregates for concrete - Specifications (Standard No. IS 383). Retrieved from https://www.iitk.ac.in/ce/test/IS-codes/is.383.1970.pdf

[11]. Butler, M., Mechtcherine, V., & Hempel, S. (2010). Durability of textile reinforced concrete made with AR glass fibre: effect of the matrix composition. Materials and Structures, 43(10), 1351-1368.

[12]. Caldová, E., Blesák, L., Wald, F., Kloiber, M., Urushadze, S., Vymlátil, P., & Designtec, S. R. O. (2014). Behaviour of timber and steel fibre reinforced concrete composite constructions with screwed connections. Wood Research, 59(4), 639-660.

[13]. Colombo, I. G., Magri, A., Zani, G., Colombo, M., & Di Prisco, M. (2013). Textile reinforced concrete: Experimental investigation on design parameters. Materials and Structures, 46(11), 1953-1971.

[14]. Dheerendra Babu, M. R. (2016). Design and detailing of RC elements. Falcon Publications.

[15]. Gayathri, C. N., Singh, R. B., & Dhanalakshmi, G. (2018). Mechanical behaviour of textile reinforced concrete. International Research Journal of Engineering and Technology (IRJET), 5(5), 2227-2231.

[16]. Ghaffar, A., Chavhan, A. S., & Tatwawadi, R. S. (2014). Steel fiber reinforced concrete. International Journal of Engineering Trends and Technology (IJETT), 9(15).

[17]. Gopinath, S., Ramachandra Murthy, A., Iyer, N. R., & Dharinee, R. (2016). Investigations on textile-reinforced concrete as cover for RC beams. Magazine of Concrete Research, 68(20), 1040-1050. https:/doi.org/10.1680/jma cr.15.00161

[18]. Gowsika, D., Balamurugan, P., & Kamalambigai, R. (2017). Experimental study on curing methods of concrete. International Journal of Ecology and Development Research (IJEDR), 5(1).

[19]. Hegger, J., & Voss, S. (2008). Investigations on the bearing behaviour and application potential of textile reinforced concrete. Engineering Structures, 30(7), 2050-2056.

[20]. Henry, R., Brooke, N., & Ingham, J. (2007). An overview of reinforced and prestressed concrete research at the University of Auckland. In Proceedings of 2007 ANCER Annual Meeting.

[21]. High, C., Seliem, H. M., El-Safty, A., & Rizkalla, S. H. (2015). Use of basalt fibers for concrete structures. Construction and Building Materials, 96, 37–46. https://doi. org/10.1016/j.conbuildmat.2015.07.138

[22]. Kandasamy, R., & Murugesan, R. (2011). Fibre reinforced concrete using domestic waste plastics as fibres. ARPN Journal of Engineering and Applied Sciences, 6(3), 75-82.

[23]. Rahman, A. F., Goh, W. I., Mohamad, N., Kamarudin, M. S., & Jhatial, A. A. (2019). Numerical analysis and experimental validation of reinforced foamed concrete beam containing partial cement replacement. Case Studies in Construction Materials, 11, e00297. https://doi. org/10.1016/j.cscm.2019.e00297.

[24]. Rai, A., & Joshi, Y. P. (2014). Applications and properties of fibre reinforced concrete. International Journal of Engineering Research and Applications, 4(5), 123-131.

[25]. Raju, N. K., & Parnesh, R. N. (2018). Reinforced concrete design IS:456-2000 Principles and practice. New Age Publications.

[26]. Reddy, K. K. (2013). A comparative study on methods of curing concrete–influence of humidity. International Journal of Engineering Research and Applications (IJERA), 3(3), 1161-1165.

[27]. Rhodes, C. C., & Evans, J. R. (1949). An appraisal of the membrane method of curing concrete pavements. Engineering Experiments Station Bulletin.

[28]. Shetty, M. S. (2006). Concrete technology, Theory and practice. S. Chand Publications.

[29]. Sutharsan, R., Ramprasanna, S. R., Gnanappa, S. B., & Ganesh, A. C. (2020). Experimental study on Bamboo as a reinforcing material in concrete. In AIP Conference Proceedings (Vol. 2204, No. 1, p. 020024). https://doi.org/1 0.1063/1.5141561.

[30]. Syal, I. C., & Goel, A. K. (2008). Reinforced Concrete Structure. S. Chand Publications.

[31]. Volkova, A., Paykov, A., Semenov, S., Stolyarov, O., & Melnikov, B. (2016). Flexural Behavior of Textile-Reinforced Concrete. In MATEC Web of Conferences (Vol. 53, p. 01016). https://doi.org/10.1051/matecconf /20165301016

[32]. Williams Portal, N., Lundgren, K., Wallbaum, H., & Malaga, K. (2015). Sustainable Potential of Textile- Reinforced Concrete. Journal of Materials in Civil Engineering, 27(7). https://doi.org/10.1061/(asce)mt.1943- 5533.0001160