Figure 1. Glass Fibre Reinforce Polymer Rebar

Concrete with fly ash as replacement for cement represents a promising solution for the construction industry to deal with the issues related to the global emissions of greenhouse gases. Although numerous studies were dedicated on the material properties of concrete with fly ash. There is a need to evaluate flexural behaviour of Glass Fibre Reinforced Polymer (GFRP) over conventional reinforced concrete using fly ash as partial replacement for cement in order to promote further field applications. To accomplish the above objective in the present study, mix design for M20, M40 and M60 is carried out. Cubes, cylinders and beam specimens are casted for assessing the compressive strength, split tensile strength and flexural behaviour of concrete respectively. The use of 30% of fly ash as replacement for cement in concrete improves the workability but slightly reduce the compressive strength, split tensile strength due to slow pozzolanic reaction. The use of GFRP as reinforcement in the beam specimens with 30% of fly ash as replacement for cement improves the flexural load carrying capacity. Based on the results it can be concluded that GFRP reinforced fly ash concrete is more ductile and it has more ductility index than steel reinforced fly ash concrete and also reduces the cracks and crack width.

Fibre Reinforced Polymer (FRP) is a composite material made of a polymer matrix reinforced with fibres. The fibres used are usually glass (in fibre glass), carbon, aramid, or basalt. Other fibres such as paper, wood, or asbestos have also been used. The polymer is usually an epoxy, vinylester, or polyester thermosetting plastic. FRPs are commonly used in the aerospace, automotive, marine and construction industries. The applications in buildings include: (a) waterproofing and damp proofing of roofs and tanks, (b) use of translucent FRP sheets in roofs, (c) in building components such as doors, window frames, wall panels etc., and (d) strengthening of RC sections. Apart from using these sheets in the constructional activities, GFRP rebars can be used. The main advantage of using these bars in the conventional reinforced concrete structures is that there will be no existence of corrosion in the structures. Hence, these rebars are widely used in RC structures subjected to coastal environment.

Yoo et al. (2015) conducted his study with 0%, 35% and 50% replacement of fly ash with cement in concrete with grades M20, M40 and M60. He observed that 50% fly ash can be suitably replaced for cement in concrete. Some tests on beam specimens was also conducted and concluded that the ductility index values for fly ash concrete beams were more than nominal concrete beams. Ashour (2006) carried some works with GFRP rebars in flexural study. Three different depths for beams were used namely 200, 250 and 300 mm. Depth and GFRP reinforcement ratio were different for each beam groups. Flexural mode and shear mode failure were observed in the specimens. Flexural failure was observed due to tensile rupture of GFRP bars. Shear failure occurred due to major diagonal crack within the shear span of beam. Adam et al. (2015) conducted a study with ten beam specimens of size 120 × 300 × 2800 mm under four point bending. Compared to steel reinforcement GFRP rebar has lower stiffness. As the reinforcement ratio increases, it reduces the minimum span deflection, crack width and also increases ultimate load carry capacity. Maranan et al. (2015) replaced GFRP rebars with conventional steel in geopolymer concrete. Based on test results it was concluded that bar diameter had no significant effect and as the reinforcement ratio increases the performance of beam serviceability. It clearly gives an indication that these bars can be used in any type of concrete.

GFRP generally exhibits a linear elastic tensile stress-strain relationship up to failure which, in comparison to steelreinforced members, may result in poor structural ductility even in properly designed (according to standard reinforced concrete design guidelines) FRP reinforced members (Li & Wang, 2002). In seismic zones, although FRP reinforced concrete members may undergo large deformations, the energy dissipation is very little (Fukuyama & Masuda, 1995). Since the structural failure due to FRP reinforcing bar rupture is rather catastrophic, the overreinforced design concept that ensures that compressive failure of concrete takes place prior to the tensile failure of FRP has been well accepted (American Concrete Institute Committee, 1996; Sonobe et al., 1997; Theriault & Benmokrane, 1998). Nanni pointed out that, for FRP reinforced concrete beams, the balanced reinforcement ratio for simultaneous failure of the concrete and the FRP reinforcing bar, is much lower than the practically adopted reinforcement ratio if the concrete is unconfined (Nanni, 1993).

Except for Carbon Fiber Reinforced Polymer (CFRP), the modulus of elasticity of most available FRP materials is only 1/5 to 1/3 that of steel. This results in larger deflections as well as larger crack widths under service loads in comparison with those of its counterpart steel-reinforced concrete element for a given reinforcement ratio (Benmokrane & Masmoudi, 1996; Nawy & Neuwerth, 1977; Nawy et al., 1971).

Figure 1. Glass Fibre Reinforce Polymer Rebar

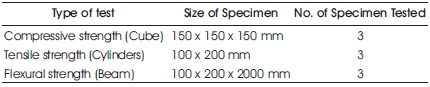

The experimental part of present research includes the details of tests conducted as given in Table 1 and they are tested in accordance with the procedure mentioned in BIS (1959) and BIS (1999a).

Table 1. Types of Test Carried Out

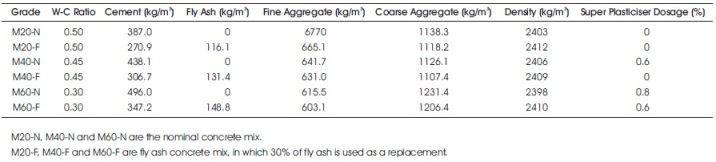

For preparing the GFRP mixes, the basic ingredients like cement and fly ash were taken in the form of percentage of the total mass of aggregates in the concrete. Several trails with different combinations of cement and fly ash were considered. Finally the mix which had cement (70%) and FA (30%) has been selected, since it yielded highest compressive strength (Pujari, 2017).

Based on the results obtained from physical properties of concrete, the details of mix proportions designed as per BIS (2009) is given in Table 2.

Table 2. Mix Proportions for Various Grades

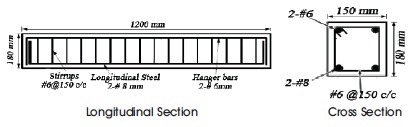

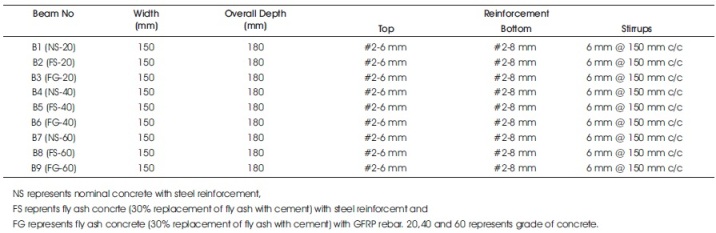

For evaluating the flexural behaviour, 9 beam specimens were prepared. The beams designed were under reinforced section for different grades of concrete. The reinforcement details are shown in Table 3 and a typical detailing is shown in Figure 2.

Figure 2. Beam Specimen Details

Table 3. Mix Proportions for Various Grades

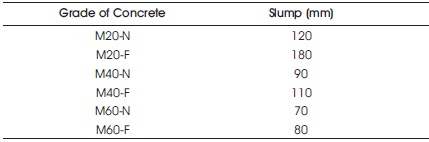

Workability for fly ash concrete is more than the nominal concrete as presented in Table 4. This is due to the fact that fly ash acting as replacement for cement in concrete reduces the voids and increases the paste volume. Comparing to workability results of nominal concrete, percentage of increase in workability for M20 grade fly ash concrete (M20-F) is 50%. Similarly, Percentage of increase in workability for M40 grade fly ash concrete and M60 grade fly ash concrete are 22.23% and 14.28% respectively. From the above results the conclusions may be found that the grade of concrete will increase as the increase in workability for fly ash concrete decreases.

Table 4. Slump Values for Different Grades of Concrete

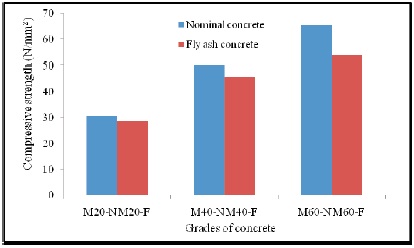

From Figure 3 it is observed that, compressive strength of nominal/conventional concrete is greater than the concrete made with fly ash in all cases. This is mainly due to the reason that the use of fly ash as replacement for cement in concrete causes slows pozzolanic reaction and develops large quantity of calcium aluminium hydrates and cementitious C-S-H phase at the later ages.

Figure 3. Compressive Strength vs Grade of Concrete (28 Days)

The results reveals that there is decrease of 5.73%, 9.31% and 17.34% respectively in compressive strength of M20, M40 and M60 grade fly ash concrete with that of nominal/conventional concrete. From the results it can be summarised that as the grade of concrete increases, the compressive strength of fly ash concrete also increases similar to that of nominal concrete.

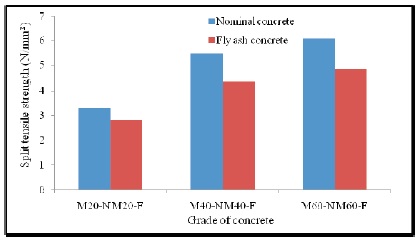

From Figure 4 it is observed that, tensile strength of nominal/ conventional concrete is greater than the concrete made with fly ash in all cases. This is mainly due to the reason that the use of fly ash as replacement for cement in concrete causes slows pozzolanic reaction and develops large quantity of calcium aluminium hydrates and cementitious C-S-H phase at the later ages.

Figure 4. Split Tensile Strength with Grade of Concrete (28 Days)

The results reveals that there is decrease of 14.94%, 19.96% and 20.39% respectively in tensile strength of M20, M40 and M60 grade fly ash concrete with that of nominal/conventional concrete. From the results it can be summarised that as the grade of concrete increases the tensile strength of fly ash concrete also increases similar to that of nominal concrete.

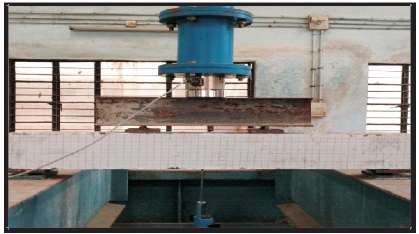

The beam specimens used in this investigation were tested under two point static loading until failure as shown in Figure 5. The most common thing observed was, as the load on the beam increased, it started to deflect and flexural cracks developed along the span. The entire beam specimen failed in the same fashion due to yielding of the tensile steel (primary tension failure) followed by crushing of concrete at the compression face (secondary compression failure). During the testing of beams the events that occurred are first cracking, yielding of the tensile reinforcement, crushing of concrete at the compression face and spalling of concrete cover. The sequences of study listed above are the typical features of reinforced concrete beams (Pujari, 2017).

Figure 5. Testing of Beam Specimens

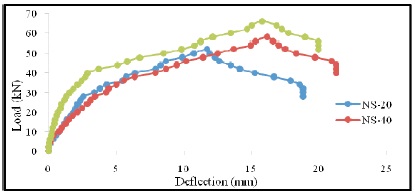

The values presented in Table 5 and Figure 6 gives the details of test results conducted. From those results it is clear that the reinforced concrete beam (NS) sections, behaves very ductile. The first crack appeared in the center span, then inclined shear cracks were induced beyond the pure moment span with increasing load. For under reinforced sections, the longitudinal tension steel yielded first, followed by the concrete crushing, which is a ductile mode of failure. The failure in these beams is governed by ordinary flexural cracks at the tension side. The mode of failure in all the types of beams were almost symmetrical.

Figure 6. Variation of Load vs Deflection for Different Grades of Nominal Concrete with Steel Rebar as Reinforcement

The flexural capacity of the beams was influenced by the longitudinal tensile reinforcement ratio and the concrete compressive strength. As the grade of concrete increases for all the three series of beams it can be noticed that, flexural capacity of the beams increased significantly. The flexural capacity varied more or less marginally with the increase in the compressive strength of the concrete. The main steel reinforcing bars yielded with the moment mentioned in Table 5, after that, large deflection occurred with slightly increased moment. The beam finally failed in crushing and spalling of the concrete in the compression zone between the two load points, resulting in a sudden load drop as mentioned by few researchers (Ashour, 2006; Fukuyama & Masuda, 1995; Li & Wand, 2002).

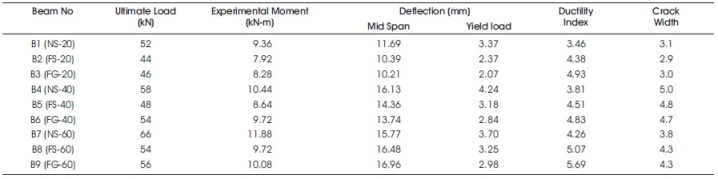

Table 5. Experimental Test Results for NS, FS and FG Beam Specimens

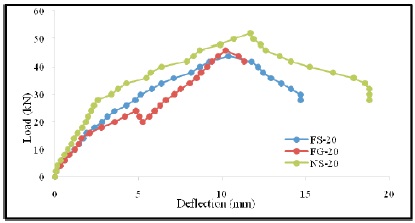

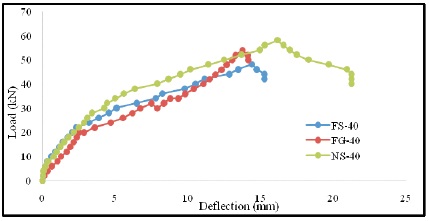

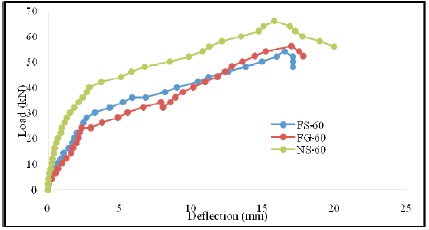

Ductility describes the ability of structural members to sustain inelastic deformation prior to failure without significant loss in load-carrying capacity. To ensure the safety of a structural member under overload, two essential performance features are required. First, the structural member should be able to undergo large deformations and associated wide cracks prior to collapse, so that an overload can be easily detected. Second, high inelastic energy absorption while maintaining load capacity is preferred to avoid elastic-brittle catastrophic failure. The ratio between deflection at ultimate load (Δu) and deflection at yield load (Δy) is defined as Ductility index (μ). The values of ductility index are presented in Table 5, which shows that FG series beams have more ductility index than that of FS and NS series beams. The variation of load and deflection for M20, M40 and M60 grade concrete are shown in Figure 7, Figure 8 and Figure 9 respectively.

Figure 7. Variation of Load vs Deflection for M20 Grade Concrete

Calculation of crack width is one of the serviceability requirements in the structural concrete element. Control of cracking is important for long term durability of concrete structures. Excessive crack width may reduce life of structure by permitting more rapid penetration of corrosive factors. Due to the lower modulus of elasticity of GFRPreinforcement (20% that of steel), resulting in reduced flexural stiffness of GFRP-reinforced concrete beams in a cracked state. The deflection and, in turn, the crack width at service load generally are much larger than those of equivalent steel reinforced beams (Fukuyama & Masuda, 1995; Li& Wand, 2002; Nanni, 1993). The crack width values for fly ash concrete with steel as reinforcement and fly ash concrete with GFRP rebar as reinforcement are nearly same as shown in Table 5. The use of fly ash in M20 and M40 grade concrete reduces the crack width by 0.93 and 0.94 times respectively than the nominal concrete, because of the fact that fly ash in concrete makes concrete denser than nominal concrete. But use of fly ash in M60 grade concrete increases the crack width by 1.13 times than the nominal concrete.

Figure 8. Variation of Load vs Deflection for M40 Grade Concrete

Figure 9. Variation of Load vs Deflection for M60 Grade Concrete

Based on the experimental investigations conducted, the following observations can be drawn.