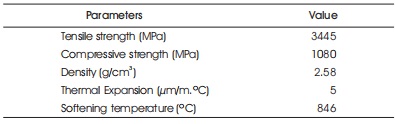

Table 1. Properties of Fiberglass (Volf, 1990)

This paper deals with the construction of a rigid pavement road which uses concrete as a construction material. This paper deals with the partial replacement of fine aggregates in the concrete with fiber glass. The concrete with fiber glass and without fiber glass is analyzed in terms of compressive strength and rise in temperature due to sunlight. The concrete considered for this research work is M20 mix. The fine aggregate replacements for the concrete ratio are 5%, 10% and 20%. The characteristic compressive strength of conventional M20 concrete and developed M20 concrete is nearly equal with a visible difference in temperatures after sunlight exposure. The outcome of this research work is that fiber glass is effectively efficient to be used for cool pavement & cool Roofing and can be adopted easily as it consumes waste.

Cool pavements indicate to a range of established and emerging materials. These pavement materials tend to heat up less and may have lower surface temperatures compared with conventional pavement materials. They can solve the problem of urban heat island effect. Urban heat island effect causes the rise of temperatures of paved surface in a city or urban area. This phenomenon happens because conventional dark roofs and dark pavements get hot in sun as they absorb 80 to 95 percent of sunlight. Hot pavements also contribute to global warming by heating the local air and radiating heat into atmosphere. Pavements comprise about one third of surface in an urban area. Hot pavements can also raise the temperature of runoff created by rainfall.

The following are the benefits of using cool pavements which can benefit the road user and overall environment.

The objectives of the study are described below.

Santamouris et al. (2012) performed an experiment in an urban park of 4500 m2 in Athens. The whole area is covered by a reflective pavement. This was the largest application of cool pavements in the world. To evaluate the thermal impact of cool paving materials, specific and detailed measurements of the climatic conditions in the park were performed before and after the installation of the new materials. It was estimated that the use of cool paving materials contributes to the reduction of the peak ambient temperature during a typical summer day, by up to 1.9 K ( At the same time, the surface temperature in the park was decreased by 12 K, while comfort conditions have been improved considerably. It was concluded that the use of reflective paving materials is a very efficient mitigation technique to improve thermal conditions in urban areas (Santamouris et al., 2012).

Yang et al. (2016) found out that pavements with different surface albedos and different thermal inertia were simulated to demonstrate influences of surface modification and heat-storage modification on the releasing sensible heat. Instantaneous solar absorption by the pavement is prone to be partitioned into heat conduction. Most of the absorption is discharged as sensible heat and long-wave emission, whereas the daily cumulative heat conduction is roughly 5% of the absorption ( Both increasing the surface albedo and enhancing the evaporative flux are effective to suppress the sensible heat and to promote cool pavements. Raising the thermal inertia of the pavement decreases the sensible heat during the daytime but increases this factor at nighttime. Therefore, it should be cautious to design cool pavements by varying their thermal inertia.

Akbari & Matthews (2012) have reviewed the literature for the solar reflectance of many standard and reflective paved surfaces including paving materials such as chip seal, slurry coating, and light-color coating. They report that the solar reflectance of freshly installed asphalt pavement is about 0.05. Aged asphalt pavements have a solar reflectance of 0.10-0.18, depending on the type of aggregate used in the asphalt mix. A light-color (low carbon content) concrete can have an initial solar reflectance of 0.35-0.40 that will age to about 0.25-0.30. They recommend using cool pavement materials in the urban area to increase the solar reflectance of paved surface by about 0.15 (Akbari & Matthews, 2012).

Current pavement construction standards do not account for the solar reflectance of pavements. However, the maximum temperature of a pavement and the diurnal range of pavement temperature is an important consideration in design of a pavement. Laboratory tests have demonstrated that cooler pavements have a longer life time.

Synnefa et al. (2012) conducted an experiment on a school building in Athens. A monitoring was done on the building before and after the application of white elastomeric coating with a solar reflectance of 0.89 on the roof of the building. An infrared camera was used to determine the difference in surface temperature before and after the application of cool roof application. The building has been modelled into TRNSYS software and the model was calibrated and validated using the experimental data. Simulation results showed a decrease in the air temperature in the classes that reaches 2.8 °C and a decrease in the annual cooling load by 40%. The corresponding heating penalty (i.e. the increase of heating load) is 10% (Synnefa et al., 2012).

Durability is one of the key parameter of reinforced concrete structure which gives the idea to withstand the structure against structures like load, pressure and atmospheric condition. There are several factors that affect the durability which are permeability, sulphate attack, chloride etc. In this series corrosion of reinforcement is also one of the most important factor that may causes damage of reinforced concrete structure (Yadav & Kushwaha, 2017).

This effect can be described as the accumulation of heat within urban area due to construction and human activities. This effect creates a huge impact on urban climate. The increase of land temperatures creates a significant impact on hydrological situations, soil properties, ecology and environment, public health and atmosphere. Urban Heat Island effect can be mitigated by improvement of urban landscape optimization, high reflectivity materials and land cultivation. Urban sustainable development is the top priority for all people and this can be done by many numerical simulation methods and research on ecological and environmental effects of urban heat island (Zhen et al., 2016). Heat island phenomenon rises the temperature of cities which in turn increases the energy requirement for cooling and deteriorates comfort conditions in the urban environment (Santamouris, 2013). To reduce the impact of this effect, important mitigation techniques have been developed and analysed. The use of cool pavements could significantly lower surface temperatures and reduced heat radiation to atmosphere appears to be one of the most important mitigation solutions. The present paper investigates and describes the actual materials that can be used as cool pavements. The existing results clearly shows that the cooling potential of cool pavements is very significant and can be highly effective in decreasing temperatures on the urban environment (Wei & Liu, 2016).

Urban heat islands are majorly caused by the heat absorption and reflectance from solar radiation with dark surfaces, which can cause the temperature in urban areas to increase in the summer. This excess heat increases the peak energy demand, as people use air conditioning to cope with high temperature which has an adverse impact on environment by increasing emissions and Green house gases. Efforts to mitigate these adverse effects focus largely on increasing the reflective properties of the built environment, such as cool pavements. Cool pavement technologies create cooler surfaces through convection or higher reflectance (Santamouris & Kolokotsa, 2013).

Glass-reinforced plastic (GRP) is a composite material or fiber-reinforced plastic made of a plastic reinforced by fine glass fibers. Like graphite-reinforced plastic, the composite material is commonly referred to as fiberglass. The glass can be in the form of a chopped strand mat (CSM) or a woven fabric. The properties of the fiberglass used are shown in Table 1 (Fitzer et al., 2008).

Table 1. Properties of Fiberglass (Volf, 1990)

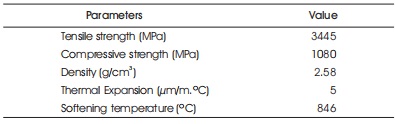

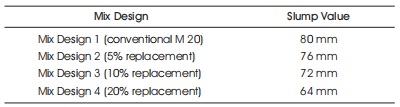

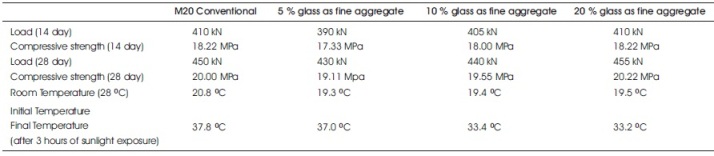

Firstly, the concrete mix is decided which is taken as M20 (1:1.5:3). The material required are calculated for the four mix designs: Mix design 1(M.D. 1), Mix design 2 (M.D. 2), Mix design 3 (M.D. 3) and Mix design 4 (M.D. 4) with Mix design 1 as the conventional M20 concrete and Mix design 2, 3 and 4 with 5%, 10% and 20% fine aggregate replacement with Fiber Glass. The Fiber Glass is obtained from the waste material of automobile industry such as garage. The Fiber Glass is then broken down to little pieces by using a jute bag and hammer. Any other industrial method can be used. For research purposes the quantity required was less so it has been done manually in this scenario. The fiber glass is sieved to obtain particle size between 2.36 mm to 4.75 mm. As the replacement is for fine aggregate we are considering size less than 4.75 mm but the cost of making fiber glass particle size less than 2.36 mm would have been high that is why the size of 2.36 mm to 4.75 mm is considered. 6 cubes for each mix design was prepared and the cubes were cast of dimension 150 mm x 150 mm x 150 mm. The water cement ratio used is 0.56 as fiber glass reduces the workability. This was observed by performing slump test on the above mentioned mix and the result are shown in Table 2. The cubes were cured for 14 days and 28 days and the compressive strength and rise in temperature due to sunlight were measured. The rise in temperature was measured using an Infrared thermometer. The results are depicted in Table 3.

Table 2. Test Results for Slump Test for Workability

Table 3. Test Results for Compressive Strength Test and Rise in Temperature.

Due to global rise in temperature all across the world, this study related to cool pavements are inevitable. The first result obtained from this study was that the fiberglass that is to be used needs processing and high energy. The result of slump test was that there was 20% reduction in slump value. This depicts that the workability is reduced when fiberglass was added.

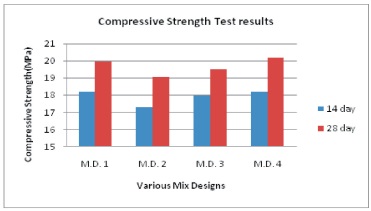

Further results of 14 day compressive strength and 28 day compressive strength was analysed. Figure 1 shows the graphical results obtained from compressive strength.

Figure 1. Compressive Strength Test Results for 14 Days and 28 Days

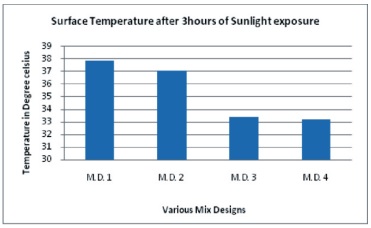

The last result which is the most important one is the comparison of surface temperature of the conventional concrete with the concrete containing fiberglass after 3 hours of sunlight exposure. It has been observed that there is a difference of 4.6 degree Celsius. Figure 2 shows the difference in surface temperaturewith various concentration of fiber glass.

Figure 2. Surface Temperature for Various Mix Designs after 3 hours of Sunlight Exposure

Important research is being carried out aiming to better document, understand and mitigate urban heat islands. New materials, systems and technologies have been developed and proposed in order to decrease the sensible heat energy to the atmosphere from different RESEARCH PAPERS urban structures like buildings and paved surfaces. As it can be observed that two types of pavement materials could be developed, one with high reflective properties or permeable pavements that use evaporation to cool the pavements.

Unfortunately, very few projects are going on the field to assess the implementation of cool pavements in a large scale. There is an urgent requirement to analyse the effects of using cool pavements on a large scale and its impact on micro climate, energy consumption, etc. Permeable pavements or pavements with vegetation could be used where water is available abundantly. Significant research should be done on the use of additional materials such as fine blast powder, industrial wastes, fly ash, etc. to make pavement materials. The characteristic compressive strength of conventional M20 concrete and developed M20 concrete is nearly equal with a visible difference in temperatures after sunlight exposure. The result of project is that fiber glass is effectively efficient of cool pavement & cool roofing and can be adopted easily as it consumes waste.

The conventional pavement surface temperature range is generally 20-30ºC (68-86°F) higher than the air/surrounding temperature due to pavement solar energy absorption during daytime, especially in the summer. The heat energy that is absorbed by the pavement surface at daytime will be released in the atmosphere after sunset. Due to large area covered by pavement surfaces it is an important factor that should be considered while solving the problem of urban heat island effect. If this concept of cool pavements is implemented in large scale then it can significantly reduce the temperature of pavement and local air. Also cool pavements that have lower surface temperature would reduce the temperature of storm water. This type of cool pavements can also help improve the service life and durability of pavement.

The main limitation of use of fiber glass is making it to the size of fine aggregate. The method used in this study was manual crushing of fiber glass and then sieving the glass. When it would be applied on a large scale manual crushing of fiber glass will not be possible. More study in this regard is needed to apply the use of fiber glass as replacement of fine aggregate.

The other factor associated with the use of fiber glass is the cost of processing fiber glass. If the waste fiber glass is properly segregated from other waste and crushed in large scale to make it as fine as sand then it can be used extensively in construction industry. This can result in less urban heat island effect if this type of concrete is used for construction of pavements and roof.