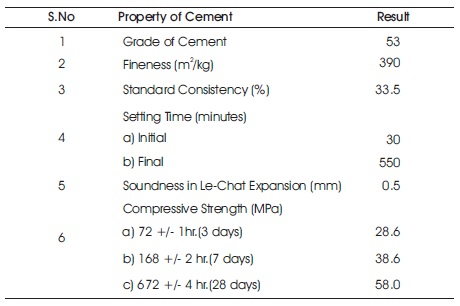

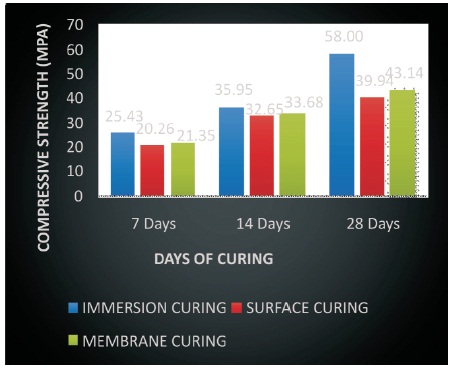

Table 1. Properties of Cement Used

Curing is the process of maintaining hardened concrete under moist condition. Curing must be undertaken for reasonable period of time, to ensure that the concrete achieves its potential strength and durability. Efficient and uninterrupted curing contributes to the superior quality of concrete. This paper aims to compare the strength parameters of M40 and M25 grade concrete under various methods of curing. For this study, we adopted curing by Immersion and Surface Curing methods. We also adopted Membrane Curing, in which the curing would be done by the application of pigmented emulsions of linseed oil on the concrete surface. Finally, after the concrete specimens have undergone curing for a certain period of time, they are tested for strength parameters such as Compressive Strength and Flexural Strength and the conclusions are drawn from it.

Concrete is considered to be one of the most versatile, legendary and strongest building materials. It is known for its simplicity in manufacturing and can be casted to fit any structural shape. It is readily available in urban areas, at an affordable cost (Bureau of Indian Standards [BIS], 2016).

Practice of concrete provides the following advantages: High durability, good fire resistance, negligible maintenance and importantly greater compressive strength. Concrete also offers some limitations such as, poor tensile strength (which could be improved by providing Reinforcement) and formwork requirement (unignorable).

Another limitation that comes into picture is that, concrete, could not attain higher strengths immediately after hardening. For this, the concrete need to be cured for a certain period of time. Curing, is a process of reducing the extent of moisture loss from concrete by providing moist conditions for the surface of concrete during cement hydration. Since the hydration of cement does take time for days and weeks together, curing must be undertaken for reasonable period of time if concrete is to achieve its potential strength and durability.

Curing is done to attain good quality concrete, with greater strength parameters. Curing is essential if the concrete is to perform its intended function during the design life of the structure, whereas excessive curing time may lead to rapid increase in the construction cost of the project and unnecessary delays (BIS, 2000).

If within the curing period, natural temperatures of concrete are in the acceptable range of values, then moisture content need not be controlled. If the natural temperature is outside the acceptable range of values, moisture content needs to be regulated for controlling the temperature of concrete, as it influences concrete's strength.

There are various methods of curing, including the following:

Many other methods are used.

Cement is one of the basic construction material that will be generally in powdered form and hardens upon the addition of water to it. It can serve as a binding material to aggregates for obtaining strength. It possesses cohesive and adhesive properties. The cement used for this study is Portland Pozzolana Cement of 53 Grade (BIS, 2013).

The properties of the cement used is presented in Table 1.

Table 1. Properties of Cement Used

The Aggregate passing through 4.75 mm sieve could be called as Fine Aggregate (BIS, 2016). Generally, Fine Aggregate is a filling material for the Concrete. The Fine Aggregate used for this study is River Sand collected from Local RMC Plant. The Specific Gravity of the Fine Aggregate used is 2.65.

The Aggregates passing through 20 mm IS sieve and retained on 4.75mm IS sieve could be called as Coarse Aggregate (BIS, 2016). Generally, Coarse Aggregate is a material that enhances the strength and stability for the Concrete. The Coarse Aggregate used for this study is collected from Miyapur Quarry. The Specific Gravity of Coarse Aggregate used is 2.83.

Water is the main ingredient used to mix all the contents. The usage of any other water may contain salts, it will cause decrease in strength of concrete. Therefore, potable water is used.

In this study, for the purpose of Membrane Curing, we have adopted the chemical which is a pigmented emulsion of linseed oil. After its application and drying, it attains a bonded white colored appearance. It is not affected by natural weathering. The visual appearance of this chemical is presented in Figure 1.

Figure 1. Chemical used for Membrane Curing

Gunny Bags are used for surface curing. These bags are generally made of Jute material and are wrapped around the concrete specimen. These bags are damped with water from time to time as a medium of curing. The Gunny Bag used for the study is presented in Figure 2.

Figure 2. Gunny Bag

For this study, we have adopted 2 concrete mixes (Reddy, 2013).

They are M40 Concrete (Design Mix) which is made with respect to BIS (2009) and M25 Concrete (Conventional Mix). The proportions for these mixes are M40 grade (1:1.67:2.92) and M25 grade (1:1:2) and the water cement ratio is taken as 0:5 for both the mixes.

The concrete is mixed with the above specified materials on both the mixes and is casted in Cubes and Prisms for Formwork and is allowed to harden for 24 hours. Then 9 cubes and 9 prisms are cured by Immersion Curing for each grade. Similarly, another 9 cubes and 9 prisms are cured by Surface Curing and Membrane Curing. Finally, we have subjected these cubes to Compression and Flexure Tests and have drawn the results (Reddy, 2013).

This curing is done by immersing the hardened concrete specimen in water for a certain period of time. This curing could give results confining only to laboratory. Practically, on site, we cannot ever adopt this Immersion Curing. The Immersion Curing is represented in Figure 3.

Figure 3. Immersion Curing

This curing had been done by wrapping the concrete surface with a water retaining medium (Kumar & Maruthachalam, 2013). For this study, we have adopted Gunny bags and wrapped them against the concrete specimen and damped these bags from time to time. This type of curing could be adopted on site, and usually uses low amount of water. The process of Surface Curing is presented in Figure 4.

Figure 4. Sprinkling of Water on Prism Covered with Gunny Bag

As mentioned in this method, we have adopted pigmented emulsions of linseed oil, as a curing agent. This material would be in liquid form and should be applied in 3 layers for the surface of concrete and must be allowed to dry. Then the concrete is left in open atmosphere for a certain period of time and later proceeded for testing. The application of curing compound is shown in Figure 5.

Figure 5. Application of Curing Compound

After the specimens are cured, they are subjected to Compressive strength and Flexural strength tests. Each test result is tabulated and analyzed.

Compression Test is done by subjecting compression load on the concrete cube surface in Digital Compression Testing Machine.

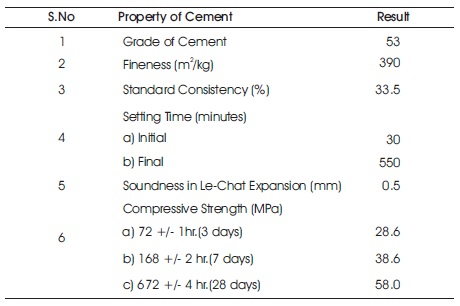

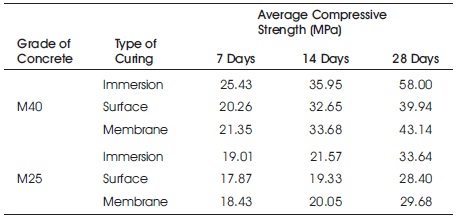

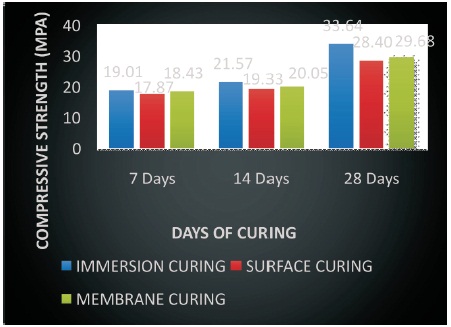

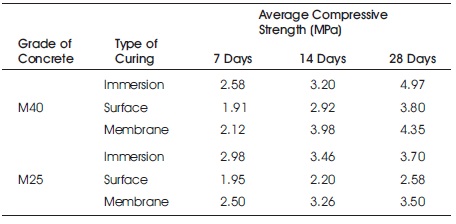

The results for this test are presented in Table 2 and Figures 6, 7 respectively.

Table 2. Compression Test Results for Various Curings and Concrete Grades

Figure 6. Variation of Compressive Strength in M40 Concrete for Various Curings

Figure 7. Variation of Compressive Strength in M25 Concrete for Various Curings

Size of cube for compression testing = 150*150*150mm

Compressive strength of concrete = Compressive Load/ (Surface area of cube)

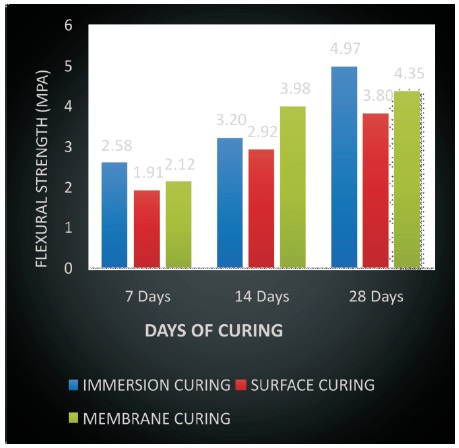

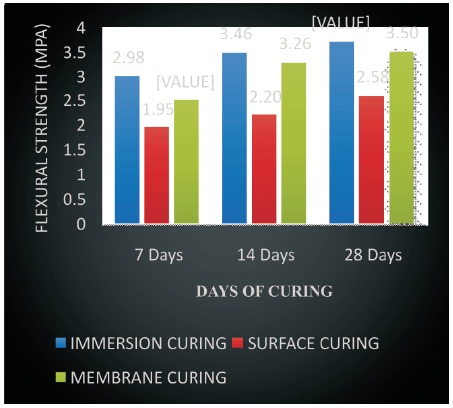

Flexure Test is done on concrete prism, by subjecting the Flexural Load in Flexure Testing Machine. According to IS 456:2000, the Flexural Strength of Concrete at 28 days age would be 0.7* (fck) 0.5 MPa (BIS, 2000). (where, fck is the grade of concrete).

Size of prism for flexure testing = 500*100*100mm

Flexure strength of concrete = (Maximum flexure load* length of prism/ width*depth2)

The results for this test are presented in Table 3 and Figures 8, 9 respectively

Table 3. Flexure Test Results for Various Curings and Concrete Grades

Figure 8. Variation of Flexural Strength in M40 Concrete for Various Curings

Figure 9. Variation of Flexural Strength in M25 Concrete for Various Curings

We (Challa Datta Karthik and Gourishetty Ruthvik) would like to thank our Project Guide Mr. G. Siva Vignan for helping us every minute to carry out this study successfully. We would also like to thank our Department of Civil Engineering at St. Martin's Engineering college for supporting us. We also like to thank our parents for imposing so much of faith and love on us.