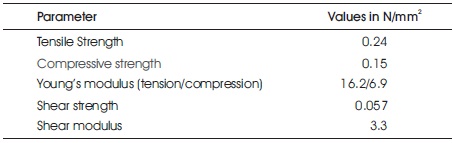

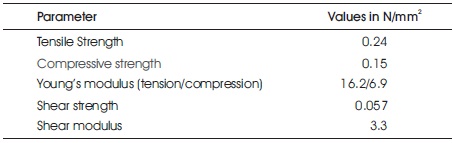

Table 1. Properties of Expanded Polystyrene

Concrete Sandwich Panel (CSP) system is an energy efficient, light weight and economic construction system for civil infrastructure. It consists of concrete wythes, shear connectors and light weight core material. This system can be used as wall, floor and roof panel for the properties of light weight, great strength and good thermal performance. The strength of Concrete Sandwich Panel systems are obtained by using high strength shear connectors and high performance concrete. Concrete strength is improved by using Textile Reinforced Concrete (TRC), Glass Fiber Reinforced Concrete (GFRC) and adding admixtures to the concrete. Thermal performance and light-weight can be achieved by using light weighted core materials, such as Expanded Polystyrene (EPS), Extruded Polystyrene (XPS) etc., and Foamed Concrete (FC) which further reduces the structural weight. Concrete Sandwich Panels (CSP) will reduce the seismic effect due to light weight and lateral strength. This article provides an overview of state-of- the-art research and development and also the applications of Concrete Sandwich Panel (CSP). It discovers the problems and future potential for the wide use of these enhanced systems in civil infrastructure.

Composite sandwich systems have been used in planes, vehicles, etc, for the applications of high thermal insulator, flexural strength and impact strength. In 1930, sandwich panels were introduced in the application of cladding (Shams et al., 2014). It was first studied by the organization of Forest Product Laboratory. Later, it was developed as a sandwich panel for structural purpose with heat reduction.

Conventional reinforced cement concrete panel is normally used in general construction. But, it has huge selfweight, consumes more construction materials and high thermal conductivity and results in higher construction cost. To overcome these problems in construction, Concrete Sandwich Panels (CSPs) were introduced.

Concrete Sandwich Panels (Kang and Kim, 2016) consists of two concrete wythes separated by light-weight insulation layer. The shear connector is used to connect the top and bottom concrete wythes through light-weight insulation layer. In this, shear connector gives adequate bond and structural strength between two concrete layers. It is available in various shapes and different materials with high tensile strength and shear strength. Insulation layer is of less weight and low thermal conductivity. It is available in various polymer forms, such as Expanded Polystyrene (EPS), Phenolic Foam (PF), Extruded Polystyrene (XPS), Polyisocyanurate foam (PIR) and Polyurethane (PUR) (O'Hegarty and Kinnane, 2020) Concrete wythes can be cast with different materials, such as foamed concrete, textile reinforced concrete, Reactive powder concrete, glass fiber reinforced Concrete, high performance concrete etc., in which foamed concrete will further reduce the self-weight of the structure.

In construction sector, structural and thermal efficiency is achieved by using Concrete Sandwich Panels. By connecting together, the thin, stiff and ductile concrete wythes with thermally-efficient light weight insulation layer, it is possible to obtain lightweight panels. These panels are energy efficient, and it can be easily handled and erected. This kind of structural solution is widely used in precast structural panels, which provide adequate weather sheltering, vapour barrier, protection against mechanical damage, acoustic performance and thermal insulation.

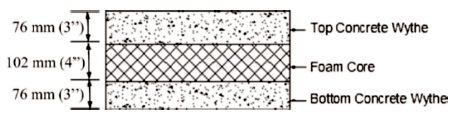

Concrete wythe is the outer layer of concrete sandwich panels shown in Figure 1. The thickness of concrete wythe mostly depends on its structural function, anchorage of the connectors, concrete cover, stripping, and finish. Although some literature provide guidelines for thickness of wythe, each Precast concrete sandwich panel producer can determine the appropriate thickness according to requirements and application. The concrete wythes are normally classified into two types. They are structural wythe and non-structural wythe (PCI Committee Report, 1997).

A structural wythe carries a major load of the concrete sandwich panel. Both concrete wythes are made with fully or partial composite sandwich panels (PCI Committee Report, 1997). One of the wythe is structural and the other is non-structural, or both wythes are structural and independently resist the applied loads in proportion to their relative stiffness in non-composite sandwich panels. If the concrete sandwich panel is pre-stressed, the minimum thickness of the structural wythe is considered as 50 mm. When it is non pre-stressed, the thickness of structural wythe is considered as 76 mm. But the thickness as small as 19 mm is used. The reinforcement of structural wythes varies based on dimensions, structural, and serviceability requirements of the panel.

The longitudinal reinforcement depends on the span of the panel, thickness of wythe, degree of composite action, load applied and serviceability requirements. This reinforcement may consist of pre-stressing strands or wires, reinforcing bars or wire mesh, or a combination of transverse reinforcement depending on the spacing of connectors, thickness of wythe, load applied, and temperature changes. This reinforcement may be small reinforcing bars or wire mesh.

A non-structural wythe, also called as cladding or a floating wythe, it has very poor load carrying capacity compared to structural wythe. It is primarily used for aesthetic purpose, weathering and to encase the insulation. The thickness of non-structural wythe should be kept minimum to reduce differential temperature across its thickness and to reduce panel weight. If neccessary, its thickness should be sufficient to provide proper reinforcement protection and anchorage of the connectors.

The thickness of non-structural wythe is generally 50 mm for a plain surfaced and 64 mm for a ribbed one. Wythes as thin as 38 mm is used. Reinforcement in these wythes is mainly used to prevent excessive cracking due to temperature, creep and shrinkage effects. It may consist of wire mesh or small reinforcing bars, and occasionally light pre-stressing. This reinforcement should be sufficient to support the weight of wythe itself. In some systems, joints are created in the non-structural wythe to control the shrinkage cracks.

The selection of insulation layer and its thickness varies based on its application, thermal properties, building temperature and thermal resistance of the panel. A minimum thickness of insulation layer 25 mm is used in general construction. The insulation layer should have low absorption capacity to reduce water loss from fresh concrete.

By eliminating butt joint and using large sized panels, the gap between two insulation layers is decreased. A gap around shear connectors leads to the penetration of concrete into the insulation layer, which reduces thermal efficiency of the concrete sandwich panel.

Expanded Polystyrene called as EPS Panel, is rigid, closed cell foam plastic (Kang & Kim, 2016). EPS has some advantages, such as high compressive strength, low thermal conductivity, low density and inert material. It can be used as a building material and can be easily molded into different shapes and sizes as per our requirements. The properties of expanded polystyrene are shown in Table 1.

Table 1. Properties of Expanded Polystyrene

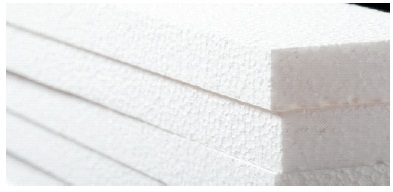

Expanded Polystyrene (EPS) as shown in Figure 2 is obtained from its resin form. The resin consists of pentane gas, which is released safely during the expansion process of Expanded Polystyrene. The Expanded Polystyrene resin expands upto 40% of its original size with the addition of steam. Then the expanded pellets are converted into a block molder.

Figure 2. Expanded Polystyrene

Connectors are used to fasten the concrete wythes together and hold the insulation layer in place. Connectors are classified into two types. They are shear connectors and non-shear connectors (PCI Committee Report, 1997).

Shear connectors are those, which can transfer longitudinal shear, resulting due to flexure in the panel, from one wythe to the other. These connectors may resist shear in one or two perpendicular directions.

Non-shear connectors can transfer only a negligible amount of longitudinal shear from one wythe to the other. They are commonly used in North America in noncomposite panels to transfer tension or compression forces due to stripping, storage, transportation, erection, wind, and seismic loads from non-structural to structural wythe. In addition to this, they prevent separation, peeling or wrinkling of non-structural wythe. They are used in composite panels in conjunction with the shear connectors, if the spacing of the shear connectors is too large.

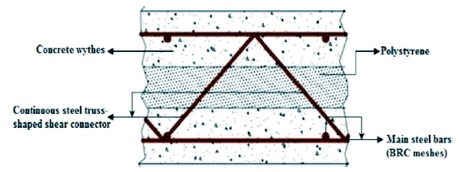

Benayoune et al. (2008) studied the structural behavior of precast concrete sandwich panels under flexural load conditions both experimentally and theoretically. They concluded that the crack patterns of precast concrete sandwich panels were similar to conventional concrete slab. The first crack load was obtained at a load from 50 to 60 percentage of the ultimate load of precast concrete sandwich panel. The composite action of concrete sandwich panel was achieved by using truss shaped shear connectors. The ultimate load is directly proportional to the number of shear connectors used in concrete sandwich panel.

Amran et al. (2016) presented an experimental and analytical investigation on Precast Foamed Concrete Sandwich Panels (PFCSPs) as shown in Figure 3. It was tested under flexural loading condition as one-way acting slabs.

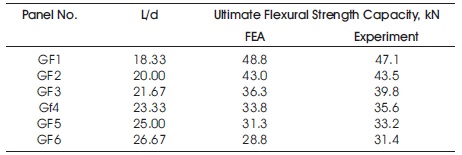

Figure 3. Cross Section View of PCSP with Truss-Shaped Shear Connector

Concrete wythes are cast by using foamed concrete to reduce the self-weight of slab with a compressive strength of 25.73 MPa. Six precast foamed concrete sandwich panels were cast by varying the aspect ratio from 18.33 to 26.67. When increasing aspect ratios from 18.33 to 26.67, it shows a reduction of 50% and 69.6% in ultimate flexural strength capacity of concrete sandwich panel. This has been obtained experimentally and in Finite Element Analysis (FEA) as shown in Table 2.

Table 2. Comparison Between Results of Experimental and FEA Models

The first flexural crack load is found at a load of 40% to 50% of the ultimate load at failure. Crack pattern of PFCSPs is similar to the conventional reinforced cement concrete solid slab.

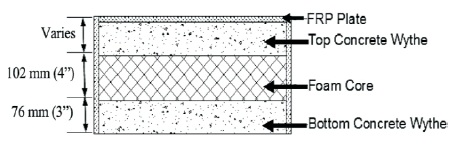

Chen et al. (2015) conducted a bending test and finite element analysis on eight concrete sandwich panels as shown in Figure 4, which are having dimensions of 2743 x 610 x 254 mm.

Figure 4. Cross Sectional View of Concrete Sandwich Panel

In this concrete sandwich panel, a fibre reinforced polymer plate is used as shear connector. Degrees of composite action are achieved by using different types of FRP plate shear connectors. Higher strength and stiffness of the concrete sandwich panels are obtained by using high stiff FRP plate shear connectors. Continuous and segmental shear connectors will give a higher result compared to discrete shear connectors. So, discrete shear connector is not recommended for construction purpose due to its poor performance.

Joseph et al. (2017) investigated the prototype concrete sandwich panels under four point loading both experimentally and analytically. To achieve composite action of panels, they used shear connectors made up of wires with an average yield strength of 651 MPa. Pre-cast Light-weight concrete sandwich panels fail in the flexural mode with the formation of numerous flexural cracks in bottom wythe similar to ferro cement.

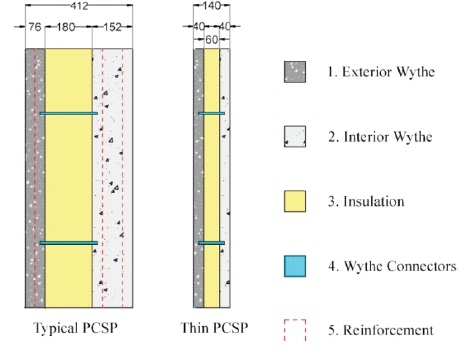

O'Hegarty et al. (2020) studied the flexural behaviour of pre-cast concrete sandwich panel as shown in Figure 5,composed of high strength fibre reinforced concrete wythes and light-weight foam insulation layer. These layers are fastened with carbon fibre reinforced polymer grid connectors.

Figure 5. Cross Section of a Standard (Left) and a Thin (Right) Precast Concrete Sandwich Panel (PCSP) with Typical Dimensions Provided in mm

The experimental test results show that, when the outer layer thickness is increased from 25 to 40 mm, the ultimate capacity and flexural rigidity of the panel increases abruptly and the mass of concrete sandwich panels also increases by 20%. The overall stiffness and strength capacity of concrete sandwich panels can be increased by achieving a higher degree of composite action.

Kazem et al. (2015) examined the effect of sustained loading and outdoor exposure of precast concrete sandwich panels tied with fiber reinforced polymer. Shear transfer mechanism is achieved by using carbon and glass FRP grid with Expanded Polystyrene and Extruded polystyrene foam. The shear strength of the precast concrete sandwich panels is reduced due to poor quality fabrication of sandwich panels. The bond between concrete and insulation layer is reduced due to entrapped air in the concrete and foam layer. To arrest creep effect of sandwich panel, the design capacity of the sandwich panels is limited to 30% of the ultimate shear strength of sandwich panel under sustained loading condition. So, a sustained load factor of 3.3 (1/0.3) is used for the concrete sandwich panel under creep effect. The light-weight insulation layer of EPS is easily susceptible with aging compared to XPS foam layer, though it is more sensible to weathering condition. So we need to protect the foam edges from being direct exposured to the environment.

Shams et al. (2014) examined a four type of Precast Concrete Sandwich Panels (PCSPs) with Textile Reinforced Concrete (TRC) wythes, different types of insulation materials and shear connectors. The bearing capacity of the Concrete Sandwich panels cross-section can be improved by pin-connectors for tensile forces perpendicular to the connecting joint, relative to sections containing only adhesive joints. Meanwhile, the pinconnectors' effect on the stiffness and bearing capacities for shear and bending loads is negligible. Textile reinforced concrete reduced the thickness of concrete wythes. PCSPs with TRC reduced the self-weight of Concrete Sandwich Panels with high structural efficiency.

Kang and Kim (2016) developed models for insulated concrete sandwich wall panels with glass fibre reinforced polymer grids to resist the flexural mode of failure. Ultimate and serviceability limit states are considered in this design by using Euro code 1990: 2002. This composite sandwich panel provides a new structural design against conventional materials, such as carbon steel and concrete. A continuous type of shear connector provides better performance against flexural failure compared to a stud type shear connector. Glass fibre reinforced polymer panels are per formed equivalent to conventional materials such as carbon steel. The statistical method adopted for determining the capacity factors of 0.5 and 0.78 are used for ultimate and limit state design methods, respectively by using the Euro code of 1990:2002.

Hopkins et al. (2017) studied the creep behavior of concrete sandwich panels under a flexural bending. This study was carried out both experimentally and analytically under creep loading. The model of insulated sandwich panels is shown in Figure 6.

Figure 6. Cross Section of Insulated Concrete Sandwich Panel

FRP top and bottom plates give a confining effect to foam core and this leads to reduced creep effect considerably. Fibre reinforced polymer precast concrete sandwich panel with thickness of 254 mm, shows the lowest deflection compared to the conventional concrete solid slab. The creep deflections are manipulated by using American Concrete Institute (ACI) equations.

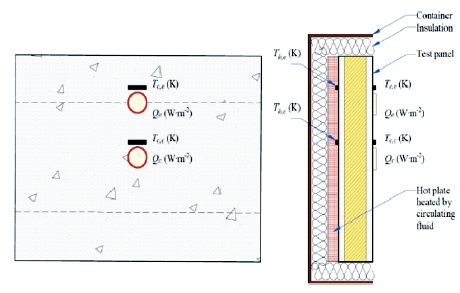

Richard et al. (2019) studied the thermal performance of light-weight precast concrete sandwich panels consisting of high-performance insulation layer between two thin concrete layers. In this study, the hot plate apparatus as shown in Figure 7, is used to evaluate the thermal performance of light-weight precast concrete sandwich panels.

Figure 7. Hot Plate Test Apparatus Illustrating Location of Sensors in Elevation (Left) and Section View of Test Setup (Right)

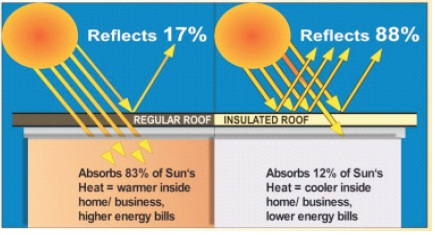

Thermal absorption of insulated roof as shown in Figure 8, absorbs only 12% of sun's heat and it tends to reduce the room temperature and lowers the energy bills.

Figure 8. Thermal Absorbtion of Insulated Roof

Concrete Sandwich Panel (CPS) fails with multiple cracks similar to conventional Reinforced Cement Concrete (RCC) slab. Truss shaped shear connectors with an angle of 45o gives more degree of composite action between concrete wythes and insulation layer. Higher strength and stiffness of concrete sandwich panels is achieved by using high stiff fibre reinforced polymer plate shear connectors.

Strength of concrete sandwich panels is decreasing with an increasing aspect ratio from 18.33 to 26.67, which shows a reduction of 50% and 69.6% in ultimate flexural strength capacity of concrete sandwich panel.

Concrete Sandwich Panels have very low self-weight and it can be easily transportable. So, it reduces the construction cost. Foamed type of concrete sandwich panel will considerably reduce the self-weight. Y. H. Amran et al. (2016) carried out the flexural strength in concrete sandwich panels by using foamed concrete with the compressive strength of 25.73 MPa. This type of foam concrete will further reduce the self-weight of Concrete Sandwich Panels.

Shams et al. (2014) found that textile reinforced concrete reduced the thickness of concrete wythes. PCSPs with TRC reduced the self-weight of concrete sandwich panels with high structural efficiency.

Concrete Sandwich Panels will reduce the base shear of seismic resistant design. In the house for all schemes, it will reduce overall construction cost of the project. Thermal transmittance (U) value of 0.324Wm-2K-1 is achieved for 150 mm thick composite sandwich panels.

Concrete Sandwich Panels will reduce the room temperature and the energy bills due to low absorption of sun's heat.

Concrete Sandwich Panel system is a modern, efficient, safe, and economic construction system for the construction of building.

We express our sincere gratitude to our Principal Dr. B. Chidambararajan, M. E., Ph.D., SRM Valliammai Engineering College for the valuable support throughout the course of study and express my sincere thanks to Dr. D. Elango, M.E., Ph.D., FIE, Professor & Head, Department of Civil Engineering for his valuable guidance, ideas and encouragement for the successful completion of this review paper.