Table 1. Materials required for 1m of QBBSCC

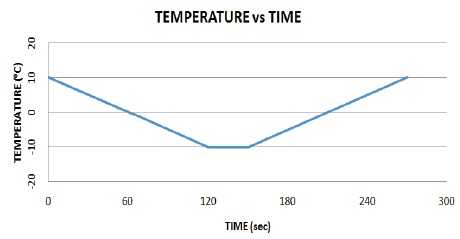

Concrete develops cracks and get deteriorated, losing its structural performance when exposed to alternate freezing and thawing. Usually, the effect of freezing and thawing in concrete is reduced by lowering the water-cement (w/c) ratio or by using an air-entraining admixture. Researches carried out on bacterial concrete have shown that the CaCO3 produced by the bacteria seals the micro-cracks and improves the properties of the concrete. In this study, an attempt has been done to investigate the effect of freezing and thawing of Quaternary Blended Bacterial Self-Compacting Concrete (QBBSCC), which is a blend of 40 % cement, 10 % micro-silica, 25 % fly ash and 25 % GGBFS (Ground- Granulated Blast-Furnace Slag). Bacillus Subtilis bacteria was selected for this study. For water-binder (w/b) ratios 0.3 and 0.4, super-plasticizer of 1.8 % and 1.6% by weight of binder respectively were used. QBBSCC cubes were subjected to 0, 5, 10, 15, 20, 25, 30, 35, 40, 45, and 50 numbers of freeze-thaw cycles in an ice-cream freezer box. Each freeze-thaw cycle comprised of freezing the samples from 10 ºC to -10 ºC within two hours, then maintaining the temperature at -10 ºC for half-an-hour and thawing from -10 ºC to 10 ºC within another two hours i.e., a freezing rate of 10ºC/hr was adopted. Weight loss, residual compressive strength, dynamic modulus of elasticity, and relative dynamic modulus of elasticity were evaluated. From the result, it was found that QBBSCC exhibited better freeze-thaw resistance than reference concrete without bacteria, Quaternary Blended Self-Compacting Concrete (QBSCC).

Freezing and thawing is one of the causes of concrete deterioration in cold regions. Concrete structures are subjected to premature failure due to cyclic freezing and thawing. At very low temperature, when the concrete contains pores saturated with water, the water freezes to ice (freezing). Ice expands and occupies 9% more volume than water. As water freezes, pressure is created inside the pores. When this pressure increases more than the tensile force of the concrete, pores break open and cause cracks in the concrete. When the temperature returns to normalcy, the ice turns back into water (thawing).

Alternate freezing and thawing induces volume expansion and thermal stresses in concrete. These are the causes of internal crack formation in concrete due to freezing and thawing. Also, higher the water-cement ratio used in concrete, higher the risk of freeze-thaw effect.

In fresh concrete, freezing causes very delayed setting of concrete. On the other hand, cement hydration reaction stops below 40 ºC, not allowing the concrete to harden. This weakens the bond between the aggregate and cement mortar.

However, in hardened concrete, the repeated freezethaw cycles inside the concrete results in surface scaling or a random pattern of cracking on the concrete surface (Shang & Yi, 2013). The cracking causes loss of strength in concrete structures.

Since both fresh and hardened concrete are affected, durability of concrete due to freeze-thaw effect is important. Freeze-thaw criteria should be taken into consideration in structural design and maintenance (Shang et al., 2014). It is mainly required for hydraulic structures, road and aircraft pavements etc., in cold areas as it causes premature failure of these structures (Cai & Liu, 1998).

Generally, the effect of freeze-thaw cycles is reduced by using an air-entraining admixture. The air bubbles relieves the pressure built-up in the pores of the concrete due to freezing. But, the compressive strength of concrete is reduced due to the use of air-entrainer. However, use of low w/c ratio (water-cement ratio) reduces the pores in the concrete and minimizes the effect of freezing. The low w/c ratio in combination with addition of GGBFS as 50 % replacement for cement was found to increase the freeze-thaw resistance of concrete (Kelly & Murphy, 2010). Researches on concrete using deicing agents like sodium chloride, calcium chloride and magnesium chloride have also been done. When applied to the concrete surface, CaCl produced the most destructive effect on 2 concrete performance whereas MgCl produced the 2 least deterioration (Šelih, 2010). It was also found that interaction of load and cyclic freezing and thawing in the presence of de-ice agents accelerates the process surface scaling in concrete (Kosior-Kazberuk, 2012). Super absorbent polymers were used to improve the freezethaw effect on pavements. It was found that it slightly increases the compressive strength of concrete due to absorption of free water by the polymer (Craeye et al., 2018).

Replacement of natural coarse aggregate with carbonated coarse recycled concrete aggregate has been found to improve resistance to freeze-thaw cycles (Li et al., 2017). Use of oil shale rock ash as partial replacement for cement has increased the freeze-thaw resistance (Oymael et al., 2019). It was observed that surface scaling in High Strength Concrete (HSC) due to freeze-thaw was lower than that of normal concrete. But, a study of HSC using silica-fume exhibited higher initial strength but poor resistance against freeze-thaw cycles compared to reference concrete and HSC containing metakaolin.

The reason for silica-fume concrete to have poor freezethaw resistance may be due to increased capillary porosity (Bumanis et al., 2018). Therefore, it is important to reduce the capillary pores in order to improve freezethaw resistance of concrete. On the other hand, flyash incorporated concrete showed better performance than silica-fume concrete (Karakurt & Bayazıt, 2015).

A study on polycarboxylate superplasticiser showed that, it improved the freeze-thaw resistance of the concrete compared to a naphalene-formaldehyde based superplasticiser. The freeze-thaw resistance will be even higher if polycarboxylate superplasticiser are used with gravel of higher freeze-thaw resistance (Shuldyakov et al., 2016). The freeze-thaw resistance of concrete treated with a bacteria-based repair system was also found to be higher than that of untreated concrete (Wiktor & Jonkers, 2015).

Self-Compacting Concrete (SCC) is widely used nowadays, for the ease with which it can be placed in difficult locations and congested reinforcement, without much compaction. On the other hand, bacteria-based concrete is gaining popularity. Bacteria precipitates CaCO3 as a result of its metabolism. If bacteria is used in SCC, the CaCO3 produced by the bacteria may seal the micro-cracks of the concrete and may reduce its effect due to freezing and thawing.

In addition to this, incorporation of mineral admixtures may contribute to sealing the pores in SCC. So far, there have been no major studies on freeze - thaw resistance of bacteria-based SCC. Thus, an attempt has been made to evaluate the freeze-thaw resistance of Quaternary Blended Bacterial Self-Compacting Concrete (QBBSCC).

The following parameters were found for the Quaternary Blended Bacterial Self-Compacting Concrete (QBBSCC) and reference concrete without bacteria (QBSCC) of w/b ratios 0.3 and 0.4 exposed to 0, 5, 10, 15, 20, 25, 30, 35, 40, 45, and 50 freeze-thaw cycles.

The materials used are as follows,

Cement: Ordinary Portland Cement (OPC) of 53 grade conforming to IS: 12269-2013 was used. The specific gravity of OPC was 3.15.

Micro-Silica: Micro-silica of specific gravity 2.63 with silica content 99% was used to partially replace cement by 10% by weight. It was used to improve the strength properties and durability.

Flyash: Flyash of specific gravity 2.18 was used to partially replace cement by 25% by weight. The thermal power plant waste was used to improve the strength, workability and durability.

Ground Granulated Blast Furnace Slag (GGBFS): GGBFS of specific gravity 2.92 was used to partially replace cement by 25% by weight. The by-product of steel industry was used to improve the strength, durability, and reduced permeability.

Fine Aggregate: The natural river sand of specific gravity 3 2.68 and loose bulk density of 1520 kg/m conforming to Zone III of IS 383-1970 was used.

Coarse Aggregate: Rounded aggregate of maximum size 20 mm of specific gravity 2.7 and loose bulk density of 1420 kg/m3 conforming to IS 383-1970 was used.

Super-Plasticiser: Master Glenium SKY 8662, a high performance polycarboxylate ether based superplasticizer cum viscosity modifying agent was used.

Bacteria: Bacillus Subtilis (MCC 2183), a non-toxic, gram positive, rod - shaped soil bacterium, which grows at pH = 12 was selected for the study. The bacteria were subcultured and preserved in nutrient agar medium for future use. Whenever required, a single colony of the culture was inoculated into an autoclaved nutrient broth (liquid medium), and incubated at 37ºC for 24 hours.

Bacterial Concentration Used: Bacillus. Subtilis concentrations of 103, 104, 105, and 106 number of cells/ml of water and reference without bacteria were used in the previous study. Out of four different concentrations, 106 number of cells/ml of water gave maximum compressive, split tensile and flexural strength. Hence, in the present investigation, the bacterial concentration of 106 number of cells/ml of water and reference concrete without bacteria were used. A 1% solution of calcium lactate was used as nutrient for Bacillus. Subtilis in concrete.

Mix Design: The QBBSCC mix proportion was designed using Nan Su method (Su et al., 2001) but the cement has been replaced by microsilica, flyash and GGBFS. Two w/b ratios 0.3 and 0.4, for which super-plasticiser of 1.8% and 1.6% by weight of binder respectively were used. The bacterial culture and calcium lactate were added into the concrete during the mixing stage. The materials 3 required for 1m of QBBSCC are given in Table 1.

For the freeze-thaw cycle experiment, an ice-cream freezer box was used. ASTM C666 recommends a freezing rate of 5 - 15 ºC/hr, which is said to be more severe than the freezing rate that prevails in actual field condition. In the present investigation, a freezing rate of 10 ºC/hr was adopted. It should be noted that lab freeze-thaw test methods do not simulate field condition, but instead give a relative freeze-thaw resistance between different specimens.

Each freeze-thaw cycle comprises of freezing the samples from 10 ºC to -10 ºC within two hours, then maintaining the temperature at -10 ºC for half-an-hour and thawing from -10 ºC to 10 ºC within another two hours (Figure 1). So it takes a total of four and a half hours to complete one cycle.

Figure 1. Variation of Temperature with Time in one Freeze - Thaw Cycle

The QBBSCC and reference concrete (QBSCC) cubes of size 100 mm x100 mm x 100 mm, were casted and watercured for 28 days. The cubes were air-dried for 1 week at room temperature. The Initial weight of the specimens was taken.

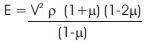

The specimens in triplicate were subjected to 0, 5, 10, 15, 20, 25, 30, 35, 40, 45, and 50 numbers of freeze-thaw cycles. After cycles, the specimens were air-dried for 1 week and weighed again, also tested for Ultrasonic Pulse Velocity (UPV) and residual compressive strength. The percentage of loss in weight, and density were found. Based on the ultrasonic pulse velocity, mass density, and poisson's ratio, the dynamic modulus was calculated using the formula,

where,

E - Dynamic modulus of elasticity (N/m2)

V - Ultrasonic pulse velocity (m/s)

ρ - Mass density (kg/m3)

μ - Poisson's ratio (assumed as 0.2)

The relative dynamic modulus was calculated using the formula,

RDM (%) = (Ec / Eo) * 100

where,

Ec - Dynamic modulus of elasticity at cycle 'c’

Eo - Initial dynamic modulus of elasticity (0 cycle)

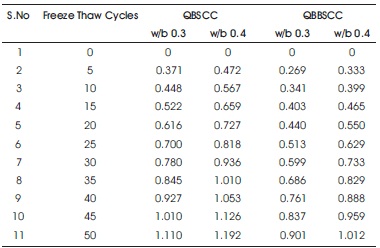

The percentage weight loss of QBSCC and QBBSCC specimens from 0 to 50 cycles are given in Table 2.

Table 2. Percentage Weight Loss of QBSCC and QBBSCC Specimens from 0 to 50 cycles (%)

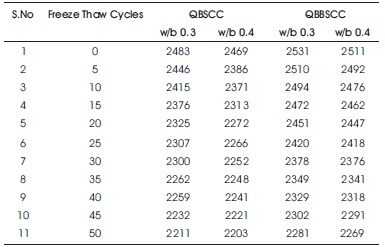

The density of QBSCC and QBBSCC specimens (kg/m3) from 0 to 50 cycles are given in Table 3.

Table 3. Density of QBSCC and QBBSCC Specimens 3 from 0 to 50 Cycles (kg/m3)

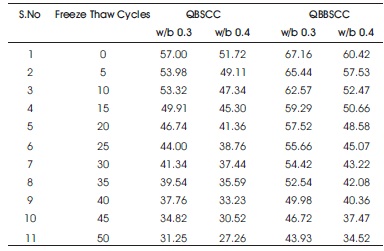

The residual compressive strength of QBSCC and QBBSCC specimens (N/mm2) from 0 to 50 cycles are given in Table 4.

Table 4. Residual Compressive Strength of QBSCC and QBBSCC Specimens from 0 to 50 Cycles (N/mm2)

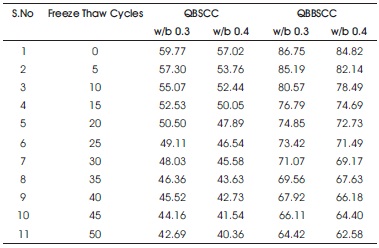

The dynamic modulus of elasticity of QBSCC and QBBSCC specimens (GPa) from 0 to 50 cycles are given in Table 5.

Table 5. Dynamic Modulus of Elasticity QBSCC and QBBSCC Specimens from 0 to 50 Cycles (Gpa)

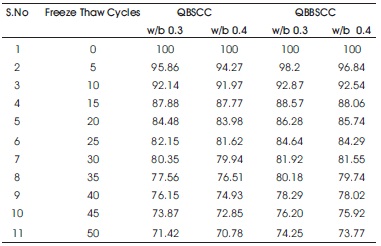

The relative dynamic modulus of elasticity of QBSCC and QBBSCC specimens (%) from 0 to 50 cycles are given in Table 6.

Table 6. Relative Dynamic Modulus of Elasticity of QBSCC and QBBSCC Specimens from 0 to 50 Cycles (%)

From Table 2, it is found that the percentage weight loss of QBBSCC for both w/b ratio 0.3 and 0.4 was less compared to reference concrete without bacteria (QBSCC) for all freeze-thaw cycles. This shows that spalling of QBBSCC surface is less than QBSCC. The percentage weight loss of QBBSCC of w/b ratio 0.3 is less compared to that of w/b ratio 0.4. This shows that the w/b ratio is less and, using formula, freeze-thaw resistance is more. The weight loss of QBSCC due to freeze-thaw cycles ranges between 0.3- 1.2% and that for QBBSCC ranges between 0.2-1.0%.

From Table 3, it is found that the density of Quaternary Blended Bacterial Self-Compacting Concrete (QBBSCC) for both w/b ratio 0.3 and 0.4 is more compared to reference concrete without bacteria (QBSCC) for all freeze-thaw cycles. The density of QBSCC due to freezethaw cycles ranges between 2200 - 2450 kg/m3 and that for QBBSCC ranges between 2200 - 2510 kg/m3.

From Table 4, it is found that the residual compressive strength of QBBSCC for both w/b ratio 0.3 and 0.4 is more compared to reference concrete (QBSCC) for all freezethaw cycles. The residual compressive strength of QBBSCC of w/b ratio 0.3 is more compared to that of w/b ratio 0.4. The reduction in compressive strength in QBBSCC is less due to plugging of pores by the calcite produced by the bacteria. The residual compressive strength of QBSCC due to freeze-thaw cycles ranges between 27-57 N/mm2 and that for QBBSCC ranges between 34 - 67 N/mm2.

From Table 5, it is found that dynamic modulus of elasticity of Quaternary Blended Bacterial Self-Compacting Concrete (QBBSCC) is more compared to reference concrete (QBSCC) for all freeze-thaw cycles and reduces gradually as freeze-thaw cycles increase. The dynamic modulus of QBSCC due to freeze-thaw cycles ranges between 40 - 60 GPa and that for QBBSCC ranges between 62 - 87 GPa. This shows that freeze-thaw resistance of QBBSCC is more than QBSCC.

From Table 6, it is found that relative dynamic modulus of elasticity of Quaternary Blended Bacterial SelfCompacting Concrete (QBBSCC) is more compared to reference concrete (QBSCC) for all freeze-thaw cycles and reduces gradually as freeze-thaw cycles increase. The relative dynamic modulus of elasticity of QBSCC due to freeze-thaw cycles ranges between 70 - 100 % and that for QBBSCC ranges between 73 - 100 %. This shows that freeze-thaw resistance of QBBSCC is more than QBSCC.

From the results, it is clear that as the number of freezethaw cycles increases, the percentage of weight loss and loss in compressive strength increases whereas density, dynamic modulus of elasticity and relative dynamic modulus of elasticity of both QBBSCC and QBSCC decreases. This is due to the development of high pore pressure, because of freezing of pore water, resulting in the formation of cracks in the interfacial transition zone between cement paste and aggregates, and volume change in concrete leading to spalling of concrete surface.

But, QBBSCC showed a better resistance to freeze-thaw effect when compared to concrete without bacteria (QBSCC). This significant improvement is due to the combined effect of calcite precipitated by bacteria, and fineness and pozzolanic reaction of supplementary cementitious materials like microsilica, flyash and GGBFS used in QBBSCC plugging the pores and not allowing the excess of water to freeze inside the pores.

The percentage of weight loss of QBBSCC is less than QBSCC. For QBSCC, it is between 0.3 - 1.2 % whereas for QBBSCC, it is between 0.2 - 1.0 % for 5 - 50 cycles of freeze-thaw cycles. This shows that the spalling of QBBSCC surface is less than QBSCC.

The density of QBBSCC is more than QBSCC, i.e., for QBSCC, it is between 2200 - 2450 kg/m3 whereas for QBBSCC, it is between 2200 - 2510 kg/m3. The residual compressive strength of QBBSCC is more than QBSCC, 2 i.e., for QBSCC, it is between 27 - 57 N/mm whereas for QBBSCC, it is between 34 - 67 N/mm2.

The dynamic modulus of elasticity of QBBSCC is more than that of QBSCC, i.e., it is between 40 - 60 GPa for QBSCC, whereas it is between 62 - 87 GPa for QBBSCC for 0 - 50 cycles of freeze-thaw cycles. The relative dynamic modulus of elasticity of QBBSCC is more than that of QBSCC, i.e., it is between 70 - 100 % for QBSCC whereas it is between 73 - 100 % for QBBSCC for 0 - 50 cycles of freeze-thaw cycles. This shows that the freeze-thaw resistance of QBBSCC is more than QBSCC. The freezethaw resistance of QBBSCC is due to plugging of pores by the calcite precipitated by bacteria.

QBBSCC of w/b ratio 0.3 showed better resistance than QBSCC of 0.4. Therefore, w/b ratio is less and freeze-thaw resistance is more in QBSCC.

The studies can be extended to more number of freezethaw cycles. Also, it can be compared with the study using air-entraining admixture. The experiment can be conducted by including de-icing agents.