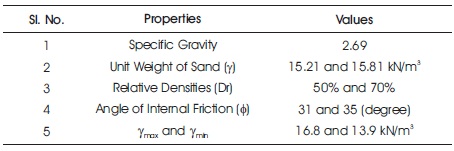

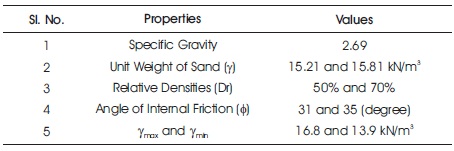

Table 1. Properties of Soil

The earth provides all the support to any structure depending on various soil conditions. Foundations are the substructures that transmit the load of the structure to earth in such a way that the soil does not get over stressed and do not deform. Types of footings used vary depending on the type of structure, for example, in structures such as transmission towers or water tower, the circular footing is used essentially. Circular footings have been used since ages, but ring footing got less attention than a circular one, despite its greater efficiency and cost-saving nature. Thus, in order to develop new and economical technologies, studying the benefits of rings over circular footing is essential, which is the prime objective of this paper. The parameter (bearing capacity) has been studied experimentally as well as an attempt of numerical analysis is done, in order to understand the behaviour of the sand under the ring footing. The experimental values of the bearing capacity of the ring footing are obtained by performing a series of laboratory tests on the model footing for three different radii ratio 0.2, 0.4, 0.6. While numerical analysis was performed using an empirical equation available in literature. The values of these analyses were then compared and it was determined that the theoretical values were quite higher than that of the experimental values of bearing capacity.

Foundation connects the structure to the ground. They transmit the weight of the superstructure to the ground distributing the load on a large area. Footings are the last element of the structure through which load is transferred to foundation soil. The load is transferred from one structural element to another. These are, in turn, transmitted to the foundation which transfers it to the underlying soil. Shape and size of the footing are a matter of concern as a particular shape of footing used for any particular structure, which may give maximum stability of structure while saving the cost. Many previous studies and tests indicate that the ring footing is better than the circular one in many aspects. Fisher (1957) had proposed a method to predict the bearing capacity and settlement of ring foundation on a semi-infinite elastic medium. In the past few years, the use of ring foundation is considered more suitable and economical for axisymmetric structures, such as silos, water tower structure, chimneys, storage tanks, telecommunication towers, liquid storage tanks, bridge piers, offshore structures, transmission towers, television antennas, oil storages, underground stops, etc. Using ring footings may fully utilize the soil capacity with less or no tension under the foundation. Any foundation should be designed in such a way that the soil below it does not fail in shear and the settlement remains within the safe permissible limits. This paper presents a note on a study comparing the experimentally obtained bearing capacity with the theoretically obtained bearing capacity of the ring footing. Basically, ring footings are mostly used for tall and large structures to resist the lateral loads and to increase the stability of structures against overturning. Using ring foundations decreases the use of construction material as well as provides adequate strength and stability. Thus the use of ring foundations leads to an economic structure. Fisher (1957) was a German and was the first to study ring foundations' behaviour and its bearing capacity.

Due to heavy infrastructural activities, availability of good construction sites is also depleting at a fast pace. Thus an engineer must survey the sites very properly and site selection must be done by doing a primary survey determining the property of the soil. After which the type of foundation must be selected according to the structure. The bearing capacity and settlement of foundation are proved to be the function of the shape of footing, foundation soil parameters, and its conditions. Different studies have been performed to calculate the bearing capacity of circular, strip, and square footings. The ring footing which seems more economical for axisymmetric structures has not received a much attention. Bearing capacity of the soil is a problem in foundation design. If we overestimate the value of the bearing capacity then the structure may not sustain as the foundation may not have that ability to bear the load of the structure, likewise if we underestimate the value of bearing capacity for any footing then it may lead to an uneconomical structure.

Many other numerical and experimental investigations are available in the literature to approximate the bearing capacity.

In the case of ring footing, the important factors influencing the behavior are as follows.

In this paper, the authors discuss the radii ratio, foundation depth, and relative density of sand. Vertical loading was applied.

Ohri et al. (1997) have performed tests on model ring footings. They have proposed that the bearing capacity reached to its maximum value for dune sand when the radii ratio of the ring is kept equal to 0.38. Hosseininia et al. (2016) have studied about the bearing capacity factors of ring footings and concluded that as the ring radii ratio increases, the value of bearing capacity factors (Nc, Nγ, Nq) decreases and is more sensible for Nγ. Also, the roughness of footing causes the bearing capacity to increase. Zaho and Wang (2008) have studied the bearing capacity factor Nc in frictional, cohesionless, and ponderable soil for ring footing and concluded that the value of Nc showed a decrease in its value if the radii ratio of the ring is increased. Moayed et al. (2012) have studied the two-layered soil system with respect to the bearing capacity of the ring footing and showed that the bearing capacity decreases with an increase in the ring radii ratio. Snodi (n.d.) have studied the bearing capacity of the ring footing and described its dependency on the ring radius ratio.

Israa (2013) had investigated the bearing capacity of both circular and ring foundations on sand and concluded that bearing capacity of ring footing at a specific range of the ratio of inner to outer diameter is greater than the circular footing with similar properties on the sand and bearing capacity reaches a maximum value at the radii ratio of 0.4. Mehrjardi (2008) have studied bearing capacity and settlement of ring footings and concluded that bearing capacity for ring footing will be maximum at radii ratio (r/R) of 0.4. Dhatrak and Gawande (2016) have studied about the behaviour of ring footing which is eccentrically loaded and resting on sand concluded that the bearing capacity of ring footing is found to be maximum a ring radii ratio ( r/R) of 0.4. Hataf and Razan (2016) have studied about the bearing capacity factors of ring footings and concluded that as the ring radii ratio increases, the value of bearing capacity factors (Nc, Nγ, Nq) decreases and is more sensible for Nγ. Also, the roughness of footing causes the bearing capacity to increase Kumar and Bhoi (2009) have done same model testing and studied the interference of two closely spaced strip footings on the sand and concluded that spacing between the footings affects bearing capacity significantly and is maximized at a certain critical spacing between two footings. Srinivasan and Ghosh (2013) have researched the interaction problems of circular footings on the homogeneous soil deposit and proposed that the bearing capacity tends to decrease with an increase in spacing between adjacent footings. Kakroo (1985) have studied the behaviour of rigid ring footing subjected to the central vertical load resting on the sand and developed an empirical equation to numerically calculate the bearing capacity of a ring footing which is as follows.

qu =γ. R. tan φ. Dr[236+ 465(r/R) -1420(r/R)2 +754(r/R)3 + 282(d/R)]

where,

γ- Unit weight of soil (kN/m3)

R - External radius of footing (m)

φ- Angle of internal friction of soil used.

Dr - Relative density of soil

r - Internal radius of footing (m)

d - embedded depth of footing (m)

Kakroo (1985) had also compared his theoretically obtained bearing capacity of the ring footing with Saha (1978) and Haroon and Mishra (1980) and experimentally obtained the bearing capacity and concluded that in case of dense/medium dense sand, bearing capacity is the maximum for radii ratio between 0.2 to 0.4 and for radii ration greater than 0.4, it decreases gradually to that of strip footing. Saha (1978) had studied the bearing capacity of annular footing and performed experiments and found that the experimental bearing capacity results were very high and the difference increases with the decreasing relative densities.

The experimental tests were conducted in a soil laboratory of MMMUT, Gorakhpur. Sand for analysis was taken from the river bank of river Rapti in Gorakhpur. It was cohesionless and was used in the preparation of a sand bed. The sand was washed, dried, and sorted by the particle size. This sand bed, acted like foundation material for the model footings. Sand was composed of sub-rounded particles. The Geotechnical and engineering properties of sand were determined by conducting various lab tests. The values of these properties, such as specific gravity, density, angle of internal friction, etc., which are relevant to this research are given in the following Table 1.

Table 1. Properties of Soil

For 50% relative density, the corresponding unit weight and angles of internal friction were obtained at 15.21 kN/m3 and 31°, respectively. While for 70% relative density, the corresponding unit weight and angle of internal friction was found at 15.81 kN/m3 and 35°, respectively.

The soil bed was prepared in a testing tank with inside dimensions of 2.2 m long, 1.1 m wide, and 1 m deep and was filled with dry sand passing through 2 mm and retaining on 450 μ sieve by using the sand raining technique (hopper method). Side walls of the tank were made smoother by using a lubricating gel to minimize the boundary effects. Sand was properly leveled. For experimental purpose, a model footing made of mild steel was used. All the experiments were performed on these model footings. The outer radius used was kept constant at 30 cm while internal radius is varied as 6 cm, 12 cm, 18 cm to get the corresponding radii ratio (internal to external diameter ration) as 0.2, 0.4, 0.6. The thickness of these model footings was kept constant to 25 mm.

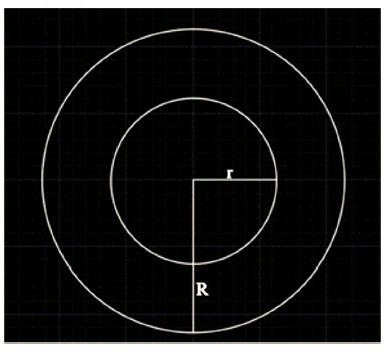

Figure 1 shows an AutoCAD drawing of the plan of the ring footing which shows the internal radius as r and external radius as R. When the sand bed preparation is finished, the model footing is placed at center of the tank after which two dial gauges were placed on the flanges of the footings. These dial gauges had sensitivity of 0.01 mm. Load was applied in the increasing manner and each increment was taken to be approximately equal to the 1/5th of expected value of ultimate bearing capacity of the footing. This increment was done with the help of screw jacks. A proving ring was also placed between the screw jack and the footing which measure the total load transferred to the footing. For ring footing, it was hard to put the hydraulic jack directly as it may slip through the center opening so to avoid such condition, first a loading platform was placed on ring footing.

Figure 1. Plan of Model Footing

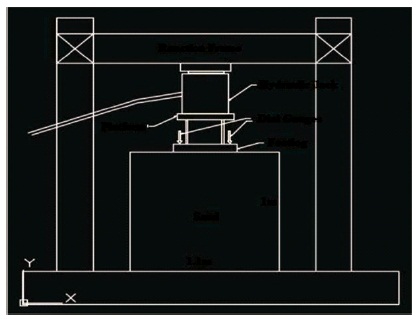

Figure 2 shows the AutoCAD drawing of the test arrangement to perform the laboratory test on the model footing in order to obtain the bearing capacity of the ring footing. This test arrangement consisted of the sand bed, hydraulic jack, dial gauges, reaction frame, and loading platform.

Figure 2. Test Setup Arrangement

To obtain the bearing capacity numerically, a formula given by Kakroo (1985) was used which is as follows.

qu = γ. R. tan φ. Dr[236+ 465(r/R) -1420(r/R)2 +754(r/R)3 + 282(d/R)]

For calculation purpose, the very same data obtained by experiments for soil has been used and it is assumed that the footing was surface footing for which embedded depth of footing (d)=0;

Case 1:

When relative density (Dr)= 50%, angle of internal friction

(φ)= 31° and unit weight of the soil (γ) = 15.21 kN/m3 Outer radius of ring footing= 0.3 m

(i) r/R = 0.2

qu = 15.21 0.3 tan31° 0.5[236+(465 0.2) -(1420 0.22)+(754 0.23)]

qu = 381.418 kN/m2

(ii) r/R = 0.4

qu = 15.21 0.3 tan31° 0.5[236+(465 0.4) -(1420 0.42)+(754 0.43)]

qu = 331.196 kN/m2

(iii) r/R = 0.6

qu = 15.21 0.3 tan31° 0.5[236+(465 0.6) -(1420 0.62 )+(754 0.63)]

qu = 228.474 kN/m2

Case 2:

When relative density (Dr)= 70%, angle of internal friction 3 (φ)= 35° and unit weight of the soil (γ) = 15.81 kN/m3

Outer radius of ring footing= 0.3 m

(i) r/R = 0.2

qu = 15.81 0.3 tan35° 0.7[236+(465 0.2) -(1420 0.22)+(754 0.23)]

qu = 646.822 kN/m2

(ii) r/R = 0.4

qu = 15.81 0.3 tan35° 0.7[236+(465 0.4) -(1420 0.42)+(754 0.43)]

qu = 565.046 kN/m2

(iii) r/R = 0.6

qu = 15.81 0.3 tan35° 0.7[236+(465 0.6) -(1420 0.62)+(754 0.63)]

qu = 387.453 kN/m2

The bearing capacities obtained experimentally by laboratory tests and theoretically by the equation is represented in Table 2. Here r represents the internal diameter of the ring footing in meter, R represents the outer diameter of ring footing in meter, γ represents the unit weight of the soil in kN/m3, φ represents the angle of internal friction in degrees, Dr represents the relative density of soil, r/R represents the radii ratio, experimental BC represents the experimental bearing capacity of ring footing in kN/m2 and theoretical BC represents the theoretically obtained bearing capacity in kN/m2. From Table 2, it is clearly visible that the values of bearing capacity obtained experimentally and theoretically are totally different; moreover, theoretical values are more than three times the values of experimental bearing capacity. Relative factor has been obtained by the ratio of experimental bearing capacity to the theoretical bearing capacity. This factor shows the difference between the above two values. Data of Table 2 clearly shows that while designing the ring footing, if we choose to obtain the bearing capacity theoretically, then bearing capacity gets overestimated and chances of failure of the structure are increased.

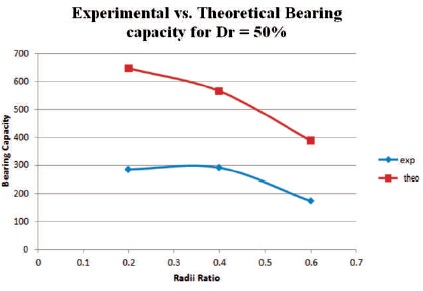

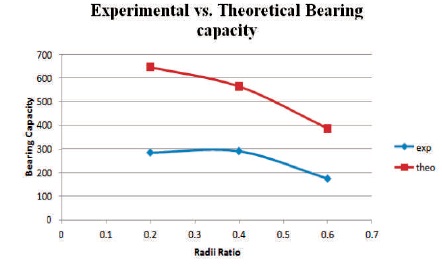

Figures 3 and 4 are the graphical representations of Table 2. The difference in the values of bearing capacity obtained theoretically and experimentally can be seen by these graphs.

Figure 3. Experimental vs. Theoretical Bearing Capacity for Dr=50%

Figure 4. Experimental vs. Theoretical Bearing Capacity for Dr=70%

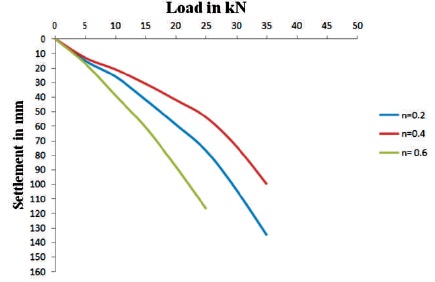

Figure 5 is for 50% relative density and is plotted between load and settlement. The load is plotted on the X-Axis and settlement is plotted on the Y-axis.

Figure 5. Load vs. Settlement for Dr=50%

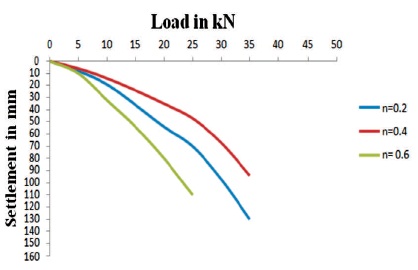

Figure 6 is for 70% relative density and is plotted between load and settlement. The load is plotted on the X-axis and settlement is plotted on the Y-axis. Figures 5 and 6 represent the settlement of the footing for the corresponding load applied for the different radii ratio of 0.2, 0.4, 0.6. It can be observed from the above figures that bearing capacity for the ring footing is found optimum at radii ratio 0.4.

Figure 6. Load vs. Settlement for Dr=70%

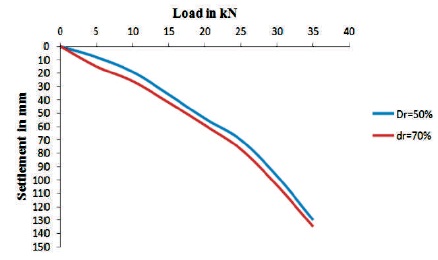

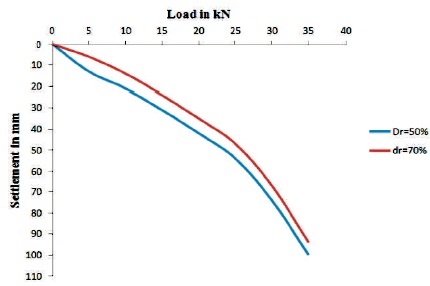

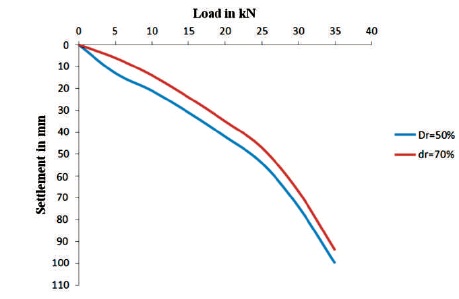

Figures 7, 8 and 9 are a comparison of load vs. settlement curve for radii ratio 0.2, 0.4 and 0.6 for relative densities at 50% and 70%. These figures show that the bearing capacity is improved at 70% relative density for all the radii ratios.

Figure 7. Load vs. Settlement for n=0.2

Figure 8. Load vs. Settlement for n=0.4

Figure 9. Load vs. Settlement for n=0.6

To understand the behavior of rigid ring footing in the sand with respect to the bearing capacity, a numerical analysis and experimental studies have been carried out. The experimental investigation consists of the tests on instrumental model footing under central vertical loading. Tests were carried out on the locally available deposited sand with two different relative densities. Model footing used has a constant external diameter with three different radius ratios. From the above analysis, the following conclusions can be given.