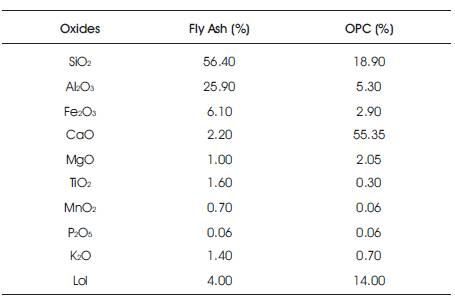

Table 1. Chemical Composition of Fly Ash and OPC

Microstructural properties of autonomically healed 0, 20, 40, and 60% OPC replaced by fly ash in cementitious composites are reported in this paper. Artificial micro-cracks were generated on cementitious cube specimens by the applications of compressive loads. NaOH (10-M) and Na2SiO3 solution were used as healing agent. The cracked specimens were either injected or submerged in the chemical solution, followed by heat curing at 600 C for 48 hours. Self-healing in terms of recovery of properties were observed in UPV measurement and compressive strength study. Specimens containing 40% fly ash content mortar specimens showed better recovery of UPV and compressive strength. For limitation and better control of some analytical testing like TGA (Thermogravimetric Analysis), FTIR (Fourier-Transform Infrared Spectroscopy), XRD (X-ray Diffraction), SEM-EDAX (Scanning Electron Microscope with Energy Dispersive X-ray Analysis) were done in paste mixes rather than mortar mixes. Sodium calcite and sodium aluminate phases were found at the crack zone after submerging and injection of the NaOH (10 M) and Na2SiO3 solution in 40% fly ash content paste mix. FTIR analysis shows higher degree of geo-polymerization after submerging. TGA confirms higher mass loss for mix without any fly ash for both submerged and injected specimens. SEM reveals that the microstructure is more homogeneous in submerged specimens.

Generations of micro-cracks in cementitious composites can decrease both the mechanical and durability properties of concrete. Autonomic healing is a smart technological approach to heal the micro-cracks. Starting from (Dry, C. M., & Sottos, N. R. 1993; Dry, C. 1994) the encapsulation technique is widely used by various researchers, which is also known as autonomic healing. Containers, such as microcapsules, glass capillary tubes, continuous glass supply pipes, ceramic tubes have been used by several researchers (Ghosh, S. K., 2009). The container in which the healing agent is kept, works like a barrier between the healing agent and the base material (cementititious composite). As concrete is a bulky material, researchers used relatively low-cost and readily available materials as healing agent. Different healing agents, such as epoxy resins, cyanacrylatates, alkali-silica solutions, dicyclopentadiene, and sodium silicate have been tried. For the encapsulation techniques, healing agent should have the ability to form a sufficiently strong bond between the surfaces of the cracks. During crack generation it also ruptures the container, the healing agent is released into the crack by capillary action or gravitational force. A chemical reaction takes place between the healing agents and the base material that results in the formation of new bond between the cracks flank, further crack propagation may stopped. That finally helps in recovering the material properties, such as stiffness, fracture toughness, and strength.

Crouch, L. K., Hewitt, R., & Byard, B. (2007) defined, high volume fly ash concrete as a “resource efficient, durable, economical, and sustainable option for ordinary concrete applications”. Fly ash and other supplementary cementitious materials were found to be sustainable option as far as the durability of cementitious composites is concerned. This supplementary material is now being used in cement-based product in various forms throughout the world. Therefore, the present research focuses on the fly ash-cement system (as host material) along with NaOH and Na2SiO3 activator (as healing agent).

Some literatures are available on the autogenic healing of cement fly ash system (Qian, S., Zhou, J., Rooij, M. R., Schlangen, E., Ye, G., & Van Breugel, 2009; Şahmaran, M., Keskin, S. A. B., Ozerkan, G., & Yaman, 2008; Watanabe, T., Fujiwara, Y., Hashimoto, C., & Ishimaru, K. 2011; Termkhajornkit, P., Nawa, T., Yamashiro, Y., & Saito, T., 2009), but a very few are available on the autonomic healing (Ahn, T. H., & Kishi, T., 2010; Ahn, T. H., & Kishi, T., 2008; Rzezniczak, A. K., 2013). Therefore, a detailed microstructural study is needed for better understanding the amalgamation of activator, cement and fly ash. This experimental study focuses on the healing properties of cementitious composite with NaOH (10 M) and Na2SiO3 chemical solution as repairing agent and comparison of the same with or without fly ash. This paper reports the changes in the microstructure and its grains boundary, especially at the crack opening. The healing agent was either injected directly into the crack opening or was kept submerged for certain period of time. The effects of fly ash and NaOH (10 M) and Na2SiO3 solution in cementitious system were studied with the help of X- ray Diffraction study (XRD), Scanning Electron Microscopy (SEM) with Energy Dispersive Spectroscopy, FTIR, and TGA study. For the first part, compressive strength and UPV (Ultrasonic Pluse Velocity) was planned to study in mortar phase and in the second part other analytical testing like FTIR, XRD, TGA, SEMEDAX were planned in paste phase for limitation of these testing and also for better control. Study of the second part was dependent on the results of the first part of the experimentation and was planned accordingly.

The cement used was Ordinary Portland Cement (OPC). Class 'F' Fly ash used in this experimentation was collected from National Thermal Power Corporation, Farakkha, West Bengal, India. The chemical analysis report of the used fly ash and cement is given in Table 1. Natural river sand was used as fine aggregate for preparing mortar specimens, having specific gravity of 2.5 and fineness modulus of 2.65. White deliquescent pellets of NaOH of 98% purity were supplied by M/S. Loba Chemie Ltd., India. Sodium silicate solution (Na2O=8%, SiO2=26.5%, and 34% Solid with 65.5% water) with silicate modulus ~ 3.3 and a bulk density of 1410 kg/m3 was also supplied by M/S. Loba Chemie Ltd., India. Potable water was used for casting and curing. The ratio of NaOH/Na2SiO3 was 1.75.

Table 1. Chemical Composition of Fly Ash and OPC

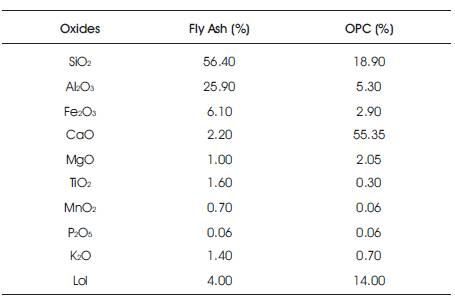

The mix proportions are summarised in Table 2. The control mix with 0% fly ash is denoted by F0, similarly fly ash containing mixes with 20%, 40%, and 60% fly ash is denoted by F20, F40, and F60, respectively. Fine aggregate (Natural River Sand) was mixed in 3 part for 1 parts of binder for all mortar mixes. The water to binder ratio for all mixes was fixed at 0.5 for mortar mixes. 70.6 mm cubes (Steel) were used for mortar and were compacted in mortar cube vibrator. All the prepared cubes were cured in potable water after removal from the moulds for 28 days. On completion of 28 days water curing, initially the compressive strength and UPV were measured. Specimens were subjected to compressive load at 50% of crushing strength at 28 days. The loss in compressive strength and UPV value was recorded. Cracked specimens were either submerged (designated as 'S') for 72 hours in the prepared NaOH (10 M) and Na2SiO3 solution or injected (designated as 'I') for healing the cracks (Tashima, M. M., Soriano, L., Borrachero, M. V., Monzó, J., & Payá, J. 2013). After completion of the immersion (submerged) or injection process, specimens were dried in ambient condition for o another 24 hours before heat curing at 60 oC for 48 hours.

Table 2. Mix Proportions

As per plan, on analysis of the UPV and compressive strength data, second part of the experimentation begins, where all the experimentation procedure kept unchanged other than preparing paste specimens (without fine aggregate) of 50 mm cubes with W/B ratio of 0.35.

Initial compressive strength and UPV at 28 days, followed by after load application for crack generation of 0, 20, 40, and 60% OPC replaced fly ash mortar specimens was measured. The loss due to partial load application (crack generation) was recorded and recovery after injection and submerging in chemical solution was measured. The recovery of compressive strength and UPV value of both NaOH (10 M) and Na2SiO3 solution injected and submerged were compared in the first part of the experimentation and based on the results, second part of the experimentation was planned.

In the second part of the experimentation, paste specimens were used throughout as discussed to have better control in the analysis and limitation of these testings. After injection or submerging in NaOH (10 M) and Na2SiO3 solution followed by heat curing, a small amount of broken specimens (approx. 5 g) were taken from each sample for XRD study. It was tried to take the specimens from the cracked zone. The specimens were then grounded in porcelain mortar pestle and passed through 150 micron sieve. XRD analyses of the powdered sample were done in BRUKER AXS- D8, using Cu Ka radiation, the value of 2-theta and D-spacing was kept 18.029 and 4.9162, respectively.

Spectra were collected on a Nicolet iS50 FTIR fitted with a single-bounce diamond ATR. Sixty-four background and 64 sample spectra were co-averaged and ratioed to generate the transmission spectrum. Two levels of zero filling (3 additional data point between each pair of data points in the interferogram), Norton-Beer strong apodization (to minimize side-lobes), and Mertz phase correction were employed. The spectral resolution was 4 wave numbers.

Thermal analysis was performed by using a TA Instrument SDT 2960 from ambient to 1000 °C at 20 °C per minute in a nitrogen atmosphere flowing at 100 ml per minute. A sample size of about 50 mg was analysed in a 110 µL platinum crucible.

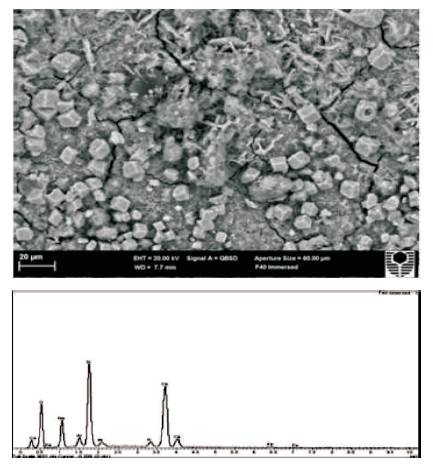

The microscope used in SEM was Zeiss Neon 40 EBS operated with high vacuum and accelerated voltages of 5 KV. Specimens were coated with platinum with a thickness of 10 micron. Several regions were examined and finally the reported figures are all at 500X magnification. The EDAX has been done on the entire region of the SEM area, not in a particular point. To identify the unknown crystal, EDAX was done in that particular point of interest.

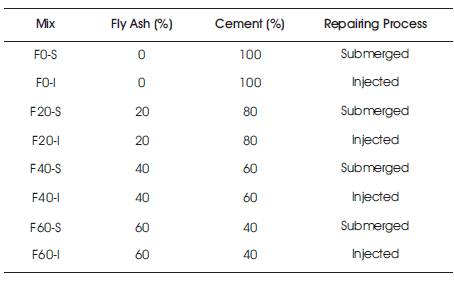

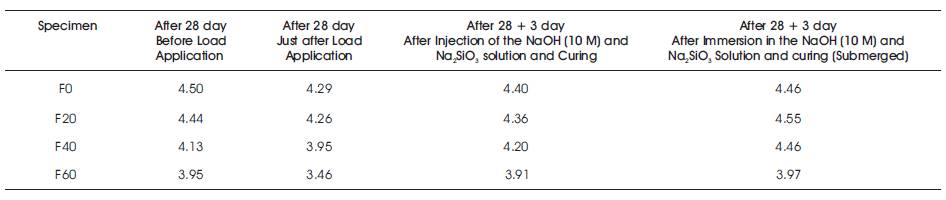

Table 3 represents the ultrasonic pulse velocity of different mortar specimens containing 0, 20, 40, and 60% fly ash of both injected and submerged specimens. Decrease in UPV value is noticed with fly ash addition. The loss in UPV value is also noticed after load application for all fly ash content mixes and is obvious. Fly ash content mixes submerged in NaOH (10 M) and Na2SiO3 solution were found to recover its previous UPV value (before load application), which was not to such extent for the OPC specimens (F0). The results of UPV value recovery confirm healing of the cracks by application of NaOH (10 M) and Na2SiO3 solution. The better results for recovery of UPV value for fly ash content mixes are may be due to the reaction of solution with unreacted fly ash and cement particles in the specimens. The F40 mix submerged in solution shows better recovery property as far as the UPV value of the specimens are concerned.

Table 3. Ultrasonic Pulse Velocity at Different Stages (km/s)

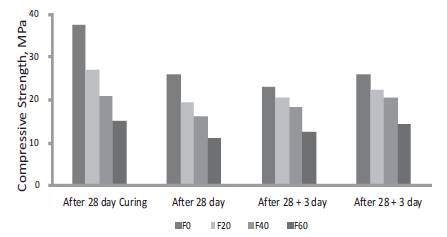

The compressive strength of four different fly ash content mortar mixes is given in Figure 1. Addition of fly ash reduces the compressive strength of the mortar samples after 28 days of water curing. Similarly, as found for UPV, the compressive strength of all the mixes deteriorates with the load application. These losses in compressive strength as well as UPV values confirm degradation of the specimens and generation of micro-cracks. Recovery of compressive strength is found for all the mixes of both injected and submerged healing technique, except for F0-I mix. The recovery was found to be more for the NaOH (10 M) and Na2 SiO3 solution submerged specimens and was more pronounced for fly ash content specimens. F40- S mix was found to recover most of its previous compressive strength.

Figure 1. Compressive Strength at Different Stages

The NaOH (10 M) and Na2SiO3 solution with unreacted fly ash particle may react chemically to create some geopolymeric bonds (Shi, C., Roy, D., & Krivenko, D., 2006) and this may be the cause for better recovery of fly ash content mix specimens.

Based on the experimental results it was planned further to continue with 40% OPC replaced specimens (both submerged and injected) rather than analyse all the batches and also to compare it with 0% OPC replaced batch. This is because the primary aim of this experimentation is to compare the healing of the fly ash based on the cement mix with normal cement based mix. 40% replacement has been found to have the better recovery for compressive strength and UPV thus all the experimentation were further carried out for 0 and 40% OPC replaced by fly ash mixes and in paste phases.

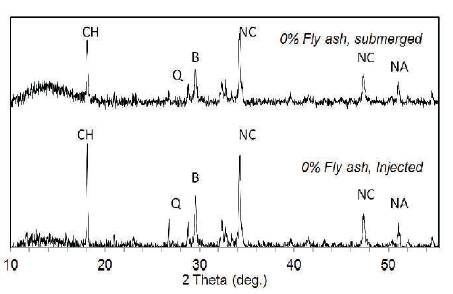

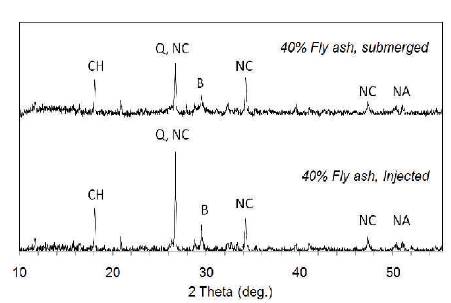

Figures 2 and 3 illustrate the XRD analysis of cement paste replaced with 0 and 40% fly ash, after submerging or injection of NaOH (10 M) and Na2SiO3 solution followed by heat curing, respectively. Calcium Hydroxide, Quartz, Sodium Calcite, Sodium Aluminate, and C2S were found to be major phases for all the mixes. Intensity of the calcium hydroxide phases was found to be low for 40% fly ash content mix. Intensity of the Belite or C2S phases was lowered and peak of quartz increased with 40% fly ash addition. Formation of new phase of sodium calcite with o higher intensity was noticed at 2 theta value of 27o for 40% fly ash content specimen. This sodium calcite phase developed after injection or submerging may have played an important role for crack healing of the cement paste, with or without fly ash.

Figure 2. XRD Patterns of 0% fly Ash Content Cement Paste

Figure 3. XRD Patterns of 40% Fly Ash Content Cement Paste

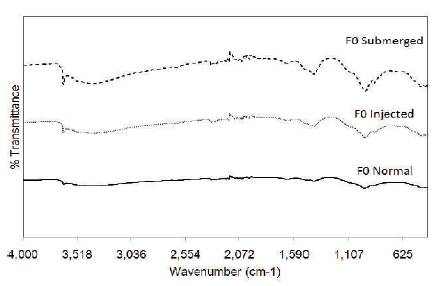

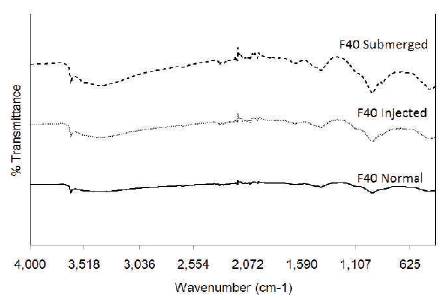

Vibrational frequencies of 0 and 40% fly ash content mix measured by FTIR (Figures 4 and 5) generally gives an indication of changes in silicate, sulphate, hydroxide, and carbonate phases. In the spectrum for powdered dry sample there was a peak at 980-1000 cm-1 , which represents the polymerization of silica to form C-S-H gel and may be geopolymeric gel. The % transmittance was found to be decreased significantly after injection and more after submerging of the specimens in NaOH (10 M) and Na2SiO3 solution for both 0 and 40% fly ash content mix. The peaks at 1440 -1455 cm-1 are due to calcium carbonate, which is added to the cement during manufacture after clinker calcination (Ylmén, R., Jäglid, U., Steenari, B. M., & Panas, I., 2009). The peak at wave number 1684-1695 cm-1 is because of the bending vibration ν2 of water in sulphates, mainly gypsum (Ylmén, 2 R., Jäglid, U., Steenari, B. M., & Panas, I., 2009; Hughes, T. L., Methven, C. M., Jones, T. G., Pelham, S. E., Fletcher, P., & Hall, C., 1995) added during manufacturing. Si-O-Si stretching vibration was detected at wave number range of 1450-980 cm-1 , which indicates the degree of geopolymerization (Rattanasak, U., & Chindaprasirt, P., 2009). The inverted peak height gives an indication of higher degree of geopolymerization for submerged specimens than injected one for both 0 and 40% fly ash content mix. The bands near 3640 cm-1 is due to the presence of calcium hydroxide after cement hydration, where the peak height again found to be increased for submerged than injected for normal specimens, respectively.

Figure 4. FTIR Analysis of Cement Replaced with 0% Fly Ash

Figure 5. FTIR Analysis of Cement Replaced with 40% Fly Ash

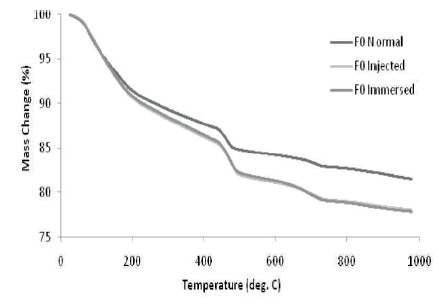

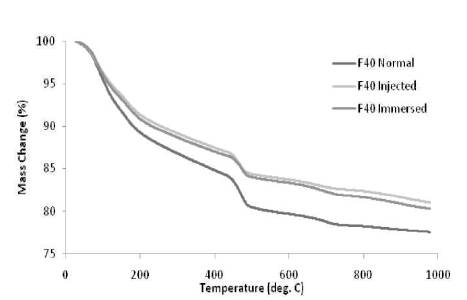

Figures 6 and 7 illustrate the thermo gravimetric analysis of 0 and 40% fly ash content mix of crack healed specimens by both injection and submerging in the NaOH (10 M) and Na2SiO3 solution. A sharp drop in % mass change can be noticed for 40% fly ash content mix at 400-500 oC, which confirm the presence of unburnt carbon in the mix. Change in mass was found to increase for both injected and submerged specimens than normal paste specimens of 0% fly ash content mix. This is due to the production of geopolymeric and C-S-H gel from water present in the NaOH (10 M) and Na2SiO3 solution, which dehydrated initially and decomposed at higher temperature. The TG patterns of 40% fly ash content mix was found to be completely different from 0% fly ash content mix. The loss in mass for injected and submerged was less compared to normal specimen. This may be due to the formation of stable geopolymeric bond developed by the reactions of NaOH (10 M) and Na2SiO3 solution with unreacted fly ash particle. No significant changes for the percentage of mass by TG analysis of both injected and submerged specimens of 0 and 40% were noticed.

Figure 6. TG Analysis of Cement Replaced with 0% Fly Ash

Figure 7. TG Analysis of Cement Replaced with 40% Fly Ash

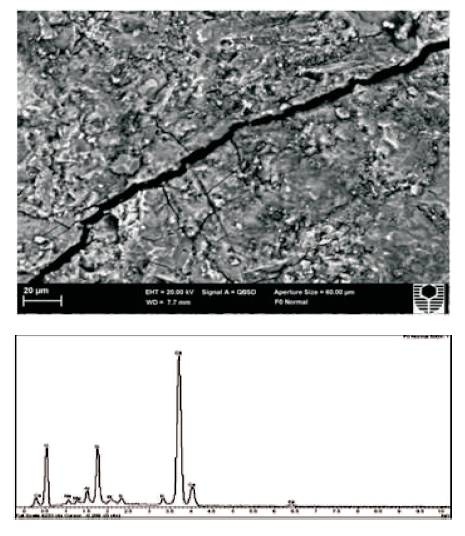

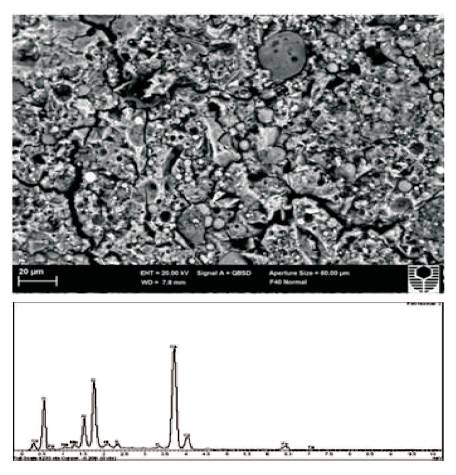

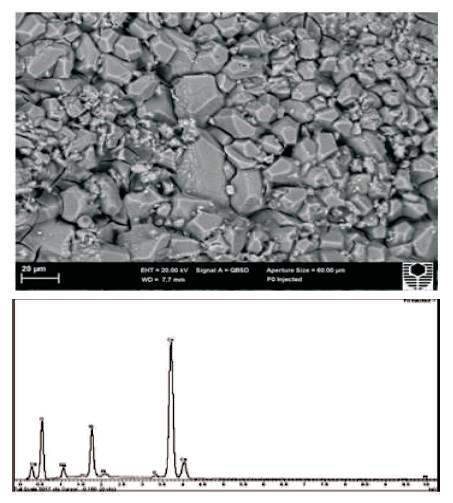

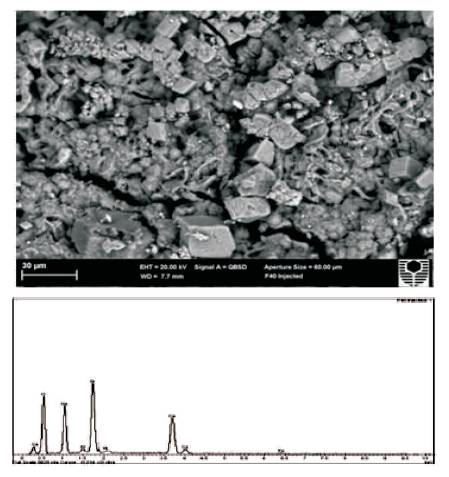

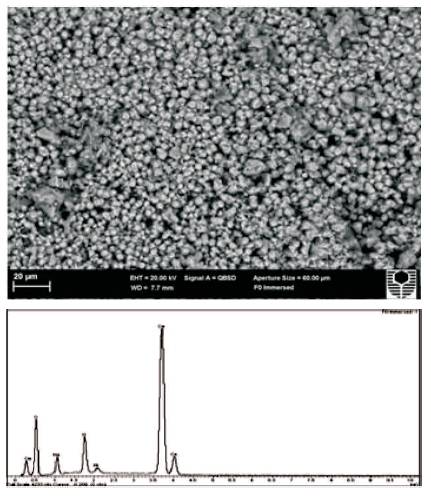

Figures 8 to 13 represent the SEM images of 0 and 40% fly ash content mix of normal, injected and NaOH (10 M) and Na2SiO3 solution submerged specimens. Different locations were examined and the given images at 500X magnification are representative of the sample. Presence of unreacted fly ash particle was found (Figure 9 spherical shape). The specimen with fly ash was found to be with more porosity and rough surface. Homogeneity of the microstructure after healing was more for NaOH (10 M) and Na2SiO3 solution submerged sample than injected sample for both 0 and 40% fly ash content mixes. Hexagonal and cubical Ca(OH)2 crystals were found to be developed for submerged and injected specimens. For 0% fly ash content mix, the surface morphology (under microscope) was found to be changed significantly to an assembly of hexagonal crystal and further to agglomeration of spherical crystal when injected and submerged, respectively. For 40% fly ash content mix, the surface morphology was seen to be more compact for submerged specimens than injected specimens.

Figure 8. SEM Image and EDAX Analysis of 0% Fly Ash Content Mix of Normal Specimen

Figure 9. SEM Image and EDAX Analysis of 40% Fly Ash Content Mix of Normal Specimen

Figure 10. SEM Image and EDAX Analysis of 0% Fly Ash Content Mix Activator Injected Specimen

Figure 11. SEM Image and EDAX Analysis of 40% Fly Ash Content Mix Activator Injected Specimen

Figure 12. SEM Image and EDAX Analysis of 0% Fly Ash Content Mix Activator Submerged Specimen

Figure 13. SEM Image and EDAX Analysis of 40% Fly Ash Content Mix Activator Submerged Specimen

Figures 8 to 13 also represent the EDAX analysis of normal, NaOH (10 M) and Na2SiO3 solution injected and after submerging of the cracked specimens in NaOH (10 M) and Na2SiO3 solution followed by heat curing. The peak height of the Ca was found to be decreased whereas Al and Si increased with 40% fly ash content specimen. The peak of Na was noticed for 0 and 40% fly ash content sample in both NaOH (10 M) and Na2SiO3 solution injected and submerged, the height is of the peak was more for submerged sample. The peak height of Ca was found to be lowered significantly for 40% fly ash content specimens healed by both NaOH (10 M) and Na2SiO3 solution injection and submerged than normal sample. The EDAX analysis of hexagonal and cubical shapes of crystal confirm it to be Ca(OH)2 .

Based on the results obtained from this study the following conclusions can be drawn:

The author is grateful to Professor Salim Barbhuiya, Department of Civil Engineering, Curtin University of Technology, Perth, Australia for the support to conduct part of the research work.