Table 1. Mix Designations

In the field of Geotechnical Engineering, elastic properties of soil and soil-lime mixtures are generally analysed with optimum moisture content. But, during compaction with the increase in water content from the dry side of optimum to the wet side of optimum, the structure of clay particles changes from a flocculated to disperse structure. Therefore, in this paper an attempt was made to study the effect of moulded water content on black cotton soil and lime treated black cotton soil at a dry side of optimum, near and wet side of optimum to investigate the elastic properties (i.e. Poisson's ratio and modulus of elasticity). The different percentages of lime used during the experimental work are 3%, 6% and 9%. Image analysis technique was used for measuring the change in lateral dimensions of the soil specimens during the process of uniaxial static loading produced by Unconfined Compression (UCC) testing machine. Then the obtained results have been used for computing Poisson's ratio. The results showed that with the decrease in moulded water content from wet to dry side of optimum, the modulus of elasticity of black cotton soil increases. But in the case of lime treated black cotton soil, with the increase in lime content and curing time, the moulded water content at the wet side of optimum gives higher modulus of elasticity compared to that of dry side of optimum.

Black cotton soil is one of the most commonly encountered materials in soil mechanics. As these soils are sensitive with increase or decrease in moisture content, the studies on the behaviour of black cotton soil at different moisture contents have been increased in the field of Geotechnical engineering. Most of the researchers concentrated on evaluating the elastic properties such as Poisson's ratio and modulus of elasticity of soils and stabilized soils at Optimum Moisture Content (OMC) [7,16,17]. As these elastic properties are used for calculating the coefficient of earth pressures for stability analysis of retaining walls [8], elastic settlements on foundations and design of flexible pavements.

In general, the chemical and physical properties of these soils can be improved by both chemical and mechanical stabilization. Chemical stabilization of soil consists of chemical additives like lime, cement and other chemical additives. In lime, which is one of the most common and efficient stabilization technique for the past 2000 years. Often, the stabilization by lime is attained in two stages. Firstly, short term reactions of cation exchange, flocculation-agglomeration, lime carbonation and secondly, long term pozzolanic reaction [1].

The partially saturated black cotton soil is susceptible to be affected by the increase or decrease in water content at the same stress conditions, since it contains clay minerals like montmorillonite, illite, kaolinite, etc. which leads to swelling of the soil on wetting and shrinkage during drying. Wetting and drying of soil usually modify the microstructure of the lime treated soils, which leads to changes in hydro mechanical properties [2].

Hence, in this paper an attempt was made to study the effect of lime content on elastic properties of black cotton soil at a dry side of optimum, optimum and wet side of optimum. And also image analysis technique was adopted to measure the lateral strains produced during the testing of the soil specimen as it was the best technique compared to the other measuring devices like Dial gauge, Linear variable differential transducer, etc. The image analysis is a technique, which has been used for manipulating and processing Images to obtain requisite data from the acquired images. The use of this technique had been widely increasing in the field of Geotechnical engineering for studying the horizontal soil shrinkage [3], measurement of in-plane displacements in soil testing [4], and analysis of particle size distribution of coarse aggregate [5].

For this purpose, Black cotton soil has been collected from Medak District of Telangana state. Hence, various relevant tests have been performed on the black cotton soil and these tests include the index properties for soil classification, the engineering properties to understand the behaviour of the soil.

The locally available hydrated lime, which contains less than 40% of calcium oxide, was used as the stabilizing agent. It has a specific gravity of 2.34.

Tap water has been used for all the experimental works.

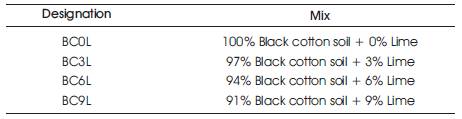

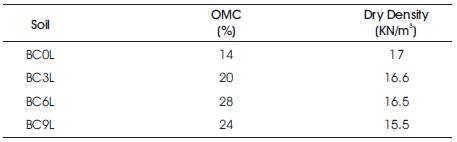

In the present study, hydrated lime was mixed with the black cotton soil in different proportions, varying from 0% to 9% in the intervals of 3% in each case. To avoid misleading, designation was given for each type of mixes. The designations for various mixes are shown in Table 1.

Table 1. Mix Designations

Specific gravity of fine grained (black cotton) soil has been determined by using density bottle, as per [9].

The Wet sieve analysis and hydrometer tests have been performed as given in [10] to determine the particle size of the soil and [15] for soil classification, so that it can be used to differentiate the coarser and finer particles.

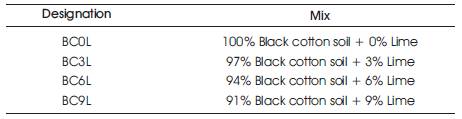

The liquid limit and plastic limit of black cotton soil and lime treated soil were determined according to [11]. The results of index properties of black cotton soil and Atterberg's limits of lime treated black cotton soil are shown in Tables 2 & 3.

Table 3. Atterberg’s Limits of Lime treated Black Cotton Soil

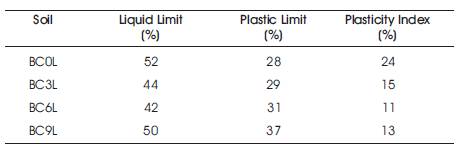

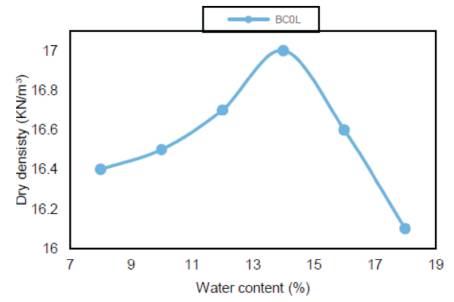

The compaction tests were conducted according to [12] of soil and [14] for stabilised soils. Initially an oven dried soil sample of 3 kg, which is passed through 4.75 mm sieve was used. Then required amount of water content is added for various identical soil samples. The hand mixing process was used during the tests, so that mixed soil samples are stored in plastic bags for a period of about 24 hours for obtaining uniform mixtures till the test begins. Then the wet sample was compacted in standard proctor mould with a rammer of 2.6 kg from a height of 31cm for three equal layers with 25 blows for each layer. By the relationship of dry density and moisture content, the optimum moisture content corresponding to the maximum dry density was determined. The soil, which is to be treated by different percentages of lime (3, 6 and 9%) by weight of oven dried soil is also taken. Similar tests were conducted on identical soil samples using the above procedure. The results obtained are shown in Table 4.

Table 4. OMC and MDD of Lime Treated Black Cotton Soil

Soil specimens, which are statically compacted through a split mould of 38 mm internal diameter x 76 mm long were adopted for testing of an untreated and lime treated soil samples. Five identical samples were prepared for each density as obtained in compaction curves. These samples were compacted at the selected moulded water contents at a dry side of optimum (i.e. 0.75 OMC & 0.9 OMC), Optimum Moisture Content (i.e. OMC) and wet side of optimum (i.e. 1.15 OMC & 1.25 OMC). To cure the samples for a period of 7, 14, and 28 days, soil specimens were wrapped in airtight plastic bags, so that the moisture change can be prevented and also these samples are placed in desiccators and maintained at a humidity of 100%.

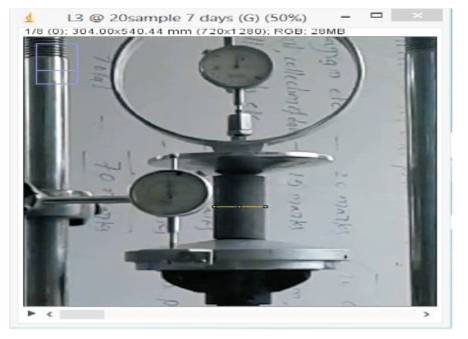

UCC test was conducted according to [13] for obtaining the strength characteristics of black cotton soil and lime treated soil of uncured and cured samples. The specimens were placed (i.e. UCC testing machine) manually in such a way that line of focus of the camera should be orthogonal to the longitudinal axis of the specimens. To capture the videos, a Nikon Coolpix L340 camera was adopted. Then the captured videos were converted into images by using a software called Free Studio. The number of images required for the analysis depends upon the yield point of the soil specimen. From earlier studies, it is known that time of the interval of 20 sec will give the best results. So, it has been adopted at a time of interval for making the images. For measuring the lateral strains in the soil specimens, the procedure followed by [6] was adopted during studies.

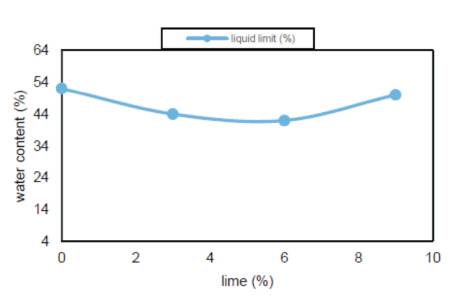

Figure 1 represents the influence of lime on liquid limit of soil. It is observed that the liquid limit decreases with the increase in lime content.

Figure 1. Influence of Lime Content on Liquid Limit of Black Cotton Soil

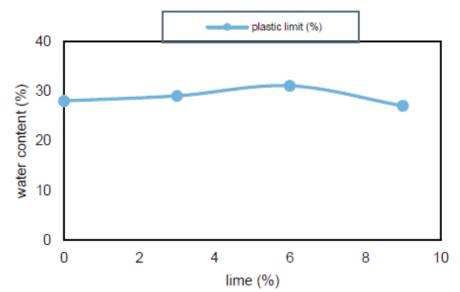

The decrease on liquid limit of lime content of 3% and 6% is high, when compared to 9%. From Figure 2, it is clearly observed that initially plastic limit of the black cotton soil increases and then decreases as lime content increases.

Figure 2. Influence of Lime Content on Plastic Limit for Black Cotton Soil

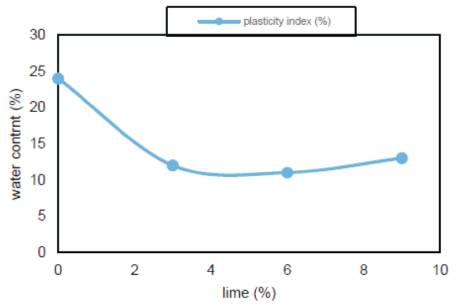

The increase in lime content also shows decrease in plasticity Index for 3%, 6% and there was a slight increase for 9%. The results for plasticity Index were shown in Figure 3.

Figure 3. Influence of Lime Content on Plasticity Index of Black Cotton Soil

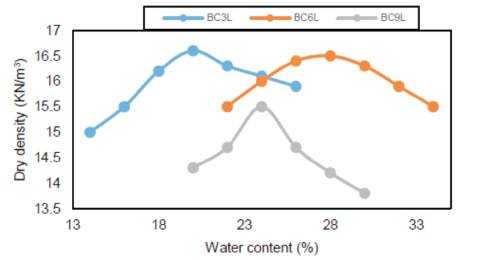

The compaction characteristics of natural and stabilised black cotton soil with different percentages of lime (3%, 6%, and 9%) have been illustrated in Figures 4 & 5 respectively. The addition of lime content shows reduction in maximum dry density due to short term reactions, while the increase in Optimum Moisture Content (OMC) is due to the increase of finer material, since hydration of lime takes place with the addition of water. It has been observed that for 3% and 6% of lime, the decrease in maximum dry density is very negligible to about of 9%. Whereas, increase in optimum moisture content of 9% is less, when compared with 3% and 6% of lime.

Figure 4. Compaction Curve for Natural Black Cotton Soil

Figure 5. Compaction Curves of Lime Treated Black Cotton Soil

It is a well-known fact that, the Poisson's ratio is defined as a ratio of lateral strain to that of axial strain in the direction of loading. The below equation represents the Poisson's ratio (υ).

Where εx is a lateral strain in the direction of x-axis and εy is a longitudinal strain in the direction of the y-axis. Therefore, in the present study, the authors obtained the lateral strain by processing the image with a free software called Image J. An example of image scaling is shown in Figure 6. And the process of scaling the images and measurement of results such as area, perimeter, length, etc. is similarly calculated referring to [6].

Figure 6. Image Scaling

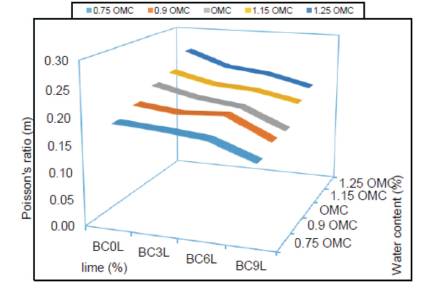

Whereas axial strain is measured from the rate of strain (1.25 mm/min) in which UCC test was conducted. From Table 1, it is known that Poisson's ratio of Black Cotton Soil (BC0L) increases with increase in moisture content. And from Table 2, it is known that Poisson's ratio of a stabilized black cotton soil (BC3L, BC6L & BC9L) exhibits an increasing trend from the dry side of optimum to the wet side of optimum for all cured and uncured samples. But, the Poisson's ratio of black cotton soil decreases with increase in lime content and curing period. An example of the variation of Poisson's ratio with increase in lime content of uncured samples at different moulded water contents are shown in Figure 7.

Figure 7. Variation of Poisson's Ratio with Different Percentage of Lime Content and Moulded Water Contents

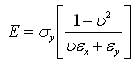

Modulus of elasticity is studied by adopting two dimensional equation, which was proposed by [6], as it is best suitable for measuring the modulus of elasticity since linearity does not exist between the obtained stress-strain curves. The following equation represents modulus of elasticity (E).

Where σy is applied stress in the direction of loading (Y-axis), υ is Poisson's ratio, εx is horizontal strain and εy is vertical strain.

Figure 8 and Table 5 represent the modulus of elasticity of black cotton soil at different moulded water contents of dry side of optimum (0.75 OMC & 0.9 OMC), near (OMC) and wet side of optimum (1.15 OMC & 1.25 OMC), from an obtained compaction curve of BC0L. Figure 8 shows that modulus of elasticity decreases (10.79 Mpa to 2.24 Mpa) with increase in water content from dry side of optimum (0.75 OMC) to wet side of optimum (1.25 OMC). The reason behind this, the soil samples which was compacted at dry side of optimum attains flocculated structure and whereas at wet side of optimum it attains dispersed structure.

Figure 8. Variation of Modulus of Elasticity for Black Cotton at Different Moulded Water Contents

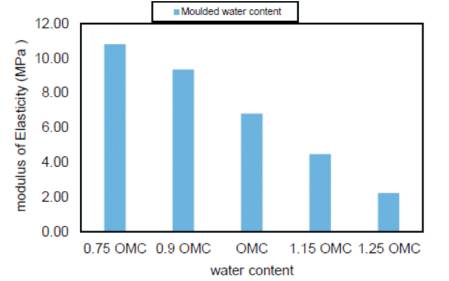

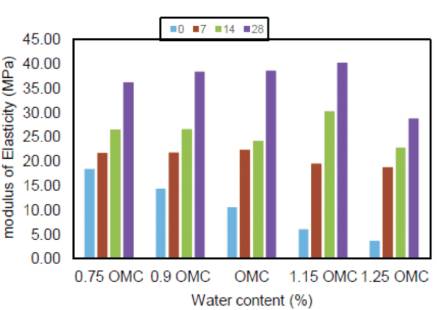

It is observed that with the increase in lime content of 3%, the modulus of elasticity of untreated soil increases from 10.79 Mpa to 14.20 Mpa at 0.75 OMC, 9.35 Mpa to 11.74 Mpa at 0.9 OMC, 6.81 Mpa to 8.69 Mpa at OMC, 4.47 Mpa to 5.38 Mpa at 1.15 OMC and 2.24 to 2.55 Mpa at 1.25 OMC. Further, with the increase in curing periods (i.e. 7, 14, and 28 days) the modulus of elasticity of lime treated soil decreases from the dry side to wet side of optimum, which is shown on Figure 9 and Table 6. Mainly, the gain in strength of stabilised black cotton soil to increase in curing period is due to long term pozzolanic reaction.

Table 6. Modulus of Elasticity Of Stabilised Soil (BC3L, BC6L and BC9L) at Different Moulded Water Contents for 0,7,14, and 28 Days of Curing Periods

Figure 9. Variation of Modulus of Elasticity for Black Cotton at Different Moulded Water Contents

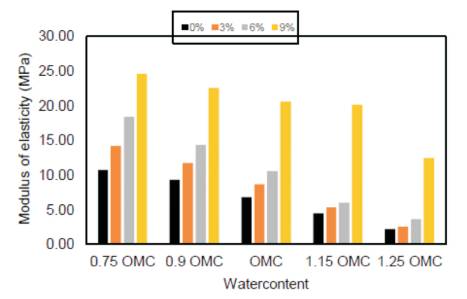

Figure 10 shows that the modulus of elasticity of 6% lime treated black cotton soil increases more than that of the natural soil (i.e. BC0L), and 3% of lime treated soil (i.e. BC3L). It is observed that at a dry side of optimum, the modulus of elasticity obtained was 18.45 Mpa at 0.75 OMC, and 14.37 Mpa at 0.9 OMC. Whereas, at wet side of optimum, it was 6.03 Mpa at 1.15 OMC and 3.68 Mpa at 1.25 OMC. This was mainly due to short term reaction of lime with black cotton soil. It has shown that with the increase in moulded water content, the modulus of elasticity decreases. From Figure 11 and Table 6, it was observed that the influence of pozzolanic reaction was the main reason for gaining the strength of soils with the increase in age of curing. But, the maximum modulus of elasticity were obtained at optimum (OMC) of 7 days, wet of optimum (1.15 OMC) of 14 days and wet of optimum (1.15 OMC) of 28 days.

Figure 10. Variation of Modulus of Elasticity of Lime Stabilised Black Cotton Soil at Different Moulded Water Content

Figure 11. Variation of Modulus of Elasticity of BC6L at Different Moulded Water Contents for 0,7,14 and 28 Days of Curing Periods

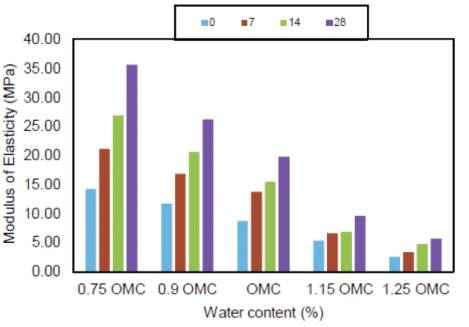

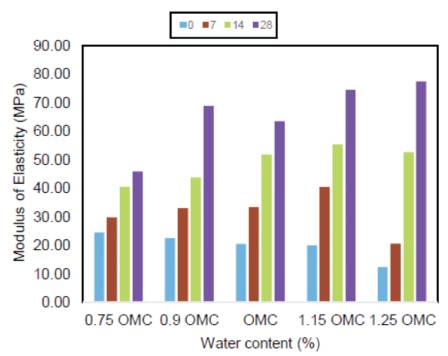

The modulus of elasticity of 9% lime treated black cotton soil shows an increase in its value, when compared with that of 0%, 3%, and 6% of lime stabilised soil. From Figure 12 and Table 7, observe that the modulus of elasticity of 9% lime treated soil decreases from the dry side of optimum to the wet side of optimum with a range of 24.56 Mpa to 12.43 Mpa. The increase in age of curing of soil specimens shows an increase in its modulus of elasticity.

Table 7. Modulus of Elasticity of Stabilised Soil (BC3L, BC6L and BC9L) at Different Moulded Water Contents for 0,7,14, and 28 Days of Curing

Figure 12. Variation of Modulus of Elasticity of BC6L at Different Moulded Water Content for 0,7,14, and 28 Days of Curing Periods

But, the maximum modulus of elasticity was obtained at the wet side of optimum of 7 days (1.15 OMC), 14 days (1.15 OMC), and 28 days (1.25 OMC) of curing with an elastic modulus of 40.44 Mpa, 55.36 Mpa, and 77.47 Mpa.

The following inferences are drawn based upon the investigation of results obtained during the experimental work.

The authors would like to thank the principal of VNR Vignana Jyothi Institute of Engineering and Technology for providing their needs and encouragement throughout the project work. The authors are also thankful to vice principal, faculty members, and colleagues of VNRVJIET for giving suggestions and helping in completion of this research work.