In the manufacture of Roller Compacted Concrete Pavement (RCCP) materials, various types of aggregates are used, namely crushed stone as coarse aggregate and river sand as fine aggregate. The main purpose of adding aggregate in RCCP is to achieve higher flexural strength. In the present experimental work, use of manufactured sand(M-Sand) with river sand as partial replacement (50%) was investigated along with the Pozzolanic effect of fly ash on RCC. Six levels of partial replacement of cement with fly ash were considered such as 10%, 20%, 30%, 40%, 50% and 60%. 50% of river sand was replaced with M-Sand. The various strength indices like specific strength (SPRCC ), specific strength of Pozzolanic effect (SPFA ), specific strength ratio (R), contribution percentage of Pozzolanic effect to strength (P) and index of specific strength were examined. Finally the results indicate that

The River sand has been used mainly as fine aggregate in the construction industry. The infra structural development that took place in the world leads to the demand for river sand. As the supply of suitable natural sand material near to the port of construction is becoming exhausted, the cost of sand is increasing. Therefore, a replacement material for river sand is needed. The finer materials from crushing operations are more suitable materials as substitute materials [1].

Xincheng Pu et al [2] investigated the Pozzolanic effect of mineral admixtures in cement and concrete by a parameter called specific strength index, with the addition of fly ash into cement, the Pozzolanic effect varies with age and percentage replacement level of fly ash. The Pozzolanic effect is increased with increase in age. The compressive strength of fly ash is increased after 1year of age from 2-3 class.

Cheng Cao et al [3] investigated the effect of high volume of fly ash on Roller Compacted Concrete and the result indicated that the fly ash effect at early ages is low and with increasing fly ash contents of 45%, 55%, 65%, 75%, 85%, and 95% levels, the Pozzolanic effect on HFRCC at long curing ages becomes more remarkable.

L-H.Yu et al [4] investigated the effect of perlite powder in concrete. The Pozzolanic effect of the mineral admixture perlite was quantitatively evaluated through specific strength indices like specific strength and contribution percentage of Pozzolanic effect to strength. This study indicated that natural perlite powder has a significant Pozzolanic effect and is a good active mineral admixture for concrete.

Tarun R. Naiket et al [5] investigated the strength and durability of Roller Compacted HVFA Concrete Pavement in two pavement projects (Project I and Project II) in Wisconsin, WI 53201. In Project I, the conventional paving concrete was made with 50% class C fly ash as partial replacement of cement, which showed excellent strength and durability performance at the age of 6 years. In project II, where the RCC pavement constructed with 30% fly ash it indicated excellent density, strength and flexural performance after two years of service.

Cengiz Dura Atis et al [6] found that HVFA Roller Compacted Concrete was an adequate material for structural and pavement applications. He replaced cement with fly ash at 50% and 70% with low-lime class F fly ashes. The strength results are satisfactory at 28 days and higher at 1 year.

Ali Mardhani et al [7] studied the effect of high volume fly ash on mechanical properties of roller compacted concrete, where cement was partially replaced by fly ash at 20, 40 and 60% levels and in another series fine aggregate was replaced with fly ash partly(20,40 60% of cement). It was concluded that in the mixtures where cement was replaced with fly ash, increase in fly ash content caused reduction in compressive, splitting tensile and flexural strength values at all the ages, up to even 180 days. On the other series, where fine aggregate was replaced with fly ash, increasing fly ash content increased the strength values of the mixture at all ages.

M.Chi, Ran Huang et al [8] studied the effect of circulating fluidized bed combustion (CFBC) ash which was used to replace fine aggregate of RCC. Test results indicated that CFBC can increase the water absorption and effectively reduce the initial surface absorption. CFBC had a positive effect on compressive strength, splitting tensile strength and surface attack resistance of RCC.

S.K.Rao et al [9] studied the effect of the M- sand on the strength characteristics of Roller compacted Concrete by replacing the river sand with M-sand at 25%, 50%, 75 % and 100%. They concluded that increase in M-sand levels increased the flexural strength of RCC.

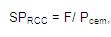

It is defined as the contribution of 1% cement to Roller Compacted Concrete strength which can be calculated as

Where,

F is the Strength of Roller Compacted Concrete,

Pcem is percent of cement to total amount of Binder

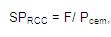

It is the contribution of fly ash to the strength of concrete with fly ash and it can be formulated as

Where,

SPFRCC = Specific Strength of Fly ash RCC

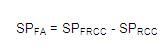

Ratio of concrete strength to cement or mineral admixture percentage, is given by the following expression, R= F/p

Where,

F= RCC strength, p is percentage of cementitious material

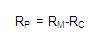

Where,

RM is the contribution of unit mineral admixture to RCC strength

RC is the contribution of unit cement to RCC strength without any mineral admixture

It is the ratio of RM to RC and is given by the following expression, K = RM /RC

It is given by the expression, P= (RP /RM )x 100, %

The main objective of this research is to investigate the Pozzolanic effect of fly ash on the Roller Compacted Concrete Pavement with M-Sand as partial replacement of River sand. Different mix proportions were considered including RCC mixture containing river sand as fine aggregate (100%).

Use of M-sand in RCC has many advantages. High fines percentage of M-sand increases the flexural strength, improved abrasion resistance and higher unit weight and lower permeability in RCC.

Therefore this experimental study was conducted to achieve the following objectives:

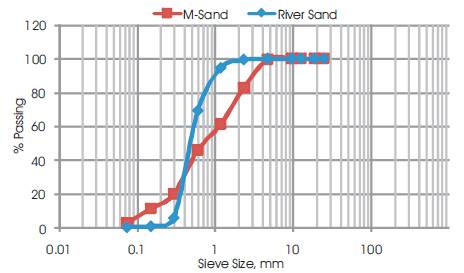

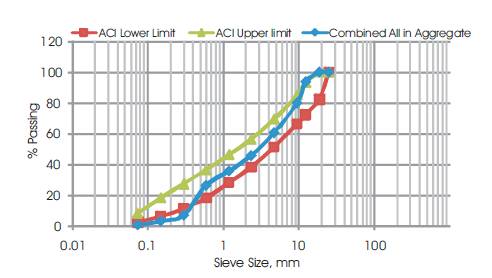

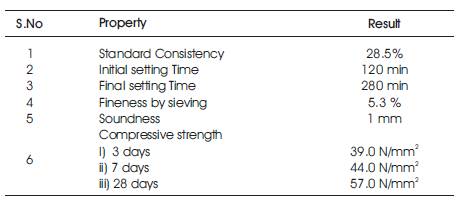

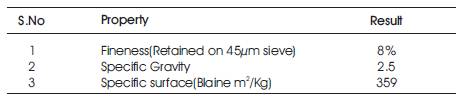

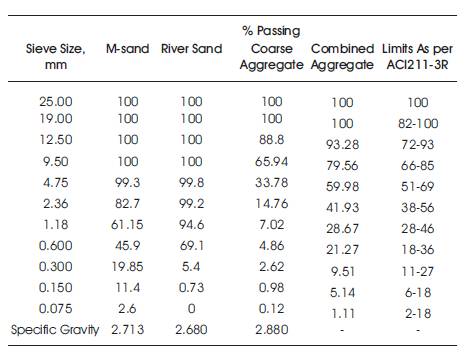

The RCC materials used in this experimental work includes cement, fly ash, natural river sand, manufactured sand, crushed granite coarse aggregate and water. The physical properties of cement and fly ash are shown in Tables 1 and 2. Cement was tested as per IS 4031:1998 [10]. Fly ash was tested as per IS 1727:1967 [11]. Two types of fine aggregates such as Natural River sand and M-sand were used and tested as per IS 383 [12] and their gradational results are shown in Figure 1 and sieve analysis test results and physical properties are shown in Table 3. Crushed angular stone aggregate with NMSA of 19mm and downgraded was used. The specific gravity was 2.87. coarse aggregates passing 20mm 10mm and 6mm sized were combined (40:40:20). The combined grading is given in Table 4. Particle size distribution curve is shown in Figure 2. Water used in RCCP mix was potable and drinking water.

Figure 1. Particle Size Distribution of Fine Aggregate

Figure 2. Particle Size distribution of all in Aggregate

Table 1. Physical Properties of OPC 53

Table 2. Physical Properties of Fly ash

Table 3. Sieve Analysis Test results of River sand, M-sand and Coarse Aggregate

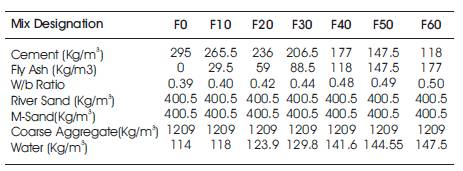

Table 4. Quantities of materials per one m3 of Roller Compacted Concrete Pavement of 5 N/mm2 Flexural Strength

Mix proportioning of RCCP was done using ACI 211 3R-02- 2004 [13] method. This method was developed for Roller compacted concrete pavements of Rigid pavement category and it is limited to mix design with nominal maximum size of aggregate of 19mm as per ACI 325.10R- 99 [14].The RCCP mix was proportioned for specified target flexural strengths of 5.0N/mm2 [9]. The cement content of control mix of RCC was 295kg/m3 . In six RCCP mixtures 10, 20, 30, 40, 50 and 60% by weight of cement were replaced with fly ash. Using six different water/binder ratios six mixtures were prepared. The identification of mix proportions and quantity of material are shown in Table 4.

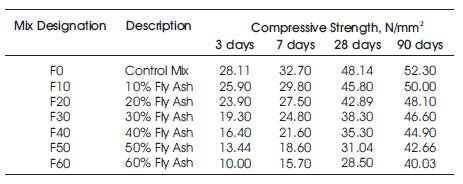

Cube specimens of size 150mmx150mmx150mm were casted for measuring compressive strength. Concrete was placed and compacted with modified proctor rammer. After 24 hours, the specimens were demolded and kept in water for curing. Then compression loading tests were conducted on a compression testing machine of capacity 3000KN. For this test, a loading rate of 2.5KN/S was applied as per IS:516-1959 [15]. The test set up is shown in Figure 3. The tests were performed at 3d,7d,28 days and 90days. Test results are shown in Table 5.

Figure 3. Compression Test on Cube Specimens

Table 5. Compressive Strength results of 150 mm cubes

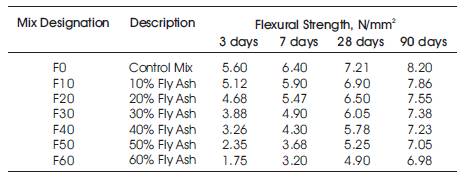

Beam specimens of size 500x100x100 mm were used for measuring flexural strength in beam moulds and compacted with modified proctor's rammer. They were demolded and kept for curing after one day. Then Flexural strength test were conducted on UTM of capacity, 1000 KN by center point loading at 3,7,28 and 90 days [15]. The test set up is shown in Figure 4. The test results are presented in Table 6. Figure 5 shows the development of crack in the prism.

Figure 4. Flexural Strength Test set up (before and after loading)

Figure 5. Development of crack in the prism

Table 6. Flexural Strength results of 500x100x100 mm beam

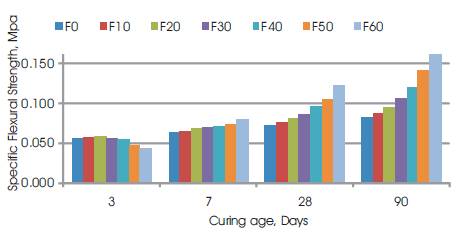

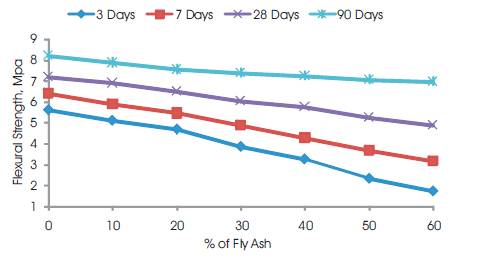

The development of flexural strength of FRCC with curing age is shown in Figure 6. In the early ages of 3 days, with the increase in fly ash content, SPRCC decreases at all levels of replacement. When it is cured for more than 28 days, the contribution of fly ash to flexural strength in FRCC is significant.

Figure 6. Specific Flexural Strength of FRCC with Curing Age

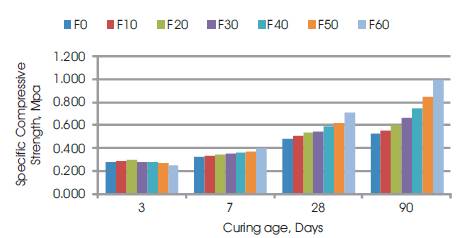

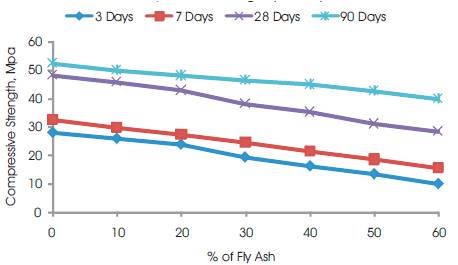

The development of compressive strength of FRCC with curing age is shown in Figure 7. In the early ages of 3 days, with the increase in fly ash content, SPRCC decreases at all levels of replacement. When it was cured for more than 28 days, the contribution of fly ash to compressive in FRCC is significant.

Figure 7. Specific Compressive Strength of FRCC with Curing Age

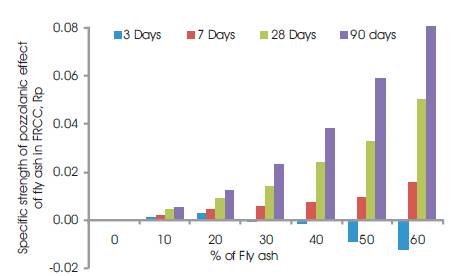

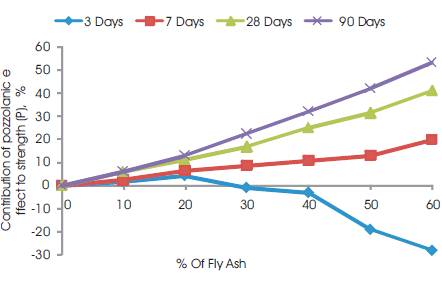

Figure 8 shows the trend of Flexural Specific Strength of Pozzolanic effect of fly ash in FRCC. At initial ages of 3 days and 7 days, the Pozzolanic effect of fly ash is very low or negative (at 3 days for mixes R30,R40,R50 and R60), but it is increasing very rapidly at 90 days with increase in fly ash content. In the long term curing age, fly ash even at 60 % replacement level provides effective contribution to strength.

Figure 8. Flexural Specific Strength of Pozzolanic effect of Fly ash with % Fly ash

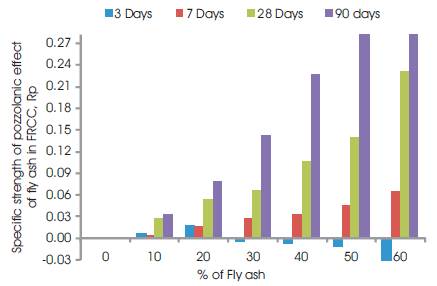

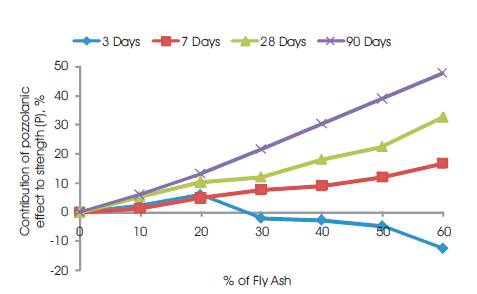

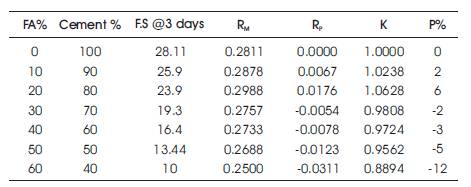

Figure 9 shows the trend of compressive Specific Strength of Pozzolanic effect of fly ash in FRCC. At initial ages of 3 days and 7 days, the Pozzolanic effect of fly ash is very low or negative (at 3 days for mixes R30,R40,R50 and R60), but it is increasing very rapidly at 90 days with increase in fly ash content. In the long term curing age, fly ash even at 60 % replacement level provides effective contribution to strength.

Figure 9. Compressive Specific Strength of Pozzolanic effect of Fly ash with % Fly ash

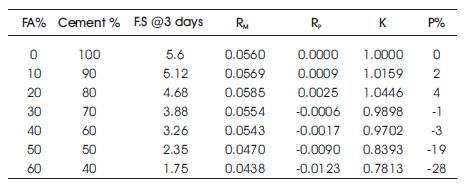

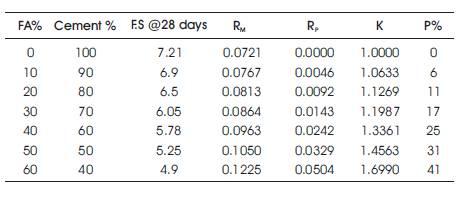

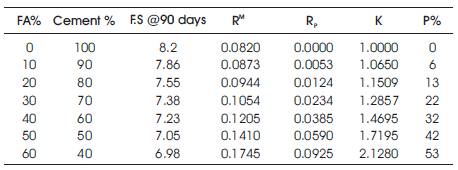

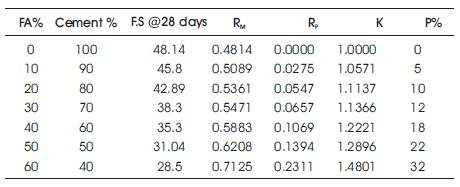

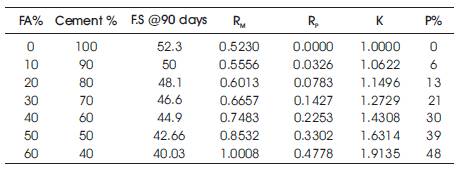

The Pozzolanic indices for flexural strength were calculated and presented in Tables 7-9 and is graphically shown in Figures 10-11. Similarly for compressive strength the Pozzolanic indices are presented in Tables 10-12. Graphical representation is shown in Figures 12-13. Table 7 shows the indices of Pozzolanic effect ( RP and P) of flexural strength at 3 days of curing age which are showing negative values when fly ash content is more than or equal to 30%. But in Table 8 and Table 9, these indices are showing improved values with increase in fly ash content at 28 days and 90 days of curing. Similar trend has been observed in Compressive Strength indices also (Table 11 and Table 12).

Figure 10. Change in Flexural strength versus percent of fly ash in the Mix

Figure 11. Variation of P with fly ash content in RCC (Flexural Strength)

Figure 12. Change in compressive strength versus percent of fly ash in the Mix

Figure 13. Variation of P with fly ash content in RCC (Compressive Strength)

Table 7. Indices of pozzolanic effect of FRCC (3 days) Flexural Strength (N/mm2 )

Table 8. Indices of Pozzolanic effect of FRCC (28 days) Flexural Strength (N/mm2 )

Table 9. Indices of Pozzolanic effect of FRCC (90 days) Flexural Strength (N/mm2 )

Table 10. Indices of Pozzolanic effect of FRCC (3 days) Compressive Strength (N/mm 2)

Table 11. Indices of Pozzolanic effect of FRCC (28 days) Compressive Strength (N/mm2 )

Table 12. Indices of Pozzolanic effect of FRCC (90 days) Compressive Strength (N/m2)

From Table 7-9 and Table 10-12, and also from Figures 10- 11 and Figures 12-13, it is clear that the flexural strength and compressive strength of FRCC and indices of Pozzolanic effect are increased with curing age. During early period of curing at 3 days the Pozzolanic effect of fly ash is minimum. As the curing age increases the contribution rate of Pozzolanic effect of fly ash also increases. This implies that curing age is an important factor on the Pozzolanic effect of Fly ash for RCC.

From the experimental work , following conclusions were drawn.