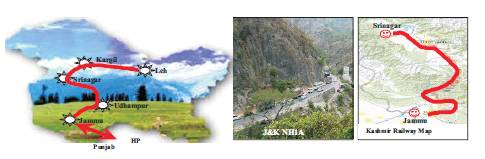

Figure 1. Jammu and Kashmir Road & Railway line

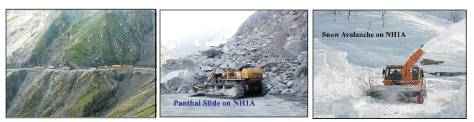

Due to monsoon and heavy snowfall, there are chances of landslides, snow avalanches and rockfalls all along National Highway thereby disturbing the normal life. In addition, there are problems like slope failures, erosion of steep slopes, lack of vegetation and drainage. (Figure 2)

Figure 2. Blockade of National Highway due to Landslides and snow avalanches

1. Transport System in J&K

Jammu and Kashmir (J&K) has a well distributed roadway network with a total length of 20,000 km. Most of the main roads classified as Distt. Roads and village roads are maintained by the Public works department of J&K. Srinagar and Jammu are the main two cities-summer and winter capitals of the State, linked by 300km-road length (NH1A). Jammu is the terminus of Northern Railway and has direct train services to all the four metropolitan cities and almost all the major cities in the country. In aviation sector, there are three major airports located at Leh (in Ladakh), Srinagar (International airport) and Jammu connecting J&K with other parts of the country. At present, there is local railway network in Kashmir valley from Qazigund to Banihal in operation. Efforts are being made to connect Kashmir valley with rest of the country through railway network. Therefore, in the landlocked state like Jammu and Kashmir, road transport is an indispensable means of communication for the regular distribution of essential and other commodities. Economic development of the state and access to the landlocked and unexposed areas are dependent on roads. The National Highway 1-A connects the capital cities of Srinagar and Jammu with rest of the country through the Jawahar Tunnel (largest road tunnel in India) at an elevation of 2064m above the mean sea level. The National Highway 1-A 294 km in length facilitates the main freight system from Jammu to Sringar, which passes through hilly terrain and steep slopes (Figure 3).

Figure 3. Topography of NH1A in J&K through hilly terrain and steep slopes

2. Causes Of Slope Failures / Landslides

The landslide area lies in a region of unstable formation. Depending upon the shear strength of soil, it can form a stable slope upto certain inclination. Beyond this, the gravitational forces acting on the soil mass may exceed the available shear strength along potential failure surface and soil mass may slide down resulting in a slope failure. As the slope is steep, the site remains dangerous during heavy rainfalls resulting in heavy landslides and cause severe damage to life and property. Thus, the national transport system is often disrupted by landslides and rockfalls at various locations on National Highway 1A between Srinagar and Jammu, J&K State (India). Figure 4 shows how the landslide develops from the incipient movement caused by the various factors including loss of vegetation, poor soil strength, steep slope and the presence of excessive surface and subsurface flow

Figure 4. Landslide due to removal of vegetation cover and construction activities

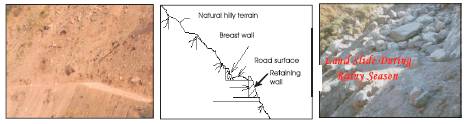

Construction of the Road due to back cutting has also caused the initial movement of the soil mass as is evident from the exposed back cutting of the slope and subsequent caving and land sliding. In a naturally hilly terrain, it is necessary to trim the soil on one side and fill the same on the other side to get a level surface. When the hill slope is already steep, it has to be made further steep to get a level surface and flatter slopes. But this involves not only large quantity of earthwork, which is uneconomical and practically not feasible, but also disturbs.

3. Prominent Landslides and Rock Falls

Landslides/ slopes failure also occurs during rainy season; due to heavy snowfall in winter and due to the denudation of the forests. Permeable and fractured shales and sandstone mixed with reddish brown clay, through which springs (particularly in rainy season) ooze out at the point of contact, cause the fragmented rocks to detach and slide down the steep mountain slopes. Over a total length of 300 km from Jammu to Srinagar, the number of spots presently under active slides is 20. The number of vulnerable spots, which are in course of their development, is much more. The prominent among them are as listed below:

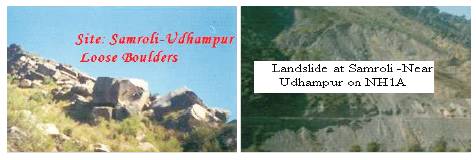

3.1 Samrauli Landslide

The soil strata at this landslide spot are composed of silty shale, brown clays and fine to medium sandstones. This is one of the major trouble spots at about 76-km from Jammu city (Figure 5). The slide occurs on the strike faced during the rainy seasons.

Figure 5. A front view of landslide near Samrauli (comprising of silty shale & sandstone)

3.2 Nashri Slide

Nashri landslide located between Batote and Ramban on the Jammu-Srinagar National Highway on Nashri bypass is under cut by river Chenab. The Chenab River is one of the trunk streams flowing through the area. The main Nashri slide occurs at 131 km and the zone between 133-134 km is highly prone to sliding. There are a number of slides active in this zone. (Figure 6).

Figure 6. A distant view of Nashri landslide

3.3 Khoni Nallah Slide

Rockfalls are abrupt free-fall movements from steep rock and slopes where material is not in continuous contact with the ground, but instead can roll, bond and skip downslope. The Best Example for Rockfall is the Khoni Nallah and Panthal Slides between Ramban and Banihal on National Highway. It involves highly jointed gneisses, which participate in planner slides along adversely oriented joint planes and the blocky nature of the rock gives rise to frequent rockfalls on the road, hurtling down from great heights and damaging the RCC bridge. Wire mesh has been provided to avoid rockfall directly on to the bridge (Figure 7)

Figure 7. A distant view of wire mesh at Khoni nalla (a) and Pangthal slide (b)

3.4 Shatian Nallah Slide

Banihal, known as the gateway of Kashmir, is located about 10 km away from Jawaharlal Tunnel. The Shatian Nallah is another danger of snow avalanches in winter due to heavy snowfall on National Highway (Figure 8). The area affected by the snow avalanche is between Nowgam and Lower Munda with a length of around 20km. The road subsidence is caused by sub-surface flow from the springs. The famous Verinag water spring is situated near Jawaharlal Tunnel at an elevation of 100m above MSL.

Figure 8. Snow avalanches near Shaitan nallah on NH1A near Jawaharlal Tunnel

4. Remedial Measures: Light Weight Materials

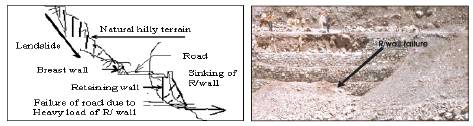

In J&K, the conventional methods are normally used as remedial measures for protection slope failures and landslides. For construction of road in a naturally hilly terrain, it is necessary to trim the soil on one side and fill the same on the other side to get a level surface. When the hill slope is already steep, it has to be made further steep to get a level surface and flatter slopes. Breast walls and retaining walls are used for stable road formation. But sometimes, in addition to the gravity force on the soil mass, the self-weight of these breast walls and retaining walls add to the instability of a slope and the road fails (Figure 9).

Figure 9. Failure of road due to heavy weight of breast

Hence, there is a dire need to search for alternative lightweight, technically viable, economically feasible and eco-friendly material for wider applications. One such popular material, which has emerged in recent years, is Geosynthetics, which is available in abundance in India. Thus, this paper will be presenting an overview of geosynthetic applications with examples as a lightweight material within the current technology of geosynthetics.

5. Geosynthetics for Soil Improvement

The use of geosynthetics material in almost all areas of civil Engineering is widespread. Geosynthetics have been increasingly used in geotechnical and environmental engineering for the last 4 decades (Palmeira et al. 2008). Embankments on soft ground and steep-sided slopes have become favourite application areas (Rao 1996). The basic types of geosynthetics are related to their most commonly applied engineering functions as under:

- Geogrids : Reinforcement and Separation

- Geotextile : Cushioning and Filtration

- Geocomposites, Geonets : Transmission

- Geomembranes : Isolation

6. Geosynthetics in Roadways

A geosynthetic is a planar product manufactured from a polymeric material used with soil, rock, earth, or other geotechnical-related material as an integral part of a civil engineering project, structure, or system. Geosynthetics have made it possible to construct roads and pavements in seemingly difficult situations such as marshy stretches, soft and organic deposits and in expansive soil areas. Soft subgrade soils are most susceptible to disturbance during construction activities such as clearing, grubbing, and initial aggregate placement. Geosynthetics can help minimize subgrade disturbance and prevent loss of aggregate during construction. Subgrade conditions in which geosynthetics are useful include poor soils (e.g., clayey silt-SC, low plasticity clays-CL, high plasticity clays- CH, low plasticity silts-ML, highly plastic silty soils-MH, low plastic organic soils-OL, highly plastic organic soils-OH, and peaty soils-PT etc.), low undrained shear strength: τf = Cu < 90ka, CBR<3%, high water table, and high sensitivity. Thus, use of geosynthetics results in significant savings, improved performance and very good serviceability in both short term and long term stability.

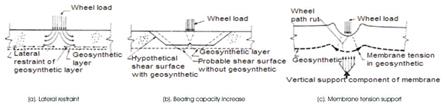

6.1 Mechanism

A number of explanations have been proposed as mechanisms of soil improvement using geosynthetics material for stable roadways. They include (Figure 10):

1. Lateral restrainment of the base and subgrade through friction and interlock between the aggregate, soil and the geosynthetic.

2. Increase the system bearing capacity by forcing the potential bearing capacity failure surface to develop along alternate, higher shear strength surfaces.

3. Membrane support of the wheel loads.

6.2 Design Approaches

In the design of sub-base or sub-grade improved with geosyntheitc materials, two main approaches are followed as given below:

1. No reinforcing effect is considered - Conservative, applicable for thin roadway sections with relatively small live loads, where ruts are 50 to 100mm.

2. Reinforcing effect is considered - Applicable for large live loads on thin roadways, where deep ruts (>100mm) may occur and for thicker roadways on softer subgrade.

There is also advantage of using a geotextile within a wearing course, which helps in restriction of reflection cracking, reduced rutting and restriction of fatigue cracking.

6.3 Scope of Geosynthetics in J&K

The use of geosynthetics is widespread in the field of civil engineering. In J&K, due to monsoon and heavy snowfall, there are chances of landslides, snow avalanches and rockfalls all along National Highway thereby disrupting the normal life. In addition, there are problems like slope failures, erosion of steep slopes, lack of vegetation and drainage. The conventional material used for various purposes often turns out to be uneconomical and even unstable. There is a lot of scope for utilization of geosynthetic material for construction of roads, rockfall protection, retaining walls, stability of slopes, railway project, erosion control, growth of vegetation, drainage etc. An overview of geosynthetic applications in some of applications is as given below.

7. Strengthening of Slopes

When steep slopes are necessary and factor of safety is not adequate, the slopes can be made stable by one of the following techniques:

7.1 Erosion control: Surface protection with Geotextile Material

Geosynthetic material can be successfully used for surface protection of steep slopes and heavy erosion of topsoil can be avoided. Generally, a net of geotextiles material made of high-density polythylene is used for the erosion control by placing it along the slope surface and anchored into the slope so that surface erosion of the soil is avoided thereby reducing the chances of landslides and slope failure in rainy seasons. A typical sketch of slope protection with geotextiles is shown in Figure 11. Hence, embankments over riverbanks or in flooded areas and river banks can be protected against erosion by using mattress of geosynthetic materials, commonly known as soft armour, where hard armour i.e., retaining walls etc are not allowed by environmental agencies

Figure 11. Protection of natural slope using geotextiles

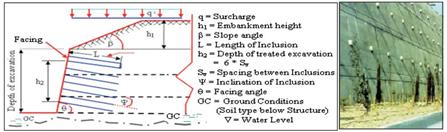

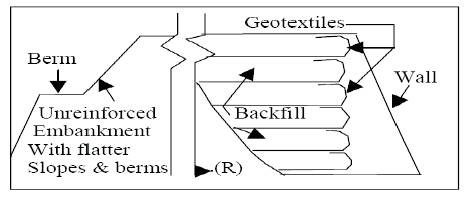

7.2 Embankment Slopes: Reinforcement with Geotextiles and Geogrids

Figure 12. Unreinforced embankment

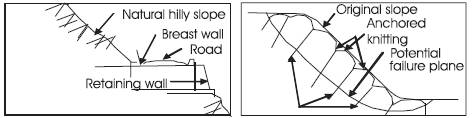

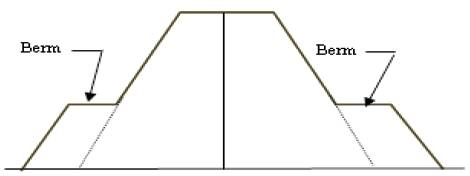

In a naturally hilly terrain, adequate space is not available for excavation and for embankments, flatter slopes will involve large quantity of earthwork and additional expenditure. As seen from Figure 12, for unreinforced embankments, adequate space is needed for flatter slope so that Factor of Safety will automatically improve. But achieving flatter slopes on either side involves large quantity of earthwork, which is uneconomical and practically not possible. Therefore, using geosynthetic materials in all constructions (like dam, road/railway embankments) in hilly terrain can be built with steepest possible slopes for economy and savings in land area occupied (Figure 13). The provision of geogrid reinforcement close to the face of the shoulder of any sandy soil embankment permits better compaction of the slope up to the edge. As a result and by virtue of pseudo cohesion developed due to reinforcement, the shearing resistance of the soil increases significantly. Thus, the overall stability of the embankment is increased. This technique can be successfully used for construction of Qazigund- Baramulla Railway line where high embankments are to be constructed and the land available is very costly. In addition to geosynthetic material applications, soil nailing technique can also be applied for stabilization of steel slopes. Soil nailing is a cost-effective alternative to conventional retaining wall structures when used in situations with ground formations suitable for nailing. Common nail wall applications include cut slope retention for roadway widening and depressed roadways, slope stabilization etc. The fundamental concept is that soil can be effectively reinforced by installing closely spaced grouted steel bars, or “nails”, into a slope or excavation as construction proceeds from the top down. The nail bars are not pre-tensioned when they are installed. They are forced into tension as the ground deforms laterally in response to the loss of support caused by continued excavation. The grouted nails increase the shear strength of the overall soil mass and limit displacement during and after excavation. Complete design parameters of a typical soil nailed system along with complete view of soil nailed slope are shown in Figure 14.

Figure 13. Geotextile reinforced embankment

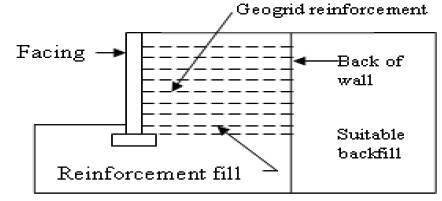

8. Reinforced Soil Walls

Reinforced soil walls in the form of geogrid reinforced segmental block walls have become a common form of construction (Castelli, and Munfakh 1986). Their aesthetic, speed of construction and low cost makes them an ideal form of retaining wall construction (Lawson and Yee 2004)] The design process (BS 8006 1995) addresses two stability conditions viz. external stability (i.e., sliding, overturning, bearing and overall deep slip failure mechanisms) and internal stability (i.e., grid reinforcement tension and pullout failure mechanism within the reinforced zone). Performance has been verified from monitored full-scale structures (Bathurst, et. al. 1988, Bathurst, et. al 2008). Many researchers (e.g. Koerner 1994, Koerner and Soong 2001) have reported numerous works on reinforced retaining walls. Versatile and efficient wall systems continue to evolve worldwide, but yet to be exploited in J&K, where tremendous potential for application and development of reinforced wall technology exists. Geosynthetic material (geotextile or geogrid) wrapped around layers of soil backfill can be provided for a vertical wall (Figure 15). The reinforcement can be either geotextile or more often a geogrid. Based upon a recent cost survey (Koerner 1998) , the above type of geosynthetic reinforced walls are the least expensive. These walls can be used to replace conventional retaining walls (Figure 16).

Figure 15. Typical X-sec. of a geogrid reinforced soil wall

Figure 16. Typical retaining wall

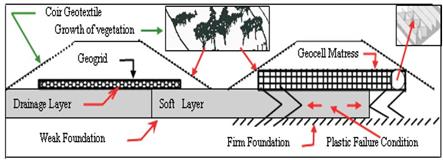

9. Applications in Highway/Railway Embankments on Soft Soil/ over Weak Soils in J&K

Geogrids can be used to reinforce embankments over weak foundations. Through the interlock between soil and the grid structure and the resulting transfer of stress, geogrid reinforces cohesive as well as granular soil. In low to medium height, embankments with moderate side slopes, horizontal layers of geogrids are used to reinforce against deep-seated failure planes. Embankments of greater height on relatively thin layers of weak soil can be constructed using a Geocell Mattress (Figure 17).

This reinforces and contains the soil to provide increase in load bearing properties and rigidity at the base of reinforcement. When slopes fail, landslide occurs along a slip circle or wedge which separates from the body of earth mass. Geogrids laid in horizontal layers reinforce the slope by intercepting potential failure surfaces passing through the embankment and anchoring the slide mass horizontally. The sides of the embankment can be covered with coir geotextile to encourage vegetation growth to prevent erosion. (Figure 17).

In a normal railway track, a layer of ballast is provided over the foundation of the soil. But during rainy season, several problems with respect to the ballast and soil interface are encountered. Mud pumping is a major problem in railways and requires regular maintenance. The dynamic load imposed by a moving train can induce a problem commonly known as erosion failure. In J&K, this problem will be dominated on Qazigund-Baramulla railway line where the soil is dominantly cohesive in nature and water table is high. Water reaching the subgrade from either a high water table or rainfall can turn the cohesive soil into slurry which will be pumped upwards through the ballast by alternating contraction and expansion of voids under dynamic loading. Therefore, to overcome these problems, a solution can be recommended by providing a layer of Geotextile at the interface of formation and ballast, over a layer of 100mm thick course sand blanket. The use of geotextiles and/or geogridf (Figure 18) between the ballast and soil subgrade considerably check the mud pumping and improper drainage, and provides tensile strength to the soil and shear strength is improved. Thus, Geosynthetics, i.e. Geogrids and Geotextiles can be recommended in road and railway construction. There are a number of approaches toward using polymeric materials in roadway cross sections that invariably have as their goal better performance, longer service lifetime, or a combination of both features. Many researchers (e.g. Rao 1995 and others] have reported a significant increase in the bearing capacity of geogrid-reinforced soil.

Conclusion

This paper presents an overview of geosynthetics as a lightweight and sustainable material for wide range of applications in various fields of construction technology in J&K. J&K State is a hilly state with diverse nature of sub-soil conditions. According to the investigation carried out onsite, the main triggering factors for landslides, rockfall and slope failures all-along NH1A are deforestation of steep slopes, back cutting of slopes for construction purposes, heavy rainfall, and snowfall. Based on the detailed review of all remedial measures, it has been concluded that the conventional methods of steep slope stabilization are not practically feasible and technically viable. Hence, it is important to search for alternative techniques and lightweight, technically viable, economically feasible and eco-friendly materials for wider applications. It has been also seen that the role of vegetation is not technically feasible at macro scale stabilization of steep slopes. Therefore, there is a dire need for utilizing other technically viable, economically feasible technique like soil nailing for stabilization of steep slopes. Among lightweight materials, Geosynthetics has emerged as an alternative material, which is available in abundance in India. Geosynthetics, as a family of products, has a wide range, primary among them are Geotextiles, Geogrids, Geomembranes and Geocomposites. These products can provide technoeconomic solutions to diverse problems starting from reinforcement applications to containment of municipal waste, surface protection, riverbank protection, permeation cut off etc. Such solutions are not only economically viable & sustainable, but also the construction procedure takes less time as compared to conventional alternatives. Therefore, in this study, an attempt has been made to utilize the available lightweight and sustainable material without affecting the earth's natural resources for the sustainable development in the capital City.