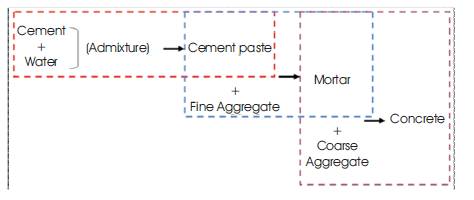

Figure 1. Composition of concrete

Concrete is the most widely used construction material. It is the second largest consumed material in the world after water. It is used in different ways in the construction industry. It can take any shape it is placed in. This makes concrete a versatile construction material. However during cold weather, if the water in the fresh concrete is allowed to freeze, the concrete will be damaged to such an extent that it is unfit for use. Even if the temperature does not drop below zero, the concrete will not gain strength as quickly as it would during the warmer months. Hence for cold weather concreting we must use an accelerator admixture to speed up the hardening of concrete. An experimental program was undertaken to determine the effect of accelerator admixture on the strength of concrete casted below zero degrees Celsius. Tests on both fresh and hardened concrete were carried out to determine their respective strengths. Different specimens with varying percentage of accelerator admixture and sizes were casted and tested after 7 days and 28 days.

Concrete is a composite construction material, composed of cement (commonly Portland cement) and other cementitious materials such as fly ash and slag cement, aggregate (generally a coarse aggregate made of gravel or crushed rocks such as limestone, or granite, plus a fine aggregate such as sand), water and chemical admixtures. Concrete solidifies and hardens after mixing with water and placement due to a chemical process known as hydration. The water reacts with the cement, which bonds the other components together, eventually creating a robust stonelike material. Concrete is used to make pavements, pipe, architectural structures, foundations, motorways/roads, bridges/overpasses, parking structures, brick/block walls and footings for gates, fences and poles. Concrete is used more than any other man-made material in the world. Concrete is the second largest consumed material on earth after water.Reinforced concrete, pre-stressed concrete and precast concrete are the most widely used types of concrete functional extensions in modern days.Admixtures interact chemically with the ingredients of the concrete and affect its performance in the fresh and hardened state [Mario C, Enco, 2005]. There are many methods that can be used in the production of concrete to accelerate rate of hydration [M.A. Bhavikatti, V.V. Karjinni, 2012]. Figure 1 shows the composition of concrete.

Figure 1. Composition of concrete

In India certain regions experience sub-zero temperatures in winter. Concrete structures in such regions undergo cycles of freezing and thawing and there durability is affected due to frost action. Fresh concrete contains considerable quantity of fresh water which gets converted into ice lenses at freezing temperature [Al-Gahtani, A.S.,2010]. The ice formation in fresh concrete results in about 9% rise in volume and causes permanent damage to concrete and structural integrity cannot be recovered even if the concrete is made to harden later at high temperature. Even during hardening the concrete should be protected from extremely low temperature, so that concreting in cold weather ensures that the temperature of fresh concrete is maintained above 0 °C and temperature during first six hours of casting should not be less than 5 °C [Buch, N.,et al., 2008].

IS 7861 part II defines Cold Weather Concreting as any operation of concreting done at about 5°C atmospheric temperature or below.

ACI 306 “Cold Weather Concreting” defines cold weather concreting as a period when for more than three consecutive days, the following conditions exist:

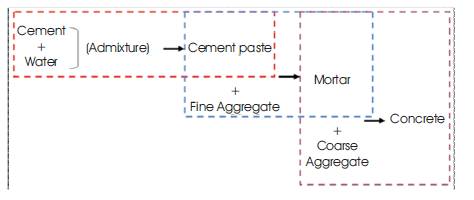

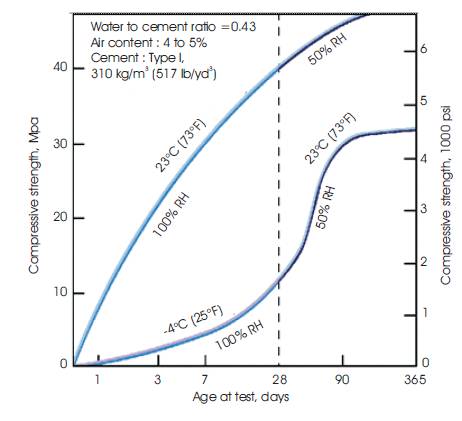

Concrete placed during cold weather will develop sufficient strength and durability to satisfy intended service requirements only if it is properly produced, placed and protected [Cheung, J. et al,2011]. Figure 2 shows the effect of temperature on strength development. Figure 3 shows the effect of low temperature on compressive strength of concrete.

Figure 2. Effect of temperature on strength

Figure 3. Effect of low temperature on development compressive strength of concrete

The objectives of cold weather concreting are to:

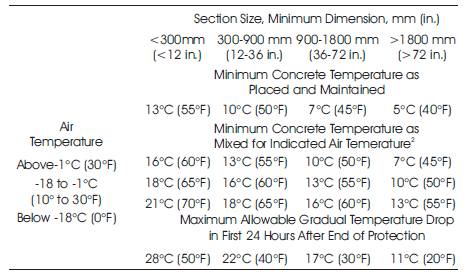

For every 10°C (18°F) reduction in concrete temperature, the setting time of the concrete doubles, thus increasing the amount of time that the concrete is vulnerable to damage due to freezing. Concrete that is protected from freezing until it has attained a compressive strength of at least 3.45 MPa (500 psi) will not be damaged by exposure to a single freezing cycle. Concrete that is protected and properly cured will mature to its potential strength despite subsequent exposure to cold weather (Neville, A.M., 1992). Except in heated, protective enclosures, little or no external supply of moisture is required for curing during cold weather. Table 1 shows various temperatures for placement and protection in concrete weather.

Table 1. Temperatures for Placement and Protection in Concrete Weather

Following deleterious effects may occur due to cold weather concreting

The reduction of setting time and the acceleration of strength gain often result in substantial savings due to shorter protection periods, faster form reuse, earlier removal of shores, and less labor in finishing flatwork.

Calcium chloride is the most cost effective accelerator available, but it causes corrosion of embedded metals in the presence of oxygen and moisture [Topcu, I.B., Toprak, M.U., 2005]. This is why limits exist on the use of chlorides in concrete .

Rapidite is a commonly used admixture in Kashmir during winter to accelerate the strength gain of concrete. It falls under Type C on the basis of ASTM classification i.e., it acts as accelerator. It also acts as anti-freeze, depressing the freezing point of water and hence protecting the fresh concrete.

Rapidite 2 in 1 is a specially developed Concrete Set Accelerator, a ready-to-use, liquid admixture. It accelerates initial setting time (cement-water chemical reaction Hydration) of normal mortar and concrete and acts as anti-freeze within cement concrete. It improves workability and strength while fastening the hydration of cement. It makes the mix easier to place and speeds construction by shortening the initial set and curing time. Time and labor are saved, because forms and other protection can be removed earlier, and finishing can be started.

Rapidite 2 in 1 is recommended for use during cool and cold weather to accelerate the set time and reduce the risk of frozen mortar and concrete mixes.

The objective of this paper is to study the effect of a commonly used admixture rapidite in Kashmir on the strength of concrete during first 24 hours when the temperature after casting will fall below zero. Casting was carried out in the period from November to February.

In our study we varied the percentage of rapidite and found its affect on the strength, we casted two specimens [IS 383: (1970)] [IS 10262: (2009)] for every percentage of rapidite, one plain and one with admixture, and monitored the relative increase in the strength of concrete. Thus we found out the optimum amount of admixture to be used during winters.

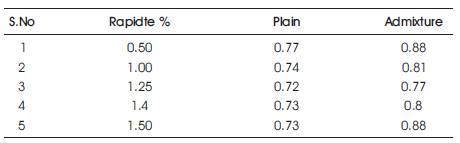

Only compaction factor was done to check the workability as the sump in most of the cases was zero.

Compaction factor test was started 3 minutes after the completion of mixing.

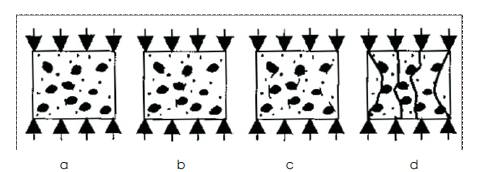

This test is conducted on cubes (150mm and 100mm) [IS 516: (1959)] which are loaded on their opposite faces in a Compression Testing Machine (CTM). Sixteen samples were casted in each casting, out of which eight were plain and eight were with admixture. Out of these, 4 cubes from each set were tested at 7 days and remaining 8 were tested at the age of 28 days. The load at which first crack appears is considered as failure load and the compressive strength is calculated corresponding to this particular value of load. Figure 4 show failure mechanism. Figure 4 a shows that at about 25-30% of the ultimate strength, random cracking are observed. Figure 4 b shows that at about 50% of ultimate strength, cracks grow. Figure 4 c shows that at about 75% of the ultimate strength major cracks are formed. The major cracks keep growing while smaller cracks tend to close Figure 4 d shows that at the ultimate load, failure occurs when the major cracks link up along the vertical direction and split the specimen.

Figure 5 and Figure 6 show cube before loading and cube at failure respectively.

Compressive strength = Load at failure /Cross sectional area

Where, cross-sectional area = (150×150) mm {in case of 150 mm cubes}

= (100×100) mm {in case of 100 mm cubes}

Figure 4. Failure mechanism

Figure 5. Cube before loading

Figure 6. Cube at failure

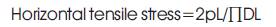

The test is carried out by placing a cylindrical specimen, horizontally between the loading surfaces of a Compression Testing Machine and the load is applied until failure of the cylinder, along the vertical diameter [IS 516: (1959)]. The loading condition produces a high compressive stress below the two surfaces to which the load is applied. But the larger portion corresponding to depth is subjected to a uniform tensile stress acting horizontally. It is estimated that the compressive stress is th th acting for both (1/6th ) depth and the remaining (5/6th ) depth is subjected to tension. The horizontal tensile stress is given by the following equation:

Where, P = Load at failure

L = Length or height of cylinder (300mm)

D = Diameter of cylinder (150mm)

Figure 7 shows the loading arrangement for split tensile strength test. Figure 8 and Figure 9 show cylinder loading and cylinder at failure.

Figure 7. Loading arrangement

Figure 8. Cylinder before loading

Figure 9. cylinder at failure for Split tensile strength test

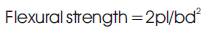

Flexural strength test of concrete is performed on beams. The loading applied on the beam is a two point loading in rd which loads are applied at (1/3rd ) points of the beam [IS 516: (1959)]. The beam is placed in the testing machine in such a way that the load points are 16.6 cm apart from each other as well as from each support. The load is increased until the specimen fails and this load is noted as failure load. Flexural strength is then calculated from the following formula:

Where, P = (Load at failure)/2

l = Length of beam between supports (500mm)

b = Breadth of beam (100mm)

d = Depth of beam (100mm)

Figure 10 shows Two-point loading arrangement for Flexural Strength test. Figure 11 and Figure 12 show beam before loading and beam at failure.

Figure 11. Beam before loading

Figure 12. Beam at failure

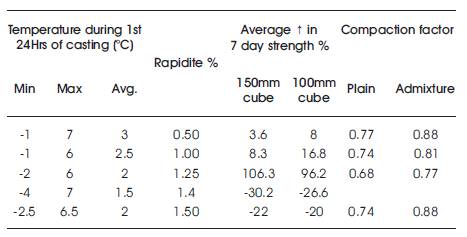

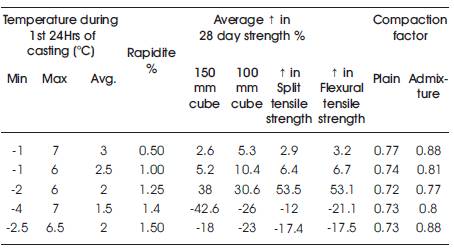

In total five castings were done at the rapidite percentage of 0.5, 1, 1.25, 1.4 and 1.5% and the minimum and maximum temperature during the first 24 Hours after casting was observed.

The Temperature during first 24 Hours after casting along with the results of various tests are shown in Tables 2,3 and 4.

Table 2. Variation of Increase in 7 day strength and C.F (Compaction Factor) with varying Rapidite percentage

Table 3. Variation of Increase in 28 day strength and C.F with varying Rapidite percentage

Table 4. Variation of C.F for plain concrete and concrete with admixture for varying rapidite percentage

In order to study the variation in the rate of gain of strength with respect to the rapidite percentage, a comparative study of the test results achieved at different rapidite percentage was performed.

Following variations were studied:

The results graphs representing the comparative study are given below.

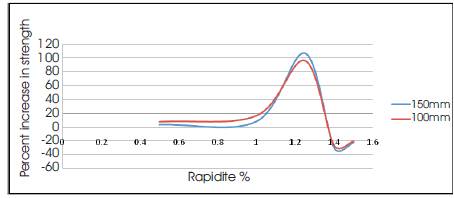

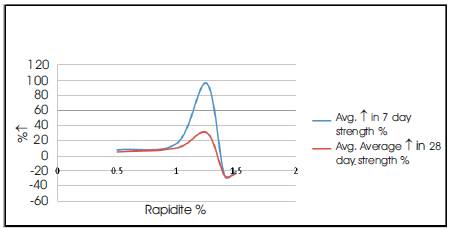

From the study of Figure 13, it is clear that by adding rapidite, the 7 day strength increases when compared to the plain concrete casted at the same temperature. Also it can be seen that, at 1.25%, there is maximum increase in strength, beyond this value there is a decrease in the strength of concrete with admixture,when compared with plain one. Also the 100mm cube shows more increase in strength when compared with 150mm cube, except at the optimum amount where, the increase in strength of 150mm cube is more than 100mm cube.

Figure 13. Variation of 7 day strength with Rapidite %

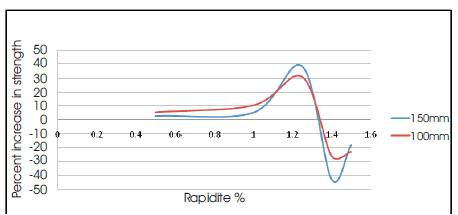

Figure 14 also shows same trend i.e, the 28 day strength also goes on increasing upto the percentage of 1.25, beyond which it decreases. Also, the 100mm cube shows more increase as compared to 150mm cube except at the optimum amount.

Figure 14. Variation of 28 day strength with Rapidite %

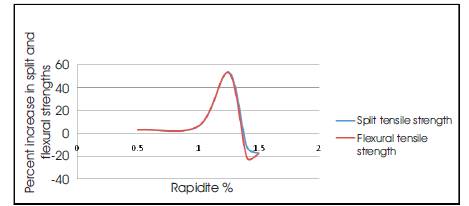

Figure 15 shows that there is an increase in both split and flexural tensile strengths up to 1.25% of rapidite, beyond this value the strength decreases in both the cases. Also the two graphs almost coincide showing that both strengths increase by equal amounts, flexural strength increasing slightly more than split strength.

Figure 15. Variation of split and flexural tensile strength with Rapidite %

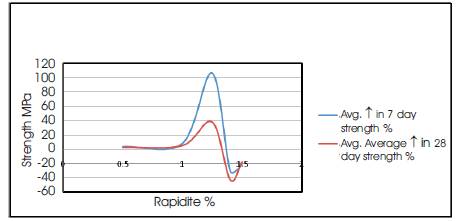

Figure 16 shows that although both 7 and 28 day strength for 150mm cube increases and reaches there maximum at the rapidite percentage of 1.25% ,the increase in 7day strength is 180% more than increase in 28 day strength.

Figure 16. Comparison of Avg. increase in 7 and 28 day strength for 150mm cube

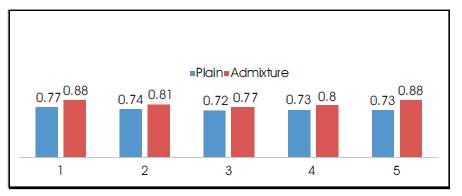

Figure 17 shows the same trend, although both 7 and 28 day strength for 100mm cube increases and reaches the maximum at the rapidite percentage of 1.25%, the increase in 7day strength is 214% more than increase in 28 day strength, which is higher than in case of 150mm cube. Figure 18 shows that the compaction factor always increases when compared with the plain concrete, thus workability increases by the addition of rapidite

Figure 17. Comparison of Avg. increase in 7 and 28 day strength for 100mm cube

Figure 18. Variation of C.F for plain concrete and concrete with admixture for different % of rapidite

After analyzing the test results, following important conclusions are drawn:

Following are some suggestions for future research.