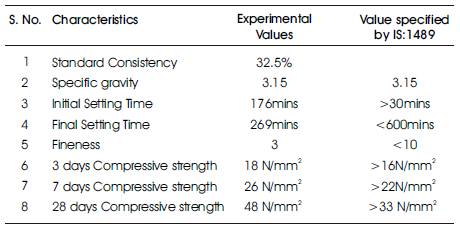

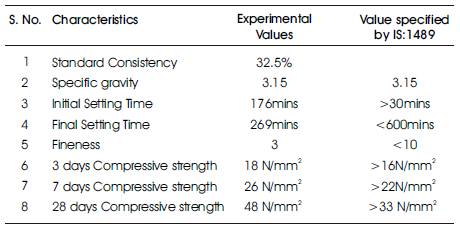

Table 1. Physical Properties of Cement

With the rise in global warming and increasing environmental imbalances, it is becoming essential to find a viable alternative to replace the conventional concrete mix ingredients. The aim of this research was to check the use of waste material as the concrete ingredients and check the impact of same with regards to strength and specific heat of concrete. This paper presents the mix design analysis, compressive strength results and specific heat results for concrete mixes prepared with part replacement of various different materials.

If human-induced climate change is to have any hope of being limited to 2 degrees, it is essential that ways are found to address rapidly rising greenhouse gas emissions in India, as elsewhere. This is a challenging

Proposition: even though India's per capita emissions are very low, (1.18ton/person/year), her 1.15 billion people are collectively a major source of greenhouse gas emissions. This fact, coupled with the immediate task of tackling widespread poverty, means that the international community must play a major role in providing financial and technological resources to support India's domestic efforts.

The environmental issues associated with CO2 and GHG, in addition to the natural resources issues has played a leading role in the sustainable development of cement and concrete industry in future years to come. Therefore, supplementary cementations materials such as fly ash, furnace blast slag; rice-husk ash, calcium carbide residue, rubber waste, kiln-dust, maize-cob ash etc should be used as much as possible as a replacement of Portland cement in concrete without compromising the industry expectations. An another interesting problem which can significantly reduce the energy consumption in the country is also taken as key objective of research problem which is control of specific heat of materials in concrete.

In current construction practices, surface area occupied by building is much more than plan area occupied over the surface of ground thus, constructed buildings absorb much more heat during the clear day time and radiate back the absorbed energy into the air when surrounding temperature falls during the night hours etc. As the constructed area by building is going on increasing day by day all around the world, this thermal inertia may be responsible for the cumulative rise in air temperature during summer months which start receding with reduction in sunny hours at end of summer months.

The main purpose of the study was to reduce the cement consumption in concrete (thereby, reducing emission of CO2 and other GHG's) and produce concrete with low specific heat/thermal conductance to minimize the energy absorption during sunny hours (and thus, reducing the air-conditioning load of building).

Thermal properties (specific heat, conductance etc) of concrete produced using these selected / feasible materials along with their physical and chemical composition, was be experimentally determined in lab and data sheet is prepared for studying their comparison and decision-making.

The selection of materials was based on following points:

A variety of materials were assessed for suitability according to scope of the study on above points. The materials that were assessed were: Kiln Dust, Calcined Clay, Rubber Waste, Light Weight Glass, Glass Aggregate, Fly Ash, Calcium Carbide Reside, Granite Marbles And Maize Cob Ash.

Based upon earlier research work, and to obtain a mix of replacement options, following mix ingredients materials were short listed for further detailed study.

A lot of research has been done on these ingredients as an ingredient of concrete and all that information was used while doing this study. Rice Husk Ash and Calcium Carbide Reside is known to have binding properties and was used as a replacement of cement. Shredded rubber waste is having particle size less than 4.75mm and was thus replaced for fine aggregates. Rubber has high specific heat which in turn was assumed to have a positive effect on concrete as an ingredient. Vitrified tiles waste has good mechanical properties and was easily rendered to replace coarse aggregates.

In order to achieve the objectives of the present study, an experimental program was planned to investigate the compressive strength and specific heat of the concrete when the cement, the fine aggregates and the coarse aggregates are replaced by rice husk ash, calcium carbide residue, rubber waste and vitrified tile waste in different percentages i.e. 0%, 5%, 10%, 15%, 20%.

Cement, fine aggregates, coarse aggregates, water, Rice Husk Ash, Calcium Carbide Residue, Rubber waste and Vitrified Tile Waste were used for this study. The specifications and the properties of the materials as determined and available are given below.

Portland Pozzolona Cement (P.P.C) from the Ambuja cements Limited (week no.50, 2009) was used in this investigation. It was fresh and without lumps. All tests on cement were conducted as per procedure laid down in Indian Standard code 12269-1987. The properties of the cement as determined in the laboratory are given in Table1.

Table 1. Physical Properties of Cement

Aggregates impart greater volume stability and durability to the concrete. They are used primarily for the purpose of providing bulk to the concrete. The aggregates provide about 75 per cent of the body of the concrete and hence its influence on the strength properties in the hardened state and on the workability in the green state is extremely important. These should, therefore, meet certain requirements if the concrete is to be workable, strong, durable and economical. The aggregate must be of proper shape, clean, hard, strong and well graded.

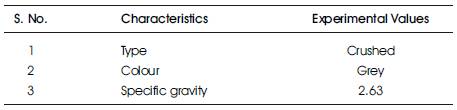

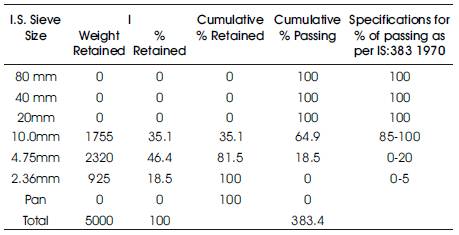

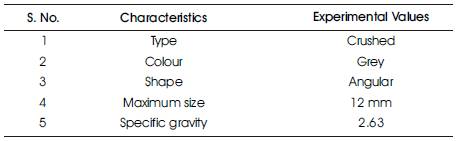

In the present investigation rubber waste and vitrified tiles are chosen to replace as large volume of the concrete as possible without effecting the fresh properties of the concrete. Coarse aggregates were tested as per Indian Standard Code: 383-1970. The Result of the sieve analysis and the physical properties are given in Tables 2 and 3 respectively.

Table 2. Physical Properties of Coarse Aggregate

Table 3. Sieve Analysis for Coarse Aggregate Total weight of sample = 5000 gm

Fineness Modulus (F.M) = 3.83

Nominal size of the Coarse Aggregate = 12.5 mm

The aggregates most of which pass through a 4.75 mm IS sieve are termed as fine aggregates.

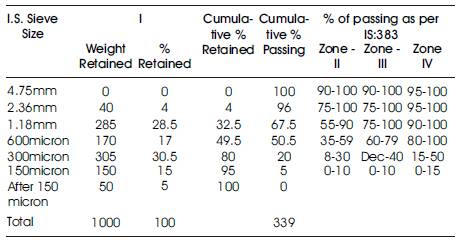

Fine aggregate assist the cement paste to hold the coarse aggregate particles in suspension. This action promotes plasticity in the mixture and prevents the possible segregation of paste and coarse aggregate, particularly when it is necessary to transport the concrete over some distance from the mixing plant to the point of placement. Coarse sand available from Zirakpur was used for this study. The sand sample was tested as per Indian Standard Code: 383-1970 and the properties obtained from the laboratory are given in Tables 4 and 5.

Table 4. Physical Properties of Fine Aggregates

Table 5 Sieve Analysis of Fine Aggregates (As Per Is:383-1970) Total weight of sample = 1000 gm

Fineness Modulus (F.M) = 3.39

Zone = II

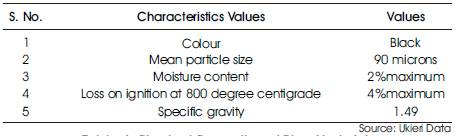

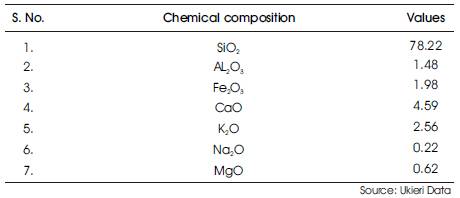

RHA used in the present study was procured from Boiler Fuel Waste of Poddar Tyres Limited, Ludhiana (Figure 1).The RHA particles can fill the voids between the larger cement grains because of their smaller size. Although RHA is not very fine in particle size, it behaves as a very reactive pozzolanic material because of its extreme surface fineness and high silica content. Due to extreme surface fineness, it increases the water-retaining capacity, and thus enhances the viscosity of concrete mixture. The physical and chemical properties are listed in Tables 6 and 7 respectively.

Figure 1. Rice Husk Ash.

Table 6. Physical Properties of Rice Husk Ash

Table 7. Chemical Composition of Rice Husk Ash

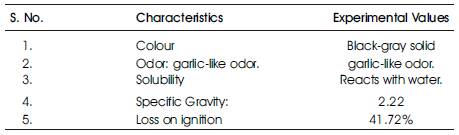

Calcium Carbide residue (Figure 2) is the waste material from gas welding. Calcium Carbide when mixed with water gives Acetylene gas which is burnt and thus the welding takes place. Calcium Carbide Residue used in the present study was procured from Mohraz Motors, Ludhiana which is a hub for all sort of repair jobs and calcium carbide residue is available in abundance. The physical and chemical properties are listed in Table 8 and 9 respectively.

Figure 2. Calcium Carbide Residue.

Table 8. Physical Properties Of Calcium Carbide Residue

Table 9. Chemical Properties Of Calcium Carbide Residue

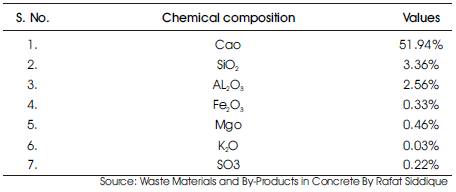

Rubber waste (Figure 3) used in the present study was procured from Poddar Tyres Limited, Ludhiana. To assess the properties of RW lab tests have been conducted in Ambuja Cements Limited Laboratory. The RW particles can fill the voids in the concrete and is used as a replacement for the fine aggregates. As rubber it is an excellent insulator of heat thus would increase the specific heat of the concrete. The physical properties and typical tyre composition are listed in Tables 10 and 11.

Figure 3. Rubber Waste

Table 10. Physical Properties of Rubber Waste

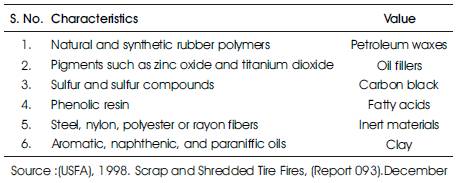

Table 11. Typical Tire Composition

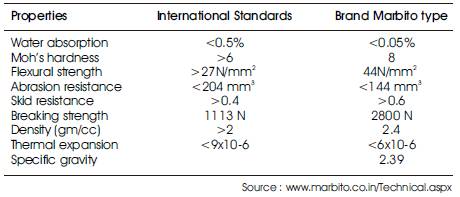

Vitrified Tile Waste (Figure 4) used in the present study was procured from Goyal Tiles, Pakhowal Road, Ludhiana and was crushed to appropriate size in Ambuja Cements Laboratory. To assess the properties of VTW laboratory tests have been conducted. The VTW is used as replacement for coarse aggregate due to crushing value comparable to the coarse aggregate. The physical and chemical properties are listed in Table12.

Figure 4. Vitrified Tile Waste

Table 12. Physical and Chemical Properties of Vitrified Tiles

As per (IS 456-2000) portable water is considered for satisfactory mixing and curing of concrete. The water should be clean and free from harmful impurities such as oil, alkali, acid etc. In general the water is fit for drinking is used for making and curing the concrete.

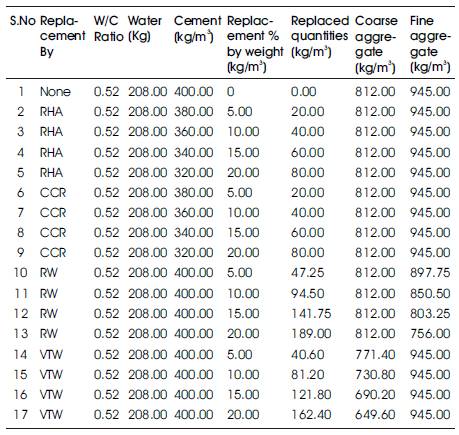

In this research, mix design of the concrete was done by ISI mix design method.

The Mix proportions for different concrete mixes are given in Table 13.

Table 13. Mix Proportions for Different Concrete Mixes

In the present experimental investigation the main aim was to check the influence of various ingredients/admixtures on the specific heat of concrete. It was ensured that the compressive strength of concrete should remain least affected by the replacements. So it was decided that waste products having some Cementitious properties must be replaced with the cement so that strength of the concrete must remain least affected and calcium carbide residue and rice husk ash was chosen for this purpose.

Similarly, vitrified tile waste was chosen to replace the coarse aggregate of the concrete. The crushing strength of these crushed tiles was found to be comparable to the normal coarse aggregate. The rubber tyre waste was used to replace the fine aggregate of the concrete. These particles were taken in the form of coarse sand.

Mix proportions obtained are given in Table 13. Total of 17 samples, each consisting of 9 cubes of size 150mm x 150mm x150mm for testing Compressive Strength and 3 cubes of size 70.6 x 70.6mm x 70.6mm for specific heat were Casted. The Samples used for finding specific heat are shown in Figure 5.

Picture 5. Samples used for Finding Specific Heat of Concrete After Partial Replacement of Mix Ingredients

Standard cubical moulds of size 150mm x 150mm x150mm made of cast iron were used to cast concrete specimens to the test compressive strength of concrete. Standard cubical moulds of size 70.6mm x 70.6mm x70.6mm made of cast iron were used to cast concrete specimens for testing the specific heat of concrete. All the moulds were cleaned properly and then oiled on inner sides well before casting of specimens to avoid sticking of the concrete to the moulds. These were tightened securely to correct dimensions before casting, to avoid leak of slurry from any leftover gaps.

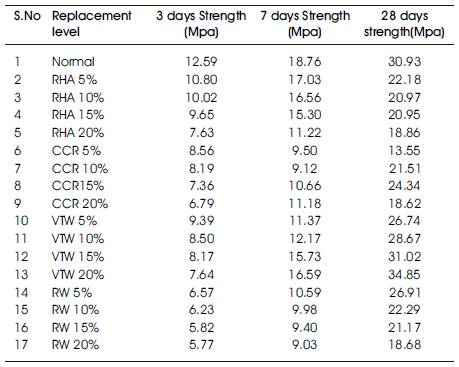

The test was conducted according to the Indian Standard Code 516-1959.Specimens were taken out from the curing tank at the age of 7, 28 and 56 days and tested after removal from the water in the surface dry condition. The position of cube while testing was at right angles to that of casting position. The load was gradually applied without any shock and increased at constant rate of 14N/ mm2/minute until failure of specimen takes place. It was tested on compression testing machine of rated capacity. The Summary of the test results of mixes under observation are given in Table 14. The actual photograph of the test is shown in Table 14.

Table 14. Summary of Compressive Strength tests

Temperature is a variable to measure “hot” and “cold”. (We was see that it is a measure of an internal kinetic energy)Heat is an energy transferred between objects because of a temperature difference. Transferring an amount of heat to an object may raise its temperature. Are heat and temperature the same or maybe the change in Temperature? NO! Heat neither can be the same thing as temperature nor the increase in temperature. The amount of heat to increase temperature depends how much mass and what material is being heated. Now specific heat is defined as the amount of heat energy (in Btu) required raising the temperature of one pound of a material by one degree Fahrenheit. Specific heat describes a material's ability to store heat energy. The specific heat of concrete and masonry can generally be assumed to be 0.2Btu/lb•°F.Heat Capacity is the amount of heat energy required to raise the temperature of a mass one degree Fahrenheit. Heat capacity is per square foot of wall area (Btu/ft2•°F) and includes all layers in a wall. For a single layer wall, HC is calculated by multiplying the density of the material times its thickness (in ft) times the specific heat of the material. HC for a multilayered wall is the sum of the heat capacities for each layer.

To produces concrete with low specific heat/thermal conductance to minimize the energy absorption during sunny hours (and thus, reducing the air-conditioning load of building). For this as stated above various combinations of waste materials along with cement and aggregates were taken for making a sustainable concrete with higher specific heat capacity.

As no apparatus was available for this experimental part at any of the external laboratories or technical institute thereby with the help of Sh. Bhattacharhge Professor Indian Institute of Technology, Delhi and Staff of Guru Nanak Dev Engineering College Ludhiana we got the same fabricated as per our requirements. The self fabricated apparatus contains two units as can be sited as in Figure 6. One part consists of heating furnace-Figure 7 and other part is temperature controller and indicator-Figure 8.

Figure 6. Fabricated apparatus

Figure 7. Heating Furnace

Figure 8. Temperature Controller and Indicator

Where K = Thermal conductivity of the material in w/mm°C.

Q = Heat applied or work done in watts.

A = Cross-sectional area of face to which heat is applied

T2 = Temperature at near end (point1).

T1 = Temperature at near end (point4).

L = length of material between point 1 and 4.

Where C = Specific heat of the material in w/kg°C.

Q = Heat applied or work done in watts.

M = Weight of material

ΔT = Difference in temperature

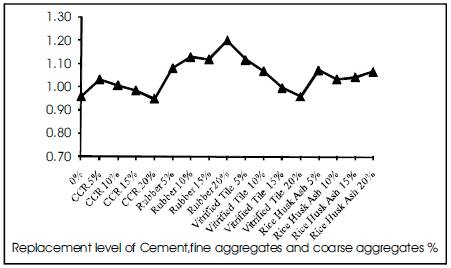

The Specific heat of concrete after partial replacement of concrete mix ingredients was studied. The compressive strength of the mixes thus obtained is also studied.

The Concrete produced with 20% replacement of coarse aggregates with vitrified tiles achieves maximum compressive strength and concrete with 20% replacement of fine aggregate with rubber achieves maximum specific heat as shown in Figure 8.

Figure 9. Variation with Percentage Replacement Of Cement by Rice Husk Ash, Fine Aggregates by Rubber Waste and Coarse Aggregates By Vitrified tile Waste.

The major conclusions drawn from the present study are

There is need for professionals to carry out further investigations in the following areas