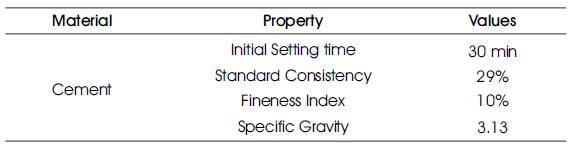

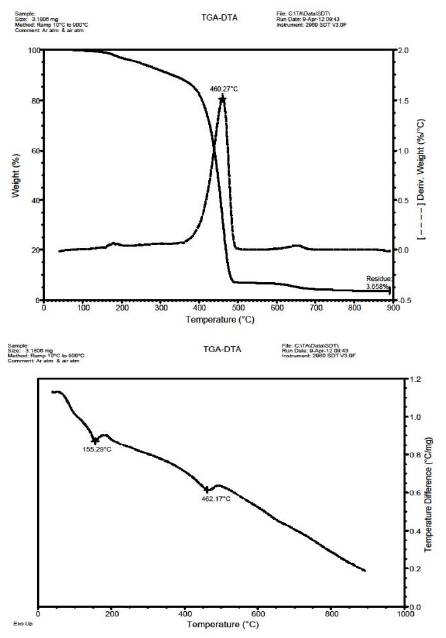

Table 1. Physical Properties of Cement

Large quantity of waste plastic could be disposed in an environmental friendly manner. Currently, most researches are focused on determining a good way to eliminate waste by using it as alternative material in the applications of civil and industrial engineering. The waste plastic materials could be powdered and mixed with the concrete and used for fabrication of structural elements. Advanced composites such as Fiber Reinforced Plastics (FRP) are promising and competitive materials that have great potential for use in high value added applications due to their superior characteristics in terms of high stiffness, low density and water absorption, high tensile strength, corrosion resistance and being used in a number of applications. The main aim of this study is to find out an environmental friendly way of disposing waste plastic by reusing principle and to study the behavior of plastic mixed concrete. In this study, the effective ways to reutilize the plastic waste particles as filler is analyzed. The strength characteristics of concrete containing recycled waste plastic material are determined.

Concrete deterioration mainly occurs due to corrosion of reinforcing steel resulting from exposure of vulnerable gases from a humid and saline environment [1]. Advanced composites such as fiber reinforced plastics are promising and competitive materials that have great potential for use in high value added applications due to their superior characteristics in terms of high stiffness, low density and water absorption, high tensile strength, corrosion resistance and being used in a number of applications [ [2]- [4]]. Plastic recycling is taking place on a significant role in the world. As much as 60% of both industrial and urban plastic waste is recycled [ [5], [6]]. Now the people knows the plastic wastes have immense economic value, as result of this, recycling of waste plastics plays a major role in providing employment, resulting in economic development of the world [ [7], [8], [9], [10]].

Plastic waste is bulky, heavy and unsuitable for disposal by incineration or composting which result in polluting the environment, posing number of problems for the well being of human race and resulting in hazardous diseases [ [11], [12]]. The main aim of the study is to find out an environmental friendly way of disposing waste plastic by reusing principle and the waste plastic materials will be powdered and mixed with the concrete and used for fabrication of structural elements. Hence this study gives us environmental friendly plastic mixed concrete behavior. This study is great advantageous for the most populated countries like China and India. Other objective of this study is Comparison between normal cement concrete and Plastic mixed Cement Concrete test results, for the future construction purposes.

The type of cement used here as Ordinary Portland (53 grade) cement conforming to Indian Standard Specifications IS 12269:1987 [13]was used and its physical properties are given in Table 1.

Table 1. Physical Properties of Cement

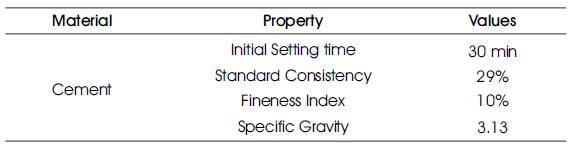

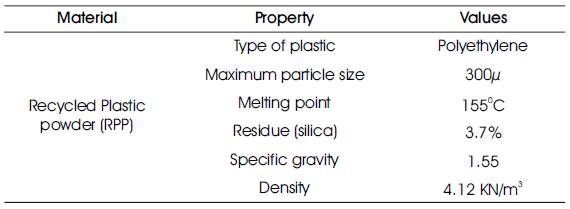

For this studies RPP of waste/ dumped polyethylene products were used. The details about this RPP given in Table 2. with analysis report of RPP sample given in Figure 1. Water absorption test on Plastic mixed concrete measured as: 6.49 % (compare to 6.49% of normal concrete).

Table 2. Details about Recycled Plastic Powder (RPP)

Figure 1. (Analysis Report of RPP sample) – TG/DTG & DTA plots

The average particle size of sample is 12 micrometer (determined by Fischer sub sieve analyzer) by sieve method all particles will goes through 300 micron. Thermogravimeteric (TG) analysis of sample shows a residue of 3.7% which is mainly silica. The balance is polymer (plastic) which decomposes completely below 500°C. The decomposition of plastic starts around 350°C with a peak temperature of decomposition at 460°C. Differential Thermal Analysis (DTA) of sample shows an endotherm at 155°C due the melting of the sample which is corresponding to the melting point of Low Density Polyethylene (LDPE). Another endotherm at 462°C corresponds to the decomposition of polymer.

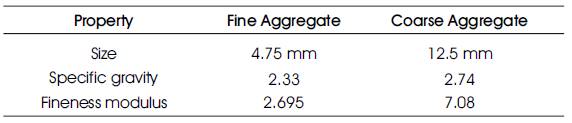

The Fine and Coarse aggregate were tested as per Indian Standard Specifications is IS 383-1970. [14] (Table 3).

Table 3. Physical Properties of Fine aggregate and Coarse aggregate

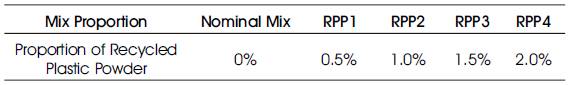

In this study, the normal concrete without adding RPP was designed as per Indian Standard Specifications IS : 10262-1982. [15] Then four levels of RPP (0.5%, 1%, 1.5%, 2%) added with normal concrete without any replacement of materials in normal concrete was investigated. The mixture proportion of normal concrete mix prepared by adding recycled plastic powder in various percentages is given in Table 4.

Table 4. The mixture proportion of normal concrete mix is prepared by adding recycled plastic powder in various percentages

As per the recommendations of IS 516-1959 [16] Standard dimensions of cubes 150 x 150 x 150 mm (6 nos) in each of the concrete casted with natural aggregates, recycled plastic powder.

Comparing with the normal concrete it was found that the compressive strength of RPP added concrete was high at both 7 days and 28 days irrespective of the percentage RPP added.

As per the recommendations of IS 516-1959 [16] Standard dimensions of cylinders of 150 mm dia x 300 mm height (6 nos) in each of the concrete casted with natural aggregates, recycled plastic powder.

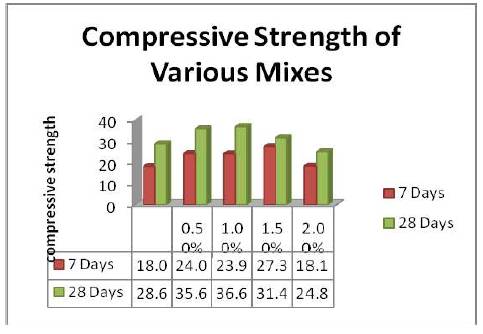

On comparing the tensile strength of RPP added concrete with normal concrete; it was found that the RPP added concrete was having a higher tensile strength of 0.5% at 7 days, and further more addition showed a decrease in tensile strength. At 28days the increase in tensile strength was up to 1.00% and after wards showed a decrease in tensile strength.

For this study casting of beam detail as given below.

Size of beam: 1.5 x 0.15 x 0.2 m (L x B x D) casted without RPP added (3 nos) and 1% RPP added mixed concrete beams (3 nos of RPPMC1 and 3 nos of RPPMC2 ) were casted and tested.

Grade of concrete used: M 20

Grade of steel used: Fe 415 HYSD bars

Beam Reinforcement details: 2 nos of 16 mm dia provided at top and 3 nos of 20 mm provided at bottom with stirrups of dia 10 mm spacing at 150 mm c/c.

Cover block provided as per IS 456-2000 (17): 20 mm

The beams casted were de moulded after 24hours and water curing was done up to 28days using gunny bags. The beams were tested on 14th and 28th day. The beams just before testing were whitewashed and the support position were measured and marked. The beam was lifted and placed on to the loading frame. 50 tonne proving ring was placed on the beam over the hydraulic jack and dial gauge is fitted to the bottom of beam to measure the deflection. After fixing all the equipments the load was applied to the beam in interval of 0.5T and corresponding deflection was measured at those intervals. The load was increased in an interval of 0.5T up to ultimate load. The load at which initial crack observed was noted. The cracks showed over the beams were marked by marker pens for enhancement.

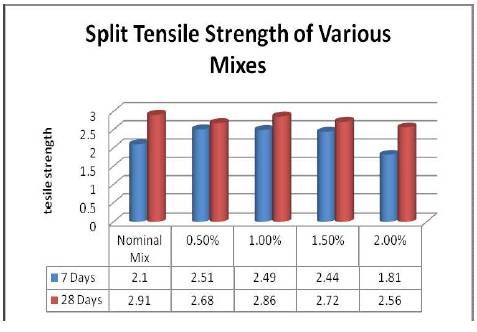

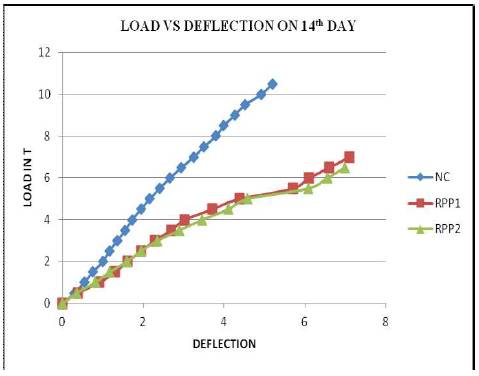

Flexural strength test was conducted to evaluate the strength development of concrete containing 1% of Recycled Plastic Powder (RPP) at the age of 14, 28 days respectively. Test results are reported in Table 5 load deflection reading for normal M20 beam & 1%RPP mixed RCC beam

The ultimate load of NC, RPP1,RPP2 respectively was 10.5T, 7T and 6.5T. Adding plastic to concrete has increased its ductility characteristics which are clearly seen in the above plot. The maximum deflection values were 5.2, 7.1 and 6.98 respectively for NC, RP1 and RP2 respectively. The initial crack in normal concrete was found at 5.5 T where as in RPP1, it was at 5 T load. At initial crack, RPP1 and RPP2 had almost the same deflection values. The design ultimate breaking load value is 6.9 T. It needs to highlight that within 14 days itself, RPP1 and RPP2 had obtained values (7T) more than the design strength.

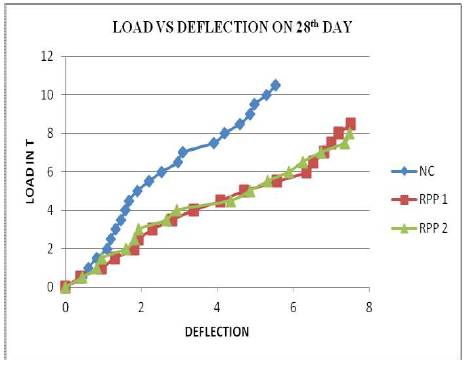

The ultimate load of NC, RPP1,RPP2 respectively was 10.5T, 8.5T and 8T. Adding plastic to concrete has increased its ductility characteristics which are clearly seen in the above plot. The maximum deflection values were 5.53, 7.51 and 7.49 respectively for NC, RPP1 and RPP2 respectively. The initial crack in normal concrete was found at 6 T where as in RPP1, it was at 5.5 T load. At initial crack, RPP1 and RPP2 had almost the same deflection values.

Figure 2(a). Sieving through 300 micron, 2(b). RPP before sieving, Figure 2( c). RPP after Sieving

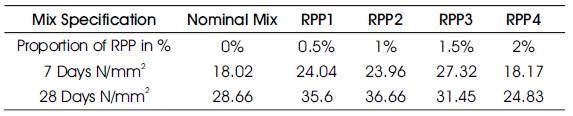

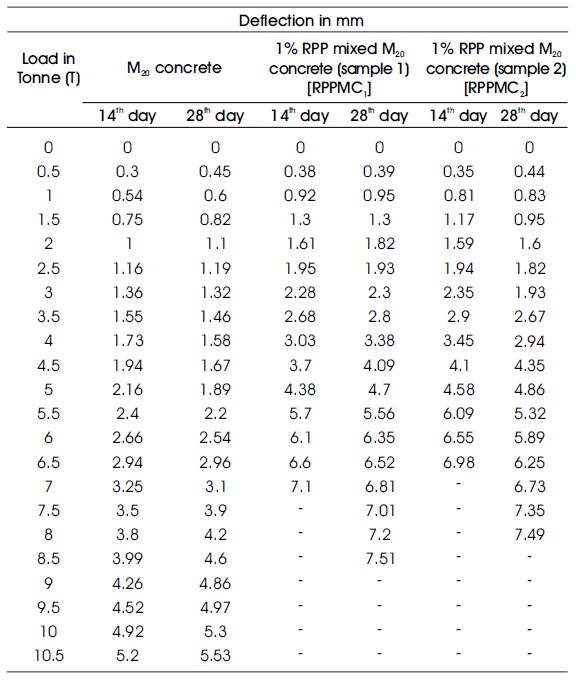

As per the recommendations of IS 516-1959 [16] Standard dimension of cubes 150 X 150 X 150mm (6 nos) in each of the concrete cast with natural aggregates recycled plastic powder. The samples are taken out at the end of 7 days and 28 days kept outside and wiped of surface moisture. Six numbers of samples in each of the concrete were subjected to compression test using the compression testing machine is shown in Figure 3. The result of the average strength of the cubes is reported in Table 5 and the comparison of compressive strength for conventional concrete and Recycled Plastic Powder Mixed Concrete (RPPMC) cube is shown in Figure 9.

Figure 3. Compression strength test for cubes

Table 5. Compression Strength Test results in N/mm2

Figure 4. Split Tensile strength of cylinders

It is found that the compressive strength on 28 days is to be increasing up to 1.00%; where as further more addition of RPP shows a decrease in trend in compressive strength. But the 14 days compressive strength shows an increasing trend up to 1.5% of RPP and a decrement afterwards.

Figure 5. Casting of Beam Details

Figure 6. Before and after testing of RCC beam on 14th day

Figure 7. RPP mixed RCC beam after failure on 14th day

Comparing with the Normal concrete it is found that the RPPMC is having a high compressive strength at both 7 days and 28days irrespective of the percentage of Recycled Plastic Powder (RPP) added.

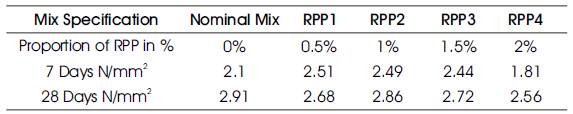

As per the recommendations of IS 516-1959 [16] Standard dimension of cylinders of 150mm dia 300mm height (6 nos) in each of the concrete cast with natural aggregates, Recycled Plastic Powder (RPP). The samples are taken out at the end of 7 days and 28 days kept outside and wiped of surface moisture. Six numbers of samples in each of the concrete were subjected to split tensile test using the compression testing machine is shown in Figure 4. The result of the average strength of the cylinders is reported in Table 6 and the comparison of compressive strength for conventional concrete and recycled plastic mixed concrete cube is shown in Figure 10.

Table 6. Split Tensile Strength Test results in N/mm2

Table 7. Load Deflection reading for normal M20 beam & 1%RPP mixed RCC beam

Figure 8. Normal and RPP mixed RCC beam after failure on 28th day

Figure 9. Comparison of compressive strength of concrete N/mm2 for various mixes

Figure 10. Comparison of tensile strength of concrete N/mm2 for various mixes

Figure 11. Load (T) Vs. Deflection (mm) on 14th day for both NC & RPP1, RPP2

At 7 days the tensile strength of 0.5% added RPPMC gives a higher value, and further more addition shows a decrease in tensile strength. At 28days the increase in tensile strength was up to 1.00% and after wards showed a decrease in tensile strength. At 7 days the tensile strength of RPPMC is found to be higher for RPP added concrete except for 2.00% comparing with Normal concrete. And for 28days the tensile strength of RPP added was lesser than Normal concrete for all values of RPPMC.

Figure 12. Load (T) Vs. Deflection (mm) on 28th day for both NC & RPP1, RPP2

RPPMC is less in weight, lesser voids and water proof when compared to normal concrete. It was having more compressive strength than normal concrete but lesser tensile strength. Hence it could be used in non-structural applications. Using RPPMC enables a safer way to dispose the waste plastic which paves the way to a green path to the future. Hence the study has successfully completed with a cloud with silver lining project of double benefit.

Based on the investigation carried out on RPP with normal concrete the following conclusions are arrived:

This Project is especially true of environmental structure projects which emphasis on development and innovation and must respond to increasingly rapid change in future and discusses various aspects of the project environment, and suggests ways in which it may be influenced in order to increase the probability of a successful outcome.

Hence this Project proves the Systematic and comprehensive review of the economic, environmental, financial, social, technical and other such aspects of this project is to determine if it will meet its objectives.

Large quantity of waste plastic could be disposed in an environmental friendly manner. Strength characteristics of column casted with both normal concrete mix and waste plastic added concrete mix and compared. Quantity of waste plastic that could be mixed with concrete without adversely affecting its physical characteristic can be found out. Various plots of results help easy calculation of waste plastic that could be disposed in a particular quantity of concrete to be used for a work.

Thus the sample is a fine powder (average particle size – 12micrometer) of low density polyethylene with a melting point of 155°C and contains about 3.7% silica.