Figure 1. Monthly Solar Irradiation Data for Site Location

Power is one of the key infrastructures for growth of industry and economy. Over the past two years, India's economy expanded at an average annual rate of 7.3% to 7.6%, placing it among the top five fastest growing nations in the world. To promote the grid connected solar power plant among the residential areas is focused now a days. Photovoltaic system simulation software is very significant to estimate the output from photovoltaic system. This paper introduces PVSyst software for sizing of grid connected photovoltaic system at Bharti Vidyapeeth Deemed University College of Engineering, Pune, Maharashtra, India.

This paper introduces the detailed system design (PV array and Inverter), and system output and system losses are studied using PVSyst software. Also, loss diagram of PV array and Inverter is obtained. By changing tilt angle, optimum output is achieved for the system. Plant of AC capacity of 100kW is simulated in the software and it was found that the optimal energy generation will be at 18° tilt angle, which can provide electricity to university throughout the year. Pitch is varied to get optimum output. Also simulations for various PV cell technologies are carried out.

Solar is one of the fastest growing and talked about energy generation technologies in globe. To increase the awareness of climate change, energy security needs, facilitation from Government, refuse in solar energy cost, and appearance of new and original business models are some of the major drivers which can be used for the growth and exploitation of solar energy (Yadav and Chandel, 2013). As an effect, the Government of India's goal of 1,00,000 MW from solar power is realistic and highly feasible. The 40,000 MW from roof top solar is a significant step to rapidly increase the solar sector (Phuangpornpitak and Tia, 2013). As the requirement of electricity is increasing, the trend for India's energy consumption out of non-conventional sources is found to increase with increased industrialization and civilization aspects of the society educational premises associated with having large roof top areas (Verzijlbergh et al., 2017). With enough roof space available, most customers are applicable to take advantage of a cheaper solar PV system through a Power Purchase Agreement (PPA) and enjoy the benefits of reduced energy bills and be protected against future energy price rises. In this paper, a solar PV system was designed with PVSyst software (Chandel et al., 2014). This will share knowledge on how to choose optimum tilt angle of the PV modules to have optimum energy generation using example of fixed tilt angle system (Karki et al., 2012). Also, pitch is decided to get maximum output according to space availability. Simulations for various PV cell technologies are carried out by Chandel et al. (2014).

PVSyst tool was developed by André Mermoud. This tool is used in the study, for sizing, and analyzing data of the complete PV system. It deals with grid-connected, stand-alone, and pumping PV systems. This software includes geographical as well as radiance level data, components database and a general solar energy tool. This software is preferred in almost all companies in the solar sector for designing and sizing of PV plant. This tool gives accurate results within short time. This software is supported by many meteorological database web applications such as SolarGIS, NASA and software, such as Meteonorm, from which meteorological data viz. global horizontal irradiance, diffuse horizontal irradiance, ambient temperature, and wind speed as input can be taken (PVsyst PhotoVoltaic System).

In this proposed system, solar resource inputs are the coordinates of the location. As per location coordinates, data is accessed from NASA website dealing with meteorological data. For Bharti Vidyapeeth's Deemed University, Pune, Latitude is 18.5°N and Longitude is 73.9°E. Wind velocity is not considered by this tool. The solar radiation data throughout a year at the proposed location is shown in Figure 1, which is used in the simulation (Padmavathi and Daniel, 2013; Verma and Singhal, 2015; Jaiswal et al., 2016).

PV plant for100 kW (AC capacity) is designed with 134 kWp DC capacity. Plant DC capacity is PV module capacity. Normally plant DC capacity is kept more than inverter capacity to accommodate losses in DC system.

From the available area and load profile, desired size of PV array can be defined. According to manufacturer, PV modules were selected based on the rating of module and type of module. In this analysis, Bharti Vidyapeeth's Deemed University, Pune, Maharashtra, India is used as the location to install the PV plant. PV module used for the analysis is silicon polycrystalline. For this site, the authors have considered Jinko Solar make polycrystalline module of model number JKM 320PP-72 which has 320 Wp as capacity at Standard Test Condition (STC). Total 420 numbers of modules are taken (14 in series and 30 in parallel) in the system (Chandel et al., 2014; Shalwala and Bleijs, 2009; Sharma and Chandel, 2013).

PV array generates DC voltage. Inverters are needed to convert DC power into standard AC power at the required distribution voltage level. Inverters are commonly used to string the inverters for such small-scale plants. The inverter operates on the nominal power, and the nominal power (Prom) of a inverter is defined as the output power i.e. the ratio of nominal power in AC to the efficiency of the inverter, the value is defined at STC and the value is usually of the order of 1.0 to 1.1.

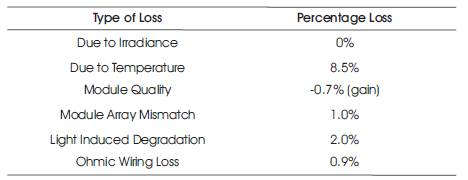

PVSyst offers a database of PV arrays based on power, technology, and manufacturer. The electrical parameters (maximum power point and temperature coefficient), efficiency and the fill factors are considered while selecting a PV array. The present system has an available area of 4312 m2 and the maximum capacity of the system is 100 kW. The maximum watt peak of a PV module is measured. Simulations were run for a 320 Wp module (readily available in market) at Standard Test Conditions (STC) and Nominal Operating Collector Temperature (NOTC) of 45 oC, free mounted modules with air circulation. The victims are the major concern while selecting a module and some victims of the preferred panel for the planned site are shown in Table 1.

Table 1. Detailed Losses

It is necessary to have optimum energy generation from the PV plant and solar inverter plays a major role in this system. Maximum Power Point Tracking (MPPT) is an efficient function of the solar inverter, which helps in achieving the maximum power output from the PV modules. In this study, 50 kW inverters are used, which have two quantity to arrive at AC capacity of 100 kW with the operating voltage of 200- 800 V. The frequency of the inverter is 50 Hz, and it has a maximum efficiency of 98.6%. The efficiency curve as a function of the output is shown in Figure 2.

After the selection and sizing of the inverter, the number of strings and number of modules in each string are designed. The sizing should be in such a way that the Pnom ratio (or the DC/AC ratio; PV array capacity to inverter capacity ratio) should be of the order 1 to 1.40 and the overload losses shall be minimized.

Therefore, number of modules are 420 to achieve 134 kWp array size and the number of modules in each string selected is 14, result of which is during operation of the plant, string voltage will remain in between the inverter Maximum Power Point Tracking (MPPT) voltage range. Subsequently, corresponding to it the number of strings vary with the number of modules in each string selected. The sizing is done in such a way that the planned output power is obtained.

Figure 3 represents the string voltage which lies in between inverter MPPT voltage range. The number of modules in each string is 14 and there are 30 similar strings. Since the inverter capacity is 50 kW, only 15 strings are connected to a single inverter and they form a subsystem; such two subsystems are interconnected for attaining the desired load (Sharma and Chandel, 2013).

The optimum PV array and inverter sizes for a grid connected PV system have been obtained for defined load.

The losses have been declined by special grouping of strings, modules, and inverter ability. The detailed losses have been explained in Figure 4. Energy generation in different stages of the system was shown in Figure 5. However, the energy injected into the grid for the first year was found to be about 222982 kWh. Figure 4 shows the loss diagram and effective energy at output of array, at input of inverter, at grid output (note: energy injected into the grid are not factored with the plant and grid availabilities, which to be factored separately as per the experience, and operation and maintenance contract).

In any power generation plant, the major and important issue is to improve the efficiency of the plant and get the energy out as maximum as possible. Thus, it is very important to orient the solar panels at optimum tilt angle and azimuth angle for any given location. Tilt angle is one of the important factor affecting the efficiency. For this PV design, azimuth angle was taken as 0° and tilt angle is varied (Karki et al., 2012).

Due to the motion of the earth around the sun, there are seasonal variations. In winter, the sun does not reach the same angle as in the summer. Ideally, solar panels should be placed horizontally in the summer more than winter. Therefore, the inclination angle is preferred less for summer than for winter operation. If one do not want to change the angle twice a year, the panels should be placed at a fixed optimum angle throughout the year, the value which lies somewhere between the optimum angle for summer and winter. Each latitude has its optimum angle of inclination of the panels.

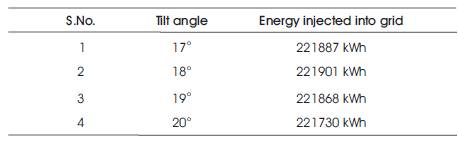

The default value of tilt angle is equal to the station's latitude. This normally maximizes annual energy production. Simulations for different tilt angles are done and value of energy injected into grid for respective angles . are obtained Table 2 shows the effect of tilt angle variation on energy injected into grid. From Table 2, it is observed that maximum output will get at tilt angle 18o (Sharma and Chandel, 2013; Kandasamy et al., 2013).

Table 2. Tilt Angle Variation and its Effect on Energy Generation

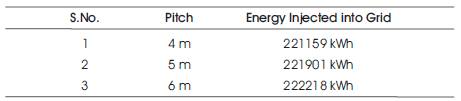

Not only tilt angle but also the distance between two arrays including module length is an important factor (Chandel et al., 2014). It is a bit of balance between getting energy from the sun in the morning and in the evening. Here tilt angle 18° is kept constant and the pitch is changed. Table 3 shows the variation in energy output with respect to pitch distance. Generally as the pitch increases, shading effect decreases and hence its output increases. But according to roof or land area availability, pitch to accommodate PV array must be decided in order to have required capacity of DC power (Chandel et al., 2014).

Table 3. Pitch Factor Variation and its Effect on Energy Generation

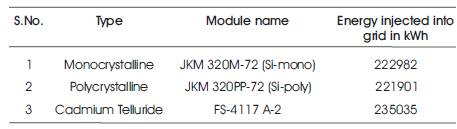

There are different types of thin film solar cells available depending upon the photovoltaic material deposited. The varieties of solar power technologies are available as per efficiency, price, durability and flexibility. Depending upon the need, the PV cell could be selected. Nowadays mainly used solar cells are silicon cells and cadmium telluride cells. Cadmium telluride PV is a simply lean film equipment with lesser costs than conventional solar cells prepared of crystalline silicon in multi-kilowatt systems (Ibrahim, 2011). Depending upon the PV module material and its type, there is variation in energy generation. Here three different types of modules are taken for simulations. The following parameters are constant for each simulation (Kumar and Nagarajan, 2016).

The simulation results are shown in Table 4.

Table 4. Different Types of Modules and Energy Generation

Maximum energy generation of 235036 kWh is obtained for Cadmium Telluride. It has low cost but its efficiency is lower than silicon cell. Hence for solar plants generally silicon monocrystalline module is selected. It has high efficiency as compared to silicon polycrystalline cell.

Different techniques are being developed by special organizations in scheduling and sizing the gridconnected PV systems. In this paper, optimal size of PV, inverter of a grid-connected PV system for proposed site in Pune, Maharashtra, India has been investigated by using PVSyst as a software tool. After simulations of different tilt angle values, the optimized output (221901 kWh) at 18° tilt angle is obtained. Hence at 18° tilt angle, performance ratio of PV plant is maximum. Then by keeping tilt angle constant at 18°, pitch is changed. As pitch is increased, energy output increases. According to roof availability, precisely suitable pitch is 5 m.

After the simulations are carried out for different materials of cells, it is observed that the energy injected to grid is greatest for cadmium telluride cell. But its efficiency is low. Hence by considering cost and efficiency, silicon monocrystalline cell have been selected for this plant.

To get optimum energy output, final design of the system would consider tilt angle as 18°, 5 m pitch and Silicon Monocrystalline PV cell. After simulations in PVSyst, loss diagram is generated. Final energy injected to grid is 222982 kWh.