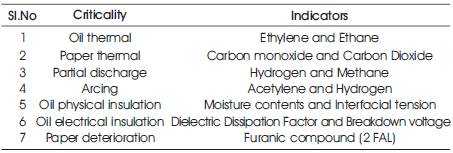

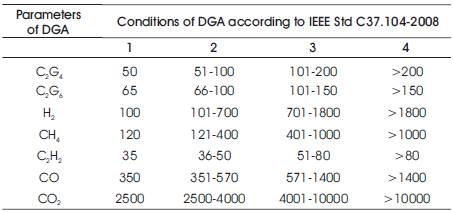

Table 1. Transformer various criticality indicators

Transformer failures in a power system very often lead to forced outages, blackouts and revenue losses. The power system can be run smoothly if the remnant life of the transformers is predicted accurately before such devices fail to perform. The remnant life estimation gives a flexible decision on replacement or relocation of power transformers. These devices are the connecting links between transmission and distribution end. The lifetime of the power transformer is mainly associated to the insulation system condition. In the present work experimental data obtained by conducting dissolve Gas Analysis, Moisture Content, Breakdown Voltage, Interfacial Tension, Furan Compounds and Dielectric Dissipation Factor or Tan Delta on the various power transformers of Himachal State Electricity Board has been utilized to develop the proposed remnant life estimation model. The proposed Fuzzy logic model utilizes the MATLAB graphical user interface tool to interpret the life expectancy of the power transformers very accurately.

Insulation oil in power transformers serves as a heat transfer medium and as an insulating liquid. The power transformers normally operate under aged conditions due to which oil moisture content increases, the dissolved aged products and particles are dispersed in the transformer oil, hence there is a need for systematic investigation of power transformer oil insulation property. A safe service is necessary by performing careful investigations of moisture contents and aging products of the transformer oil. The condition of the transformer oil reflects the healthiness of the transformer because all the energized and high temperature components are immersed in the oil. The dissolved oil components act as vital clue in the diagnosis analysis. It has been estimated that every year about 30 to 40 billion liters of insulating oil is used as a dielectric medium in transformers in the world [1] . Transformers which operate beyond their ratings experience an increase in winding temperature, overheating of oil and insulation, increase in leakage flux density causing additional eddy currents and heating in the core. Further there is an increase in moisture and gas content, insulation deterioration increases and dielectric strength decreases due to an increase in thermal stress. Consequently, improper maintenance leads to the failure of transformer before such devices reach their designed life. The failure rate of transformer in India has increased to three times generally because of poor maintenance. During the past ten years the average age of transformers due to insulation condition has been worked out to be 18- 20 years [1]. However, it is not economical to replace the transformers as these devices are very costly. Therefore, to enhance and prolong the working life of these devices, condition monitoring of these has become very essential in recent years. Important information is obtained from the dielectric response of power transformer as cellulose insulation and oil insulation degrades with age. With the rise in operating temperature and moisture content, it has been experienced that the transformers insulation degrades which affects the electrical and thermal properties of oil and paper insulation system.

To minimize the capital expenditure of electrical power system, it is important to operate the transformers at their design parameters limits. Transformer failures lead to huge revenue losses. Catastrophic failure generally leads to substantial costs in terms of the connected equipment destruction, environmental damages and unexpected loss of resources. Therefore, economic and expected life is essential for the existing aged transformer, thus, necessitating proper planning for their maintenance, relocation or retirement. Successful life management of power transformers helps in the financial benefits with an increased reliability and extension in life. Consequently, regular monitoring is very important in order to find the remnant life of the transformer [2]. To evaluate the immediate acceptability of the insulating system some important tests need to be conducted on transformer oil such as Dissolve Gas Analysis, Furanic Compounds, Dielectric Breakdown Voltage, Moisture Content, Interfacial Tension and Dielectric Dissipation Factor. These tests are performed in order to verify that there are no sudden changes in the transformer and to determine whether there is any possibility of moisture or other contaminants being present in the oil. If there are sudden changes in the transformer, then the reasons for such changes are to be carefully checked and assessed. According to as IEEE C57.91-1995 publications a power transformer life span is about 20 years [3]. At present, common belief is that an oil filled transformer is designed for a life expectancy of 30 to 40 years [3]. In India the average age of the transformer is currently expected to be 20-30 years [4].

Therefore, in the present work a Fuzzy logic model has been developed in MATLAB environment utilizing various indicators obtained by conducting different oil tests to determine very accurately the remnant life of the power transformers. This information is very useful from the utilities point of view. The rest of the paper has been organized as follows: Section 1 discusses the experimental details and the various test conducted on the transformer oil. Proposed Fuzzy logic model is discussed in section 2. Results and discussion are given in section 3 and finally conclusions are drawn.

The data used to develop the Fuzzy logic model for remnant life estimation have been obtained by conducting different experiments on the transformers oil. These tests are performed according to American Society for Testing and Materials standards [5] [6] . Table 1 shows different critical condition indicators which influence the remnant life of power transformers. Details of different tests conducted on transformer oil are given in the subsequent sub-section.

An oil sample of 250ml is taken during normal operation using a gas tight syringe. The DGA is performed according to ASTM D 3612 discussed in reference [5]. DGA is worldwide proven effective diagnostic method and performed on the transformer in a yearly basis. Analysis of the gases dissolved in transformer oil are Hydrogen, Methane, Ethane, Ethylene, Acetylene, CO, CO2, Oxygen, Nitrogen. Diagnosis and condition of the transformer is determined by first 7 gases. This test further recommends for testing and maintenance activities to be performed on the faulty transformers.

This test is performed according to ASTM D 1533 using Karl Fischer apparatus [6]. It is used to determine the humidity or moisture presence in the oil sample. Since the cellulose insulation used in power transformers is known for producing water when it degrades, water in oil indicates paper aging. The water content of oil can therefore be used for the determination of paper humidity [6]. The moisture migrates from the solid insulation into the liquid insulation when the transformer warms up and when the transformer cools the moisture returns to the solid insulation at a lower rate.

This test is performed according to ASTM D 971 by Pierre Du Noüy ring method using a tensiometer [6]. In this interfacial tension measurement the platinum ring is lifted through the water-oil interface. The oil hovers on the water surface due to the density difference in these two liquids. Water has a higher surface tension than the oil and therefore force is needed to detach the ring from the water surface. The measured force is used to calculate the interfacial tension (mN/m) between oil and water interface with a tensiometer, determining the tension between 0-100mN/m [6]. This is a non equilibrium method as it takes 30 sec to stabilize the interface and again 30 sec for movement of the ring.

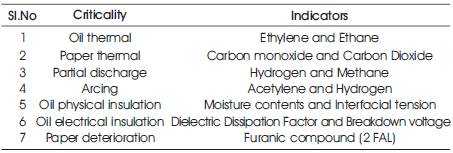

Table 1. Transformer various criticality indicators

ASTM D 924-08 standard is utilized to measure the loss tangent or dielectric dissipation factor of transformer oil. A high value of loss tangent indicates the presence of the contaminants which may be due to oxidation produced due to stresses or presence of soluble varnishes or resins [6]. The automatic dielectric constant tan delta ADTR-2K instrument is used to measure loss tangent. The dielectric power loss in the insulation of an alternating field is given by P = ωCV2 (tanδ); hence power loss is directly proportional to tanδ.

The dielectric breakdown voltage test is performed according to ASTM D-877 [6]. To conduct this test an oil sample is placed between two electrodes having 2.5mm gap with an air gap space of 40mm. A constant increasing voltage is then applied until the oil discharges at a certain kV. New oil should have a minimum dielectric strength of 35 kV. Lower values indicate damp or dirty oil. The breakdown voltage is measured by automatic test machine having output capacity of 0-100kV. The rate of rise of voltage is specified to 3kv/mm.

According to ASTM D-5837 the Furan analysis is performed using High Performance Liquid Chromatography (HPLC) [7][8]. HPLC determines the degradation of the solid insulation like paper, pressboard etc. Furan contents measurement consist of measuring five furfurals dissolved in transformer oil that differ in their stability. The furanic compounds are composed of 5-hydroxymethyl-2-furfural (5H2F), 2-furfuryl alcohol or furfurol (2FOL), 2-furfural or 2- furfuraldehyde or 2-furaldehyde (2FAL), 5-methyl-2- furfural (5M2F) and 2-acetyl furan (2ACF). 2-furaldehyde is the most stable compound for measurement; [7][8]. however, all other furan compounds, except 2-furfuryl alcohol, are detected in insulating oil up to 14000 C.

Fuzzy logic based model has been developed to estimate precisely the remnant life of power transformers. Different inputs required in the proposed fuzzy model are obtained from the different tests as discussed in section 1 of the paper. Various inputs are dissolved gases of transformer oil viz. ethylene, ethane, hydrogen, methane, acetylene, carbon dioxide and carbon monoxide. This data has been obtained from the DGA test on the oil. Further these gases are helpful to find the total criticality of transformer oil. Other inputs required are furanic compounds to find the critical condition of insulation level of the paper. Further, moisture content and IFT provide the critical condition of oil physical property. Break down voltage and dissipation factor or tan δ provides the critical condition of oil electrical property. All the above inputs are systematically interrelated in the proposed Fuzzy model to determine the exact remaining life of the transformers [9]. Figure 1 shows the proposed Fuzzy model developed in MATLAB for estimating the remnant transformer life.

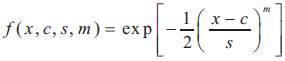

The proposed model is very helpful to understand the transformers reliability, maintainability and availability. The method shall prove to be very effective to identify power transformers criticality, rate of ageing and remnant life. Each input used in the model has been Fuzzified into five sets of Gaussian combination membership function (MF) governed by the equation (1), according to reference [3].

where,

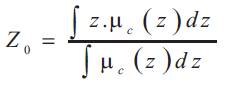

c is centre, s is width and m is Fuzzification factor. The function set developed for each input is a combination of s and c parameters. Result of fuzzification from each input is applied to Fuzzy operator in the antecedent and related to the consequence, by IF-AND-THEN application method (3). Defuzzification is done by centre of gravity which is widely used in fuzzy models method to calculate the desired output Z0 using equation (2).

where,

µc(z) is the membership function of the output. Dissolve gas analysis provides seven gases viz. ethylene, ethane, hydrogen, methane, acetylene, carbon monoxide, carbon dioxide. These gases help to find the total DGA critical condition.

Remnant life estimation model of power transformer is based on three important parameters viz. total DGA critical condition, oil physical and electrical critical condition and furanic compound critical condition.

Fifteen power transformer oil samples of Himachal State Electrical Board India and three power transformer oil results of Doble client conference [10]. are taken for study and data collection in the present work. These transformers are different manufacturing companies' viz. General Electric Company, Crompton Greaves and Computing Tabulating Recording (CTR) having different installation year but of same MVA rating i.e. 25 MVA. KV rating of each is 132/33KV. These transformers are tested for DGA, moisture contents, Interfacial tension, dielectric dissipation factor, breakdown voltage and furanic compounds. All tests are done according to their ASTM Standards. The DGA standard test values according to IEEE Std C37.104-2008 [5][11]. are given in Table 2. Corresponding DGA test results, oil insulation test results and estimated remnant life of power transformers as obtained from the proposed model are presented in Table 3.

Table 2. DGA standard values

where, 1,2, 3 and 4 (row 2) indicate as follow,

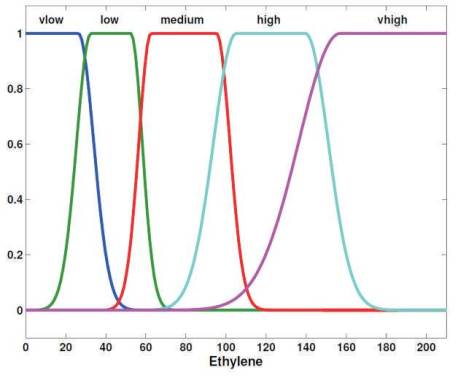

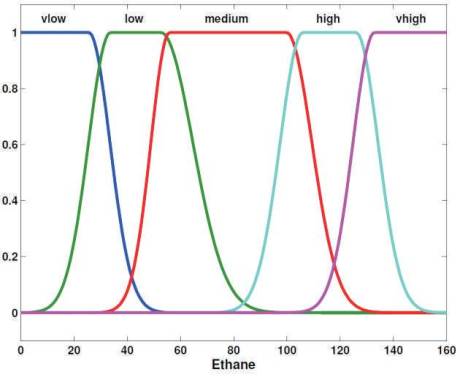

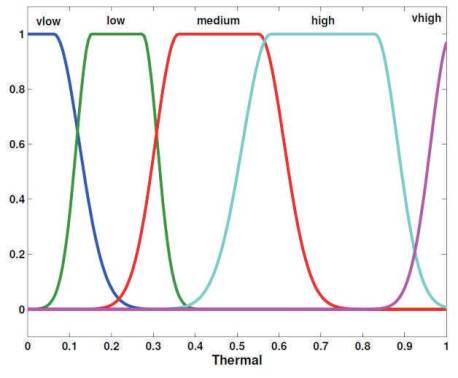

The input membership functions plot for ethylene and ethane used in Figure 1 has been used as an input to find the thermal critical condition of the power transformers oil. This is shown in Figure 2 and Figure 3 respectively. The output membership function plot of oil thermal critical condition is shown in Figure 4. All the membership functions are fuzzified as very low, low, medium, high, very high. Figure 5 shows the rules developed for the ethylene and ethane fuzzy model to find the thermal critical condition of the transformer oil. The corresponding three dimensional graphs between ethylene, ethane and oil thermal critical condition is shown in Figure 6. The graph shows that as the value of ethylene and ethane increase from zero to their maximum value the thermal critical condition of transformer oil also increases from 0 to 1.

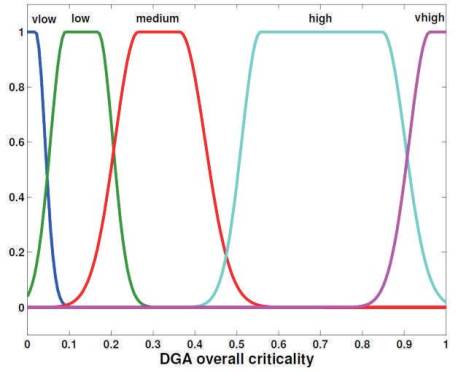

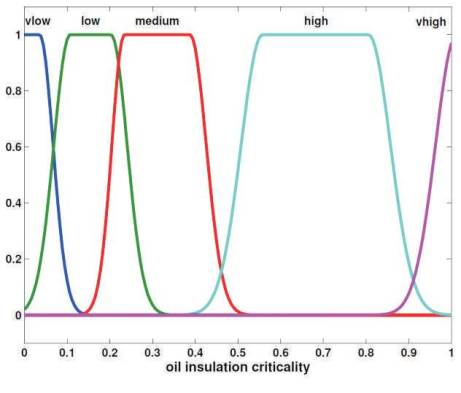

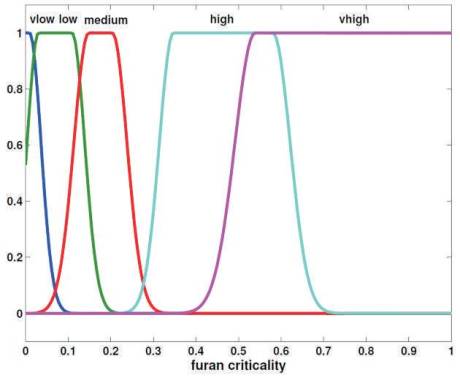

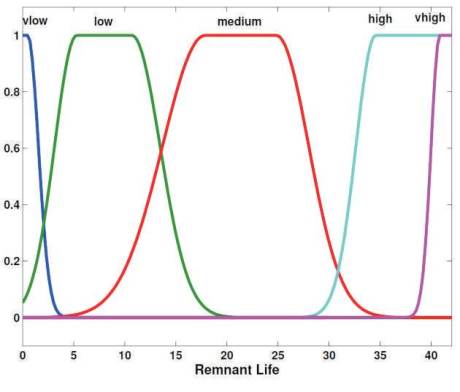

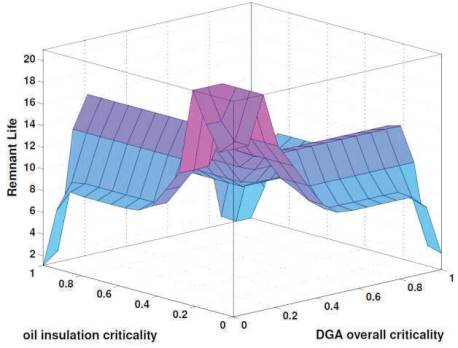

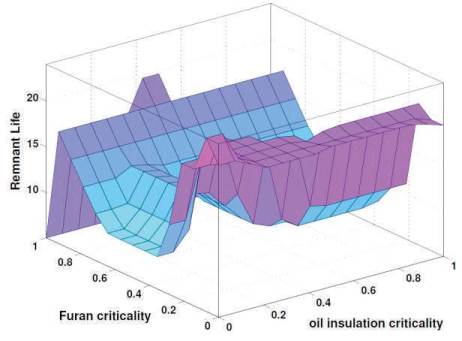

Figures 7, 8 and 9 show the input membership function plots of DGA overall critical condition, oil thermal critical condition and Furan critical condition respectively to estimate the remnant life of power transformers. Figure 10 shows the output membership function plot for estimated remnant life. For this case the membership functions are classified as very low, low, medium, high and very high. Total 30 rules are developed to find the estimated remnant life of the power transformer which are shown in Figure 12. In Figures 11 and 13 three dimensional graph between DGA critical condition, oil insulation critical condition, Furanic critical condition and remnant life of power transformers are given. All three dimensional graphs show that as the DGA insulation critical condition, oil insulation critical condition and furanic critical condition increase, the remnant life of power transformers decreases.

From the model given in Figure 1, it is found that the transformer at serial number three in Table 3 has an expected life of 36.4 years, which is quite good. Transformers at serial number 12, 17 and 18 in Table 3 do not require any filtrations as their estimated remnant life are 33.75, 28.74 and 29.9 years respectively. Oil in these transformers does not require any filtrations because the DGA results, oil insulation test results and furanic compounds are well within their limits.

Figure 2. Input Membership function plot for ethylene

Figure 3. Input Membership function plot for ethane

Figure 4. Output Membership function plot for thermal critical condition of transformer oil

Figure 7. Input 1 Membership function plot for DGA overall criticality

For the transformers at serial number 1, 5 and 9 the remnant life is expected to be 8.68, 7.82 and 10.5 years. In these transformers oil must be treated and reclaimed immediately because of the high value of DGA gases, moisture content, DDF and low value of BDV & IFT.

For transformers at serial number 2, 6, 7, 8, 13 and 15 the life is expected to be 20.8, 19.7, 23.8, 16.1, 18.4 and 16.3 years. In all these transformers oil must be treated for double filtering and degassing. Results show a high value of DGA gases, moisture content, DDF and low value of BDV and IFT. Thus the remnant life of these transformers is expected to be medium.

Figure 8. Input 2 Membership function plot for total oil Insulation criticality

Figure 9. Input 3 Membership function plot for Furanic criticality

Figure 10. Output Membership function plot for transformer Remnant life estimation

Figure 11. 3D Graph between DGA overall critical condition, Oil Insulation critical condition and Remnant Life

Figure 13. 3D Graph between Oil Insulation critical condition, Furan critical condition and Remnant Life

For the transformer numbered four the remnant life is found to be 1.61 years. The DGA results show that all the gases have crossed their limits and the moisture content, DDF and Furan value have increased to their higher limits. The BDV and IFT values have deceased to their lower limits. The transformer oil must be immediately removed and not be used.

It is suggested that the oil samples of transformers at serial number 10, 11, 14 and 16 must be treated for single filtering and degassing as the estimated remnant life are 24.6, 22.8, 22.1 and 25.52 years respectively.

This paper presents fuzzy logic technique to estimate the remaining life of power transformers. When the residual life of the transformer is determined precisely, it can then be extended by taking suitable remedial actions. Failure chances of the transformers can be simultaneously reduced by proper maintenance and condition monitoring. The model developed provides an approach to estimate the residual life of the transformer before it gets into any critical conditions. It also plays an important role in diagnostics area of transformers without any need to hire experts for the interpretations of results.

The authors are thankful to the Technology Information Forecasting and Assessment Council and Centre of Relevance & Excellence (TIFAC-CORE) at NIT Hamirpur for providing the necessary facilities to perform the research work. Authors are also thankful to the Himachal Pradesh Electricity Board (HPSEB), India for providing the transformer oil samples for conducting the necessary experiments.