Table 1. Chemical Composition of Aluminium Alloy Al7068 in Weight Percentage

Aluminium and its alloys have high strength to weight ratio and are used for variety of applications like automobile industries, aerospace and structural applications, electronic circuits, etc. The manufacturing industry has witnessed significant increase in the use of aluminium alloys due to their unique characteristics of good strength and light weight. Other important properties of aluminium alloys include high thermal and electrical conductivity, good corrosion resistance, low melting point, excellent formability, etc. The present work deals with optimization of process parameters for turning of aluminium alloy Al7068 by varying the composition of Zinc in the alloy. There are different methods for process parameter optimization like Taguchi technique, ANOVA method, fuzzy logic, Response Surface Methodology, etc., but Taguchi technique and ANOVA method are widely used. Taguchi method helps to determine optimal condition with lesser number of experiments. ANOVA approach gives which process parameters have a significant influence on the machining response/outputs. Turning experiments were conducted on a ULTRA LYNX CNC machine. The coolant Ipol Aqua cut 125 has been used for turning operation. Taguchi’s L16 Orthogonal Array has been used to conduct turning experiments on the aluminium Al7068 alloy with varying Zn% composition to get the optimized values of the turning parameters. The turning parameters selected were feed, speed, depth of cut, tool nose radius and material composition which were varied in 4 levels. ANOVA (Analysis of Variance) has been performed to validate the results. The percentage contribution of the turning process parameters on machining outputs such as surface roughness, material removal rate, machining time, machining force and machining power has been determined. ANOVA results indicate that material composition has the highest contribution on surface roughness, material removal rate, machining time, machining force and machining power.

Aluminium alloys due to their light weight, attractive mechanical and thermal properties are used in most of modern day applications. Machinability of aluminium alloys quantifies the machining performance and is defined by various criteria like surface finish, material removal rate, machine tool power consumption, etc. (Songmene et al., 2011). Turning is an important machining process in production engineering that is used to produce rotational parts by removing unwanted material. A good quality turning surface leads to improvement in properties like corrosion resistance, fatigue strength and thermal resistance. Proper selection of process parameters is important during machining. Improper selection of process parameters causes the machine not to run under optimal condition which further leads to poor surface quality, decrease in tool life, higher time consumption during machining etc. To understand machining, it is essential to be familiar with the chip formation process, very well discussed by Trent and Wright (2000) in their masterpiece Metal Cutting Principles. CNC turning provides better improvement of productivity, is a fully automated operation used to produce good quality parts. It has proved to be a versatile and useful machining operation in most of the modern manufacturing industries. Pure aluminium melts at a temperature of 650 °C, whereas aluminium alloys do not melt at a fixed temperature but over a range of temperatures which depends on the chemical composition. Because of their complex metallurgical structure, their machining characteristics are superior to those of pure aluminium. Alloys containing more than 10% Si are the most difficult to machine because hard particles of free silicon cause rapid wear.

Wang and Lan (2008) considered four parameters, feed, speed, depth of cut and tool nose radius for optimizing three responses such as surface roughness, tool wear and material removal rate (MRR) in precision turning on an ECOCA-3807 CNC lathe by using Orthogonal array of Taguchi paired with the Grey Relational Analysis (GRA). The results of the investigation showed improvement in the surface roughness and tool wear ratio with minor decrease on the Metal Removal Rate (MRR).

Xiao et al. (2017) investigated the influence of feed, speed, depth of cut on surface finish by ANOVA and regression model. They determined that speed has the highest influence on surface roughness compared to depth of cut and speed.

Mia and Dhar (2017) analyzed surface roughness in turning of steel and determined that the most important factor affecting surface roughness had been material hardness. Increase in the cutting speed resulted in good surface finish with high pressure coolant condition.

Rao et al. (2013) investigated the influence of cutting parameters on cutting forces and surface roughness and determined that feed rate had a significant influence on cutting force and surface roughness.

Varadarajan et al. (2002) reported the overall performance of the cutting tools during minimal cutting fluid application and found it to be superior to that of dry turning and conventional wet turning.

Murthy et al. (2013) have studied the effect of various cutting parameters on the surface finish of Al 6061 aluminium alloy. Turning experiments were conducted based on L16 orthogonal array on Al6061 T6 using CNC LT- 16 turner with carbide tipped tool. The cutting parameters selected were feed, spindle speed, depth of cut and tool nose radius. ANOVA and the regression equation were used to validate the results obtained for predicting the surface roughness. They found that the feed is the most significant in influencing the surface roughness.

Das et al. (2013) have studied surface roughness for turning operation using CNC lathe. Cutting speed, feed rate, depth of cut were the process parameters used in the experiment. They concluded that feed rate is the significant parameter influencing the surface finish of the machined surface.

Prabhakar et al. (2014) have studied the influence of machining parameters on surface roughness and material removal rate. The experiments have been conducted on Aluminium alloy Al6253 using CNC turner with carbide tip tool and experimental results were analyzed by using ANOVA and the regression equation for predicting the surface roughness and MRR. The ANOVA and ANN results revealed that feed rate and depth of cut are the most significant influencing factors on the material removal rate and surface finish.

Sahin (2009) compared the tool life of Cubic Boron Nitride (CBN) and eeramic inserts in turning hard steel using Taguchi method. Cutting speed, feed rate and tool hardness were selected as cutting parameters and their effect on tool life using orthogonal array, signal to noise ratio and variance analysis has been determined.

Yang et al. (2017) investigated the processing factors in turning and created a predictor for surface roughness using Design of Experiments. Their results from the experiments revealed that feed has been the most dominant factor influencing surface roughness.

Tzeng et al. (2009) have studied the effect of cutting parameters on average roughness, maximum roughness and roundness while turning SKD11 tool steel via grey relational analysis. The results indicates depth of cut to be the most influential factor on the average roughness and cutting speed as the most influential factor on maximum roughness and the roundness.

Lima et al. (2005) observed that the surface finish of the machined part improved as cutting speed has been elevated and deteriorated with feed rate. Depth of cut had little effect on the Ra values. Best surface finish has been produced by cutting with larger nose radius (PCBN).

Aneiro et al. (2008) reported surface roughness values obtained in turning with coated carbide are similar to those obtained by normal grinding. It has been observed that the most significant parameter affecting surface roughness is feed rate.

The aluminium alloy Al7068 has been cast using the basic compositions and the effect of variation in composition of one of the major alloying elements Zn in the alloy on optimization of turning parameters were studied. The general composition of Al7068 is shown in Table 1. The Zinc composition in the alloy Al7068 varies between 7.3-8.3% as shown in Table 1.

In the present work, the composition of Zn, one of the major elements in the alloy is varied.

Turning of Aluminium alloy Al7068 has been carried out on ULTRA LYNX CNC machine shown in Figure 1. The coolant used for turning operation is Ipol Aqua cut 125. TNMG inserts with 0.4 and 0.8 mm tool nose radii were used.

Figure 1. ULTRA LYNX CNC used for Turning of Aluminium Alloy Al7068

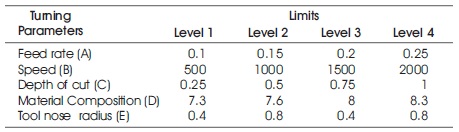

Table 2 shows the turning parameters selected and the levels they are varied during turning of aluminium alloy Al7068 with varying Zn composition.

Table 2. Assignment of Levels for Turning of Al7068 with Zn% Variation

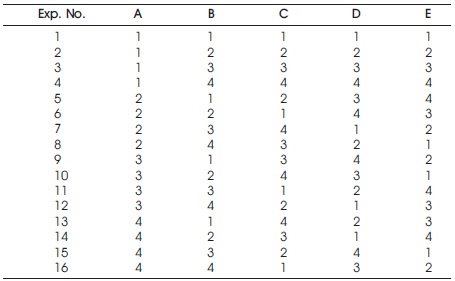

The turning experiments were conducted based on L16 orthogonal array as shown in Table 3. The turning parameters selected were feed rate, speed, depth of cut, material composition and tool nose radius. The machining responses measured/calculated were surface roughness, material removal rate, machining time, machining force and machining power.

Table 3. Taguchi L16 Orthogonal Array with Five Parameters and Four Levels

The surface roughness has been measured by a portable surface roughness tester, Mitotoyo SJ-201P. Three measurements of surface roughness at different points on the work piece were carried out and the average value of 'R ' recorded. The machining time has been measured a using a stop watch. Machining force has been measured using lathe tool dynamometer.

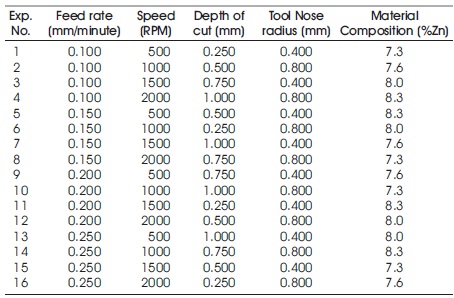

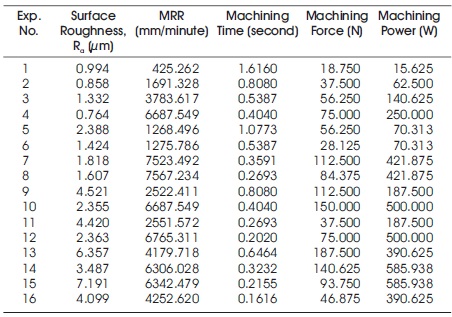

Table 4 gives the design of experiments using Taguchi L16 orthogonal array for turning of Al7068 with Zn% variation. Table 5 gives the results for turning of Al7068 with Zn% variation.

Table 4. Design of Experiments using Taguchi L16 Orthogonal Array for Turning of Al7068 with Zn %wt Variation

Table 5. Results for Turning of Al7068 with Zn% Variation under L16 Orthogonal Array

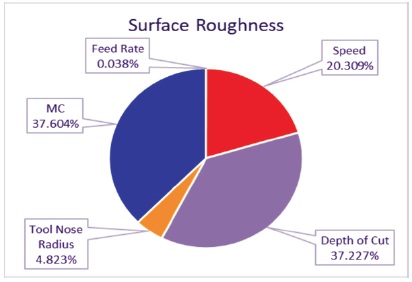

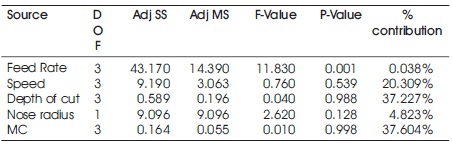

Figure 2 shows the graphical representation of % contribution of turning parameters on surface roughness of the results obtained in Table 6. ANOVA results indicate that material composition has the highest contribution on surface roughness in turning of aluminium alloy Al7068 with varying Zn% followed by depth of cut, speed, tool nose radius and feed rate respectively.

Figure 2. Contribution Chart for Effect of Turning Parameters on Surface Roughness During Turning of Al7068 with Zn% Variation under L16 Orthogonal Array

Table 6. ANOVA Table for Effect of Turning Parameters on Surface Roughness During Turning of Al7068 with Zn% Variation under L16 Orthogonal Array

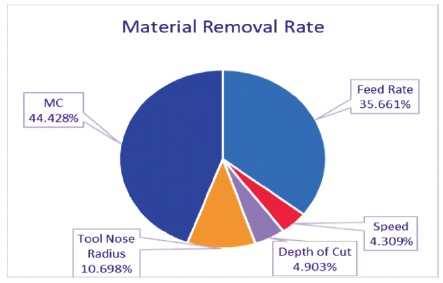

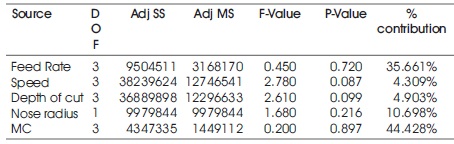

Figure 3 shows the graphical representation of % contribution of turning parameters on material removal rate of the results obtained in Table 7. It can be seen that material composition (MC), has the highest contribution on material removal rate in turning of aluminium alloy Al7068 with varying Zn% followed by feed rate, tool nose radius, depth of cut and speed respectively.

Figure 3. Contribution Chart for Effect of Turning Parameters on Material Removal Rate During Turning of Al7068 with Zn% Variation under L16 Orthogonal Array

Table 7. ANOVA Table for Effect of Turning Parameters on Material Removal Rate during Turning of Al7068 with Zn% Variation under L16 Orthogonal Array

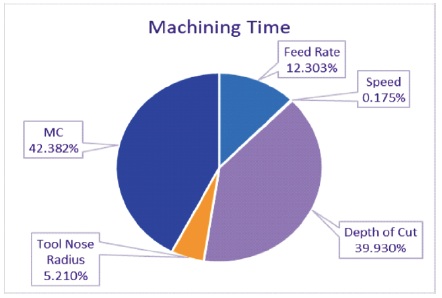

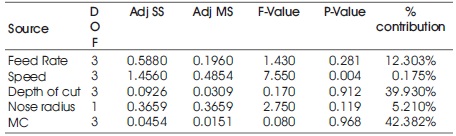

Figure 4 shows the graphical representation of % contribution of turning parameters on machining time of the results obtained in Table 8. It can be seen that material composition (MC), has the highest contribution on machining time in turning of aluminium alloy Al7068 with varying Zn% followed by depth of cut, feed rate, tool nose radius and speed respectively.

Figure 4. Contribution Chart for Effect of Turning Parameters on Machining Time During Turning of Al7068 with Zn% Variation under L16 Orthogonal Array

Table 8. ANOVA Table for Effect of Turning Parameters on Machining Time During Turning of Al7068 With Zn% Variation under L16 Orthogonal Array

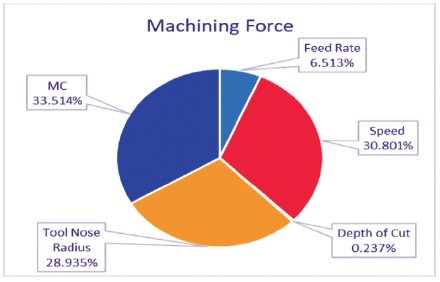

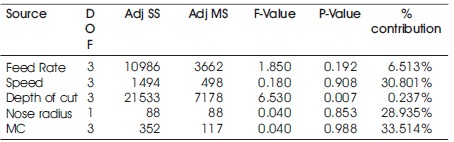

Figure 5 shows the graphical representation of % contribution of turning parameters on machining force of the results obtained in Table 9. It can be seen that material composition (MC), has the highest contribution on machining force in turning of aluminium alloy Al7068 with varying Zn% followed by speed, tool nose radius, feed rate and depth of cut respectively.

Figure 5. Contribution Chart for Effect of Turning Parameters on Machining Force During Turning of Al7068 with Zn% Variation under L16 Orthogonal Array

Table 9. ANOVA Table for Effect of Turning Parameters on Machining Force During Turning of Al7068 with Zn% Variation under L16 Orthogonal Array

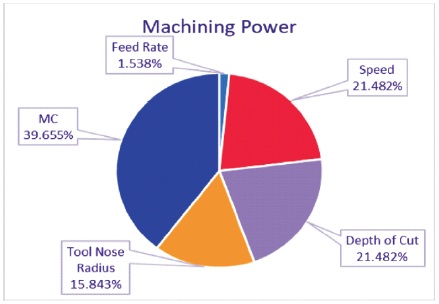

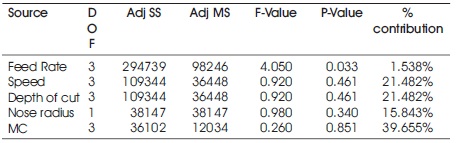

Figure 6 shows the graphical representation of the % contribution of turning parameters on machining power of the results obtained in Table 10. It can be seen that material composition (MC), has the highest contribution on machining power in turning of aluminium alloy Al7068 with varying Zn% followed by depth of cut and speed, tool nose radius, feed rate respectively.

Figure 6. Contribution Chart for Effect of Turning Parameters on Machining Power During Turning of Al7068 with Zn% Variation under L16 Orthogonal Array

Table 10. ANOVA Table for Effect of Turning Parameters on Machining Power During Turning of Al7068 with Zn% Variation under L16 Orthogonal Array

The present work deals with the optimization of turning process parameters such as feed, speed, depth of cut, tool nose radius and material composition using Taguchi method by varying Zn composition in the alloy Al7068. Turning experiments were conducted by using Taguchi's L16 orthogonal array to get the optimized values of turning parameters. To determine the percentage influence of turning parameters on the machining outputs such as surface roughness, material removal rate, machining time, etc., ANOVA has been used. The following conclusions can be drawn from the results obtained.