Figure 1. Exfoliated Vermiculite

Concrete is mostly used as a building material and while preparing concrete mix the natural resources are being used extensively. Due to large-scale construction being taken up, a steady sand mining is taking place at an alarming rate. To overcome the problem Vermiculite aggregate is partially used as a replacement to sand. Exfoliated Vermiculite (EV) can be effectively utilized in a silica-based material in building industry. In this present study, an attempt has been made to study the mechanical properties of EV cement mortar with different percentages of i.e. 5%, 10%, and 15% of Micro Silica and Ultrafine Fly Ash mineral admixtures as partial replacements of cement, and EV at 20%, 40%, 60%, and 80% by weight as partial replacement of fine aggregate. It has been observed that the required compressive and flexural strength of mortar are achieved when 10% Micro Silica and 5% Ultrafine Fly Ash are used as partial replacement by weight of cement and 20% EV is used as a partial replacement by weight of fine aggregate.

The lightweight concrete can be defined as a type of concrete, which includes an expanding agent when added it increases the volume of the mixture and giving additional qualities such as nail ability and lessened dead weight. The main advantages of lightweight concrete are its lower density and thermal conductivity due to which there is a reduction in dead load, faster building rates in construction and lower haulage and handling costs.

Structural lightweight concrete usually manufactured by using artificial lightweight aggregates such as expanded clay, shale and slate. However, rapidly increasing fuel prices in recent decades and a corresponding increase in the production costs of these aggregates have renewed the interest in natural lightweight aggregates such as Pumice, Scoria, Rhyolite, Perlite and Vermiculite.

The use of lightweight concrete started from more than two thousand years ago in the Roman Empire. The most known structures built using lightweight concrete during that time were the Port of Cosa, the Pantheon Dome and the Coliseum (ACI 213R-03, 2003). The Port of Cosa was built on the west coast of Italy, in 273 BC. The designers of the port used natural lightweight aggregates (Pumice and Scoria) from the volcanic resources located at 40 km away instead of using locally available aggregates such as beach sand and gravel for the construction. The harbour consists of four piers, which had resisted the forces of nature except for the surface abrasion for almost two thousand years and it is now abandoned due to siltation. Today, the applications of lightweight structural concrete extended not only to high-rise buildings but also to bridges and marine structures. Stolmen Bridge and Heidrun Tension Leg Platform are significant examples of recent applications. However, few studies are available with a focus on natural lightweight aggregates and even less with a focus on natural vermiculite aggregate.

Shideler (1957) conducted tests to study the mechanical properties of lightweight-aggregate concrete for structural quality. The author used eight Light Weight Aggregate (LWA) and one Normal Weight Aggregate (NWA) concrete of plain, conventionally reinforced, and pre-stressed concrete beams and specimens for the study. The author compared the results based on equal compressive strengths; normal weight concrete showed superior performance. However, the advantages resulting from the reduced unit weight of the LWA concretes can't be ignored. Walker (1961) conducted a study on the increase in the volume of commercial grade product is 8–12 times better than that of the unprocessed crude material, thereby producing a highly porous lightweight material. Reichard (1971) has conducted various tests on vermiculite concrete to determine elastic properties, drying shrinkage, thermally induced movements and behaviour of reinforced insulating concrete slabs under short and long-term loads. The moisture content of a test specimen at the time of test greatly affected the measured compressive strength and also the length of curing time. The water absorption is inversely proportional to the dry density of lightweight concretes and concluded that the coefficient of thermal expansion LWC is almost the same for the values reported by earlier authors. Litvan (1985) investigated the use of Particulate Admixtures for Enhanced Freeze-Thaw Resistance of Concrete to assess the performance of Vermiculite, Perlite, and Pumice in protecting cement paste, mortar, and concrete from damage due to freezing and thawing. For this purpose, mortar bars were cast and cured in fog room. The prisms were tested for shrinkage and frost resistance and found that the mortar specimens made of cement, mortar, and concrete protected with any of the particulate admixtures showed higher resistance to freezing and thawing. Novokshchenov and Whitcomb (1990) experimented with Expanded Siliceous aggregates to obtain a High Strength Concrete. For a HSC general tendency is to use strong coarse aggregates. When a strong mortar mixes are created in the range of 60 to 90 MPa the contribution of a lightweight aggregate towards the strength of LWAC becomes less critical. For this reason, to obtain concrete with a high strength-to-weight ratio, it may be more advantageous to employ lighter and subsequently weaker aggregates than stronger but heavier varieties. The authors concluded that structural properties of Egg Shells Ash (ESA) concretes are comparable to those of traditional LWAC, while the strength-to-unit weight ratio is higher. Demirboğa and Gül (2003) have studied the effects of expanded Perlite aggregate, silica fume and fly ash on the thermal conductivity of lightweight concrete as a replacement to cement. They observed a decrease in thermal conductivity with the increase of silica fume and fly ash as replacement of cement. Al-Jabri, Hago, Al- Nuaimi, & Al-Saidy (2005) reviewed the current systems used in construction to produce masonry walls with high thermal insulation properties by using indigenous and by-product materials. The authors prepared thirteen mixes with different proportions of leca, polystyrene foam and vermiculite and cast concrete block specimens with 100 mm and variable thickness for measuring the thermal conductivity. A casting-steel box was used for measuring the thermal properties, which were insulated from inside by thermo-bricks. A heating coil was connected inside the box in front of the test specimen and was connected with an electric current source and a switch. Two thermocouples were connected on two parallel faces of the concrete test block. The test specimen was exposed to a given high temperature at one face, while the temperature at the other face was recorded at different times and reported that the percentage of heat transmission for the mixes prepared with vermiculite was 12.9%, which reflects the superiority of aerated concrete in resisting high temperature. Folorunso, Dodds, Dimitrakis, and Kingman (2012) studied the morphology of the vermiculite samples using Scanning Electron Microscopy (SEM), and the changes in vermiculite structures using X-ray Diffraction (XRD) analysis. Sancak, Sari, and Simsek (2008) have investigated lightweight structural concrete produced by Pumice and concrete with normal lightweight aggregate. After exposure to high temperatures, the compressive strength and weight loss of the concrete was observed. They replaced the Portland cement by silica fume in different ratios and added superplasticizer. The authors observed the rate of deterioration was higher in ordinary concrete when compared to lightweight concrete. Silva, Ribeiro, Labrincha, and Ferreira (2010) investigated the effects of vermiculite and perlite on the properties of cement mortar with a typical ratio of 1:1:6. The designed mortar can be used for indoor and outdoor purposes, and it was evaluated for the fresh and hardened product characteristics. It was observed that porosity plays a major role not only over the mechanical properties but also on all other important characteristics such as water absorption. The authors reported that open porosity and capillarity and all other properties depend upon the content and the nature of the lightweight filler. Schackow, Effting, Folgueras, Güths, and Mendes (2014) compared the mechanical and thermal properties of LWA concretes using vermiculite, Expanded Polystyrene (EPS) at (55% and 65%) along with air-entraining agent at (0.5% and 1.0%) and a small dosage of superplasticizer. The authors concluded that the addition of the air-entraining agent made the LWC lighter and weak. EPS lightweight concrete has a higher strength and is lighter than the vermiculite. Vermiculite concrete had lower thermal conductivity than with EPS. The best aggregate content was 55% of the total aggregate. Koksal, Gencel, and Kaya (2015) studied the properties of cement mortars admixed with 4, 6, and 8 Exfoliated vermiculite/ cement ratio (V/C) by volume and 0-15% silica fume at ambient and elevated temperatures. Tests such as physical, mechanical, thermal and microstructure properties of mortars are conducted. In total, 114 mortar bars were cast and o subjected to 300, 600, and 900 C for 6 hours. It was observed that the presence of silica fume increased both strength and durability at elevated temperatures of mortars with vermiculite. Thermal conductivity coefficient of mortars indicated a decreased dependency on the V/C ratio of mortar. The authors concluded that mortars produced using Exfoliated vermiculite aggregate showed a better performance in terms of preservation of mechanical strength to elevated temperature. Shoukry, Kotkata, Abo-EL-Enein, Morsy, and Shebl (2016) investigated the influence of Nano Metakaolin (NMK) on various mechanical properties of Exfoliated vermiculite (EV) which was replaced at 0-10% of EV. White cement mortar was prepared by 70% by volume of EV. A Differential scanning calorimeter and SEM was used to study the phase transitions and the microstructure characteristics of blended mortar. The author's experimental results have shown a significant enhancement of 57, 59% and a decrement of 74% in compression, flexure and capillary water absorption respectively with 10% NMK replacement and led to considerable improvements in the microstructure characteristics. There is no change in the density, and thermal conductivity due to the replacement of NMK was observed. Kumar, Manojjkumar, and Pai (2015) designed the tiles, which accept the heat resisting parameters fulfilling the heat insulation property replacing conventional weathering coarse tiles. Various mixes were prepared using a different percentage of vermiculite and water-cement ratios. The developed vermiculite cement tiles exhibited low water absorption, better strength properties compared with the traditional famous conventional tiles used for flooring in the Chettinad area. The unique characteristics and usage of vermiculite material are to decrease the structural weight and considering thermal characteristics; it is quite a good material, if it is replaced partially gives better results.

Aggregates with an oven-dry particle density less 2000 kg/m3 or an oven-dry loose bulk density less than 1200 kg/m3 are called as lightweight aggregates according to EN 206-1:2000. Lightweight aggregates are divided according to their sources such as Natural Lightweight Aggregates and Manufactured (Synthetic) Lightweight Aggregates (EN 206-1, 2000). Natural lightweight aggregates are obtained by processing volcanic rocks. Pumice, Scoria, Tuff, and Perlite are some of the examples which fall in this category.

The meaning at the name vermiculite is a combination of the Latin word vermisest meaning “to breed worms”, and the English suffix-ite, meaning mineral or rock. The Exfoliated form of vermiculite has a very low density and thermal conductivity, which makes it alluring for use as a soil amendment, lightweight construction aggregate, and thermal insulation filler. Vermiculite is the geological name given to a group of hydrated laminar minerals which are aluminium-iron-magnesium silicates, resembling mica in appearance.

Vermiculite is the name of a group of 2.1 phyllosilicate minerals that are composed of hydrated sheet silicates, which contain layers of water molecules within their internal structure; it is formed by the hydrothermal alteration of mica. When heated rapidly, vermiculite exfoliates as the interlayer water turns into steam, forcing the layers apart Neville (2011) has stated that concrete strength is dependent upon the behaviour of its constituent phases such as aggregates, cement mortar and aggregate–paste interface. Moreover, a stronger and durable concrete could be achieved by modifying the behaviour of cement mortar. Therefore, investigations have been carried out to improve the behaviour of cement mortar and paste. In this process, finely divided pozzolanic materials have been added in cement paste and mortar to enhance its mechanical properties.

The objectives of this study are,

An experimental study is conducted to find out the mechanical properties of ternary blended cement mortar admixed with Exfoliated vermiculite after 7 and 28 days of curing. In cement mortar, the partial replacement of cement is by Micro silica at (0, 5, 10, 15), and Ultra Fine fly ash (0, 5, 10, 15) by weight and Exfoliated Vermiculite with replacement to river sand with increments of 20% was considered.

3.1.1 Cement

Ordinary Portland cement 43-grade brand conforming to IS standard is used in the present investigation.

3.1.2 Fine Aggregate

The locally available sand is used as fine aggregate in the present investigation. The sand is free from clayey matter, salt and organic impurities. The sand is tested for various properties like specific gravity, bulk density etc., in accordance with IS: 2386-1963 (Part-IV) (IS: 2386,1963).

3.1.3 Water

Potable water available in the laboratory was used.

3.1.4 Exfoliated Vermiculite (EV)

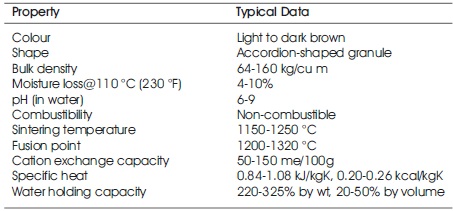

The Vermiculite is used as a filler material, and it is obtainable in golden brown (Figure 1). The specific gravity of vermiculite is 1.5. Typical properties of EV are listed in Table 1.

Figure 1. Exfoliated Vermiculite

Table 1. Typical Physical Properties of EV

3.1.5 Micro silica (SF)

The material is procured from M/s ELKEM India Pvt. Ltd, Mumbai with 85% SiO – amorphous, some aluminium 2 oxide, iron oxide and alkaline.

3.1.6 Ultrafine Fly Ash (UFFA)

The material is procured from M/s Dirk (I) Pvt. Ltd, Nasik. Particle size: 25% of the particle volume less than 100 nm, 25% of particle volume less than 25 μm, Specific surface (BET) typically 20 m2/g (range 15-30).

The casting of specimens were done by batching of materials, preparation of moulds and placing of cement mortar and concrete in the moulds. Hand compaction was done after every 1/3 filling of material into the mould, and the top surface was levelled adequately at the end. They were allowed to dry for 24 hours, and proper identification marks were written and kept into the curing tank for various ages of testing.

To investigate the ternary effects of Pozzolanic materials on the properties of cement mortar cubes and beams with EV, either silica fume and/or UFFA replacing cement was prepared. In many cases, it is the specific strength of Mortar rather than strength itself, which determines its suitability for a particular application. Therefore, a comparison of mortar cube properties at similar specific strength is more logical than a comparison at similar strength.

As Neville (2011) stated, mortar is the one component which governs the strength of concrete. Hence preliminary studies were done on mortar making and its basic properties like consistency, Initial setting time and strength activity index. In this project, initially mortar mixtures with partial cement substitutions were prepared by SF and UFFA in three different percentages and combinations to improve the mechanical properties of the mixtures, for which destructive mechanical tests were carried out. The results are compared to find the best substitution mixture.

The standard mortar mix is prepared with one part of cement and three parts of sand with a fixed w/c ratio of 0.5 by weight of cement. The size of the specimen for each mix is 70 mm x 70 mm x 70 mm cubes of three numbers. The aim of this combination is to obtain the optimum quantity of EV and its utilization as a lightweight material in the concrete making, and this has risen following four combinations in the making of mortar.

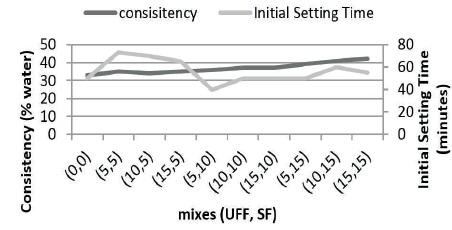

The first mix is a control mix without any pozzolans, and other blends are either a combination of SF or UFFA. The consistency of the cement paste is observed as 30.5. It is observed from Figure 2 that as the percentage of SF increased, the water demand of the pastes is also increased and reached to the maximum with 15% SF. Hence, to improve the strength and workability of concrete, there is a need for utilizing the Super plasticizers to reduce water demand.

Figure 2. Consistency and Initial Setting Times of Mortar

When the paste is prepared with UFFA and along with SF the water demand for consistency is only 2% higher and this increase is due to the presence of SF.

The cement mortar cubes and prisms are prepared with a 1:3 cement-sand ratio and with a water content of 0.5 times the cement weight. The mortar cubes are cast in 70 mm steel moulds and tested after 7 and 28 days of curing. The mortar prisms are made in a 160 mm x 40 mm x 40 mm size moulds. The strength of mortar cubes was tested under Compression Testing Machine available in the lab by the standard test method as specified by IS 516:1969 and strength is compared with control cube.

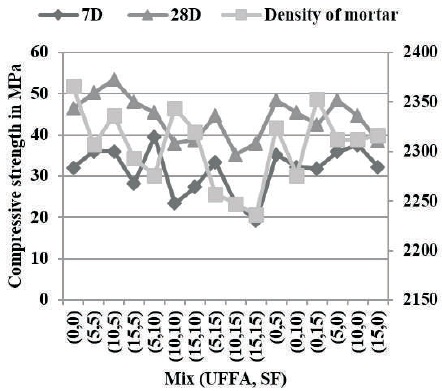

5.2.1 Influence of Triple Blending on Cement Mortar Compressive Strength with a Fixed w/b Ratio of 0.5

Figure 3, an UFFA at 5% replacement to cement is giving a marginal increase in strength, and as its content is increased, there is a reduction in strength. However, reduction in water content is suggested for constant workability. This may enhance the strength which needs to be confirmed by conducting appropriate tests. When the triple blending of mortar is done by the UFFA and SF the compressive strength of cement mortar is showing an increasing trend as SF is increasing for a maximum mineral admixture content of 15% and further increase in mineral admixture content has shown a reduction in strength. However, when 25% of cement is replaced by mineral admixture (10% SF and 15% UFFA) though a reduction in strength of 16% was observed, it may be used due to reduced density and sustainability point of view.

Figure 3. Variation of Mortar Compressive Strength and Density while Replacing Cement with Pozzolans and Sand kept at Constant Ratio

5.2.2 Influence of Ternary Blending on Density

When cement is replaced by pozzolans the weight of specimens is in decreasing trend up to maximum of 2% as shown in Figure 4.

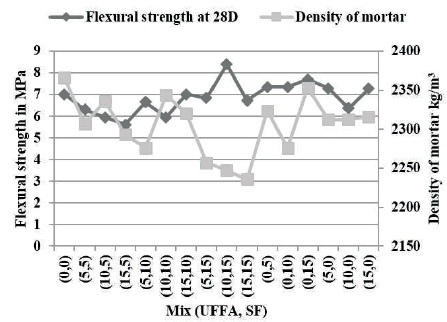

Figure 4. Flexural Strength of Cement Mortar Prisms and Density

5.2.3 Influence of Triple Blending on Mortar Prism Flexural Strength

The flexural strength of the prisms after 28 days of curing was found in a flexure beam testing machine using single point concentrated load increment. Refer to Figure 4 when binary blends are considered they are showing an improving strength than control. The presence of SF is showing a increase in strength and UFFA is also showing an improved flexural strength. The combination of UFFA at 15% and SF at 10% is giving a flexural strength of 7 MPa on par with control mix at reduced densities due to the presence of pozzolans.

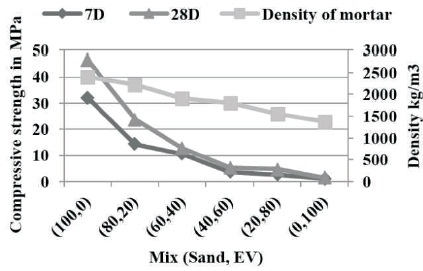

The cement mortar mixes were prepared with Exfoliated Vermiculite (EV) by replacing the sand with an increment of 20% by weight. The results are shown in Figure 5. When EV is used in making the mortars and concrete it is in a fully saturated condition and due to its lightweight and high porosity EV absorbs a large quantity of water and this adds more water to the mix, and it is one of the cause for reduction in strength.

Figure 5. Cement Mortar Compressive Strength with the Replacement of Sand by EV and no SCM's

5.3.1 EV Mortar Cube Compressive Strength

Figure 5 when the sand is replaced by EV, the compressive strength is reduced and a maximum strength loss of 50% was observed at 20% replacement. However, the strength of cement mortar cubes with 60% EV as partial replacement of cement has given strength of 3.15 MPa which is equal to the strength of the lowest grade brick available in Hyderabad, i.e. 3.5 MPa as per IS: 3102 – 1971 Common burnt clay brick specifications.

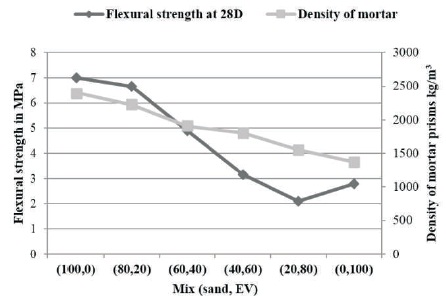

5.3.2 EV Mortar Prism Flexural Strength

Figure 6 at 20% replacement of sand by EV, the flexural strength is 85% of the control, and at 60% replacement, it is at 45% of the control. As the brick flexural strength is not specified in the code, this is useful to resist the tension.

5.3.3 EV Mortar Density

Figure 6, EV Mortar prism densities were found after 28 days of curing. It is observed that as the replacement levels are increasing the density is decreasing drastically and finally at 100% replacement it is of 1300 kg/m3 which is 50% lighter than an ordinary clay brick.

Figure 6. Flexural Strength and Density of Cement Mortar with Variable Sand and EV

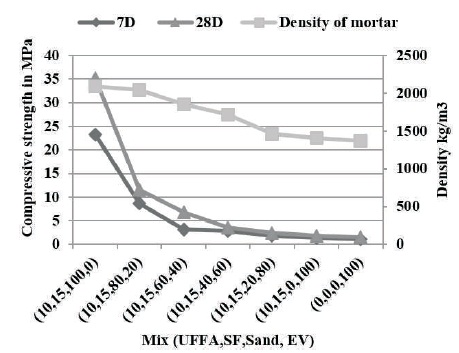

In this mortar preparation, the sand was replaced by EV at 20% increment, and cement is blended with pozzolans at a constant proportion of 10% UFFA, and 15% SF and the results were shown in Figures 7 and 8. The properties studied were compressive strength, density and flexural strength.

5.4.1 Mortar Cube Compressive Strength

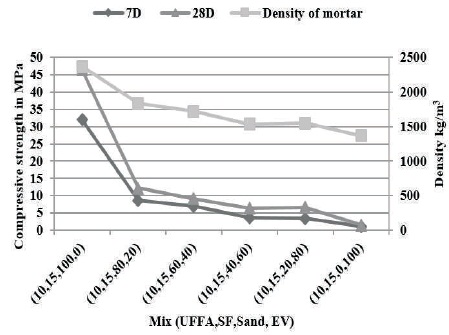

A total of seven numbers of combinations were considered. It is observed from Figure 7 that the compressive strength of mortar with 20% EV is 11.6MPa which is of 33% of that of control specimen. There is a rise in the compressive strength is observed with age.

Figure 7. Cement Mortar Compressive Strength with the Replacement of Sand by EV and Cement by SCM's

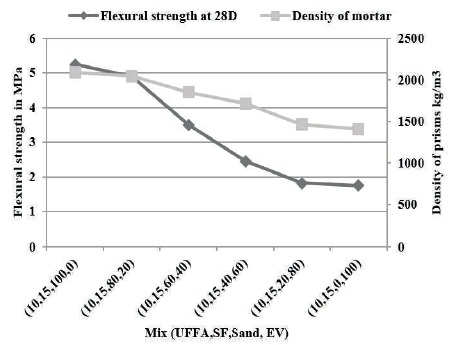

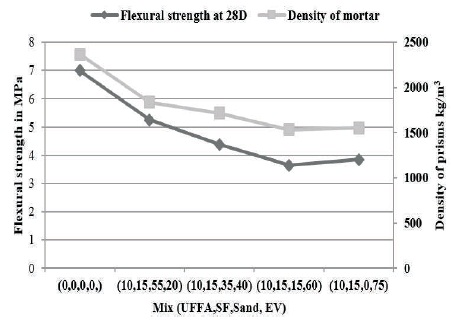

5.4.2 EV Mortar Bar Flexural Strength

The flexural strength of specimens are also following the same trend as compressive strength (Figure 8), but the reduction in strength, is less compared to compressive strength which is advantageous where flexure is required. The flexural strength of mortar with 20% EV is 95% of that of control mix while it is 45% for the mix with 60% EV.

5.4.3 EV Mortar Density

The density of a specimen is decreasing as the EV content is increasing which is advantageous. The reduction in weight is also following the same trend as compressive strength (Figure 8).

Figure 8. Cement Mortar Flexural Strength and Density with the Replacement of Sand by EV and Cement by SCM

In these mixes of the cement content, UFFA and SF were maintained constant and EV is varied as replacement of sand in the increments of 20%. The results were shown in Figures 9 and 10.

5.5.1 Mortar Cube Compressive Strength

With the increase in curing time the strength is also on the rise but the total strength of the mixtures is less than control mortar cube by 65% (Figure 9) while it is more than the Compressive strength of mortars with Supplementary Cementing Materials (SCMs) as partial replacement of cement. However, SCMs are used as partial or full replacement of fine aggregate.

Figure 9. Cement Mortar Compressive Strength with the Replacement of Sand by EV and also SCM with a Constant Cement Content

5.5.2 Mortar Bar Flexural Strength

From Figure 10, it is observed that the reduction in flexural strength is less compared to compression. The flexural strength of 100% EV with pozzolans is 3.85 MPa which is higher than that of mortar with 60% EV. Apart from reduced density this is giving good flexural strength.

Figure 10. Cement Mortar Prism Flexural Strength and Density with the Replacement of Sand by EV and also SCM with a Constant Cement Content

5.5.3 The Density of Mortar Cube after 28 days

The densities of mortar cubes were found after 28 days of curing, and there is 50% reduction in strength similar to earlier observations.

Based on the experimental investigations conducted on the casted cubes and prisms the following conclusions were drawn.

There is no conflict of interest.

The authors express their sincere thanks to the Principal and management of Vasavi College of Engineering, Hyderabad, for the facilities provided for the experimentation work in connection with the present paper. The authors convey their special thanks to Professor & Head Dr. B.Sridhar, for his constant encouragement and help.