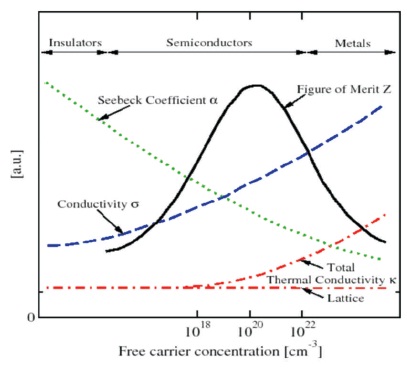

Figure 1. Variation in Seebeck Coefficient, Conductivity, Thermal Conductivity, and Figure of Merit with Respect to Free Carrier Concentration (Abd & Qader, 2011)

Global Warming and energy crisis are the major problems of today's world. So, the uses of thermoelectric devices are very demanding. The materials used in thermoelectric devices to generate electricity from waste heat emitted by vehicles, industries are known as thermoelectric materials. But unfortunately a small part of waste heat is used for the generation of electricity and rest part is lost as waste heat due to low efficient TE devices. So, it's a challenging task for researchers to develop new thermoelectric materials with high efficiency. On review basis telluride based alloys are known to be best thermoelectric materials. Efficiency of TE devices depends on a dimensionless quantity termed as Figure of merit (ZT) of a material which indicates the ability of producing electricity from waste heat. Greater is the value of ZT indicates highly efficient device and larger the production of electricity. So, present work uses the strategies to enhance the efficiency of thermoelectric materials by fabricating super lattice structures of Bi2Te3 and Sb2Te3 compounds and by doping with Se in these compounds may increase the value of ZT. So, finally it can be concluded that present experimental work explores the improved thermoelectric properties of these materials with many future aspects & applications.

In present era, when fossil fuels are becoming exhausted, pollution and global warming are the big environmental problems. So, there is a big need for the alternative, clean, sustainable and more effective energy resources (Neeli, Behara, & Kumar, 2016). In Goldsmid, Sheard, and Wright (1950) investigated that thermoelectric materials can convert these types of waste heat into electricity and can also generate power. The devices made by these materials are very reliable, compact and ecofriendly. But the problem is that demand of these devices is less due to high cost, less availability and low efficiency. In the age of nanotechnology, the size of any electronic device becomes dense or compact. Nano scaled materials exhibit excellent thermoelectric properties rather than bulk or composites (Sharma & Purohit, 2016). There are lots of applications of thermoelectric devices, like, automobile cooling, cooling of electronics, personnel cooling, space power, low-voltage power sources, refrigeration, sensors, transportation (sensor in passenger cars), medicine (energy autonomous implants) or industries (wireless sensors networks). At present there are many thermoelectric materials but uses of these materials are less because they are low efficient materials, too expensive, low durability at high temperatures, toxic compounds and low abundance of raw materials. So, a huge gap is identified in need and availability of thermoelectric materials. So many researches are going on to develop new materials of low cost and high efficiency. The efficiency of thermoelectric materials depends upon figure of merit (ZT), which is defined as Z = S2 σ T/K, where 'S' is Seebeck coefficient, 'σ' is electrical conductivity, 'K' is thermal conductivity and 'T' temperature. For good thermoelectric materials 'S' and 's' should be high with low value of 'K' and semiconductors show relatively large Seebeck coefficient than metals.

The important parameters that should be considered when looking for new materials to increase the value of “ZT” are:

In Figure 1 it is shown that metals have high value of electrical conductivity but have low value of Seebeck coefficient and on other hand insulators have high value of Seebeck coefficient but low value of electrical conductivity. Only semiconductors have wide range of Seebeck coefficient with relatively better electrical conductivities. So, only semiconductors are good thermoelectric materials with high value of ZT.

Figure 1. Variation in Seebeck Coefficient, Conductivity, Thermal Conductivity, and Figure of Merit with Respect to Free Carrier Concentration (Abd & Qader, 2011)

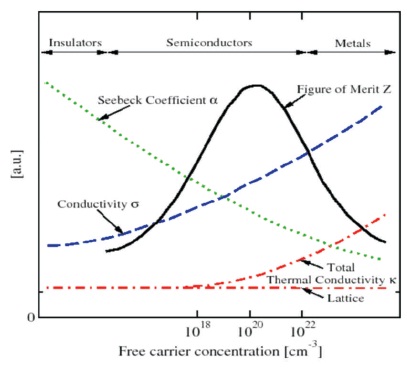

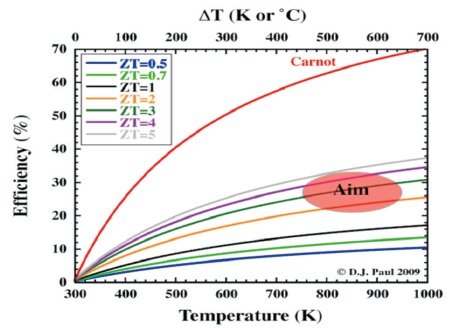

Researchers are trying to develop new semiconductor based thermoelectric materials or by doping to maximize the value of ZT. But the problem arises in maximizing ZT as electrical resistivity and thermal conductivity are interdependent. Reduction in electrical resistivity increases the value of thermal conductivity. And for high ZT, material has high value of electrical conductivity with relatively low thermal conductivity. High figure of merit (around ZT = 3 to 4) can convert around (30 – 40)% part of waste heat into electricity as shown in Figure 2. The study of thermoelectric properties was going on since 1960, but enhancement in ZT is very slow. In this period most of the work was on bulk semiconducting thermoelectric materials. But with the beginning of 1990's a concept of phonon was introduced and by using this concept researchers are tr ying to minimize the thermal conductivity and maximize the electronic properties. The graph in Figure 3 represents the progress in the value of ZT from 1940 to 2018.

Figure 2. Enhancement in Efficiency of Thermoelectric Materials with Temperature (Paul, 2014).

Figure 3. Progress in Thermoelectric Efficiency ZT over a Decade (Cheng, Chen, Harrison, Yu, & Mao, 1994)

Hicks and Dresselhaus (1993) predicts that thermoelectric devices fabricated as 2-D quantum well, or 1-D nano wires could have ZT ≥ 3. Superlattice structures of telluride based compounds also have possibility to increase ZT due to their arrangement in particular orientation. It has also been reported that highest value of figure of merit ZT = 2.4 was in ultrasonic thin layers of two alternating layers (Gonçalves, Couto, Alpuim, Rowe, & Correia, 2006; Venkatasubramanian, Siivola, Colpitts, & O'quinn, 2001). The most common materials found in low temperature range are Bi2Te3 and Sb2Te3 and the mixing of these two compounds will produce phonon scattering due to which phonon thermal conductivity decreased (Goldsmid et al., 1958). To improve the efficiency of thermoelectric materials multiple layers of Bi2Te3 and Sb2Te3 are required. Superlattice structure of Bi2Te3 / Sb2Te3 with film thickness range from few micrometers (μm) to about 15 μm has been made with high performance microcoolers with reported ZT ~ 2.4 at 300 K. (Pradyumnan & Swathikrishanan, 2009) The present work report the multiple alternate layers of thin films of Bismuth Telluride and Antimony Telluride from (nanometers to micrometers), fabricated on glass or silicon substrate by electron beam coevaporation method.

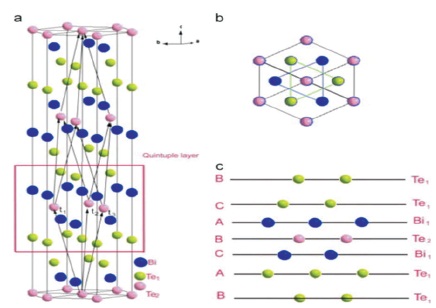

Bismuth telluride exhibits best thermoelectric properties at room temperature. Basically it is a topological insulator but physically it behaves like a semiconductor and when it is doped with Se or Sb then it became an efficient thermoelectric material which can be used in cooling devices or portable power generation (Lin, Chen, & Lin, 2013). It is a semiconductor that shows a large electrical conductivity, low thermal conductivity lies in between 1.97 – 3.38 w/(m-k) and large seebeck coefficient (~ -287μV/K at 300K). It exhibits rhombohedral crystal with layer structure and each layer composite of Te-Bi-Te-Bi-Te units as shown in Figure 4. Bismuth telluride and antimony telluride materials have narrow band gap semiconductor with trigonal structure. It can cleave easily along the trigonal axis due to Vander Walls bonding between neighbouring atoms. Due to this property it has high Seebeck coefficient rather than other materials and its based materials can be used for power generation and cooling applications (Caywood & Miller, 1970). But higher Seebeck coefficient results in decrement of carrier concentration and electrical conductivity which may leads to decrement in figure of merit (ZT) (Svechnikova, Nikhezina, & Polikarpova, 2000).

Figure 4. (a) Crystal Structure of Bi2Te3 with Three Primitive Lattice Vectors t1,2,3 and Quintuple Layer with Bi-Te1-Te2 (b) Top View Along Z-Direction (c) Side View of Quintuple Layer Structure (Chen, Han, Yang, Cheng, & Zou, 2012)

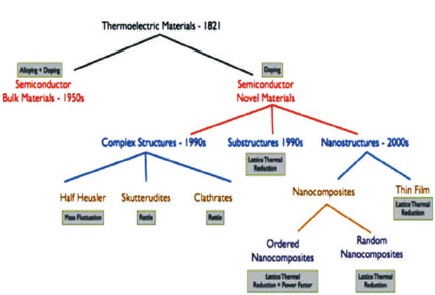

With the continuous development of society during the century, the problems like global warming, energy crisis and pollution is also increasing day by day. So, there is a big need for sustained energy for future. So, there is a great demand of those materials which are environment friendly and also convert waste energy into useful energy. Thermoelectric materials have capability to convert waste heat into electricity. Older TE devices were bulky and their efficiency also very poor (~5 – 8) %. But recent TE devices are small in size and based on semiconductor. So, researchers made TE devices from different materials, including an array of multiple thermocouples made of pn junction diode sandwiched between ceramic wafers. TE devices have capability to convert any source of waste heat like ocean heat, solar heat, geothermal heat, Thermal heat etc., and their efficiency can also be increase by choosing suitable material and doping of certain materials. Telluride based materials have high efficiency at low temperatures. That is the reason why TE materials are in demand in today's world. Figure 5 shows overview of historical background of thermoelectric materials.

Figure 5. Historical Background of Thermoelectric Materials (Alam & Ramakrishna, 2013)

Table 1 shows some results of thermoelectric materials like type of carrier concentration, figure of merit, lattice thermal conductivity, which shows that superlattice structure of Bi2Te3 / Sb2Te3 prepared by molecular beam epitaxy has highest value of ZT ~ 2.4 at room temperature.

Thin films show high thermoelectric efficiency as compared to bulk materials because enhancement in ZT in bulk materials is more difficult in comparison to thin films, a bulk materials show mutual interdependence of electrical conductivity and thermal conductivity. If one has to try to increase the value of electrical conductivity, thermal conductivity will also increase so this will lower the value of ZT. But this problem can be avoided at nanoscale level as the quantum effects involved with these parameters become independent to each other. So, electrical conductivity can be increased without affecting the thermal conductivity parameter. That is the reason why thin films are more efficient thermoelectric materials as compared to bulk.

Svechnikova et al. (2000) studied the effect of doping with Sn in Bismuth Telluride crystals. Weak effect on electrical properties was measured when doped with low Sn concentration (0.2 to 0.5%) and as Sn concentration. Increased from (0.7 to 1%) electrical conductivity increased and thermoelectric power decreased.

Yamashita and Tomiyoshi (2003) investigated the thermoelectric properties of P-type (Bi0.25Sb0.75) 2Te3 doped with 3 wt % excess Te and n-type Bi2(Te0.94Te0.06) doped with 0.07 wt % I and 0.02 wt % Te by Bridgman method in temperature range from 473 to 673 K. The maximum thermoelectric figure of merit ZT at 298 K for P-type and n-type are 1.26 and 1.19, respectively.

Takashiri, Shirakawa, Miyazaki, and Tsukamoto (2007) designed ethermoelectric generator of p-type Bi0.4Te3.0Sb1.6 and n-type Bi2.0Te2.7Se0.3 thin films by flash evaporation 2.0 2.7 0.3 method. Results showed best electrical performance with Seebeck coefficient, Resistivity, and power factor of 254.4 μv/k, 4.1 m Wcm, 15.9 mw/cmk2 for p-type and -179μv/k, 1.5 2 m W cm, 21.5 mw/cmk2 for n-type.

Li et al. (2008) developed a thermoelectric material of Bismuth Telluride with a figure of merit, ZT, approximately. 1 at 300 K with thickness from 100 to 350 μm based on electro deposition technique. Se and Sb were doped in Bismuth Telluride for further improvement in thermoelectric performance.

Hatsuta, Takemori, and Takashiri (2016) investigated the effect of thermal annealing on thermoelectric properties of antimony telluride thin films. P-type Sb Te thin films were deposited on steel substrate by electro deposition method. Annealing was performed at the temperatures from 200 oC to 400 oC for 1 hr. Results showed that impurities were abserved at over 300 oC and obtained maximum power factor of 13.6 μW/(cmk2) at 300 oC.

N-type Bismuth telluride thin films were deposited by co-sputtering method and these thin films are annealed at different temperatures. Results shows that the stoichiometric N-type Bi2Te3 was achieved at 400 oC and has maximum power factor 0.821X10-3 Wm-1K-2. The structural and thermoelectric properties were greatly improved by annealing (Cai et al., 2013).

N-type Bi2Te3 films were fabricated on SiO2/Si substrate by RF magnetron co-sputtering technique. Films were annealed from (150-350 °C). Results showed that crystallization was improved as annealing temperature increased and optimum Seebeck coefficient and power factor was about -242 μV/K and 21 μW/K2 cm obtained at 300 °C (Wang, He, Wang, & Miao, 2013)

N-type Bi2Te3 thin films were fabricated on SiO2/Si substrate by thermal evaporation technique. Films were annealed in temparature range 100-250 °C. Results have showed that both Seebeck coefficient and power factor were enhanced as annealing temperature increase (Lin et al., 2013).

Bi2Te3 and its alloys are widely used for refrigeration. The figure of merit ZT, usually rises with temperature as long as there is one type of charge carrier and as minority carrier become significant, ZT decreased above a certain temperature. This is due to chemical decomposition of vapourization of Tellurium (Goldsmid, 2014)

Sb2Te3 thin films were prepared by thermal evaporation method and effect of substrate temperature was observed. The result shows that as temperature was greater than 150 °C, Sb2Te3 was hard to deposit and Seebeck coefficient and power factor were decreased from RT to 500 oC and after that these values increased to 1500 °C (Lin, Chen, Yang, & Chen, 2015).

Rostek and his coworkers were fabricated thin films of Bismuth Telluride by electrodeposition method. The sample showed n-type behavior with Seebeck coefficient -130 μv/k at 25 °C (Rostek, Sklyarenko, & Woias, 2011)

Saleemi and his coworkers synthesized bulk material of Bi2Te3 with figure of merit ZT around 1. Spark plasma sintering has been employed and results showed very high densification. Seebeck coefficient and power factor were enhanced by 30% especially in low temperature region (Saleemi, Toprak, Li, Johnsson, & Muhammed, 2012).

Bulman et al. (2016) research on p-type Sb2Te3 /Bi2Te3 superlattice-based thin film of total thickness 8.1 mm. Thermoelectric modules of these thin films have high cooling fluxes of 258 Wcm2 which enhance thermoelectric efficiency. Doping of Se increases the carrier concentration without change in mobility.

Hansen et al. (2014), synthesized a high quality Bi2Te3(1 nm) / Sb2Te3 (5 nm) superlattice thin film by molecular beam epitaxy. Results showed that superlattice structures are not stable against inter diffusion of the components with micro and nanostructural changes occurring at temperatures below 200 °C. At 300 °C these layers are mostly inter diffused and formed thermodynamically stable films.

Peranio, Eibl, and Nurnus (2006) synthesized Bi2Te3 thin film and Bi2Te3 / Bi2 (Te0.88Se0.12) superlattices. Results showed that best figure of merit ZT '1' and power factor were achieved for superlattice (SL) structures better than Bi2Te3.

Venkatasubramaniam et al. (1997) synthesized Bi2Te3, Sb2Te3 and their multilayers by MOCVD method on GaAs substrate. Results indicated that figure of merit ZT in superlattice structure were significantly higher than single layer structure.

Anwar, Mishra, and Anwar (2016) deposited single and multiple layers of Bi2Te3, and Sb2Te3 by sputtering technique. Results showed that as the number of layers increased from 5-10 the Seebeck coefficient increase from -145 μV/K to -170 μV/K.

Superlattice structure of Bi2Te3/ Sb2Te3 prepared by MOCVD method have an outstanding performance in the field of thermo electricity by achieving the figure of merit ZT of 2.4 (Winkler et al., 2012).

Hicks and Dresselhaus (1993) developed a new method to improve the value of ZT by two dimensional quantum well structure of Bi2Te3 and also suggested that lattice thermal conductivity can also be reduced if the layer thickness of Bi2Te3 would be less than phonon mfp (Mean fase path).

Chowdhary et al. (2009) enhanced the thermoelectric performance of two dimensional superlattice based thin films of Bi2Te3.

Shakouri (2005) considered that enhancement in ZT in superlattice structures may occur due to sharp features in electronic density of states. Doping level increase in quantum-confined structures between hot and cold terminals resulting in a large average transport energy and large number of charge carriers moving in the material (i.e., a large value of Seebeck coefficient and electrical conductivity).

From above discussion it can be concluded that superlattice structure based thin films of Bi2Te3/ Sb2Te3 have promising area in future for enhancing the value of figure of ZT merit to a great extent and also the efficiency of TE devices.

Although a lot of work has been done in the field of thermoelectricity and focused on increasing thermoelectric figure of merit ZT, the maximum value of ZT so far reaches only up to 2.4 but this value is too low for practical applications. Present work tries to increase the value of ZT by introducing the superlattices of Bi2Te3/ Sb2Te3 in micro dimension range and also doping of Se in Bi2Te3 in Bi2Te3 / Sb2Te3 superlattices may enhance ZT. So, telluride based materials are very promising in thermoelectric but due to less availability, high cost and toxicity, the practical use of these materials are less. From above discussion it can be concluded that there are many scope for the researchers to explore new materials of low cost, good availability of materials and having better thermoelectric properties that can transform waste heat into electricity.

Researchers are continuously trying to increase the efficiency of thermoelectric materials by exploring new materials to increase the value of ZT to 3 or greater. It is possible only when reduction in thermal conductivity and increase in electron conductivity is possible. Further reduction in thermal conductivity is possible if number of phonon modes that propagate can reduce but leads to result of correlated scattering effects. At present, it seems almost impossible for reduction of thermal conductivity by such mechanism. So, in future researchers need to focus on new scattering mechanism and concepts for further reduction in thermal conductivity and increasing electronic conductivity. These steps will definitely increase the value of ZT to a great extent and increase the efficiency of thermoelectric devices.