Figure 1. 1930's Ford Woodie (Source: Schnabel 1938)

This paper presents an assessment of the growing use of Glass Fibre Reinforced Plastic and Carbon Fibre Reinforced Plastic composites in the automotive and marine industry through the decades to current use. This report investigates how legislation such as the End of Life of Vehicles (ELV) will force the automotive industry to prepare for end of life recycling and gauge their progress with the aid of reports from the Knowledge Transfer Network (KTN) and Stella Job, who is a Supply Chain and Environment Officer for the UK trade association Composites UK, outlining the process of pyrolysis and solvolysis, with the aid of informal industry interviews and a case study at a small British sports car manufacturer to consider the practical work required.

Composites have been used for a relatively short amount of time, but the properties they offer of weight saving and offering increased strength; have arguably transformed the approach to design in both the automotive and marine industry. Glass Fibre Reinforced Plastic (GFRP) has made boat ownership more affordable to a wider section of people. In the automotive industry, the use of GFRP and later Carbon Fibre Reinforced Plastic (CFRP) has influenced the design of firstly racing cars and then this knowledge has trickled down into the mass produced models.

However, little attention was paid to the problems of recycling. Legislation to cut emissions and increase fuel efficiency has increased the need for and use of composites, but the ELV directive has also placed the responsibility of recycling directly with the automotive industry. The industry has appeared to be reluctant and slow to respond, but high land fill taxes have provided the financial incentive for investment in research. Germany has lead the way in this field and has a healthy commercial GFRP and CRFP industry several years ahead of the UK. Meanwhile in the UK, Hambleside Danelaw, a manufacturer for the building industry and Filon, who also make GFRP products for the construction industry; have made advances in recycling composite waste from their own roofing products.

Due to the high value of CFRP, the recycling of this composite has been more successful. Newly founded car company Zenos Cars, has decided to use recycled CFRP in the construction of their E10 sports car, and an informal interview and case study was conducted. Informal interviews in the automotive and marine industry have reported their considerations, perspective and the challenges they face. In the United Kingdom, the government looks to organise the recruitment of professionals and researchers in the form of Knowledge Transfer Network (KTN) and Composites UK have provided information and networking. Car companies have responded by forming partnerships with composite manufacturers to pool their research and knowledge, as well as to secure supply chains. The main objectives are to: assess the use of composites; understand the problems of recycling (the materials in question); consider the impact of the end of life directive; and gauge the response from automotive and marine industry to recycling.

The aims are to explore the increased use of GFRP and CFRP composites, how advances in research have enabled techniques to be refined for mass production, analysing if these advances has meant that research into recycling composites has kept pace with the growing application of composite materials recycling, and assess their current use. Coming to an understanding of how current and upcoming legislation such as the end of life directive will affect their use, especially in relation to recycling. Gauge how the industry has developed commercial recycling of composites with an outline of the process of pyrolysis and solvolysis and assess how the industry is prepared for the future increase use of composites and therefore increased need for recycling.

Composites such as Glass Fibre Reinforced Plastics (GFRP) and Carbon Fibre Reinforced Plastics (CFRP) have been used in manufacturing for decades, for example in low volume sports car production, but have not been widely used in mass production because of the lack of funding in research for improved production methods. In the past, the Automotive and marine industry were heavily reliant on wood and steel for materials, like that of the 1930's American Ford 'Woodie' (Figure 1).

Figure 1. 1930's Ford Woodie (Source: Schnabel 1938)

Since the Second World War, the marine industry has embraced the use of composites. While the automotive industry preferred steel due to its ease of mass production methods. The marine industry is often considered a low volume production, but low volume in automotive terms still contain a higher number of units, typically in the thousands to that of the marine industry, which would be in the tens, or hundreds depending on the product. Glass fibre is made from a mixture of silica and recycled glass. The mixture is heated, and extruded into fine strands, the strands are collected onto bobbins. The bobbins can either be used directly into making a product, or it can be produced into woven, unidirectional, braided and chopped matt configurations.

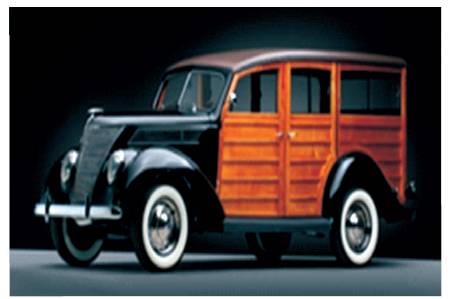

The process of producing carbon fibre is a fairly complicated and lengthy process in comparison to glass fibre; this is one of the reasons for the difference in cost. The starting material is a precursor based on acrylic fibres. Several complex oxidation and carbonisation processes convert the precursor into carbon fibres; the exact processors are considered closely guarded trade secrets. The precursor is drawn into long fibres (as seen in Figure 2), and heated to reduce the composition of the fibres to consist of carbon atoms with a purity rating of over 95%. The fibres are collected into bobbins just like the glass fibre. The carbon fibre bobbins can also be produced into woven, unidirectional, braided and chopped matt configurations, just like the glass fibre.

Figure 2. SGL Automotive Carbon Fibres, 2013

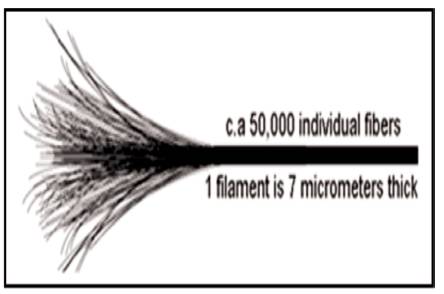

The 1953 Chevrolet Corvette (Figure 3) was the first mass produced production car to be made from GFRP, it was a revolutionary material that worked well as a USP (Unique Selling Point) over its competitors. The body and all of its panels were produced from the material, with a steel Chassis supporting the running gear and body structure.

Figure 3. 1953 Corvette Components (Source: Montrief, 2007)

In 1956, Colin Chapman researched, designed, and created a monocoque GFRP vehicle. The car was named the Lotus Elite (Figure 4), and was the first vehicle to use GFRP for the entire structure of the vehicle. The running gear bolted directly onto the GFRP monocoque structure. Between 1957 and 1964, 1078 vehicles were produced, (Hayes, 2007:51) however during the production run, techniques were refined and improved upon. Chapman applied the experience he had gained from the local boat industry in Norfolk.

Figure 4. 1957 Lotus Elite Monocoque (Source: Ortenburger & McCormack, 1977)

Rolls Royce started quietly researching (CFRP) Carbon Fibre Reinforced Plastics within the RB211-22 engine (Figure 5). Rolls Royce heavily invested into the material, redesigning major components, like fan blades, out of CFRP. However, towards the end of the project, safety tests restricted the amount of CFRP used within the engine, resulting in Rolls Royce replacing many components with titanium, carrying only the CFRP cowl through to production, in some variations.

Figure 5. Rolls Royce RB211-22 Engine (Brossett, 2002)

By the late 70's, The Lotus Type 88 (Figure 6) was the first carbon fibre monocoque race car, which was designed by Colin Chapman. The car was produced in time for the 1981 season; however, it was disqualified for having a trick multi-sprung duel chassis system.

Figure 6. 1981 Lotus Type 88 Race Car (Source: Collantine, 2011)

At the same time, McLaren were also working on a Carbon fibre monocoque design (Figure 7) for their 1981 MP4/1 designed by John Barnard, but had difficulties and sought outside help from Hercules Aerospace in the USA. The car was not ready for the 1981 season, and was subsequently entered into the next season. The performance of the composite material was generally unknown, to the public, until the McLaren was in a very serious crash, breaking in half (McLaren Automotive Limited, 2014). This meant that the material dissipated the energy very well, with the driver's safety cell remaining intact. This was the point when carbon composite construction started to attract attention for its possible uses in a wide range of industries. By the mid 80's, all of the Formula One race cars had moved to a CFRP monocoque construction.

Figure 7. McLaren MP4/1 CFRP tub (Source: McLaren Automotive Limited, 2011)

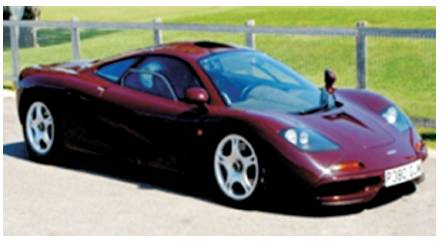

The first road car to feature a full CFRP monocoque was the McLaren F1 (Figure 8) designed by Gordon Murray, The initial idea was sketched up in 1988 to produce a homologated race car with a road car derivative. The first customer car was launched in 1993, with a total of 106 vehicles produced over a production span of 5 years. Composite engineer Antony Dodworth was recruited to help design a carbon monocoque, which took 3000 hours to produce (McLaren Automotive Limited, 2014). The race vehicle inspired design made the vehicle highly repairable after damage. Many other companies were using CFRP and GFRP within homologated road cars, like Ferrari F40 and Lamborghini Countach; however these used tube section aluminium and steel for the main chassis.

Figure 8. 1993 McLaren F1 (Source: Campbell, 2013)

In 2003, the first series production CFRP monocoque car was a joint venture between formula one teams Mercedes and McLaren, The Mercedes McLaren SLR (Figure 9), was also designed by Gordon Murray. Production was set at 3500 units, but was discontinued in 2009, after only half that figure was produced.

Figure 9. Mercedes McLaren SLR Monocoque (Source: Hodzic, 2007)

CFRP monocoque sports cars have become increasingly common since the McLaren F1 in 1993, with manufactures realising the potential, however up until recently, they have only been available to wealthy customers purchasing cars for prices more than, for example half a million pounds in 2003. The EU commission state that mandatory CO2 emissions must average (for a manufacturers fleet) 95 g/km by 2020 down from 130 g/km in 2015 (European Commission, 2014). The drive to lower emissions put out by vehicles has increased dramatically prompting manufacturers to research and invest in lightweight materials. Composites such as CFRP have become one of the many focuses, as it offers strength to weight ratios far better than other materials in the industry.

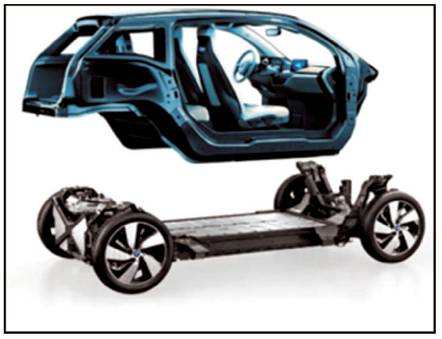

With the research into production techniques realising new methods, the cost has decreased significantly. In 2015, the cheapest vehicle made from a CFRP material is the Zenos E10 Sports car which starts from just under £25,000 (Zenos Cars Ltd, 2014), which uses carbon for the occupants tub, and aluminium chassis sections. The cheapest conventional car is the BMW i3 (Figure 10) priced at £31,000 (BMW UK Ltd, 2015), which also uses CFRP for the monocoque 'life module', with an aluminium 'drive module'.

Figure 10. BMW i3 Construction (BMW, 2015)

The i3 is made in the Leipzig vehicle plant in Germany, which is carbon neutral and advertised as being 'one of the world's most modern and sustainable automobile factories' (BMW Group, 2014), winning many awards in the process. The i3 is mainly constructed from CFRP and is perhaps the forerunner of this new generation. There are three main disadvantages of this model: cost of production is higher; relative duration of production is longer; and CFRP supply chains are unstable and inconsistent.

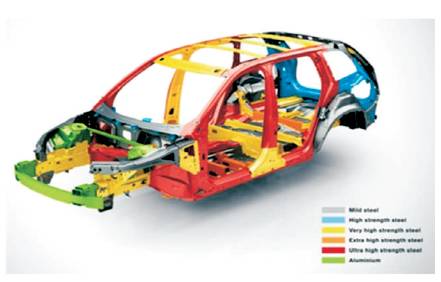

When compared to an equivalent conventional car, the units and costs are significantly different. However, it could be argued that these are teething problems and cost, duration and suppliers will improve as technologies develop. When BMW first started creating CFRP components in mass production in 2009, they developed a business partnership with Carbon Fibre manufacturer SGL Group. This guaranteed a CFRP supply chain, especially for their own products. A new state-of-the-art factory was built in North America, which is powered by renewable resources, (which is good as CFRP production is seen to be inefficient). In contrast, Volvo's latest XC90 Sports Utility Vehicle (SUV) is constructed from various different grades of steel (Figure 11), and uses this reason to advertise it as one of the safest vehicles in the world while boasting of its efficient capabilities (Volvo Car Group, 2014).

Figure 11. New Volvo XC90 Steel Structure (Volvo Car Group, 2014)

Jaguar Land Rover has also made advances into lightweight aluminium vehicle construction, no doubt helped by the parent company TATA steel. Jaguar Land Rover has made the move from steel construction to a 'state-of-the-art lightweight aluminium structure' (Jaguar Land Rover, 2012) construction saving 420 kg from the previous model. Whereas, the Porsche Automobil Holding SE, is such a large organisation consisting of twelve automobile manufacturers, they can invest in exploring both directions, as they own a mixture of mass production such as Porsche and Volkswagen and low volume manufacturers like Lamborghini and Bugatti. This large association of manufacturers means that they can share vehicle architecture, components and research which they could otherwise not be able to do independently.

It could however be argued that, due to the expense and high maintenance costs of current vehicles with their onboard hardware and software, cars which develop an electrical fault may not be commercially viable to repair and therefore the generally accepted 13 year current lifespan of a car is dropping to perhaps ten years. With an average annual mileage being 7,900 miles (Department for Transport, 2013:21) the lifetime of a car is possibly 79,000 miles. Therefore, the gap between the break-even point could be considered unviable. These problems of longevity and recycling need to be addressed.

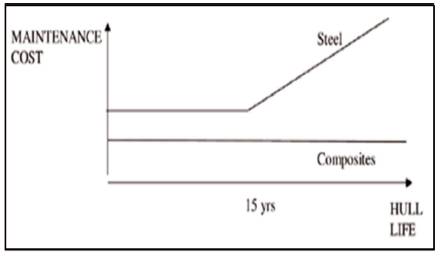

Depending on the quality of the initial build most GFRP boats have a long lifespan. It has been noted that over the lifespan of a GFRP boat, the maintenance costs remain the same, whereas with a steel boat, the costs increase over time (Figure 12) (Russell, 2005:39). Although osmosis can cause problems, this can be rectified and more recently prevented. Boat owners in general, usually have different expectations to that of the average car owner, as high maintenance or re-fitting costs are quite common throughout the life of the boat.

Figure 12. Structural Maintenance Costs Over Boat Lifetime (Russell, 2005: 39)

If they owned a wooden boat, this would need major work every two to three years. GFRP boats in comparison require much less time spent on them. This is one of the factors why composites have been embraced by both the manufacturer and purchaser. Figure 13 displays a GFRP mould for an Oyster 575.

Figure 13. GFRP mould for an Oyster 575 (57ft Sailing Yacht)

The Materials KTN was set up to improve the position of the UK with composites. They are funded by the UK Governments Technology Strategy Board. Stella Job, has worked as an advisor for KTN, and is currently a freelance consultant in the composited sector, and works part time as Supply Chain and Environment Officer for the UK trade association Composites UK. In a report, the KTN commissioned in September 2010, Stella Job explained “UK carbon fibre composite production amounts to about 2,130 tonnes. While carbon fibre composites represent about 40% of UK composites production by value, they correspond to about 2% of UK composites production by volume, the vast majority being glass fibre composites” (Job, 2010:3). Job stated that in 2010, there were only two functioning composite recycling companies in the UK.

Job also stated that it is more profitable to recycle carbon fibre commercially, than glass fibre, due to the high costs of carbon fibre (Job, 2013a). She reported on ELG Carbon Fibre, a carbon fibre recycling centre in the West Midlands, they use the pyrolysis process, which is the most widespread recycling method, which uses thermal decomposition in an inert atmosphere (Job, 2013b). Pimenta and Pinho state that “Pryolsis is currently the one recycling method with full size commercial scale implications” (Pimenta and Pinho, 2014). Figure 14 displays the methods of recycling, and the potential application for the reclaimed material.

Figure 14. Pyrolysis Recycling Process (Pimenta and Pinho, 2014)

ELG Carbon Fibre's website currently lists their products as: pellets for compounding; milled fibres for coatings; yarns for Direct Injection Moulding and weaving; and mats for press forming and pre-pregging. Job has also done research on composite recycling companies worldwide. Germany has very strict land fill regulations, and have had little option, but to embrace the composite recycling processes. Reprocover based in Belgium has had success with recycling GFRP into manhole covers. With this experience, they have branched out to manufacture planters, ashtray bins, cable duct covers and post boxes (Job, 2014). Reprocover charge companies to take their waste that would otherwise incur landfill taxes.

Job suggested that the solvolysis process for recycling CFRP could be of “particular interest” (Job, 2010:3). Figure 15 displays the brief differences between pyrolysis and sovolysis processes. The Hitachi Chemical Company Ltd and Siemens Corporate Technology have researched this process intensively and are excited by the results. It is said to be “more environmentally friendly than pyrolysis” (Gardiner, 2014).

Figure 15. Recycling Technologies for Composite Waste (Morin et al., 2012)

Germany, because of landfill restrictions, has developed a lead in recycling GFRP; the 'economic case' has been proven to be more viable to industry, thereby in 2014, Job reported an increased use of GFRP waste. It was being added to cement as a filler in Germany. The Belgian company Reprocover not only manufactured manhole covers, but were also developing their own railway sleepers, which have proved in testing to be better than traditional wooden sleepers. Railway companies are currently researching alternatives for the traditional sleepers, as due to European Union legislation in 2018 that will restrict the use of creosote, which is a carcinogenic wood preservative. The market for this could be vast.

Recently, Nordic countries have begun studies to gather information on their leisure boat ownership. It is estimated that Norway, Sweden, Denmark and Finland have between them half of the six million leisure craft thought to be in Europe (Eklund, et al., 2013). Concerns had been raised as many of these small boats were reaching their end of life and were being abandoned on river banks. The Båtskroten project in Sweden is due to start in the latter half of 2015, to collect and dismantle these boats. Recycling opportunities are being considered. In the UK, the Broads Authority in Norfolk collects old abandoned boats from the river banks (Figure 16).

Figure 16. Abandoned Broads Cruiser Boat (Dibbler, 2005)

But recycling opportunities are limited. Unlike Oyster Yachts, these small crafts have limited value, but require river tax that would outweigh the worth of the boat. In the past, a culture of sinking and abandoning Norfolk Wherries (traditional old wooden craft seen in Figure 17) in 'wherry graveyards' was accepted, however, most of these crafts have decomposed. One or two have been refloated and restored at great expense. It could be argued that the marine industry has escaped the legislation that the automotive industry has been forced to comply with, but the author thinks that this is a situation that will change.

Figure 17. 1898 Albion Norfolk Wherry (Broads Authority, 2014)

The methodology used to collect empirical data was by informal interviews with professionals in the relevant industries. Because of the nature of informal interviews, the questions varied slightly, and were personalised to the responses and the interviewee. The interviews offer a valuable insight into the various industries, but it must be remembered that the views expressed, were personal opinions and could be biased. Each interview will be analysed separately.

Figure 18. Oyster 575 (Oyster Yachts, 2013)

Figure 19. Zenos E10s (Zenos Cars, 2014)

Figure 20. Aston Martin CC100 Concept Car (CFTech Multimatic, 2012)

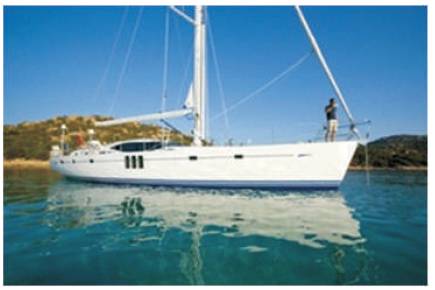

All Oyster Yachts are made from GFRP; a lot of components are made from CFRP. The motivation for customers to have CFRP was it seemed mostly for the image and aesthetic reasons, as instrument panels and steering wheels would save negligible weight, but would be on display as a fashion statement. Mast, booms, rudders and bulkheads would save a significant amount of weight for the keen racer, who can afford the extreme costs for these optional extras. Carbon material sails have also been provided to help cut down on weight, and increase longevity in comparison to regular sails. Although Oyster has not provided lightweight racing boat hulls made from CFRP, these can be obtained.

One incident Kevin recounted (in this case thankfully not an Oyster yacht), a carbon fibre mast snapped in a transatlantic race several years ago. Had this been aluminium, it would have cracked through metal fatigue, and this would have provided warning, enabling the crew to reduce the amount of sail, and make repairs. However, the CRFP mast snapped and fell overboard. The crew had to cut the lines and let the mast go. This was worth in the region of £40,000.

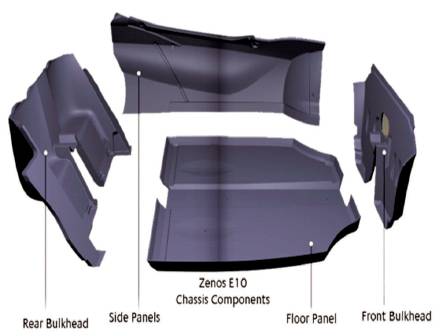

The Zenos E10, which is currently the only car in the Zenos range, is made from recycled CFRP, aluminium and steel. The CFRP is used in the occupants tub built around an aluminium extruded frame. The suspension and drive train components are attached to steel front and rear sub frames. For the company's first vehicle, this has been well received, and has obtained credit in the automotive journalists around the world.

The reasons for using recycled CFRP are firstly safety, and secondly cost, as recycled CFRP is 10% of the cost of virgin carbon fibre, and thirdly innovation to give the product a “USP”. The recycled carbon has 70% of the strength of the virgin carbon fibre, but this is combined with the steel protection frame. More carbon fibre would have been used, but this would have been limited by cost, performance has not been compromised.

The end of life has been considered from when the product was designed. Matt said that materials and coatings had been planned carefully. The outer body panels are made from GFRP, and have been designed to be easily removable. GFRP can be repaired easily for minor issues. In the UK, GFRP recycling opportunities are limited. Matt was aware that Germany was “leading the way”, but as a business decision, could not justify the cost of transporting waste to Germany.

The first part of this interview was about the people transport company called River simple, who are trying to establish a new business model, where a vehicle is leased, rather than sold. The vehicle's manufacturer, partners and suppliers would in effect, retain ownership and be responsible for the vehicle. Their aim is to achieve enhanced longevity and recyclability designed from the outset. Gavin did not think that this would be a viable business model stating “it's basically going to be good, until they damage it, and at that point, what's that got to do with me because I made it”. Apart from Riversimple, no other customers have mentioned recycling to Gavin.

The company explored the uses of reclaimed carbon fibre, but after some tests and experimenting, they concluded that the material would not have the properties that would interest them. They try to keep waste to a minimum; they had explored the possibility of recycling either cured or uncured carbon. But we are surprised that they would have to pay for this service. Gavin said “I'm sure that is the way it will go, but at the moment, there isn't really an incentive for us to do it….. If you are going to use [recycled] filler then great, it's a recycled waste product, but you know being hard-nosed about it, I want the benefit or I might as well stick it in a hole in the ground”.

The ELV will force car manufacturers to take recycling seriously. The larger car companies have already spent time planning for this. Gavin supplies to Aston Martin in creating CFRP components for their niche vehicles, which are either concept vehicles for motor shows, or for production numbers less than 10. The very nature of these vehicles means that they will either end up in museums or car collections, where they will be cherished and preserved. End of life of this sort of product would not apply in the same time scale.

The author was invited by Matt Windle, Head of Engineering at Zenos Cars, to visit the factory in Wymondham, Norfolk, showing in detail the product, and how the application of recycled carbon fibre is used. The E10 sports car is a new vehicle designed from the floor up. Matt explained that the project started out with a price that Zenos aimed to sell the cars for, in this case, £25,000. Since their competitors have moved upmarket, a gap in the market opened, offering similar performance for a fraction of the cost.

With a price established, costs were calculated, as well as links with suppliers and partners. Zenos plan to build 200 cars a year with four teams of two assemblers, aiming for a build time of 60 hours per unit. However, Matt mentioned that, the current build time is significantly longer. But the company is only just starting to build their first few vehicles, and the build time is expected to reach the target as the teams become familiar with the build, and small niggles are refined and amended. Initial engineering drawings were produced, with all main running gear, suspension components and chassis complete. The passenger tub was then designed around the occupant’s needs. A basic layout was created with rough dimensions and positions from a wooden mock up (Figure 21) mimicking the tub and central extruded chassis.

Figure 21. Ergonomic Mock Up (Trent, 2013)

This enabled an effective, yet cost effective way to test ergonomic seating positions to accommodate a wide range of people from a range of markets, ensuring the “perfect driving position” is achieved. The steel impact and roll over protection system was then designed around these findings, which is well hidden from view within the body of the vehicle.

The Zenos E10 features a chassis that takes the appearance of a central spine. This extruded aluminium chassis is anodised using automotive techniques to protect the metal against the elements throughout its life. The running gear, suspension components and steel impact protection system with roll over hoops bolted to the central chassis (Figure 22). The vehicle is built to be used with track days and small series racing in mind. So the car has been designed and engineered to be easily dismantled and repaired as efficiently as possible.

Figure 22. Left–Bare Aluminium Spine Chassis, Middle-Impact Protection and Running Gear Attached, Right–Part of the Carbon Tub in Position (Zenos Cars, 2014)

The body panels are relatively small, to aid removal and to minimise cost. The recycled carbon fibre tub has also been constructed in several sections with this philosophy in mind; the tub is then bonded together and fastened to the central aluminium spine. But unlike conventional carbon fibre tubs like that of the McLaren F1, the CFRP would be expensive and far more time consuming to repair, due to the use of continuous weave carbon fibre, this in theory creates a single constructed component. The recycled CFRP components that make up the occupants tub in the Zenos E10 can be seen in Figure 23.

Figure 23. Components that make the Zenos E10 CFRP tub

The recycled Carbon Fibre (rCFRP) Panels are made up of three parts. An outer layer of rCFRP, a centre layer consisting of recycled polycarbonate drinking straws arranged in a honeycomb pattern, and an inner layer of rCFRP. The Carbon used within the production of the Zenos E10 sports car uses recycled continuous woven virgin carbon fabric offcuts. This is the best type of carbon to use, as it is not prepregnated with resin, and is not cured. The strands are chopped up (Figure 24) and stitched together (Figure 25), and formed in an aluminium die technique.

Figure 24. Recycled CFRP (Pimenta and Pinho, 2014: 274)

Figure 25. SGL RECATEXTM Recycled Carbon Fibre Nonwoven

Zenos Cars worked with Antony Dodworth to further develop the material to work within the financial restrictions Zenos was experiencing. Dodworth is the past principle research manager for carbon fibre at Bentley (and also a previous composite engineer for the McLaren F1 road car project) and Larry Holt, CEO of global automotive component manufacturer Multimatic. Zenos Cars appeared to have found a niche in a tough market, with many respected brands already established. Matt mentioned that they had so far taken over 100 orders for their E10 model, numbers which are expected to rise with the media embargo being lifted the week after the author’s visit.

In conclusion, the use of composites has grown over the decades since their introduction in the 1950's. The benefits they offer such as their strength to weight ratio are well worth the investment in plant, and research development. With the use of composites in highly desirable products such as super cars and high specification yachts, consumers have embraced the innovations they offer. The marine industry at many levels has already become familiar with the products. Increasingly, the mainstream automotive industry has looked to what has been learned by the racing industry, and has adopted and adapted the use of composites for mass production, especially CFRP. The BMW i range is of special interest, together with the mid-priced E10 track car from Zenos. These examples show how, as Antony Dodsworth has stated “the industry can expect a steady progression of design maturation as vehicles are developed to accommodate composites, not vice versa” (Dodworth cited in Sloan, 2012).

As with the aeronautic industry, composite materials are a vital factor in the search for technology that will improve fuel efficiency and therefore reduce emissions in the automotive industry. Legislation has prompted this development and further legislation, through the ELV, has forced the responsibility for increased recycling to be with the car manufacturers. Pickering (2006) noted with alarm that the response to this deadline was slow with no commercial “viable” composite recycling industry worldwide in 2006. However, governments have recognised the vast task that they have obliged the vehicle manufacturers to take on. Support in the form of information, education and networking has been made available. In the UK, the KTN and UK trade association Composites UK, Stella Job working for both organisations has used her research to provide vital information to the industry, but calls for more investment and research. Companies in the UK such as Hambleside Danelaw and Filon with their recycling techniques for GFRP and ELG Carbon Fibre in the West Midlands have been noted for their investment in this field. In Europe, Germany is acknowledged as having the most advanced commercial facilities for recycling composites. Those interviewed in the automotive industry in this report were aware of this and acknowledged that the UK must improve its position.

Several global brands have made partnerships to advance their development in this field. Their motivation initially may not have been 'green', but simply to comply with legislation. The marine industry may have been more willing to take up the use of composites initially. However, the automotive industry has made more progress in the use of recycled composites. There is a need for further research and investment, as the use of composites is set to increase.