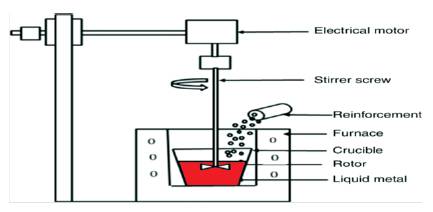

Figure 1. Stir Casting Setup

Aluminium matrix composites are widely used in various advance industries like aerospace, transportation, defence, marine and auto-mobile, piston cylinder and sports, due to their better corrosion resistance, good mechanical property and high strength to weight ratio. Attention is being paid by researchers towards increasing the mechanical properties, and also to provide the attractive aesthetic appearance of the existing material by adding various reinforcement particles. Hence, in the proposed work, silicon carbide and boron carbide is considered to improve the mechanical properties like Tensile strength, hardness, wear resistance and density of the casted aluminium alloy LM6. Aluminium alloy metal matrix composites are prepared by varying the weight percentage of silicon carbide (5, 5, 7.5) and boron carbide (2, 4, 4) using stir casting technique, which is the simple and economical method. When vortex is generated by the stirrer, on the centre of the liquid matrix in the furnace, 220 mesh of boron carbide and 240 mesh size of silicon carbide particle are added on the matrix. Casted Aluminium metal matrix composite has to be tested to find the various mechanical properties. Brinell hardness tester is used to evaluate the bonding strength between reinforcement and the matrix, with 10 mm diameter of steel ball indenter. Atomic force microscopy is used to know the distribution of reinforcement in the matrix.

In recent years, Aluminium Matrix Composite (AMC) replaces conventional material for large number of industrial applications such as Aerospace Engineering, Automobile industries, Marine and Defence application, due to its excellent mechanical property. Several methods like stir casting method [1,2], squeeze casting [3], spray codeposition, powder metallurgy [4], friction stir process [5], resin transfer moulding [6], etc., have been implemented by researchers, to enhance the mechanical properties like tensile strength, hardness, impact test and wear resistance and, distribution of reinforcement in the AMC have been seen by Atomic Force Microscopy (AFM). However, the stir casting method is paid attention, due to its cost effective technique. The Stir casting method is widely used for fabrication of molten metal and reinforcement particle. In this experiment, Silicon carbide [7] and Boron carbide are used as the reinforcement for making the composite. Due to the hardness and low density, there is an increased weight to strength ratio. Fly ash is mixed with aluminium and magnesium alloys to produce a new type of MMC called syntactic foams or Ash alloys [5]. Fly ashes reduce the density and amount of waste product in a industry. When reinforced particle size decreases to Nanometer range, the mechanical and tribological property of the metal matrix composite increases [8].

Several research papers analyze the effect of various reinforcements like alumina, silicon carbide, graphite, fly ash, coconut ash, boron carbide, epoxy, polyester, etc., their size and volume fraction and, ageing behaviour with Al based MMC. Researchers used different methods to fabricate the material, like stir casting, powder metallurgy, friction stir, resin transfer moulding, novel ultrasonic cavitation, squeeze casting, electromagnetic stir casting, etc.

Alaneme and Aluko (2012) [9] casted Al 6063 with 3, 6, 9 and 12 volume percentage of SiC composite prepared by double stir casting method, which is subjected to age hardening treatment for 3 hours at 180oC. Kala et al. (2014) [10] studied about the mechanical properties like Tensile test, hardness test, wear test, SEM and impact test. Various alloys of aluminium matrix were used as the matrix of the composite like Al6061, Al6063, Al356, LM25, etc. Kulkarni et al. (2014) [1] researched on the aluminium matrix composite and stated that the reinforcement mix in the aluminium matrix increased the mechanical property, chemical property and the physical property. Suresh et al. (2013) [11] have taken glass fibre as the base matrix, and Al2 O3 -SiC as the reinforcement composite. Poovazhagan et al. (2013) [12] worked on AMC 6061 composite, where the composite is made by aluminium 6061 alloy, SiC and B4 C were chosen as the reinforcement. Srinivasu et al. (2014) [5] investigated SiC, with B4 C powder as reinforcement and chose as the base matrix. Wear test, SEM were used to characterise the metal matrix composite. Ramanath et al. [7] mixed B4 C and SiC particles with aluminium alloy LM-25, which is used as a base material to improve tensile test, flexural test, impact test, and compression test of the metal matrix composite. Kumar et al. (2013) [13] used Al356 as the base matrix, Al2 O3 as the reinforcement with various wt% of 2%, 4%, 6% and 8%. Electromagnetic stir casting method is used to fabricate the aluminium alloy Al356 and Al2 O3 . J. Jebeen Moses et al. (2014) [14] have taken various percentages of 0%, 5%, 10%, and 15% of Silicon carbide particle with AA6061 aluminium alloy as the base matrix, by stir casting method. Micro-structure of the composite has been seen by SEM. Rahman et al. (2014) [15] made metal matrix composite using stir casting method. Rajkumar et al. (2014) [16] have taken Boron carbide and graphite as reinforcement of the composite and Al-6061 as the base matrix, by stir casting method.

In this experimental work preparing metal-matrix composite, aluminium alloy (LM 6) is used as the base material, silicon carbide and boron carbide are used as the reinforcements in powder form, having 240 and 220 mesh size respectively. Aluminium alloy (LM6) ingot is cut into small pieces of 10×4×3 cm; so that it can be easily placed in graphite crucible for melting.

Silicon Carbide is made by combining silicon and carbon, its chemical formula is SiC, also known as carborandum. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics that are widely used in applications requiring high endurance, such as car brakes, car clutches and ceramic plates in bulletproof vests.

Boron Carbide is the one of the third hardest material in the universe after diamond and boron nitride, whose chemical formula is B4 C. Due to its rhombohedra structure, B4 C is hard. Boron carbide has stability to ionizing radiation. It has toughness similar to diamond, it is difficult to sinter to high relative densities without the use of sintering aids. Boron carbide power has been prepared by reacting carbon with B2 O3 in an electric arc furnace, through carbo thermal or by gas phase reaction.

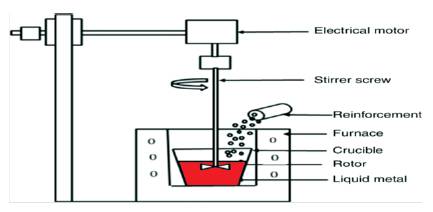

Schematic view of stir casting set-up is shown in Figure 1. Aluminium alloy LM-6 was melted in a graphite crucible by heating in a muffle furnace in 750oC for two hours. 220 mesh of Boron carbide and 240 mesh of Silicon carbide particles are preheated in graphite crucible for one hour to make their surfaces oxidised. The furnace temperature was raised above melting point temperature of aluminium alloy LM-6 about 700o C, to melt the alloy completely. Automatic stirring was rotated with the help of an electric motor. When stirrer was rotated at 300 rpm, vortex is generated in the aluminium matrix alloy. At that time, SiC and B4 C particles are added on the vortex of the molten metal, where stirrer was rotated at a temperature of about 700o C. After stirring process, molten sample was poured in to the die cavity. Diameter and length of the die is 25 mm and 220 mm respectively. The presence of reinforcement in the prepared sample was inspected by a cutting sample at different positions under atomic force microscopic examination. Compositions of prepared sample are shown in Figure 2. Chemical composition of the metal matrix alloy of the prepared sample are shown in Table 1.

Figure 1. Stir Casting Setup

Figure 2. Casted Specimen

Table 1. Chemical Composition of Metal Matrix Alloy

Following steps were involved after sample preparation.

In this section, results of the experimental value are discussed and the figures and tables are shown for every experimental value.

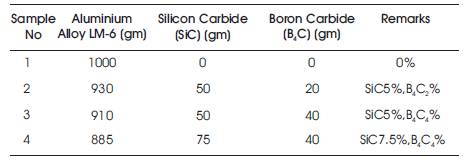

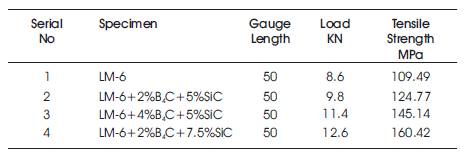

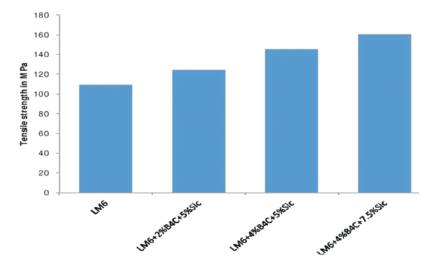

Prepared specimens are tested on the universal testing machine and the observed experimental values are tabulated in Table 2. It can be seen that while increasing the reinforcement particle, tensile strength increases. The bar graph of experimental value and the broken specimen are depicted in Figure 3 and Figure 4 respectively. The vertical axis represents the value of tensile strength in Mpa and horizontal axis represents the composition of metal matrix composite.

Table 2. Experimental Values of Tensile Test

Figure 3. Graph of Tensile Strength

Figure 4. Specimen after Tensile Test

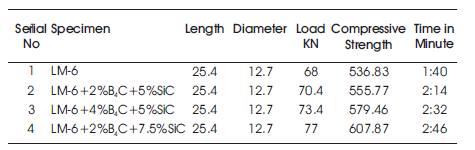

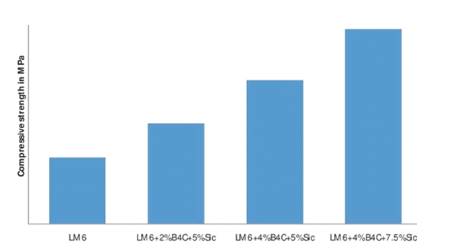

Prepared specimens are tested on the universal testing machine and the observed experimental values are tabulated in Table 3, it can be seen that, with increasing reinforcement value, particle compressive strength also increases. The bar graph of experimental value and the broken specimen are depicted in Figure 5 and Figure 6 respectively. The vertical axis represents the value of compressive strength in Mpa and horizontal axis represents the composition of metal matrix composite.

Table 3. Experimental Values of Compression Test

Figure 5. Graph of Compression Test

Figure 6. Specimen after Compression Test

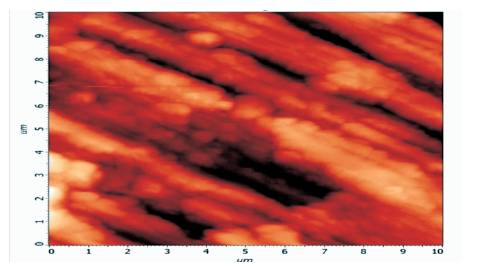

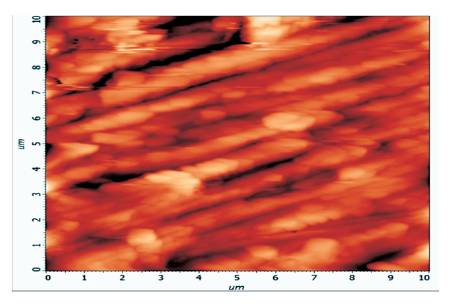

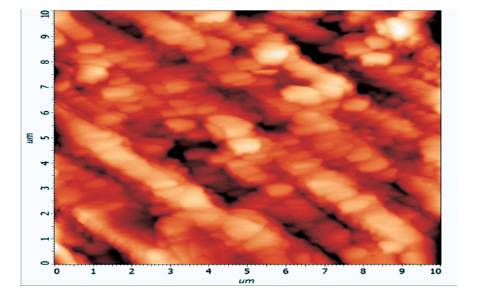

Microstructure was visualised with the help of Atomic Force Microscopy (AFM). The specimen were visualised on different magnification to show the presence of reinforcement and its distribution on the metal matrix. The microstructures of the entire sample are shown in Figures 7, 8 and 9. They are presented with the micro photograph of cast LM-6, SiC and B4C composite respectively. From these figures, it can be observed that, distributions of reinforcement in the respective matrix are uniformly distributed. The micrograph clearly reveals that the increased filler content in the composites; cracks are also seen in the microstructure.

Figure 7. Microstructure of LM-6+2% B4 C+5% SiC

Figure 8. Microstructure of LM-6+4% B4 C+5% SiC

Figure 9. Microstructure of LM-6+4% B4 C +7.5% SiC

In this research, an attempt has been made to fabricate AMC using stir casting method. The various steps related to the method have been established and test has been carried out to know the property and structure of the distribution of the reinforcement in the matrix. The conclusions drawn from the present investigation are as follows:-