Composites are becoming more and more important as it can help in improving the quality of life. Now-a-days, composites are used in aeronautics, automobiles, boats, pipelines, buildings, roads, bridges, and dozens of other products. Researchers are finding ways to improve the qualities of composites so that they may be strong, lightweight, long-lasting, and inexpensive to produce. But the main factor which plays a major role in use of composites, is the cost of matrix and reinforcement. This paper provides information about easy availability of fibres, by-products and wastes from industries, technical properties and their potential for utilization in development and use of fibres’ composites materials in civil engineering field and construction industries. The matrix (Prime) material alone cannot achieve the good properties of composites. The focus is also kept in developing and making available, durable and reliable at reasonably minimum competitive price or cost.

From the time immemorial i.e. evolution of civilization mankind has been familiar with composite materials in the field of Civil Engineering. With the development and requirements in properties, it insists more research and development towards new materials. In Civil Engineering applications, materials used for structures are characterized by low creep as expected when the structure must resist significant permanent loads (Burgoyne, 1997). In case of conditions where conventional construction materials fail to work efficiently, there composite materials can be used. Researches, have proved the effectiveness of these materials in high elevated temperature zones, moisture prone areas, sea water or harbor shore structures, high pressure areas, high strength and light weight combinations, high rise buildings ,bridge decks, floorings etc. Therefore, the use of composite materials is widespread in all areas of engineering such as mechanical, automobile, aviations, sports, wind energy, costal structures, and Civil Engineering. For more structural applications, high stiffness fibres i.e. carbon, glass, aramid and polyesters are used but high strength is obtained at high cost. Therefore locally available natural fibres and by products have been advocated in this paper.

But now due to strong emphasis on environmental awareness, much attention has been brought in the development of recyclable and environmentally sustainable composite materials which are generated at considerable interests in low costs and which can be prepared from wastage or by-products. Also, use of natural fibers (hemp, Grewia optiva, sisal, jute, bagasse) in composites help in reducing carbon emission which is economically and ecologically beneficial. Various studies show that composites are light weight, eco friendly and are locally available and reusable (Nguong, Lee & Sujan, 2013).

During the last five decades, various composite materials are being researched and developed by various researchers, using different combinations of polymer matrix (poly propylene, poly ethylene, polyester, vinyl ester, epoxy and PLA etc) and fibres (glass, aramid, carbon, etc.). The matrix constituents of composite materials are not locally available but has to be obtained from industries. But in case of reinforcement, if we use by-products or wastes of industries or locally available fibers, then considerable savings can be achieved. These materials are proved to be renewable, sustainable and hence considerably reduce the environmental related problems (Huda, Drzal, Mohanty & Mishra, 2005).

Locally available fibres and by products can be classified in to three categories as given under:

Main species of natural fibers are available in Uttarakhand, India.

Some major species which are available in the state of Uttarakhand, are listed below:

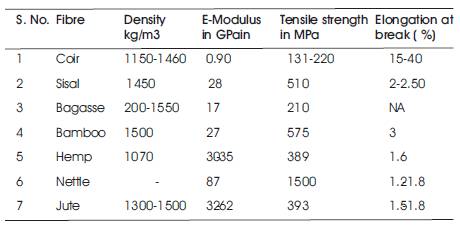

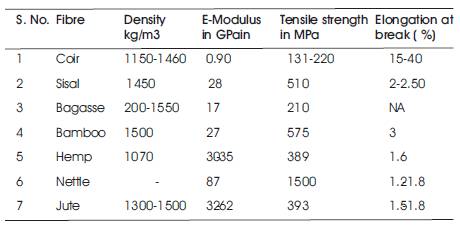

Table 1 shows various mechanical properties of locally available natural fibers, which are quite comparable with the synthetic fibers.

Table 1. Properties of some locally available natural fibers (Bajpai, Singh & Madaan, 2012)

In the state of Uttrakhand, Uttarakhand Bamboo and Fibre Development Board (UBFDB) and Women Development Board (WDB) at Dehradun are carrying out research work in the field of locally available fibres and coordinating with various engineering colleges and IITs. These fibres can be used for manufacturing of various civil engineering construction components like door, windows, panels, frames, furnitures, fibre boards, and sports goods. Even these can be developed as alternatives to wood and timbers also. It is an emerging field in which research works are being carried out extensively (Zini and Scandola, 2011).

By the use of by-products or waste materials, ecological degradation can be checked which is a global arising problem. The use of locally available wastes can minimize the dumping areas as well as the health problems associated with such materials. Industrial wastes or byproducts which can be used for the development of composites are mentioned below.

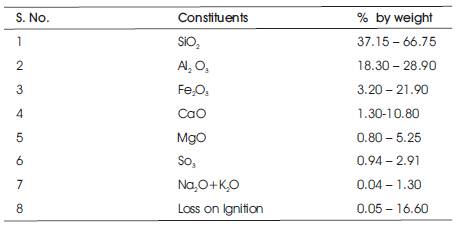

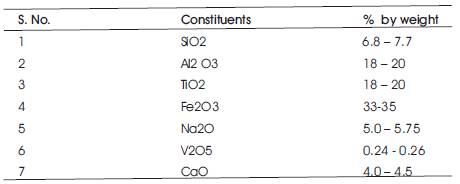

Fly AshThese are obtained as by-products from thermal power stations. They can be used for manufacturing of Portland pozzolana cement by using 15-35 % of fly ash. Cement concrete lime fly ash mortar, cellular concrete, bricks and tiles, are being used now-a-days for stabilized work. These are considered best because of its engineering and mechanical properties. Table 2 shows the major constituents of fly ash.

Table 2. Constituents of Indian Fly Ash (BMTPC)

These are obtained from the glass and ceramics industries as by-product. They can be used for the manufacturing of insulating bricks and tiles, decorative panels, flooring and roofing tiles etc.

Gypsum by-productsThese are obtained from ammonium phosphate fertilizer, hydrofluoric acid and boric acid factories as by-product. It can be used as a replacement for gypsum in making fibrous plaster boards, blocks, composite mortar etc.

Rice HuskInorganic ashes of plants like rice husk are good source of silica, having good binding properties. It is obtained after incineration of rice husk type materials. These materials are used for manufacturing of pozzolana cement, replacement for natural or clay pozzolana, bricks and manufacturing of lime pozzolana composites.

Metal Alloy WastesThe wastes obtained from metals and alloy industries can be reused as masonary cement composites, cement concrete replacing natural aggregate and cementious binder.

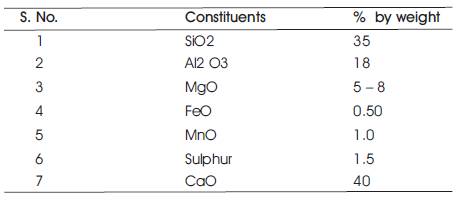

Blast Furnace SlagThese are obtained from the manufacturing of steel as by product. It is of three types:

Table 3 shows the major constituents of blast furnace slag. The use of this by product is in replacement of aggregate in concrete as well as in light weight aggregate. Now-a-days blast furnace slag cement is also being manufactured by using this.

Table 3. Constituents of Blast Furnace Slag (BMTPC)

It is obtained as by product from sugar, paper, acetylenes and tannery industries. After calcinations it can be used in composite mortar, plaster and lime pozzolana composites.

Vermiculate Mica and Slate WastesIt is obtained as by product from the mining of by-product of ibid materials. After calcinations, it can be used in light weight composite mortar, plaster and lime pozzolana composites.

Red MudIt is obtained as by product from aluminum industries. It can be used for blended cement, bricks tiles compositions and fiber reinforced panel productions. Table 4 shows the major constituents of Red Mud

These are obtained by the beneficiation of Zinc, Copper, Iron, Gold, Bauxite ores and minerals. These can be used for replacement in composite mortar, concrete, masonry, cellular concrete, sand lime bricks instead of sand.

Laterite WastesThese are obtained as by-product from the cutting and dressing of laterite block industries. These can be used for stabilized laterite bricks/blocks using cement or lime as binder and fibers as reinforcement.

Following commercial products are available in the market and are still in developing stages. Lots of research works have been carried out in the field of composites by using locally available by-products, wastes and natural fiber reinforced composites. These are less costly, light-weight and so problems related to their disposal will also be minimized, as these are biodegradable in nature. They will prove to be sustainable and renewable materials in the field of civil engineering materials. (Faruk, Bledzki, Fink and Sen, 2012).

Bagasse Board

These are manufactured by using waste from sugar industries and resins. Wall panels, false ceiling, door, windows shutters, furniture, flooring and light weight partition walls are being manufactured (Mishra, 2009).

Coir CompositesThe coir fibres are obtained from the coconut fruit. Fibres are very strong and used with polymers for the manufacturing of wall panels, false ceiling, partitions, and roofing boards.

Rice Husk BoardsRice husk is used with synthetic resin. These are used for manufacturing of Wall panels, false ceiling, flooring, roofing, light weight partition walls and door windows shutters.

Jute, Red Mud and PVC RoofingRed mud is used with PVC and jute fibers for manufacturing roofing sheets, panels etc. These are strong enough, cheaper, and efficient and serve as good construction material.

Stramit BoardThese are manufactured by using dry un-pulped straw and paper. These are light in weight and can be used for manufacturing roofing, cladding, wall panels, false ceiling and light weight partition walls.

MDFB (Medium Density Fiber Boards)For manufacturing of MDFB wood fibers, cotton plain scantlings and resins are used. The applications of these boards are for door windows shutters and frames, furniture,

Cement bonded Particle BoardsFor manufacturing of Cement bonded particle boards cement is used as binder and wood like eucalyptus, casurine are used as fibrous materials. These are used for manufacturing of wall panels, false ceiling, door windows shutters, furniture, flooring, light weight partition walls, roofing and linings etc.

Polyester Jute Fiber BoardPolyester is used as matrix material and jute fibers are used as reinforcement for manufacturing of the boards. It has good strength and light weight when compared to other materials.

Bitumen, Paper pulp or FibersBitumen is used as matrix material and paper pulp or fibers are used as reinforcement. These are used for the manufacturing of corrugation roofing sheets and packing sheets/boards. The bitumen has certain environmental associated problems, therefore it is not widely used.

Polyester, Red Mud, Sisal and Glass Fiber SheetsSisal is easily available and used as fibers, where as polyester is used as matrix. Red mud acts as filler material and glass fibers improves the strength of the sheets. As by products have been used for the manufacturing of sheets, they reduce the dumping area problems and environmental degradation also. So they are used for making panels, tiles and roofing, flooring sheets.

These are being manufactured by using waste fibres 5 %, cement 65% and fly ash 30%. The use of these boards is recognised for roofing, partition and panels. Everest roofing Ltd. Bombay is successfully manufacturing it.

Fiber Reinforced Phosphor Gypsum CompositesFor manufacturing fibre reinforced phospho-gypsum composites, coir or glass fibres are used with purified phosphor gypsum plaster’s. It is Successfully used for walling, roofing panels and blocks. M/s IDL Salzban, Vishakhapattanam is manufacturing these composites commercially in India.

ELatomation Bonding PlantThis technology is used for manufacturing cement/polymer bonded boards. These products can be used for roofing sheets, panels, partition, door/window frames and shutters. They are commercially manufactured by Synergy International Ltd., New Delhi.

Fly Ash Red Mud Polymer CompositesPolyester polymer is used with fly ash and red mud. Composites are successfully used for manufacturing of door shutters. These are commercially being produced by M/s Dual build Tech (P) Ltd., Chennai.

Fly Ash Cellular ConcreteFly ash cement/lime, gypsum and aluminium powder is used for making this concrete. Due to air entraining in the concrete, mass cells are produced, it is light weight and stronger too. It can be used for the manufacturing of slabs and blocks for prefabricated components. These are commercially being manufactured by Ballarpur Industries Ltd.

Cement Fly Ash BlocksFly ash is a by-product of the thermal power stations having active silica that can be used with cement for manufacturing cement fly ash blocks. 80-90% fly ash and 10-20% cement is mixed. These can be used for walling, foundation etc. Gujrat Electricity Board Fly Ash company, Ahmadabad is manufacturing it successfully.

Fly Ash lime Gypsum Blocks (FAL-G)The combination of fly ash, lime and gypsum can be used for the making of blocks or bricks of medium strength. Fly ash 60%, lime 10-20%, gypsum 10-20% is used. M/s Bhadrachalam Paper Board (AP) is producing it successfully.

Clay Fly Ash BlocksThe combination of clay 60-65%and fly ash 35-45% is used for making blocks. These blocks can be replaced by brick blocks. It is being manufactured by Calcutta Mech. Bricks Pvt. Ltd. Kolkata successfully.

Sand lime Fly Ash BlocksThe combination of fly ash 70%, sand 10-20% and lime 7- 10% is used for the making of these blocks. These blocks can be replaced by brick blocks. It is being manufactured by Pulver Ash Ltd., Bundel West Bengal.

Fly Ash lime and Sand Lime BricksThese are aesthetically good and have improved appearance. These are white coloured brick blocks and hollow blocks can also be manufactured by using sand 90%, lime 10% or fly ash 60-70%, lime 30-40%. It is being manufactured by Sand Plast India (P) Ltd. Behror, Alwar, Rajasthan.

As composite is an emerging field in the construction industry, different types and kinds of processing equipment and testing devices are necessary for research, development and manufacturing of natural fiber composites. Following Instruments, Equipment and devices are required for the fiber extraction and processing purpose.

For conducting various tests and checking suitability and integrity of fibers, following are the equipments required for testing.

FRP (Fibre-Reinforced Plastic) composites are advanced and have tailor made properties, strength and performance. Innovation and, development by the use of FRP for construction work is an emerging field in the area of civil engineering. Special emphasis has risen for the improvement of the performance, serviceability, durability and long lasting of composites over other materials of constructions i.e. concrete, bricks, steel, wood etc.(Benmokrane,2001). FRP composites can be utilized in infrastructure development, construction and structural retro-fitting also (Singh, Chandel, Nayak, and Bhatnagar 2004).

Civil engineers have used FRP widely in the area of construction. Bridges, columns, Girders etc. are constructed by using FRP, which has proved to be highly durable and have good performance with limited or lesser repair and maintenance work (Tang & Podolny, 1998). Also for long term use, they have been proved as economical and sustainable. FRP is widely used in Europe and Japan for the following purposes: (Hiel, 2001)

Some major practical applications of fiber composites are mentioned below:

FRP has revolutionized the highway bridge construction Industry (Tang & Podolny, 1998). FRP Bridge deck, stringers, beam, abutment panel, reinforcement bars, dowels and post, columns etc are used widely after satisfactory performance evaluation (Griffith, 2000). Their use can be broadened by the manufacturing of ready to use pipe culverts, small span culverts i.e. up to 3.0m span, sound barriers, guardrails, sign post and boards. Research shows that its ultimate strength has increased 6 times and cost has decreased 3 times since 20 years of innovation (FHWA publication, 2001).

Example

Goat Farm Bridge with FRP deck Wirt country, West Virginia pleasant plain Road Bridge. Montgomery county Ohio, Market Street Bridge with FRP deck built in 2000 Wheeling in West Virginia.

FRP pavements are the latest application of composite materials. Constructed Facilities Centre at West Virginia University have researched, developed and evaluated FRP pavements. Bakers Ridge road near University High School Morgan town, West Virginia USA is the first to field evaluated GFRC composite panels for road pavement application (July 2009) Modular pavements of required specific size have been developed and proved to be efficient, time saving and durable in operation.

Example

Route 9 West Virginia Martinsburg. FRP rebar Elkins corridor H project WV.

Initially utility poles were made up of iron, pre-stressed concrete and wood. FRP utility poles are free from corrosion, non conductor, ductile, light weight and easily installable. These properties have made FRP utility poles as an alternate to iron, pre-stressed, concrete and wood poles. Wood is costly and deterioration in it is possible due to rot, decay and adverse effects of environment. Since Iron poles are conductor so also costly is is not advisable. PSC poles are heavy weight and are not portable. The use of FRP poles for electrical and telecommunication is a boon. In US, 130 million utility poles are in service. New installation and replacement market is around $ 4 Billion/year (Hiel, 2001)

Pipe lines are used in transportation for sewer, oil, gas, water and petroleum. These are badly affected by corrosion and puncture due to heavy loads. The transportation proves costly and the corroded pipes require replacement at certain intervals. In US 161189 miles of liquid fuel pipe lines and, 307809 miles natural gas transmission pipe lines are available (US Dot office pipe line safety statistics). These are made of steel and have corrosion problems. On Sept 9, 2010 in San Bruno CA, USA 4 people were killed in pipelines accident. Also hundreds of homes were burned which caused damages to hundreds of millions of dollars, the reason being old corrosion pipe only. The pipeline industry is also searching substitute in FRP so that they will prove reliable, safe, and cheaper than steel pipes with longer life and low cost.

Example: Polyurethane based pipes of 16 inch diameter is being tested in West Virginia, USA.

One of the renewable sources of energy is wind energy. It is a non conventional source of energy. Turbines are rotated by the use of huge blades. Global wind power market has over 155% yearly growth and have reached 240 GW installed in USA. (Liang and Hota, 2009). Blades of turbines are successfully made of composite applications which is rapidly growing. Researchers are working for innovation of producing quality blades at minimum cost to reduce the cost of power generation.

FRP is successfully used with high durability. Chemicals are corrosion prone for steel containers but FRP has solved this problem and has over come this, and handled with underground tank Pang, Miao, Yang and Zhang, 2011).

Example

Sugar industries, chemical, petroleum industries., acid manufacturing units and molasses storages etc.

In thermal plants where high rise chimneys are used to exhaust hot gases generated from coal combustions, FRP liners have been used successfully. FRP liners make them efficient and environmentally eco-friendly.

Example

International chimney is installed in FRP lines at Fort martin power plant near Morgan town USA. The plant has 60' diameter and 529' highly reinforced concrete chimney that takes about two rows of 400' tall FRP liners 25' diameters and 31' high.

Pre engineered, prefab houses have completely changed the direction of housing industries. Conventional housing requires bricks, concrete, sand, aggregate, timber, steel etc., but in the case of prefab houses, all components are manufactured in factory and assembled within a short period at site. FRP is being used for panels, windows, doors, walling, roofing sheet and complete hutment too. Watch tower, hut, canopy, dome shaded houses are readily available. They have the following benefits:

FRP prefab houses are suitable for military operations in adverse climatic conditions and in disaster prone areas. Example: Greenhouse, ware house, army huts and watching towers, school, office, dormitory, remote location, disaster affected areas etc.

FRP has revolutionized the construction industries and structure associated with harbour, dock and sea shore. They have been associated with problem of saline water whereas FRP is successful in such adverse condition. They can be used effectively for main decks, pipe, post, bridge, fenders, docking system, boat/ship hulls, piles etc.(Nanni, 1999)

US Navy has developed an advanced destroyer DDG1000 ZUMWALT class (LeGault, 2010). It has been designed to work in both sea and land missions. It is featured with a “Tumble home” wave piercing hull and upper section deckhouse made of FRP sandwich composite. Hull shape and composite deckhouse reduces the radar cross section and foot print.

Damages to infrastructure due to aging, natural calamities i.e. earthquake, flood, hurricane etc, fire and, corrosion of steel, retrofitting/strengthening is required. Nearly 575600 highways in USA are structurally deficient. It is not possible to replace them easily. Hence new material is required which can serve as “Band Aid” (Codispoti & Oliveira,2013).

FRP wraps have been proved to be a boon in such situations. Advantages associated with them are

Example

Damaged piles of 11 temper rail road bridge on South

Branch Valley Railroad (SRVR) lines in Moorefield were

rapidly rehabilitated and restored in site without affecting

the rail. With the use of GFRP (in July 2010), timber Bridge

Span 75 feet to 1200 feet with timber pile bent spaced 15-

20 feet apart. Deteriorated piles were cracked, heart rotted

and damaged. Service life was increased by use of FRP

retrofitting solutions (Meier, 1995).

In RCC structures, insufficient cover to reinforcement, poor design practices and presence of large amount of aggressive agents lead to cracking of concrete and simultaneously corrosion to steel reinforcement bars. FRP rebars are good replacement to the steel reinforcement bars (Matthys, De Schutter &. Taerwe, 1996) (Gerritse,1996) (Ku, Wang, Pattarachaiyakoop and Trada, 2007). The features and benefits of rebars are mentioned below:

FRP has many advantages and properties which keep them as leaders in innovative construction material race. The Architect/Designer can think of special shapes and sizes, aesthetic structural forms which are not possible by cement concrete or brick and other conventional materials (Misseler, 1993),

Main advantages of composites in this area are:

These are new concepts for sustainable dwellings. Green building consumes less energy and produces less wastes. These are energy efficient and eco friendly in nature having zero carbon footprint. By the help of FRP composites, green construction materials which have zero impact on environment can be developed, and innovated for sustainability (Liang and Hota, 2009). Living wall concept with flow channel and phase change materials are also being researched by many teams at University of Colorado at Boulder, USA. By the use of FRP composites durable, strong, stiff composites panels made of natural fibers and natural resins can be developed.

These are the latest invention in the line of FRP composites. These types of composites can be developed, but were only in dreams previously (Burgoyne, 1999). Phase changing materials for energy storage and release, conductive polymers for solar cells, protective selfcleaning material, de-polluting coatings, self deicing, self assessing materials, self healing materials, coating sensors. Coating composed of nano fibers can be used as sensors, to detect microwaves, fire and hazardous chemicals. Electrically conductive coating in conjunction with wireless network is being developed to detect fire and other structural hazards.

The following challenges are being faced by the use of composites in the civil engineering and infrastructure industries. The wide use of composites can be feasible in the infrastructure industries if it overcomes the following problems (Kim and Seo, 2006 & Mukherjee & Kao, 2011).

Although the FRP composites are being used successfully in Japan and European countries, it is still not widely recognized. An FRP composite poses challenge in developing standards and regulations. Lots of work have been made but some are void. ACI (American Concrete Institute), many federal and state government agencies have developed design and construction specification for composites rebars, wraps for strengthening (ACI 440.IR03 and AASTHO LRFD Bridge design Guide). Recently new design code “Pre Standard For Load and Resistance Factor Design (LRFD) of pultruded Fiber Reinforce Polymer (FRP) structures” was launched by American Composites Manufactures Association (ACMA) and American Society of Civil Engineers (ASCE).The code allows Engineers and Architects to use FRP composites in construction work for stronger, safe and better works. Other codes and specifications are in developing stages.

The use of FRP composite materials in sustainable construction work has bright future. Locally available industrial waste, by-product, fibers can be selected and their potential can be assessed (Mishra, Nayak, and Satapathy, 2010). Being a new emerging field, research institute and production units' liaison is necessary. There is wide scope in infrastructure area of FRP composites as new construction of bridges, deck, pre fabricated hut, reinforced bars and amazing smart materials.

The challenges in this field is lack of standardization and hesitation of using of FRP but with their uniqueness and tailor made properties, they could emerge as a new wonder smart material and can substitute/alter conventional construction materials. Also, we can say that coming decades are composite material decades.