Figure 1. Demand & Supply Dynamics.

Sustainable marketing strategies get pruned in the shadow of uncertainties in the supply chain. We need to identify the causes for such uncertainties and minimize their impact on sustainability. With the objectives of identifying major factors of uncertainties in supply chain and assessing their impact on green logistics, this analytical library research is based on published data. Making logistics 'sustainable' in the longer term will involve more than cutting carbon emissions. Sustainability is a combination of Technology & Ecology. Green logistics pivots on a set of key parameters for logistical decision making at different levels. Supply chain uncertainties are found to be can be mitigated through Ascertaining Actual Demand, Synergizing Information, Cascading Forecasting, Leveraging Leverages, Bulldozer Wheeling, Consumer Involved Design and Mass Customization. Collective Green Consciousness Quotient indicates how an organization is consciously practicing green practices. Consumers as responsible world citizens must be Green House Gas conscious and thereby necessitate business too falling in line because sustainability is truly a collective bargain.

We need to have a shared commitment to developing an eco supply chain and we need to continuously reduce emissions (Swanepoel, 2010). A major inhibitor to supply chain customer value delivery is uncertainty (Davis, 1993), which yields increased total operational costs. Traditionally, the focus of managing uncertainty has been on manufacturing operations transport operations (Rodrigues, Stantchev, Potter, Naim, & Whiteing, 2007). The factors that govern supply chain uncertainty are important for supply chain management (Lee & Billington, 1993). Uncertain factors cause to generate any unstable processes along supply chains, and then also reduce supply chain performance. Some sources of uncertainty of agri-food supply chains are distinct from general supply chains such as variable harvest and production yields, and a huge impact of climate conditions. Companies know that reducing the environmental impact of their supply chains saves their organization money, costs and resources, not to mention being good for the planet (enviance.com, 2012).

It has been suggested that competition is no longer between companies but supply chains, which is being driven by cost pressures, increased consumer choice and shortening product life cycles. The conclusion is supported by the above reviewed researches: the number of researches in this area, of which with cost measurement. In the last ten year, because of the increasing of diversity in customer preference, the saturation of market, the subject of uncertainty in customer demand get more attention.

The need to change the way of regarding demand as deterministic to uncertainty is a good way for the modern organization to survive in today's environment. Such requirement is especially unavoidable in some situations like late product individualization proposed in when customer requirements are more difficult to catch. That is why Li and Schulze mentioned with emphasis of considering uncertainty in their further research of logistics network design for late auto individualization.

Supply Chain Management as an independent field was originated from Marketing and Strategic Management (Sanchez Rodrigues, 2006). The Council of Logistics Management defines Supply Chain Management as the strategic coordination of the core functions and tactics across these functions within a specific organization and across its partners within the supply chain for the purposes of improving the long-term performance of the individual organizations and the supply chain as a whole. This definition recognizes the strategic nature of coordination between trading partners and to explain the dual purpose of Supply Chain Management: to improve the performance of an individual organization and to improve the performance of the whole supply chain (Li, Nathan, Nathan, & Rao, 2006).

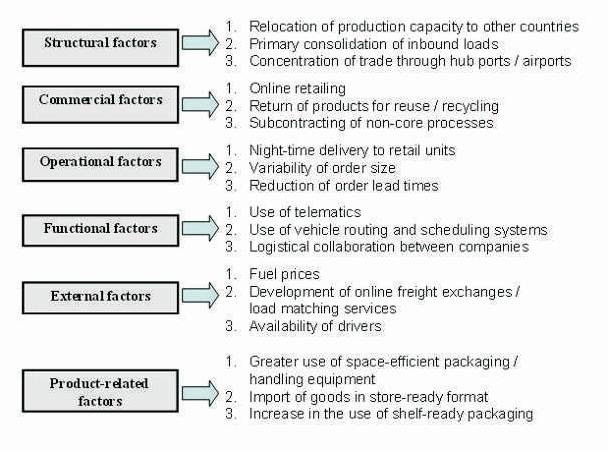

Regarding to green logistics, these three factors affect the performance of transport providers that are directly and indirectly linked to supply chains (Sanchez Rodrigues, 2006). Geographical dispersion has a direct impact on the economic and environmental performance of the supply chain, since the more geographical dispersed is the supply chain, likely the highest will be the external and internal costs of transport (Sanchez Rodrigues, 2006). However, there should be ways of mitigating that negative impact of geographical dispersion on the sustainable performance of supply chain and transport, such as the horizontal and vertical integration of transport flows, so logistics integration is the third but not least important factor, which according to (Stock, Greis, & Kasarda, 2000), have a considerable impact on supply-chain performance. Refer to Figure 1.

Figure 1. Demand & Supply Dynamics.

Gartner's predictions (Log India, 2012) for global logistics organizations in 2016 include:

According to World Bank's latest survey on trade logistics, Singapore is the top performer among the 155 economies included in the Logistics Performance Indicators (LPI) which are part of the “Connecting to Compete 2012 Trade Logistics in the Global Economy” report (Log India, 2012).

In India, supply chain expertise is not as matured as is the case in other markets (Baum, 2012). There is higher degree of inefficiency in Indian road transportation which has got huge cost implications for the economy, another loss being excessive fuel consumption.

Every citizen of this world is socially responsible for passing on the mother earth to the next generation as worth living on. We need to limit depletion of natural resources while minimizing damage or pollution of the atmosphere. Organizations do attempt green practices in most of their operations especially in marketing but supply chain uncertainties hamper such noble objectives. Sustainable marketing strategies get pruned in the shadow of uncertainties in the supply chain. Thus there emerges an inherent need to identify the causes for such uncertainties and minimize their impact on sustainability.

This analytical library research is based on analysis of historical records and documents. The secondary data collected from journals, magazines, websites and printed materials is compiled, linked and related for achieving the research objectives.

Uncertainty is the “unpredictability of environmental or organizational variables that have an impact on corporate performance” (Miller, 1993). Definition of environmental uncertainty in organisation theory summarised by (Milliken, 1987) are “an inability to assign probability as to the likelihood of future events, a lack of information about cause-effect relationship, and an inability to predict accurately what the outcomes of a decision might be” (Duncan, 1972). Environmental uncertainty is “an individual's perceived inability to predict something accurately” (Milliken, 1987). Components of external environment in organisation perspectives are customers, suppliers, competitors, socio politics, and technology, while internal environment are organizational personnel, functions and levels (Duncan, 1972).

Optimal deployment of current resources like vehicles, drivers, systems and continuous baseline reductions when new enabling technologies, fuels and systems propulsion become available. Five key focal areas lead to green logistics with cost savings:

We can also shorten the distance travelled especially in the last mile by having proper coordination with concerned stakeholders.

Concepts of extra distance, dead kilometres help to minimize waste run which does not add value to the customer. Equipment selection, design and optimization reduce carbon emissions. We have to use transportation technology that would reduce fuel consumption and carbon emission. Retraining of drivers would also add value in this regard.

Integrating sustainability practices throughout the supply chain can deliver tangible, economical, environmental and social benefits. Refer Figure 2.

Figure 2. Factors expected to shape logistics and supply chain structures.

There are three distinct sources of uncertainty in supply chain - supply uncertainty, process uncertainty, and demand uncertainty. Supply uncertainty is caused by the variability of supplier performance.

The final major source of uncertainty lies in customer demand. Forecasting demand is the most valuable source for the organization in production scheduling. However, there are always a gap between forecasting and reality.

With the products with limited shelf life, it could be more complicated when the products are expired. Moreover, stock out means the organization fails to satisfy their customer, and often with that, the organization loses their customers to other rivals.

It is estimated that freight transport accounts for roughly 8 per cent of energy-related CO2 emissions worldwide (Kahn & Kobayashi, 2007). The inclusion of warehousing and good handling is likely to add around 2-3 per cent to this total. Making logistics 'sustainable' in the longer term will involve more than cutting carbon emissions (McKinnon A. , 2010). Furthermore, sustainability does not only have an environmental dimension. Sustainable development was originally portrayed as the reconciliation of environmental, economic and social objectives (Brundtland Commission, 1987).

Considering stochastic parameters in an analytical supply chain model, most research can be distinguished as two primary approaches, referred as the probabilistic approach and the scenario approach.

According to Zimmermann, the choice of an appropriate uncertainty calculation may depend on: the cause of uncertainty, the availability of both quantity and quality of information, type of required information and the language required by the final observer. These measures may be categorized as either qualitative or quantitative.

Qualitative performances are the measures which cannot or are hard to model direct by numerical measurement. The qualitative performance measures can be categorized into:

Quantitative performance measures, in contrast are those measures that may be directly described numerically. They can be divided into objectives that are based on cost or profit and objectives that are based on some measure of customer responsiveness (Beamon, 1998).

(Alonso-Ayuso, Escudero, Garin, Ortuno, & Perez, 2003) defined the benefit as the product net profit over the time horizon minus the investment depreciation and operations costs. The goal of the model is to minimize the expected benefit, in which the product net price and demand are uncertain.

According to (Melo, Nickel, & Saldanha-da-Gama, 2009), the contexts are classified into: the Case study refers to a real life scenario, even if it was not implemented in practice, while the category industrial context stands for a study using randomly generated data for a specific industry.

(Tsiakis, Shah, & Pantelides, 2001) considered a European wide supply chain with three manufacturing plants in three different countries, producing 14 different types of products and sharing production resources.

In cooperation with the Norwegian Meat Cooperative, (Schütz, 2009) provided the model for the slaughter location case of Norwegian industry. Jung et al. conducted the research with a case study based on an application provided by a major US polyethylene producer has been developed to examine the performance of the framework.

In the energy industry context, (Kim, Lee, & Moon, 2008) considered modelling a hydrogen supply chain of Korea in the near future. Hydrogen is potential to become the major energy carrier in the future, thus designing logistics network for hydrogen is necessary.

In strategic logistic network design problem with random parameters, there are two main optimization approaches are appropriate to find a good solution: stochastic optimization and robust optimization.

Considering instances a logistics network model with uncertain demand, stochastic optimization will design the model with least expected cost. However, extra costs can appear with the probability of stock out.

The robust optimization is often used to tackle with problems, where no probability information is known, but the data are within certain bounds, or only known to belong to some uncertainty set; for example “-15 % average”, “average” and “+15 % average”.

(Ferretti, Zanoni, & Zavanella) designed a distribution network that has the lowest total cost under the whole set of possible demand scenarios. Two possible strategies are defined: the robust distribution network and the stable distribution network while the former minimizes the total expected costs over the scenarios and the latter minimizes the variability of the different cost components over the different scenarios.

(Butler, Ammons, & Sokol) presented a robust optimization model for strategic production and distribution planning for a new product. Only robust optimization is suitable for this problem, because of the lack of information in customer demand and cost. The variability model control the spread of the costs by adding standard deviation, variance, or other measures to the objective function.

Stochastic optimization is another method, which incorporates random data. Both stochastic and robust optimizations aim to well performance of the network under any possible realization of the uncertain parameters.

With stochastic programming, the decision maker is allowed to analyze uncertainty explicitly. All these decisions are called first stage decisions and the period when these decisions are taken is called the first stage.

The second group means that a number of decisions can be taken after the experiment. They are called second stage decisions. The corresponding period is called the second stage.

The first decision stage establishes the capacity expansion schedule for the planning horizon, while the second stage decision constitutes taking recourse actions in order to correct the failure.

The second stage therefore called “wait and see” recourse decision. A recourse decision can then be made in the second stage that compensates for any bad effects that might have been experienced as a result of the first stage decision.

At a strategic level, uncertainty can be divided in two main categories, external vulnerability and supply chain agility (Prater, Biehl, & Smith, International Supply Chain Agility - Tradeoffs Between Flexibility and Uncertainty, 2001). Therefore, it is important to determine the impact of external vulnerability and supply chain agility on green logistics performance (Sanchez Rodrigues, 2006).

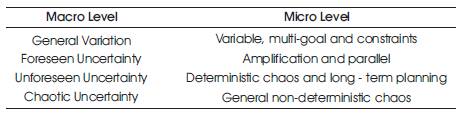

Prater, 2005 developed an uncertainty framework that can be used to determine the causes of supply chain and transport uncertainty. This framework classified uncertainty from a macro to micro level. Foreseen uncertainty is caused by amplification and parallel interactions.

Wilding, 1998 emphasised 'the importance of treating the supply chain as a complete system. Taking a supply chain and transport perspective, the impact of parallel transport providers interactions and parallel customer- transport providers interactions should be established, since it could represent a very significant source of transport uncertainty, and as a consequence, have a considerable impact on green logistics performance (Sanchez Rodrigues, 2006). Refer Figure 3:

Figure 3. Micro-level Types of Uncertainty in Supply Chains (Source: Prater, 2005)

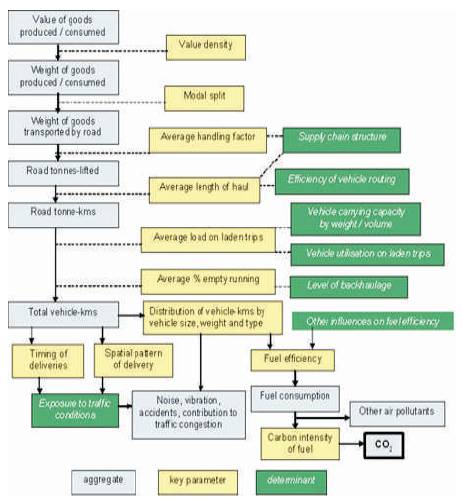

Mason-Jones & Towill, 1999 developed the uncertainty circles framework, determining the main uncertainty sources, from a manufacturing perspective, which are supply side, demand side, process, and control systems. Please refer Figure 4:

Figure 4. Framework for analysing the environmental impacts of road freight transport.

Freight and logistics related activities account for up to 15 per cent of human carbon dioxide emissions in India, the main reason being aversion towards IT applications. Majority of warehouse operators are still reluctant to opt for basic Warehouse Management Systems.

Presently, India is one of the fastest growing economies in the world and this trend is likely to continue over the next few years. Moreover, the government's policies aimed at making the Indian manufacturing industry competitive, have created enormous potential for growth of the logistics sector in India (Gosh, 2012). Major factors, which can make the supply chain more efficient and prevent losses include Warehousing (Location, Facility Design, Productivity), Inventory Management, Transportation and Adoption of IT Driven Systems besides Policy Initiatives like GST and Infrastructure.

(Source: Radhakrishna Foodland)

Situation: Multiple warehouses located in different areas getting order from a common supplier. But the trip loads were not enough to send a dedicated truck from the supplier to each warehouse, receiving on-time deliveries and food safety of the products was a challenge. This had affected the inventory holing in warehouses leading to higher inventory carrying cost, higher inventory-days, threat of stock-ou situation and in-transit damages, safety of food items in-transit and higher inbound cost. The need to transport products in a cost effective manner and ensure on-time availability without compromising on the quality, was identified.

Strategy: To ensure consolidation of stock at the nearest warehouse and move full truck loads, the following steps were taken:

Results : The results were as follows:

Logistics Technecology : Sustainability is a combination of Technology & Ecology which can be called Technecology. Jonathan Weeks, a former chairman of the UK Institute of Logistics redefined logistics as the movement of materials from the earth through production, distribution and consumption back to the earth. This incorporates the return of waste product and packaging for reuse, recycling and disposal, an activity that is now regarded as a key part of green logistics (McKinnon A. , 2010).

Green logistics is a relationship between the material outputs of an economy and the monetary value of the logistics externalities into a series of key parameters and statistical aggregates. This relationship pivots on a set of key parameters (McKinnon A. , 2010):

Modifying these parameters requires different levels of logistical decision making. (McKinnon & Woodburn, 1996) differentiated four levels:

Automobile sector is having direct impact on the environment and energy sustainability by reducing emissions for environmental protection and improving fuel efficiency of the vehicles for energy conservation (BIS, 2012). Multiple environmental aspects including noise levels, emission of green house gases, and emission of pollutants, alternate fuels, drive train efficiency, electric power sourcing and manufacturing efficiency – all contribute to developing a vehicle that could be termed as truly environmentally friendly (BIS, 2012).

Effective warehouse design means short routes for goods and staff. Using containers in conjunction with intelligent conveyor systems speed up and optimise logistics operations, resulting in faster, flexible and efficient services. The industry needs specialists and awareness for world class facilities. The problem with us is that we have a tendency of measuring everything in monetary terms. If you evaluate on the total cost basis, including reduction in manpower, you would realize that technology is playing a crucial role in ensuring smooth functioning of warehouses and storage facilities (Siddiqui, 2012). The emergence of ecommerce would surely improve the growth in this sector.

Backward linkages are imperative for an efficient supply chain. In 1989, when Pepsico launched its agribusiness, it faced a few challenges like poor quality of inputs, lower yield from farms, inadequate quantity and no modern practices in agriculture. Pepsico took these challenges head on and devised an innovative backward linkage with the farmers (Udhaye, 2012). There are several other similar successful examples from companies like Amul, Nestle, McDonald etc.

With increasingly large bulk volumes under shipment, the scope for cost reduction on the packaging front is possible. Outsourcing logistics business to third party players can help the industry to reduce logistics cost globally (Ghagardare, 2012). Companies that concentrate on their core competency can outsource their logistics business to a Logistics Service Provider (LSP) who is an expert in dealing with this business.

CGCQ is an index of how are the organization is consciously practicing green practices and this can be equivalent to a credit rating in sustainability.

CGCQ = f(x1, x2, x3, ..........xn)

where x1, x2, x3...xn are various factors influencing GHC emission.

Marketing strategies shape the logistics activities, which has got larger impact on the sustainability of environment. In fact, sustainability has got multiple dimensions like environmental, economic and social objectives. Collaborative and shared supply chain models prove to be better options.

In similar lines as value added services, socially responsible organizations and consumers shall merit GHC depleting services which is a broad based category of activities which deliberately attempt to debit the GHC credit accumulated in the process of making and delivering the product in the hands of the consumer.

There is a greater need of employing methods and techniques at the earliest to prevent potential harm to environment in future (Assocham, 2012). The following are to be given importance by the responsible organizations : Innovations, Efficient Utilization of Resources, Usage of Alternative Resources, Eco Friendly Technology and cost Reduction.

A team of educated and trained personnel can help in increasing the efficiency of the logistics system (Kohli, 2012). Multimodal transportation should be encouraged where long distance services may be provided by the railways and the last mile connectivity may be provided by the roads. More use of railways is environmental friendly (Logistics Times, 2012).

The geography of our country often poses as a major hindrance for the logistics service prodders as well as manufacturer (ASSOCHAM, 2012). Emerging technologies like Geographic Information System (GIS) is being used to improve the efficiency of operation while the product is on the move. IT too has become a boon for companies which are keen to introduce process level efficiencies and improve the entire supply chain (ASSOCHAM, 2012 ).

One of the main objectives in the optimization of a supply chain is to reduce uncertainty in order fulfilment time. Overall system performance can be improved by addressing external and internal factors that contribute to uncertainty. By using an information theoretic approach, we will be able to categorize contributions of individual elements to the uncertainty of the system and its output.