Table 1. Types of Brake Performance Tests (IS 11852. Part 3; ECE R13; Federal Motor Vehicle Safety Standards, 2005)

One of the most relevant parameters for vehicle authentication is the brake performance of the vehicle. Countries follow their own automotive standards for various components manufactured. Criteria put forth by these standards may vary accordingly. The key brake performance parameters considered are its stopping distance, deceleration, and stopping time. This article delivers a comparative study on three brake testing standards: Indian Standard, European Economic Commission, and Federal Motor Vehicle Safety Standards. The article provides an outline to brake testing procedure of service, secondary and parking brakes of automobiles with four or more wheels without trailer. Parameters like Mean Fully Developed Deceleration (MFDD) and Stopping Distance are discussed in detail. Tests prescribed by the three standards like P type test, F type test, H type test, and Burnishing test are detailed. Parameters have been compared according to the specifications as per the standards. This article shall be of assistance to policymakers and industrial experts to select the best criteria out of these three standards while framing revised editions of testing standards.

Over the years, innovation in automotive industry has been booming all around the world. These innovations are intended to convey safe and sound transportation. To serve this purpose in an organized manner, automobiles are subject to a set of regulations. Vehicles have to pass though these regulations mentioned in standards to be road equipped (Gillespie,1992). There are various automotive standards worldwide.

Automotive brakes play an important role in the smooth functioning of automobiles. Performance of brake system in an automobile is very critical (Stone & Ball, 2004; Crolla, 2009). Several standards worldwide include test prerequisites, test parameters, test procedures, and limiting values. This paper deals with the comparative study of brake standards for automobiles with four or more wheels without trailer. Standards like Indian Standards (IS), Federal Motor Vehicle Safety Standards (FMVSS) and European Economic Commission (ECE) Standards are compared in this article.

This article presents the brake parameters, preparations required and instrumentation required for each test in each standard. Performance parameters are the decisive factors in each tests and they have been intricately described. Brake tests along with their respective requirements have been explained. The standards used for this study are: IS 11852 (Part 3):2001, FMVSS 105, and ECE R13, where IS - Indian Standards, FMVSS - Federal Motor Vehicle Safety Standards, ECE - European Economic Commission Standards. This study shall be useful while framing new editions or revising the standing brake standards. The scope of the discussion made here is restricted to the service, secondary and parking brakes of automobiles with four or more wheels without trailer only.

Performance parameters are those parameters which decide the validity of a brake system configuration for a particular vehicle. The important performance parameters for a brake system are as follows.

Stopping Distance is the distance covered by the vehicle from the moment when the driver begins to trigger the control of the device until the moment when the vehicle stops (IS 11852: Part 1).

Stopping time is the time between the moment when the component of the control device on which the control force acts, starts to move, and the moment when the braking force ceases. If the vehicle stops before the braking force ceases, the time of the end of movement constitutes the end of the stopping time (IS 11852: Part 1).

MFDD is the mean value of deceleration over the period of the fully developed deceleration between instant when the deceleration reaches its stabilized value and instant when the vehicle stops (IS 11852: Part 1).

Vehicles have been categorized according to the number of seated persons and the tonnage capacity. Vehicle categories as per IS 11852 (Part2):2001 are as follows (IS 11852: Part 2-3).

Category M - Motor vehicles used for transporting passengers and having at least four wheels.

Category Ml - Vehicles used for transporting passengers and containing not more than eight seats in addition to the driver's seat.

Category M2 - Vehicles used for transporting passengers, containing more than eight seats in addition to the driver's seat and having a maximum mass not more than 5 t.

Category M3 - Vehicles used for transporting passengers, containing more than eight seats in addition to the driver's seat and having a maximum mass more than 5 t.

Category N - Motor vehicles used for transporting goods and having at least four wheels.

Category N1 - Vehicles used for transporting goods and having a maximum mass not more than 3.5 t.

Category N2 - Vehicles used for transporting goods and having a maximum mass more than 3.5 t but not more than 12 t.

Category N3 - Vehicles used for transporting goods and having a maximum mass more than 12 t.

Category T - Trailers (including semi-trailers).

The ECE standards’ categorizes are similar to IS as, Category M, N, and O (ECE R13).

FMVSS categorized vehicles according to Gross Vehicle Weight (GVW) are less than and above 8,000 and 10,000 pounds (FMVSS 105).

The performance quantified for braking devices is based on stopping distance and/or the MFDD (Kumbhar et al., 2017). The performance of a braking device is determined by evaluating the stopping distance in relation to the initial speed of the vehicle and/or by computing the MFDD during the test. The Mean Fully Developed Deceleration (dm) is calculated as the average of distance over the interval Vb to Ve according to the following formula (IS11852: Part 3),

MFDD (dm) = (Vb2 - Ve2 ) / (25.92(Se -Sb))

where,

Vi - Initial vehicle speed in km/h,

Vb- vehicle speed at 0.8 Vi in km/h,

Ve - vehicle speed at 0.1 Vi in km/h,

Sb- distance travelled between Vi and Vb in meters, and

Se - distance travelled between Vi and Ve in meters.

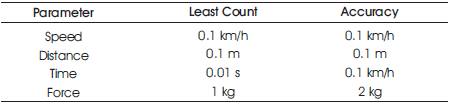

According to IS 11852 (Part 3):2001, following are the tests conducted to assess braking performance of a vehicle (IS 11852: Part 3).

Table 1 shows the types of brake performance tests specified in the three standards considered for the study. These tests are explained in the following sections.

Table 1. Types of Brake Performance Tests (IS 11852. Part 3; ECE R13; Federal Motor Vehicle Safety Standards, 2005)

The brakes shall be cold. A brake is supposed to be cold when the temperature measured on the disc or on the exterior of the drum is below 1000 oC (IS 11852: Part 3). The vehicle is to be in laden condition with the distribution of its mass among axles as quantified by the manufacturer. The bounds suggested for least performance in unladen and laden vehicle condition are those specified for each category of vehicle.

The vehicle has to fulfill both the stated stopping distance and/or the stated MFDD for the appropriate vehicle category. The test is piloted at initial speeds and load settings as quantified in the standard. The vehicle is started and speed is picked up to some extent above the specified initial test speed.

As the vehicle approaches the test area, vehicle speed is maintained slightly above the stated initial speed, the throttle is closed fully and the engine is disengaged. The same is conducted for engine engaged condition also (IS 11852: Part 3, ECE R13). If recording devices of distance, speed, or deceleration are not automatic, the devices are started. When the speed of the vehicle drops within the acceptable range of the initial speed, the brake control is applied quickly, continuously, and smoothly so as to stop the vehicle.

The above test procedure is repeated for increasing control force until best performance is observed without wheel lock. Thus the appropriate control force is obtained and about four readings is recorded in the neighborhood of the attained control force.

The service brakes of vehicles in categories Ml, M2, M3, N1, N2, and N3 shall be tested by applying and releasing the brakes, a number of times. This test is performed so as to evaluate the brake behavior after repetitive use, since the effectiveness of brake decreases with rise in temperature. The initial speed, control force, and use of gear and clutch control are maintained as per the standard. After each stop, the vehicle is accelerated to reach the initial speed and maintained at that speed till the initiation of the next stop. Immediately after this test, the residual performance of the service braking device shall be measured under the same conditions, as for the Type P test with the engine disconnected (IS 11852: Part 3, ECE R13).

This test is conducted for vehicles fitting to N3 and M3 category. In this test, the vehicle is driven downhill at the test speed, and then brake is applied. The corresponding stopping distance and deceleration are measured and compared with the respective limiting values. During this run, exhaust brake and other retarders, if fitted, are made use of. The gear engaged shall be such that the speed in revolutions per minute (rpm) of the engine does not exceed the maximum value prescribed by the manufacturer. The hot performance of the service braking device is measured in the same settings as for the Type 'P' test, with the engine disconnected, at the end of the test (IS 11852: Part 3, ECE R13).

Burnish stops could be carried out on any surface. For vehicles with Gross Vehicle Weight Rating (GVWR) of 10,000 pounds or less, burnishing is carried out by making 200 stops from 40 mph at 12 fpsps. The interval from the start of one service brake application to the start of the next shall be either the time essential to decrease the initial brake temperature to between 230 °F and 270 °F, or the distance of 1 mile, whichever occurs first.

For vehicles with a GVWR greater than 10,000 pounds, 500 snubs between 40 mph and 20 mph at a deceleration rate of 10 fpsps is carried out. The brakes could be adjusted three times during the burnish procedure after 125, 250, and 375 snubs (FMVSS 105).

The vehicle's mass shall be as prescribed for each type of test. The test shall be carried out at the speeds prescribed for each type of test. The road surface shall be dry with a coefficient of adhesion to be greater than 0.8. The tests shall be performed with the wind velocity less than 3 m/s in any direction. At the start of the tests, the tires are to be inflated to the pressure prescribed by the vehicle manufacturer, for the load borne by the wheels when the vehicle is stationary. The recommended performance shall be obtained without locking of wheels. However, brief wheel locking towards the end up to 3 m is permissible. The ambient temperature should be preferably between 150 oC and 400 oC and relative humidity should be <75%. The speed and distance shall be determined using instrumentation having an accuracy of ±1 percent at the prescribed speed for the test (IS 11852: Part 2).

It shall be ensured that the service brake control may be triggered with both the hands on the steering control with the safety belt, if provided. It is also ensured that the secondary brake control may be triggered from the driving seat while keeping at least one hand on the steering wheel, even with the wearing of safety belt. Parking brake control may be triggered by the driver from the driving seat even with the wearing of safety belt, if provided and that the parking brake may be held on by a purely mechanical device. It shall be ensured that all brakes have provision for manual or automatic tuning for wear, which is easily accessible and operable.

Installation of sensors and measuring devices for speed, temperature, pressure, control force, and pedal travel is carried out and the data is recorded in a live condition on a data logger (Rudolf, 2011).

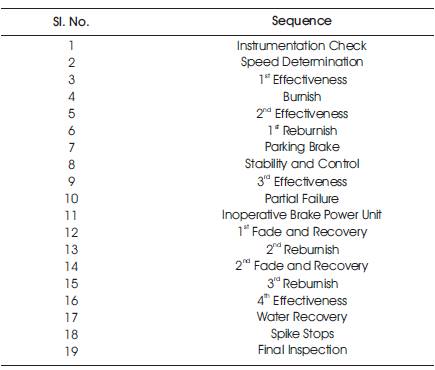

Global Positioning Device (GPS) is the widely used device to measure the speed, stopping distance, and deceleration. The data is logged in continuously at the frequency rate set by the testing agency (Approx. 100 Hz). Data logger starts recording data when the control force and speed crosses the threshold value, and stops when it drops back again. Within the range, values of speed, stopping distance, and the deceleration gets recorded continuously. Least count and accuracy of instrument used is detailed in Table 2 (IS 11852: Part 2).

Table 2. Instrumentation Least Count and Accuracy Requirement (IS 11852-Part 1)

Load cells are used to measure the control force. The data is also recorded in a continuous manner in the data logger.

Load cells are used to measure the control force. The data is also recorded in a continuous manner in the data logger.

A Linear Variable Differential Transformer (LVDT) is used to measure the pedal travel. One end of the LVDT is connected to the pedal and the other end is fixed to the body of vehicle. Thus a differential movement is obtained.

Plug-type thermocouples are installed at the preferred locations to log the data required. They can be used to find the temperature of brake fluid, brake pad at the inside and outside regions.

Pressure sensors are also installed at preferred locations based on the requirement. The connection is temporarily removed and T split (3-way) is installed in the layout. At one end, the pressure sensor is installed, and the other two are used to re-establish the connection.

The standards IS 11852 (Part 3):2001, FMVSS 105 and ECE R13 are compared in this section.

FMVSS 105 evaluates the performance based on stopping distance only. ECE R13 as well as IS 11852 specifies the evaluation of vehicle brake performance either by stopping distance or mean fully developed deceleration.

FMVSS 105 states that the test surface has to be 12-foot-wide, level roadway, with a skid number of 81 if vehicle's GVW is less than 10,000 pounds (4536 kg) else a peak co-efficient of friction of 0.9. The ECE R13 describes the test surface to be level, dry, and affords good adhesion. It does not specify the coefficient of friction for the test surface. IS 11852 specifies the road surface to be dry with a coefficient of adhesion to be greater than 0.8 (Kumbhar et al., 2017).

According to FMVSS 105, testing has to follow a specific sequence as per the category of vehicle. It starts first with effectiveness followed by the fade tests, partial failure tests, and re-burnish tests, and at last, water recovery and spike stops as mentioned in Table 3. There is no specific test order in the ECE R13 and IS 11852.

Table 3. Test Sequence as per FMVSS 105 (Federal Motor Vehicle Safety Standards, 2005)

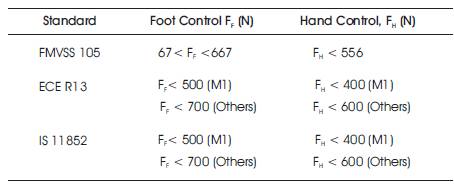

Control force is the amount of force required to actuate the brake system. Table 4 summarizes the limiting control force requirement.

Table 4. Brake Actuation Forces (IS 11852-Part 3)

FMVSS 105 states the use of plug-type thermocouples in the approximate center of the facing length and width of the most heavily loaded shoe or disc pad, one per brake. The initial brake temperature shall be 150 °F to 200 °F. ECE R13 and IS 11852 specifies the initial brake temperature as not more than 100 °C, measured at the outside surface of the drums or discs.

FMVSS 105 mentions a burnishing procedure, whereas ECE R13 does not include any burnishing procedure for brake testing.

This procedure specifies the vehicle to be put to stop for about 200 times from 40 mph (GVW less than 10,000 pound) and 500 stops between 40 mph and 20 mph. IS 11852 also does not require burnishing of brakes during their testing. ECE R13 does not include any burnishing procedure for brake testing. IS 11852 also does not require burnishing of brakes during their testing.

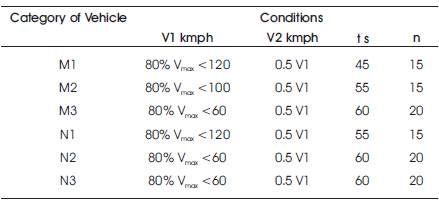

FMVSS states a series of effectiveness tests at 30 mph and 60 mph. The vehicle need to be put to stop from 60 mph, and also from 30 mph. The stopping distance is to be within the limit of 65 ft to 242 ft. ECE R13 and IS 11852 specifies the vehicle to be stopped from 30%, 80% of maximum speed, and also from the speed mentioned for each category. The stopping distance is expressed as a function of initial velocity and the deceleration limits have been mentioned for each category of vehicle (Rudolf, 2011). Two conditions, i.e. engine engaged and engine disengaged are considered. The details have been listed down in Table 5 (IS 11852: Part 2).

5.8 Fade Test FMVSS states that the vehicle should be stopped from 60 mph at 15 fpsps for 5 snubs (GVW less than 10,000 pound), 40 mph to 20 mph at 10 fpsps for 10 snubs (GVW greater than 10,000 pound). ECE R13 and IS 11852 specifies the initial velocity and final velocity along with the number of snubs and duration of braking cycle as per Table 6 (IS 11852: Part 2-3). Hot performance test of the brake after the fade test is also recommended.

Table 6. Specifications of Fade Test (IS 11852-Part 3)

FMVSS does not state any downhill behavior tests. ECE R13 and IS 11852 state the necessity of downhill behavior test only for M3 and N3 category vehicles. The test instructs the vehicle to be driven at an average speed of 30 km/h on a 6 per cent down-gradient for a distance of 6 km. After the test, hot performance is also to be determined.

FMVSS specifies the secondary braking performance as to be measured at 60 mph with a control force of 15 to 150 pounds. The limiting stopping distance is specified to be 517 ft for 1-4 stops.

ECE R13 and IS 11852 specifies the stopping distance as a function of initial velocity and deceleration is mentioned to be 2.2-2.9 m/s2 . If the control is hand-controlled, the prescribed performance must be obtained by applying a force not more than 400 N in case of vehicles of category M1, and 600 N in the case of other vehicles.

If it is a foot control, the prescribed performance must be obtained by applying to the control, a force not more than 500 N in case of vehicles of category M1, and 700 N in case of other vehicles. Vehicles should also be tested with engine disengaged.

All three standards emphasize on the usage of a solely mechanical brake system for parking. FMVSS limits the control force to 57 kg for a foot-operated system and to 41 kg for hand-operated system (GVW less than 10,000 pound), and to 68 kg for foot-operated system and to 57 kg for hand-operated system (GVW greater than 10,000 pound). It should hold the vehicle at 20% up or down gradient for 5 minutes.

ECE R13 and IS 11852 state that the vehicle should be held at 18% up or down gradient. No time limitation is specified. The control force is limited to 400 N in case of vehicles of category M1, and 600 N in case of all other vehicles, if hand operated. If it is a foot control, the control force must not exceed 500 N in case of vehicles of category M1, and 700 N in case of all other vehicles.

From the in-depth analysis conducted on the three brake standards FMVSS, ECE, and IS, a comprehensive conclusion could be reached, as shown in Table 7.

The article provides a critical comparative study on the brake testing standards existing worldwide: IS, ECE, and FMVSS. An outline to the categorization of vehicles, testing parameters, instrumentation required, and various tests performed have been discussed. The paper intends to be of assistance to policymakers, industries and other institutions while drafting or revising brake testing standards. Two critical additions or improvements need to be incorporated. They are in terms of testing sequence and also the need of performance testing of burnished brakes. Burnished brake testing has been elaborately investigated by FMVSS, to verify the minimum performance of worn out brakes. Similar studies on vehicle with trailers, Antilock Brake System (ABS) could provide assistance to the authorities for future revisions.