The use of dental hand-pieces endangers the dentist to ultra-vibrations. It is known that the vibration of dental handpieces is harmful to a long run in the frequency range above 1250 Hz. The daily endanger amplitude for dentist handarm vibrations shall be as per ISO 5349-1:2001. There is very less information available on the physical and other health issues about using dental hand-pieces. Till date, no study has been conducted in this area in the Asian continent. Handpieces are manufactured based on findings carried out on European dentists. The current study aims to study the exposure level of Indian dentists to vibration because of use of dental hand-pieces. A study to analyze the vibration transmissibility of hand-pieces used by the dentist during drilling operation is proposed. The current research work aims to analyze the vibration exposure and its transmissibility of Indian dentists during the drilling operation. The objective of this research is to study the change in the behaviour of vibration during idling to drilling in different conditions. The measuring instrument was biometric setup which includes; the accelerometer, the conditional amplifier, and the analysis software. The total number of hand-pieces analyzed in all directions were 20 during idling. The work was also studied by drilling on actual teeth and mandible in the skull. The weighted vibrations were also compared to standard ISO 5349:2001-1. Coolant injection had the least effect on the vibration transmissibility of dental hand-pieces. Under idling condition, the weighted vibrations transmissibility of used micro-motor hand-pieces was higher compared to new ones and also the weighted vibrations transmissibility of new and used air-turbine hand-pieces was nearly of the same amplitude. Drilling on the teeth did increase the vibration amplitude and transmissibility of micro-motor and air-turbine hand-pieces. But the effect of drilling is more on micro-motor hand-pieces than on air-turbine hand-pieces.

The use of dental hand-pieces endangers the dentist to ultra-vibrations. It is known that the vibration of dental handpieces is harmful to a long run in the frequency range above 1250 Hz [16]. The daily endanger amplitude for dentist hand-arm vibrations shall be as per ISO 5349- 1:2001. Dental personnel is subjected to very high amplitude and frequency of vibrations [2, 9,11,17]. The sensation values of dentist's fingers were higher among 10 female dentists with more than 10 years of work experience than among the selected personnel [15]. Among 120 dental personnel, CTS was acknowledged in 4 dental personnel as an occupational disease [14].

ISO 5349:2001 [12] describes the vibration exposure response of the mean acceleration amplitude of the handpieces in the 1/3rd -octave band of 6.3-1250 Hz. The model for risk prediction contains many uncertainties, such as a change in individual susceptibility and other related factors, change in work methods, and uncertainty in predicting total effective vibration exposure [10]. The consequence of ageing on vibration amplitude of dental hand-pieces is not completely known. The aim of this work was to calculate the vibration amplitude of new and used handpieces according to the ISO 5349:2001 and to analyze the high-frequency vibration effects of these handpieces.

The daily endangered value for hand-arm vibration amplitude as per available data shall be 2.5 m/s2 . Vibration amplitude exposure of dentists during daily work have not been reported. There is very less information available on the physical and other health issues about using dental hand-pieces. Personnel subject to high vibration magnitude in the dental environment is a possible risk for the development of neurological and other circulatory disturbances in dentist's hands [18]. The risk of injury to women dentists reported higher in Sweden than among other dental personnel [8]. A study that depicts the relationship between vibration amplitude and MSD symptoms in dental hygiene students showed that MSD symptoms may increase abruptly with the use of manual and ultrasonic handpieces [13].

The aim of this work was to calculate the transmissibility of handpieces from tool measurement point to grasping point of dentist, tool measuring point to wrist end of dentist, grasping point to wrist end of dentist and also measure and analyse vibration amplitude of dental handpieces during normal clinical work, under different type of handpieces based on their time of use. Work was also simulated by use of coolant at maximum and minimum level. Effect of force during drilling was also predicted based on individual dentist’s tendency to apply force. The effect of hand posture and location of the accelerometer on hand-piece was also studied and made fixed for analysis.

Vibration transmissibility [1], [3-7] is defined as the ratio of the vibration measured on the hand–arm system to the input vibration on the hand-piece. It can be represented as,

where, Aml = ameasured is the acceleration at the grasp point on hand, wrist point, elbow, respectively and Ahv , the acceleration at the hand-piece (position 2) in three different axes x, y and z in the frequency range of 6.3-1250 Hz.

Also, the vibration is dependent on frequency response characteristics. Vibration transmissibility is determined at the individual frequencies within the 1/3rd -octave band at an anatomical location on the hand–arm system. The frequency response of vibration transmissibility is defined as,

where, w is the excitation frequency.

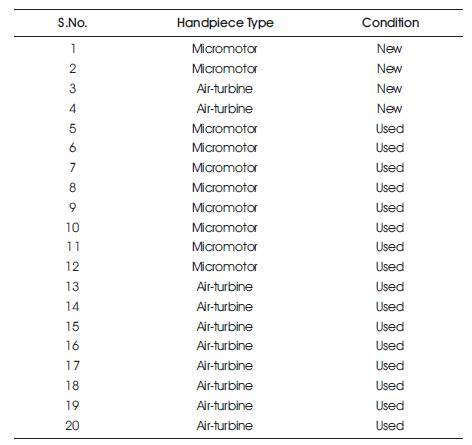

Micro-motor hand-pieces of two new and eight used, and air-turbine hand-pieces of two new and eight used, were tested in the actual dental work environment at a Dental Hospital in UIDS & H, PU, (University Institute of Dental Sciences and Hospital, Punjab University), India. The numbering of hand-pieces is shown in Table 1.

Table 1. Handpieces Numbering

1 and 2 were new and 5-12 were used micro-motor handpieces and, 3 and 4 were new and 13-20 were used airturbine hand-pieces. The rotational speed of the micromotor hand-piece was 25000-40000 rpm and the rotational speed of air-turbine hand-piece was 35000- 400000 rpm, but the speed of both hand-pieces are restricted to 35000 rpm. During testing, the burrs of the airturbine hand-piece and the micro-motor hand-piece were made up of steel with tungsten carbide coating. The handpieces were made according to the manufacturer guidelines.

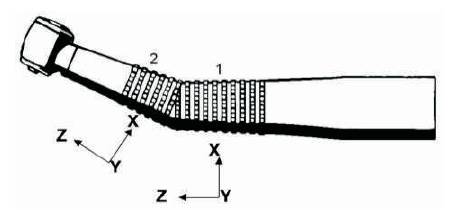

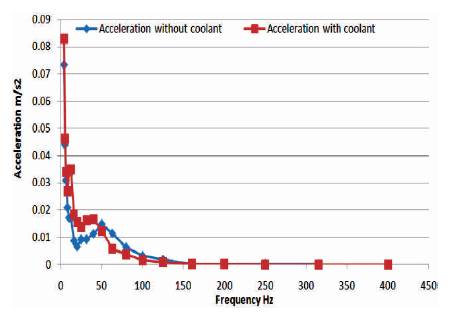

The vibrations were calculated in all three directions. Elbowarm angle was set fixed at 120 degrees and the wrist-hand angle was measured using goniometer. Two positions of accelerometer attachment on the hand-piece were selected based on previous studies. Maximum force (Position 2) and maximum torque (Position 1) are the set parameters for selecting the position of accelerometer attachment as shown in Figure 1. But, maximum force (position 2) was selected as selecting criteria for accelerometer attachment on hand-piece. Various doctors were also analyzed before selecting the position of accelerometer attachment on hand-pieces. Elbow-arm angle was set to 120 degrees before analyzing various practitioners. The consequences of the hand effort of the dentist on the vibration amplitude of the hand pieces were studied by applying forces; 0%, 35%, 75%, and 100% of actual force applied by the dentist during normal working. The applied force was measured with the help of dynamometer. In addition, tempt of coolant on the vibration of air-turbine hand-pieces was tested. As it is known, nowadays, only air-turbine hand-pieces use inbuilt cooling and micro-motor hand-pieces do not use coolant method. Thus, only coolant effect can be analyzed for airturbine hand-pieces. All these tests were performed during idling.

Figure 1. Location of Measurement Position

The RMS vibrations were analyzed in the 1/3rd -octave band in the frequency range 6.3-1250 Hz. The total number of hand-pieces tested was 20 during idling in all directions. The weighted vibrations were also compared to standard ISO 5349:2001-1. The work was also plotted by drilling on actual teeth mounted on a manikin with all new and four used hand-pieces. During drilling on teeth, coolant was adjusted to maximum and minimum value and its effect was depicted. Idling results depict that vibration amplitude obtained in position 2 sufficiently represents the vibration of hand-pieces and thus the succeeding tests were performed in this position.

The vibration of 20 dental hand-pieces was studied during idling. The measuring instrument was biometric setup which includes; the accelerometer (10G, 16G), the conditional amplifier (data logger) and the analysis software as shown in Figure 2. The accelerometer was attached with glue and surgical tape to the proper measuring position of the handpiece.

Figure 2. Data Logger and Accelerometer

The recorded readings were analyzed in biometric setup and VATS software and corresponding weighted acceleration in a 1/3rd -octave band in the frequency range 6.3–1250 Hz. The weighted vibrations were also compared to standard ISO 5349:2001-1. The measured time of each dental hand-piece depicts drilling time for which the dentist works with each patient.

Coolant injection had the least effect on the vibration amplitude of dental hand-pieces and its transmissibility. Effect of elbow-arm posture had a significant effect on vibration amplitude and its transmissibility. Wrist angle had a huge effect on grip force applied by dental personnel. Grip force also had its effect on vibration amplitude and its transmissibility, but not so significant as compared to other factors. Under idling condition, the weighted vibrations of used micro-motor hand-pieces were higher compared to new ones and also the weighted vibrations of new and used air-turbine hand-pieces were nearly of the same amplitude. Vibration amplitude of micro-motor handpieces in the frequency range of 230-600 Hz concurs with the rotational speed of the micro-motor. Vibration amplitude of air-turbine hand-pieces in the frequency range 280-650 Hz concurs with the rotational speed of air-turbine.

Vibration Transmissibility of handpieces is more from grip position of the dentist to the wrist end of the dentist. Vibration Transmissibility is significant from tool measuring position (position 2) to grasping point and also from tool point to wrist end of the dentist. Most dangerous transmissibility is from tool point to wrist end because grip point can damp vibrations to a large extent. Drilling did increase the transmissibility of vibrations. Drilling on the teeth did increase the vibration amplitude of micro-motor and air-turbine hand-pieces. But the effect of drilling is more on micro-motor hand-pieces than on air-turbine hand-pieces.

The weighted vibration transmissibility of air-turbine handpieces during drilling on teeth was in the range of 0.1-1.4 and weighted transmissibility amplitude of micro-motor hand-pieces during drilling on teeth was in the range of 0.1- 1.9. In most of the handpieces, the transmissibility value approaches nearly unity which is the area to take into considerations, assuming that the weighted value of vibration is equal in all the three measuring directions. The weighted value of acceleration amplitude was below the harmful acceleration amplitude plotted in the ISO 5349:2001. The vibration amplitude of the hand-pieces was harmful at very high frequencies, but its effects are not well known.

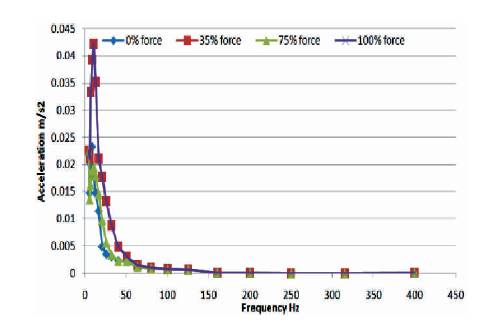

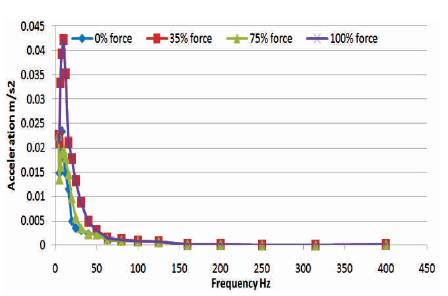

The results are presented by acceleration (m/s2) versus frequency (Hz) plots. The effect of the grip force of fingers on the 1/3rd -octave band vibration of Air-Turbine handpieces, when measured at position 2, is shown in rd Figure 3. The effect of the grip force of fingers on the 1/3rd - octave band vibration of Micro-motor handpieces, when measured at position 2, is shown in Figure 4. The effect of the coolant, i.e. water spraying on the 1/3rd -octave band vibration of Air-Turbine handpieces when measured at position 2 is shown in Figure 5.

Figure 3. 1/3rd -octave Band Acceleration of Air Turbine Handpieces due to Grip Force at Position 2

Figure 4. 1/3rd -octave Band Acceleration of Micro-motor Handpieces due to Grip Force at Position 2

Figure 5. The Effect of the Coolant, i.e. Water Spraying on the Vibration of Air-turbine Handpieces when grasped at Position 2

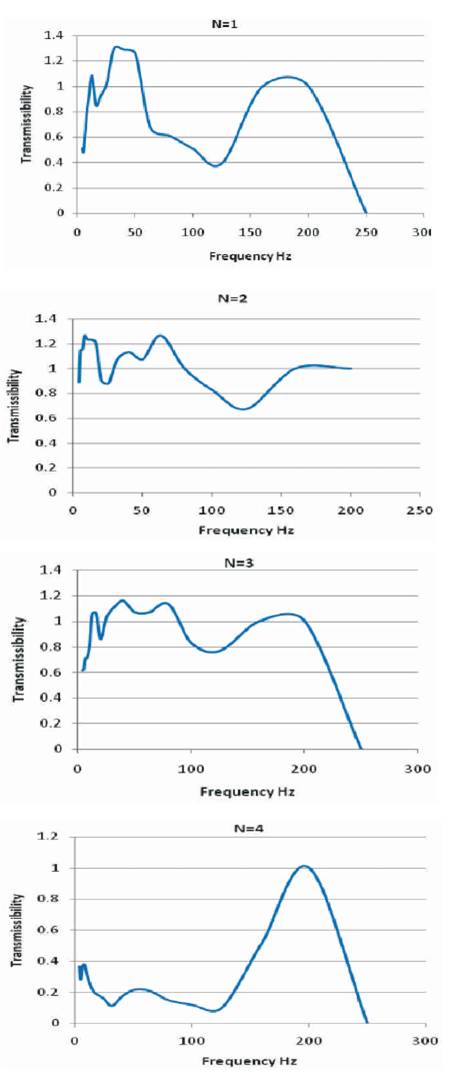

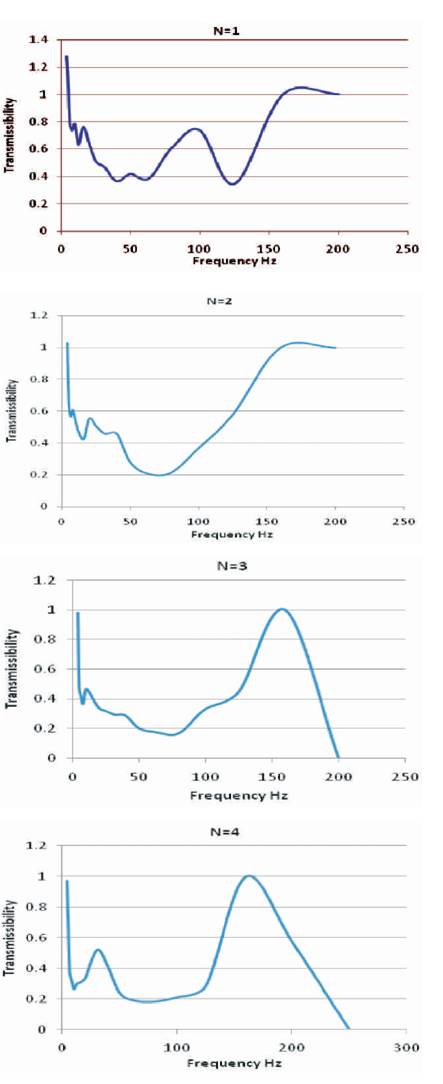

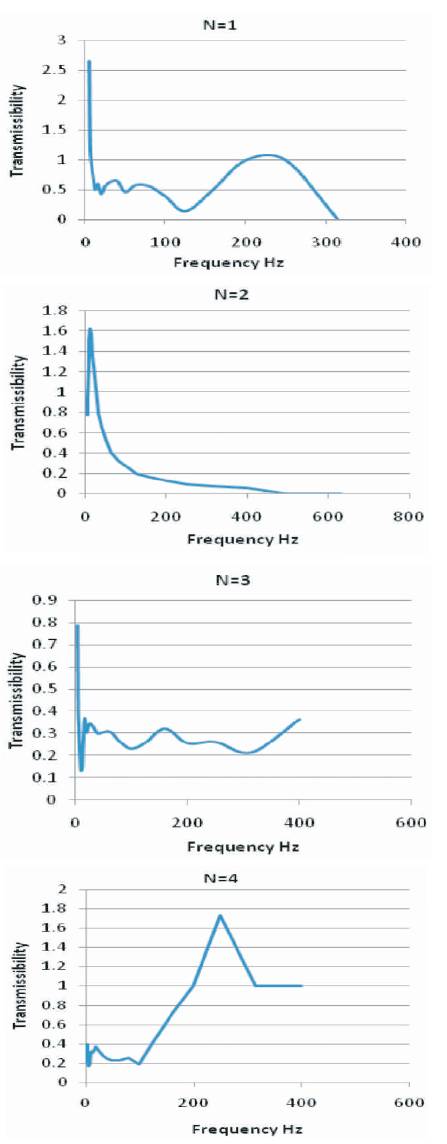

The 1/3rd -octave band vibration transmissibility of Air–turbine handpiece from tool point at position 2 to grip point of the dentist is given in Figure 6. The 1/3rd -octave band vibration transmissibility of Air–turbine handpiece from grip point of the dentist to the wrist end of the dentist is given in Figure 7. The 1/3rd -octave band vibration transmissibility of Air–turbine handpiece from tool point at position 2 to wrist end of the dentist is given in Figure 8.

Figure 6. Vibration Transmissibility of Air-turbine Handpieces from Tool Point to Grasp Point when Grasped at Position 2

Figure 7. Vibration Transmissibility of Air-turbine Handpieces from Grasp Point to Wrist End when Grasped at Position 2

Figure 8. Vibration Transmissibility of Air-turbine Handpieces from Tool Point to Wrist End when Grasped at Position 2

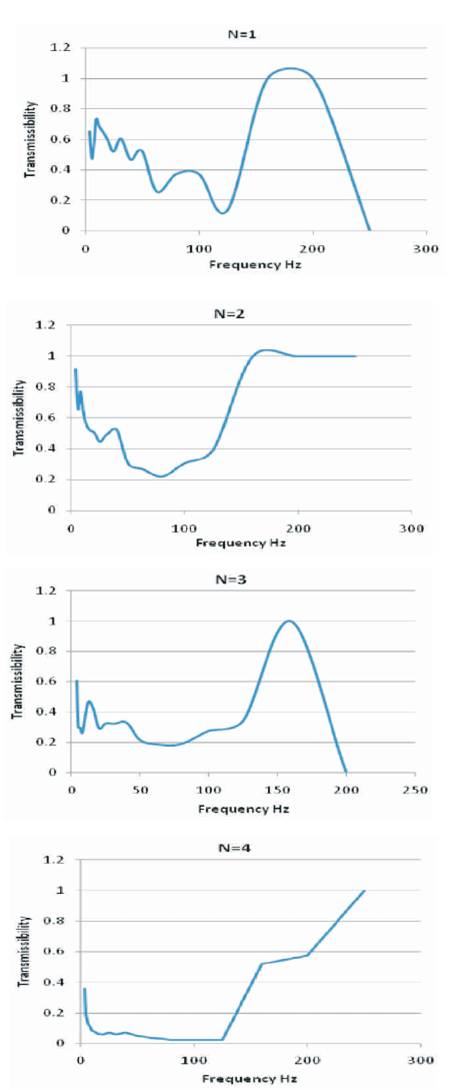

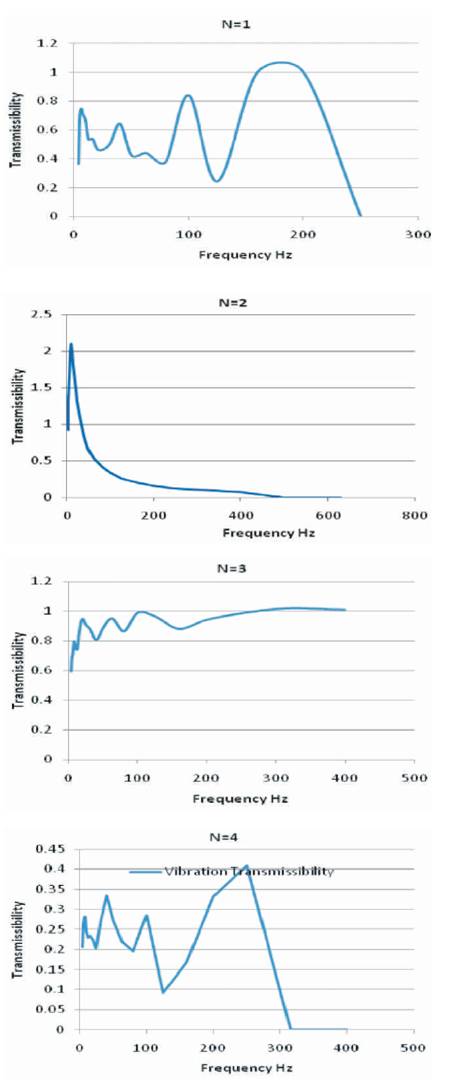

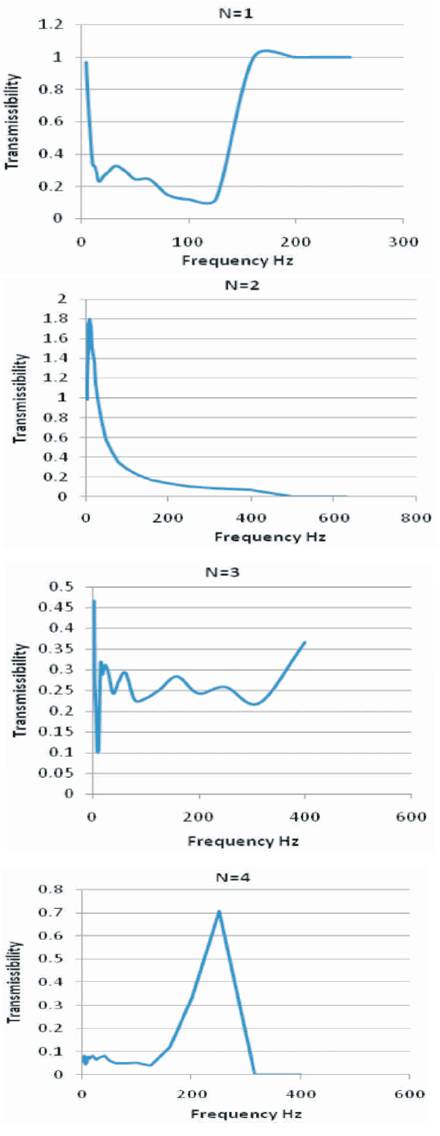

The 1/3rd -octave band vibration transmissibility of Micromotor hand-piece from tool point at position 2 to grip point of the dentist is given in Figure 9. The 1/3rd -octave band vibration transmissibility of Micro-motor hand-piece from grip point of the dentist to the wrist end of the dentist is given in Figure 10. The 1/3rd -octave band vibration transmissibility of Micro-motor hand-piece from tool point at position 2 to wrist end of the dentist is given in Figure 11.

Figure 9. Vibration Transmissibility of Micro-motor Handpieces from Tool Point to Grasp Point when Grasped at Position 2

Figure 10. Vibration Transmissibility of Micro-motor Handpieces from Grasp Point to Wrist End when Grasped at Position 2

Figure 11. Vibration Transmissibility of Micro-motor Handpieces from Tool Point to Wrist End when Grasped at Position 2

Coolant injection had the least effect on the vibration transmissibility of air turbine dental hand-pieces. Measurement position 2 had a huge effect on vibration amplitude and its transmissibility to hand compared to position 1. In general, more close is the measuring point, more precise be the measurement in its analysis. Wrist angle had a huge effect on grip force applied by dental personnel, but most doctors work with wrist angle nearly 180±10 degrees so, of less importance. Grip force also had its effect on vibration amplitude and it changes according to hand anthropometry, gender, mental and physical condition of the dentist. Under idling condition, the vibration transmissibility of used micro-motor hand-pieces was higher compared to air-turbine hand-pieces. Drilling on the teeth did increase the vibration transmissibility of micro-motor and air-turbine hand-pieces. But the effect of drilling is more on micro-motor hand-pieces than on airturbine hand-pieces. The weighted value of acceleration amplitude was below the harmful acceleration amplitude plotted in the ISO 5349:2001.