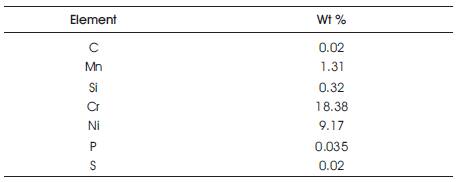

Table 1. Chemical composition of AISI 304 stainless steel

AISI 304 stainless steel has wide applications in fabrication, architectural panelling, paper industry, food and pharmaceutical production equipment, nuclear vessels and cryogenic vessels. Austenitic steels are hard materials to machine, due to their high strength, high ductility, low thermal conductivity and excellent corrosion resistance in a wide variety of environments. This paper presents optimisation of machining parameters for milling AISI 304 stainless steel. In this work, a plan of experiments based on Taguchi's L27 orthogonal array was established and milling experiments were conducted with prefixed process parameters using tungsten carbide end mill. The machining parameters such as, cutting speed, feed rate and depth of cut were optimised with the objective of minimizing the surface roughness (Ra) and maximizing the Material Removal Rate (MRR). Finally an analysis of variance (ANOVA) was performed for finding the effects of each parameter on the surface roughness and the Material Removal Rate. It is being inferred that cutting speed has the main influence on the surface roughness and as it increases, the surface roughness also increases. The depth of cut has the most important influence on material removal rate and as it increases, the material removal rate also increases.

AISI 304 is the most versatile and widely used stainless steel. AISI 304 Austenitic stainless steels are grades of chromiumnickel steels, having its typical applications in fabrication, architectural panelling, paper industry, food and pharmaceutical production equipment, nuclear vessels and cryogenic vessels. Austenitic stainless steels cannot be hardened by traditional heat treatment processes but they can be strengthened by cold working [1].

AISI 304 steel is hard to machine due to their high strength, high ductility, low thermal conductivity, high fracture toughness and excellent corrosion resistance in a wide variety of environments[2, 3].

In machining, milling is the most versatile process capable of producing well-defined and high quality surfaces. Milling processes are widely used in the aerospace, aircraft and automotive industries. The surface roughness (Ra) and Material Removal Rate (MRR) have been identified as quality attributes and are assumed to be directly related to the the performance of mechanical pieces, productivity and production costs. Both the surface roughness and material removal rate greatly vary with the change of cutting process parameters. It is important to choose the best machining parameters for achieving optimum performance characteristics for machining process. The desired machining parameters are usually selected with the help of referred handbooks, past experience and various trails. However, the selected machining parameters may not be optimal or near optimal machining parameters. Taguchi method can be applied for optimisation of process parameters to produce high quality products with lower manufacturing costs. Taguchi's parameter design is one of the important tools for robust design, which offers a systematic approach for parameters optimisation in terms of performance, quality and cost [4, 5].

Yang and Tarng [6] used the Taguchi method for determining optimum cutting parameters, i.e. cutting speed, feed rate and depth of cut for surface roughness and tool life in turning S45C steel bars using tungsten carbide cutting tools.

The Taguchi method for finding out the optimal value of surface roughness under optimum cutting condition in turning SCM 440 alloy steel was done by Thamizhmanii et al. [7]. They concluded that depth of cut was the only significant factor which contributed to the surface roughness.

Bhattacharya et al. [8] presented Taguchi and analysis of variance (ANOVA) techniques to analyse the effect of cutting parameters on surface finish and power consumption during high speed machining of AISI 1045 steel.

The optimisation of the machining parameters on surface roughness and power consumption in turning Al-15% SiCp metal matrix composites using desirability function analysis was done by Ramanujam et al [9]. They reported that the machining performance can be improved effectively through the proposed approach.

Julie et al. [10] performed optimisation of surface roughness in an end-milling operation using the Taguchi method. Maintaining good surface quality usually involves additional manufacturing cost or loss of productivity. Moshat et al. [11] studied on optimisation of CNC milling process parameters on surface roughness and material removal rate using PCA based Taguchi method.

Gopalsamy et al. [12] applied Taguchi method to find optimum process parameters for end milling while hard machining of hardened steel. A L16 array, signal-to-noise ratio and ANOVA were applied to study performance characteristics of machining parameters (cutting speed, feed, depth of cut and width of cut) with consideration of surface finish and tool life.

Kadirgama and Noor [13] highlighted about optimisation of the surface roughness when milling Aluminium alloys (AA6061-T6) with carbide coated inserts using Response surface method (RSM) and Radian basis function network (RBFN) to predict thrust force and surface roughness.

Lou et al. [14] developed the prediction technique for the surface roughness of the CNC end milling process using multiple regression analysis.

Thangarasu et al. [15] established the relationship with the basic parameters to the responses namely surface roughness and Material Removal Rate. They adopted Taguchi based Box-Behnken RSM method and Multi Objective Genetic Algorithm (MOGA) for optimisation of CNC milling process.

Abele and Frolich [16] have compiled the case study of high speed milling of titanium alloys and have provided base for different metallurgical and machining conditions to be taken into account for the study. The case study of titanium based alloys were conducted for the high speed milling process for sets of input parameters with moderate cutting speeds and feed rate to get better material removal of aircraft materials.

It can be observed from the above review of literatures that, for achieving optimum performance characteristics in any machining process, it is required to find the optimum combination of machining parameters. Surface quality (surface roughness) and Material Removal Rate are strongly dependent on cutting parameters, tool geometry and cutting forces.

This paper presents optimisation of the machining characteristics, i.e. surface roughness and Material Removal Rate on milling AISI 304 stainless steel with tungsten carbide end mill using Taguchi method. The influence of machining parameters on the surface roughness and material removal rate are performed using ANOVA.

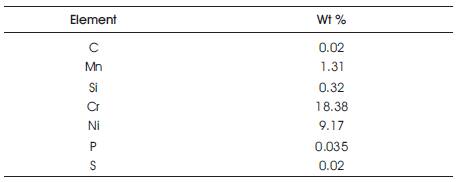

The experimental investigation was carried out on a CNC milling (Manufactured by KENT Ind. Co. Ltd., Taiwan) with 7.5 kW power and maximum spindle speed of 8000 rpm. The work material selected for the study was AISI 304 stainless steel with high strength, high ductility and low thermal conductivity. The selection of the AISI 304 stainless steel was made taking into account its use in almost all industrial applications for approximately 50% of the world's stainless steel production and consumption. The important characteristics responsible for the commercial popularity of this material are its ability of resistance to corrosion and staining. Low maintenance, relatively low cost and familiar lustre make it an ideal base material for a host of commercial applications. The chemical composition of the workpiece material and its physical and mechanical properties are given in Table 1 and Table 2 respectively. The dimension of the work pieces used in the experiments was 460 mm X 100 mm X 10 mm of rectangular shape. The cutting tool is made up of tungsten carbide end mill with 4 flutes of 10 mm diameter. A schematic diagram of the experimental set-up for present investigation is shown in Figure 1.

Table 1. Chemical composition of AISI 304 stainless steel

Table 2. Physical and mechanical properties of AISI 304 stainless steel

Figure 1. Experimental setup in the CNC machining centre

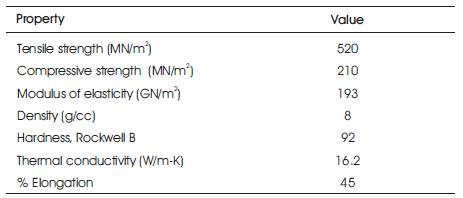

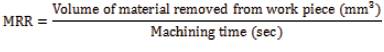

The responses considered in this study were surface roughness (Ra) and Material Removal Rate (MRR). Surface roughness can generally be described as the geometric features of the surface. The surface roughness was evaluated using a Mitutoyo Surf test 211 with the cut-off length set as 2.5 mm. Each trail was repeated for three times and the average roughness values were obtained. Material removal rate is used to evaluate a machining performance. Material removal rate is expressed as the amount of material removed under a period of machining time and is calculated using the formula given in Equation 1:

Here, Volume of material removed from work piece (mm3) = Depth of cut (mm) * breadth of the work piece (mm) * groove width (mm).

The concept of the Taguchi method is that the parameters design is performed to reduce the sources of variation on the quality characteristics of product, and reach a target of process robustness [17]. It utilizes the orthogonal arrays from experimental design theory to study a large number of variables with a small number of experiments [18, 19]. The experiments are conducted based on orthogonal arrays, which provide a set of well balanced (minimum) experiments.

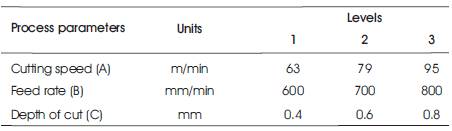

To perform the experimental design, a total of three parameters namely cutting speed (A), feed rate (B) and depth of cut (C) were chosen for the controlling factor, and each parameter is designed to have three levels, namely low, medium, and high, denoted by 1, 2 and 3, as shown in Table 3. It was also decided to study the two factor interaction effects on multiple performance characteristics. The selected interactions were between cutting speed and feed rate (AxC), and between feed rate and depth of cut (BxC). To select an appropriate orthogonal array for the experiments, the total Degrees Of Freedom (DOF) need to be computed. With three parameters each at three levels and three second-order interactions, the total degree of freedom required is 18, since a three level parameter has 2 DOF and each second order interaction has 4 DOF (Product of DOF of interacting parameters). As per Taguchi's method, the DOF for the orthogonal array should be greater than or equal to the total DOF required for the experiment. In this study, an L27 orthogonal array having 26 DOF (Number of trials -1) was selected. The experimental combinations of the machining parameters using the L27 orthogonal array are presented in Table 4.

Table 3. Process parameters and their levels

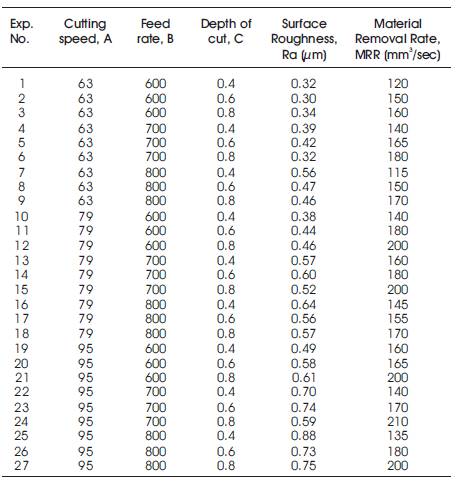

In the CNC milling process, lower surface roughness and higher Material Removal Rate are indications of better performance. Taguchi's L27 orthogonal array was used for experimental investigation. Based on the designed orthogonal array, twenty seven milling operations are performed on AISI 304 stainless steel and the experimental results are summarized in Table 4. The experimentally collected data were subjected to Taguchi analysis and ANOVA for optimisation of machining parameters. For analyzing the experimental results, surface roughness is taken as “smaller is better” and Material Removal Rate is taken as “larger is better”.

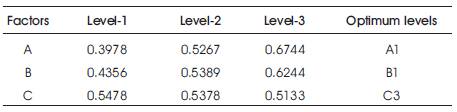

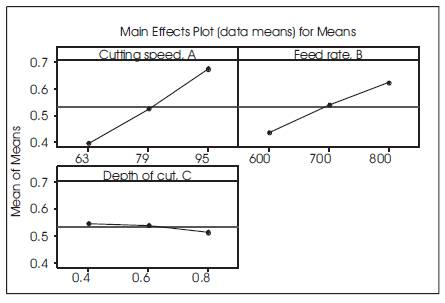

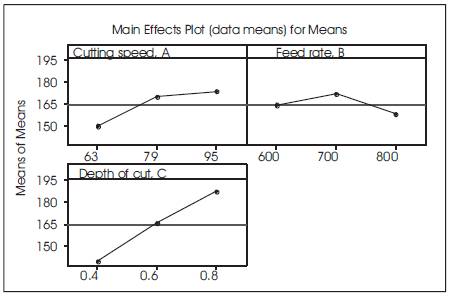

The effect of different machining parameters on AISI 304 stainless steel can be studied by using response graph and response table. The mean response values for each level of parameter on surface roughness is calculated and presented in Table 5. Based on the mean response values presented in Table 5, the influence of cutting parameters on surface roughness is graphically shown in Figure 2. From Figure 2, it is realized that surface roughness increases with increasing the cutting speed and feed rate, whereas surface roughness decreases with increasing the depth of cut. Based on the response table and response graph for surface roughness, the optimal combination of process parameters for minimum surface roughness is obtained at 63 m/min cutting speed, 600 mm/min feed rate and 0.8 mm of depth of cut (A1 B1 C3).

Table 4. Experimental design using L27 orthogonal array and their responses

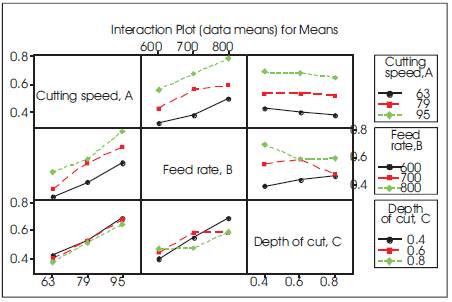

The interaction plots for surface roughness which is shown in Figure 3 are between cutting speed and feed rate (AxC), and between feed rate and depth of cut (BxC). Results of interaction plots for surface roughness show that there is a slight interaction effect in between feed rate and depth of cut (BxC). Parallel lines show that there is no interaction effect between the parameters.

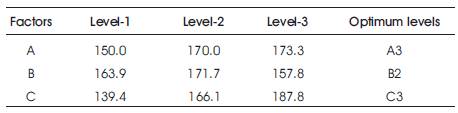

The mean response values for each level of parameter on Material Removal Rate is calculated and presented in Table 6. Based on the mean response values presented in Table 6, the influence of cutting parameters on Material Removal Rate is graphically shown in Figure 4. From Figure 4, it is observed that the Material Removal Rate increases with increasing cutting speed and depth of cut whereas Material Removal Rate increases with feed rate up to 700 mm/min after which it starts decreasing. Based on the response table and response graph for Material Removal Rate, the optimal combination of process parameters for maximum Material Removal Rate is obtained at 95 m/min cutting speed, 700 mm/min feed rate and 0.8 mm of depth of cut (A3 B2 C3).

Table 5. Response table (mean) for surface roughness

Figure 2. Response graph for surface roughness

Figure 3. Interaction plots for surface roughness

Table 6. Response table (mean) for material removal rate

Figure 4. Response graph for material removal rate

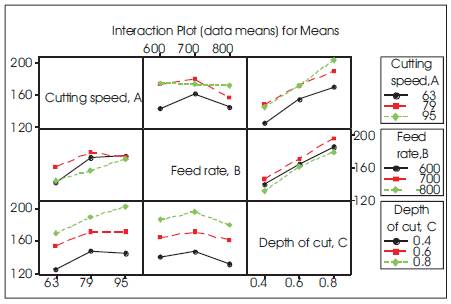

The interaction plots for Material Removal Rate which is shown in Figure 5 are between cutting speed and feed rate (AxB), between cutting speed and depth of cut (AxC), and between feed rate and depth of cut (BxC). It is observed from the interaction plots for Material Removal Rate that there is a less interaction effect between cutting speed and feed rate (AXC).

Figure 5. Interaction plots for material removal rate

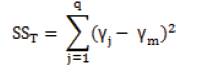

The purpose of the statistical ANOVA is to investigate which design parameter significantly affects the performance characteristic. This is accomplished by separating the total variability of the output response value, which is measured by the sum of the squared deviations from the total mean of the output response value, into contributions by each machining parameter and the error. First, the total sum of the squared deviations SST from the total mean of the output response value Ym can be calculated as,

where q is the number of experiments in the orthogonal array and Yj is the output response value for the jth experiment. The total sum of the squared deviations SST is decomposed in to two sources: the sum of the squared deviations SSd due to each machining parameter and its interaction effects and the sum of the squared error SSe . The percentage contribution (P) by each of the machining parameter in the total sum of the squared deviations SS can be used to evaluate the importance of the machining parameter change on the performance characteristic. In addition, the Fisher's F-test can also be used to determine which machining parameters have a significant effect on the performance characteristic. Usually, the change of the machining parameters has a significant effect on performance characteristic when F is large. The analysis is carried out for the level of significance of 5% (the level of confidence is 95%).

Table 7 shows the result of ANOVA for the surface roughness. From Table 7, it is observed that the cutting speed (Percentage contribution, P = 60.23%) is the more significant machining parameter and feed rate (P = 28.12%) is the next significant parameter affecting surface roughness.

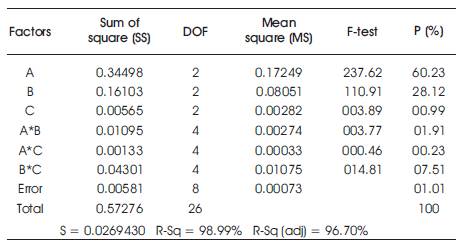

The result of ANOVA for the Material Removal Rate is shown in Table 8. From Table 8, it is observed that the depth of cut (Percentage contribution, P = 65.06 %) is the more significant machining parameter affecting Material Removal Rate followed by cutting speed (P = 17.68%) and feed rate (P = 5.38%).

The Taguchi experimental design was used to obtain optimum cutting parameters on milling AISI 304 stainless steel. Experimental results were analyzed using ANOVA. The results obtained in this study are given below:

Table 7. ANOVA for surface roughness

Table 8. ANOVA for material removal rate