Figure 1. Damage Due to Unmixed Fuel

The analysis of IC engine piston is carried out using the finite element method to determine stress and displacement distribution due to the flue gas pressure and temperature. Simulation of an IC engine piston provides the necessary details which may be further used in the design process. The piston is subjected to mechanical and thermal loads under service conditions which need to be controlled. Temperature, type of fuel, engine speed, piston material etc. affects the performance of an IC engine. Deformation behavior of the piston material is analyzed through the CAE software and the response data is generated. A comparative study has been also carried out between an alloy and metal matrix composite which were used as a piston material. Response surface optimization is conducted using Taguchi design of experiments to determine design points. Under structural loading conditions, the metal matrix composite (MMC) performs better than the eutectic alloy. The piston crown area has been subjected to maximum deformation under structural and thermal loading conditions.

The combustion of fuel causes expansion of gas and generates thermal energy. Piston is required to convey expansion of gas to crankshaft via connection rod. The geometry of piston is like a cylindrical plug making up and down motion inside cylinder. Piston finds its application in pneumatic cylinders and pumps and IC engines. It generates reciprocating motion inside IC engine cylinder under different combustion strokes. The fuel combustion generates thrust which is exerted on piston. The piston transmits this thrust to connecting rod. The piston needs to have huge strength and heat resistance residences to face up to the gas stress and inertia forces. They must have minimum weight to minimize the inertia forces. The material of the piston should have accurate and short dissipation of warmth from the crown to the bearing vicinity to the cylinder walls. It has to form a powerful gasoline and oil seal.

Material of the piston needs to possess appropriate carrying qualities, so that the piston is ready to preserve enough surface-hardness unto the working temperatures. Piston has to have inflexible creation to withstand thermal, mechanical distortion and sufficient region to prevent undue wear. It has even growth underneath thermal masses so ought to be unfastened as viable from discontinuities. The design of piston head depends upon working conditions which is determined by thrust caused by explosion in engine cylinder and quick heat dissipation capacity of piston head to cylinder walls.

Piston skirt is attached in four stroke as well as two stroke engines. It performs different functions for different IC engines. These skirts are short in length and are fitted to act as a guide and stabilise the position of the piston inside the cylinder in large cross head two stroke engines with uni-flow scavenging. The pin travels through bosses on the inside of the piston skirt and the bush on the connecting rod's small end. To offset the twisting effect of friction and achieve consistent pressure distribution between the piston and the cylinder liner, the centre of the piston pin should be 0.02 D to 0.04 D above the middle of the skirt. The case-hardened steel alloy containing nickel, chromium, molybdenum or vanadium is normally used for the piston pin. The piston should be properly supported, bear mechanical distortion, dissipate heat to walls of cylinder and high bearing area to minimize wear. The most commonly used materials for pistons of IC engines are forged iron, cast aluminum, forged metal and solid steel (Buyukkaya & Cerit, 2007; Cerit, 2011). The piston having speeds below 6 m/s uses solid iron as the material and aluminium alloy pistons are used for exceedingly rated engines going for walks at higher piston speeds.

There are various causes of piston failure under the given operating conditions;

The piston shown in Figure 1 has severe scouring marks on the exhaust skirt with the largest damage on the clutch side. All of these damages were caused by running the straight fuel. The minimum quantity of lubrication on the piston has caused it to seize to the cylinder wall. The revealed damage has been in the moments before the piston stuck, which seized the engine.

Figure 1. Damage Due to Unmixed Fuel

The damage caused by over-throttling the engine is shown in Figure 2 which has rounded edge caused when rings were caught in exhaust port. This causes high frequency vibration which eventually breaks the ringland.

Figure 2. Damage Due to Over-throttling Engine

Figure 3 shows piston broken by detonation due to heat causing piston seizure within the cylinder noticeable at the piston facet. This type of damage ruins both piston as well as cylinder. The usual remedy of detonation is switching to higher octane fuel.

Figure 3. Damage Due to Detonation

The excess heat is the reason for piston seizure as shown in Figure 4. Low engine oil setting, lean carburetor tunings, partially plugged oil filters, and over-revving the engine are the most common causes, and can be avoided by correcting any of the problems.

Figure 4. Damage from Heat Seizure

Buyukkaya and Cerit (2007) conducted thermal analysis on coated piston with MgO-ZrO2 and compared results with uncoated piston. The FEA analysis has shown that maximum surface temperature of covered piston has low thermal conductivity which improved the efficiency of IC engine.

Cerit (2011) conducted analysis on piston with 0.4 mm ceramic coating thickness to determine its effect on temperature and stress distribution and compared it with piston without any coating. The findings have shown that with increase in thickness of coating the stress decreases and thermal performance of piston improved.

Junker (2011) in his work discussed about different types of pistons, loading cases on pistons and schematics. He also discussed about piston characteristics, types of piston and design calculations. The properties of piston materials, FEA analysis and cooling characteristics of piston are also discussed.

Jalaludin et al. (2013) investigated the effect of coating materials on piston. The coating materials investigated are partially stabilized zirconia (psz) which is sprayed on piston crowns. The surface roughness, microstructure and thermal stresses are investigated and found to have significant improvements.

Zhuravlev et al. (2013) investigated Al2O3 and urea as an organic fuel and its effect on piston thermal characteristics. The combustion analysis has been conducted at 600 oC to 800 oC and results have shown that through spectroscopy technique, the low temperature alumina is formed due to thermal decomposition.

Zhuravlev et al. (2013) investigated effect of natural gas combustion on direct ignition system (CNGDI). The analysis has shown generation of high thermal stresses which could be reduced with the use of layered NiCrAl and stabilized zirconia.

Kumar et al. (2013) conducted analysis on improvement of thermal characteristics of IC engine piston using thermal barrier coating and improving engine performance. The fuels investigated are biodiesel and findings have shown that TBC improved thermodynamic performance of IC engines and ANN (artificial neural network) is a viable tool which takes less time and cost.

Mittal et al. (2013) has highlighted the importance of ceramic coatings on piston with respect to improving fuel efficiency, reduction of exhaust gas emission. Butanol fuel has higher performance as compared to ordinary gasoline fuel in case of IC engines.

Rajam et al. (2013) has analysed piston which is more lightweight and possess high strength using ANSYS software. The design of piston is optimized by changing barrel thickness with 31%, and ring land thickness with 25%. The FEA analysis has shown significant improvement in strength of piston with modification in design.

Lu et al. (2013) investigated four ring piston of diesel engine to determine its thermal flux and temperature distribution and the effect of film lubrication on heat dissipation. The numerical analysis results are approximately same as experimental results and thin film lubrication is a very effective technique.

Lima et al. (2013) conducted FEA analysis on thin lined piston for different thickness of coatings and its effect on compressive strain, stress generation etc.

Wang et al. (2014) investigated the residual stress generation on piston with usage of thermal barrier coating (TBC's) and thermal insulation effect. The research results show that barrier coating thickness of 300 μm is ideal for the application.

Freiburg et al. (2014) has highlighted the importance of thermal coatings and advantage of lightweight materials for manufacturing of engine blocks. The coatings on piston rings are important to improve thermal characteristics of piston.

Sagade et al. (2014) has supplied the experimental results of the prototype compound parabolic trough manufactured from silver lined selective floor. The overall performance of collector has been evaluated with three forms of receiver covered with styles of receiver coatings like black copper and black zinc and pinnacle cover. This line focusing parabolic trough yields immediate performance of 60% with pinnacle cover. A simple dating between the parameters has been worked out with the regression evaluation.

Roberts et al. (2014) has analysed the importance of effective lubrication of IC engine to reduce pollution, as emission standards are getting more stringent. The research highlighted the suitable viscosity of the lubricant and enhanced viscosity at lower temperatures decreased frictional losses of the piston and proper combustion.

The aim of this research is to analyse new class of materials known as metal matrix composites in manufacturing of IC engine pistons which could improve life and that might help us in future to substitute the conventional materials used in piston. The CAD model of piston is developed in Creo design software and analyzed using ANSYS software.

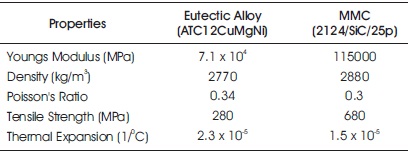

In this process original design of the IC engine piston is modelled using CAD software and analysed using ANSYS. The IC engine piston material has been changed and further investigated using ANSYS for material optimization. The properties of the piston material used for analysis have been shown in Table 1.

Table 1. Properties of Piston Material

The CAD modelling of piston is done using Creo 2.0 software which is a sketch based parametric 3D modelling package. The tools used for modelling is revolve and sketch (Barriga et al., 2014; Jaber & Rai, 2014; Sharma, 2015). The sketch comprises of cross section of piston and revolves about axis as shown in Figure 5.

Figure 5. CAD Model of a Piston

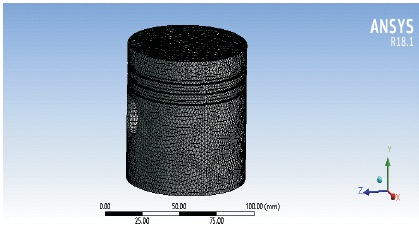

It consists of three stages; pre-processing, analysis and post processing. The model is meshed using tetra elements of appropriate size and shape. After meshing, appropriate loads and boundary conditions are assigned. Initially element stiffness matrix is formulated, the element stiffness matrix are assembled to form global stiffness matrix. When solver is set to run, the software calculates results at nodes and results are interpolated for entire element edge length. In the last stage, the optimization of input design variables like piston diameter and mean diameter is envisaged (Mishra, 2014; Srivastav et al., 2015; Vaishali & Khamankar, 2015). Accordingly, changes are made in initial design and previous steps are repeated. The meshed images are shown in Figure 6.

Figure 6. Meshing of Piston Suspension using ANSYS Design Modeller

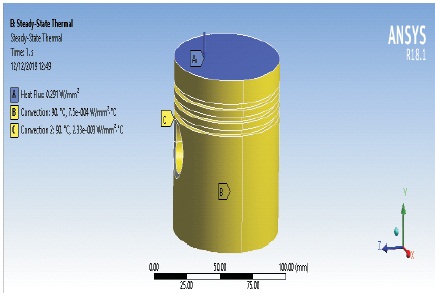

CAD model of piston is applied with thermal loads and boundary conditions as shown in Figure 7. The top surface is applied with 2.91 x 105 W/m2 heat flux and side surfaces are applied with thermal convection coefficients.

Figure 7. Applied Thermal Loads and Boundary Conditions

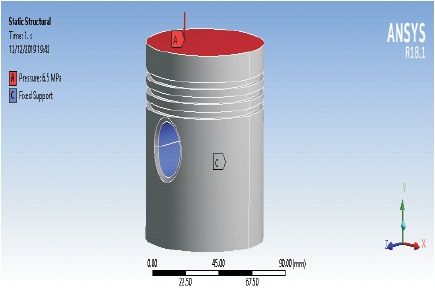

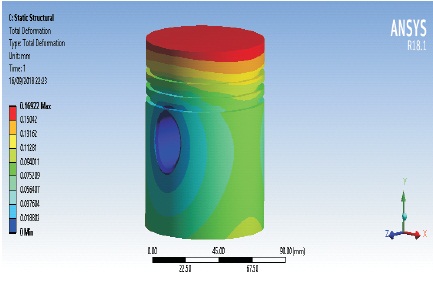

For structural loads, the piston top surface is applied with 6.5 MPa pressure and cylindrical hole is applied with fixed support as shown in Figure 8.

Figure 8. Applied Structural Loads and Boundary Conditions

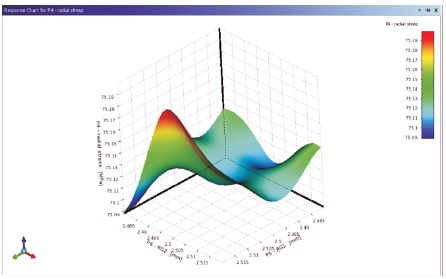

The two variables RG1 and RG2 are optimized using response surface optimization technique. The output variables studied are tangential stress and radial stress. The design points are generated using Design of Experiments (DOE) and 3D response surface plots are generated along with sensitivity plots which depict behavior of each optimization variable on output parameter (Cioată et al., 2017; Pandey & Bajpai, 2016; Srinadh & Rajasekhara, 2015).

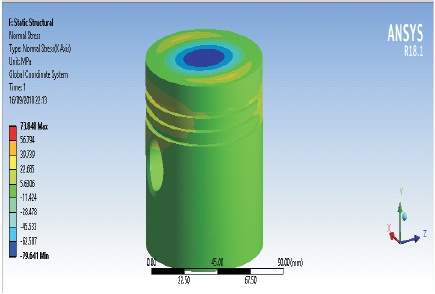

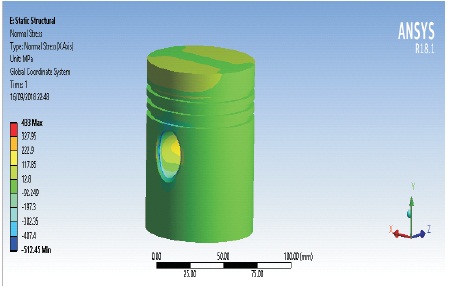

The radial stress plot generated for eutectic alloy shows higher value of radial stress on piston crown region with magnitude of 79.64 MPa shown by dark blue colour in Figure 9, which reduces towards piston skirt region and piston groves. The stress near piston groves is 39.739 MPa.

Figure 9. Radial Stress Distributions in Piston of Eutectic Alloy

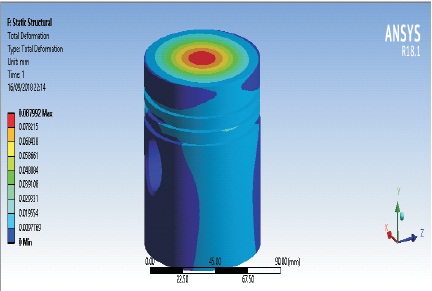

From deformation plot shown in Figure 10, the maximum deformation is observed near piston crown region shown by dark red colour of magnitude 0.0879 mm and minimum deformation is observed on piston skirt region and piston boss shown by dark blue colour.

Figure 10. Deformation Plot on Piston of Eutectic Alloy

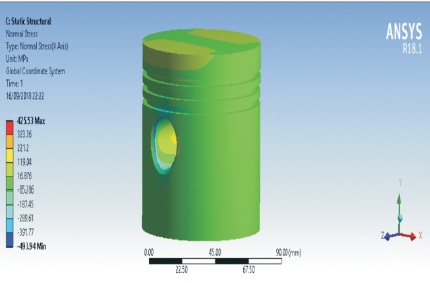

The radial stress plot generated for eutectic alloy shows higher value of radial stress on piston boss region with magnitude of 493.94 MPa shown by dark blue colour as shown in Figure 11, which reduces towards piston skirt region and piston groves by magnitude 85 MPa.

Figure 11. Radial Stress Distributions on Piston (Thermal Loading)

From deformation plot shown in Figure 12, the maximum deformation is observed near piston crown region shown by dark red colour of magnitude 0.169 mm and minimum deformation is observed on piston skirt region and piston boss shown by dark blue colour.

Figure 12. Deformation Plot on Piston (Thermal Loading) using Eutectic Alloy

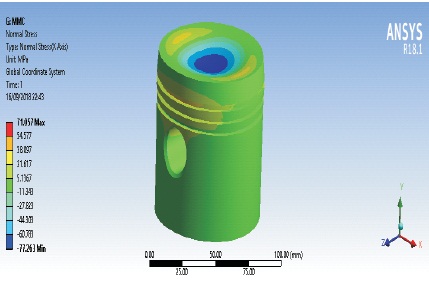

The radial stress plot generated for MMC is shown in Figure 13. It has higher value of radial stress on piston crown region with magnitude of 77.263 MPa shown by dark blue colour which reduces towards piston skirt region and piston groves. The stress near piston groves is 38.097 MPa.

Figure 13. Radial Stress Distributions on Piston of MMC

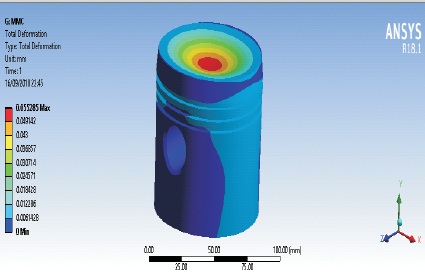

From deformation plot shown in Figure 14, the maximum deformation is observed near piston crown region shown by dark red colour of magnitude 0.055 mm and minimum deformation is observed on piston skirt region and piston boss shown by dark blue colour.

Figure 14. Deformation Plot on Piston of MMC

The radial stress plot generated for MMC shows higher value of radial stress on piston boss region with magnitude of 512.45 MPa shown by dark blue colour in Figure 15, which reduces towards piston skirt region and piston groves of magnitude 92 Mpa.

Figure 15. Radial Stress Distributions on Piston of MMC (Thermal Loading)

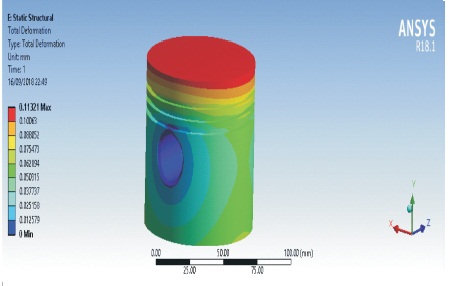

From deformation plot shown in Figure 16, the maximum deformation is observed near piston crown region shown by dark red colour of magnitude 0.1132mm shown by red colour and minimum deformation is observed on piston skirt region and piston boss shown by dark blue colour.

Figure 16. Deformation Plot on Piston of MMC (Thermal Loading)

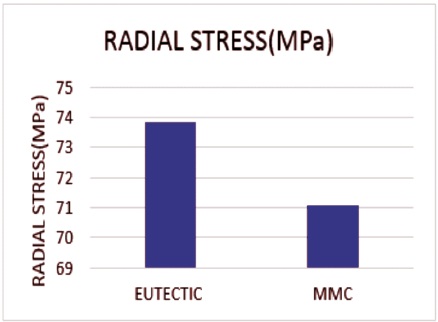

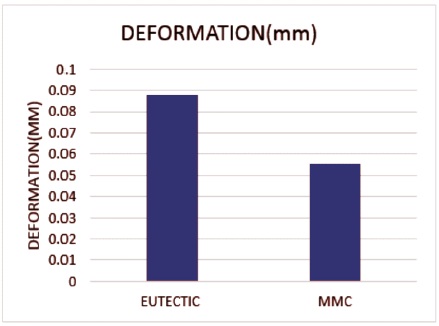

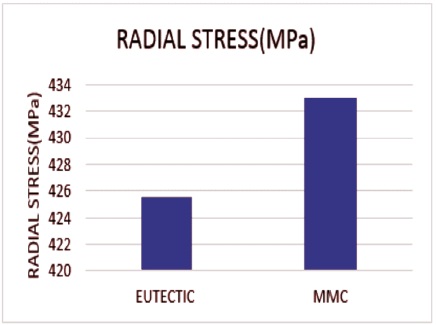

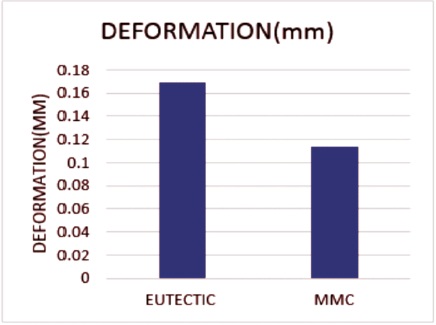

The graph is used to compare the results between eutectic alloy and MMC through the data obtained by structural and thermal analysis as shown in Figures 17, 18, 19 and 20.

Figure 17. Radial Stress Comparison through Structural Analysis

Figure 18. Deformation Comparisons through Structural Analysis

Figure 19. Radial Stress Comparisons through Thermal Analysis

Figure 20. Deformation Comparisons through Thermal Analysis

The response surface plot of RG1 and RG2 variable versus radial stress are shown in Figure 21. The maximum radial stress is observed for RG2 value ranging from 2.495 mm to 2.51 mm and RG1 value ranging from 2.51 mm to 2.52 mm. The radial stress is minimum for RG1 value ranging from 2.48 mm to 2.485 mm and RG2 value ranging from 2.48 mm to 2.485 mm.

Figure 21. Response Surface Plot of Radial Stress in Horizontal Direction

The FEA analysis has been conducted on the material of IC engine piston by ANSYS software. The benefits of using this software led to the saving of time in determining deformation and stresses from thermal and structural analysis respectively. The use of metal matrix composite material in piston has shown motivating results as compared to the conventional eutectic alloy. The detailed results are as: