Figure1. Electrolux Refrigeration System

The continuous increase in the cost and demand for energy has led to more research and development to utilize available energy resources efficiently by minimizing waste energy. Absorption refrigeration systems increasingly attract research interests [15]. Vapour Absorption Refrigeration System (VARS) offers the possibility of using heat to provide cooling. The Vapour absorption refrigeration system utilizing solar energy would generally be more efficient. For this purpose, heat from conventional boiler can be used or waste heat and solar energy. Absorption system falls into two categories depending upon the working fluid. These are the LiBr- H2O and NH3-H2O Absorption Refrigeration system. In LiBr-H2O system, water is used as a refrigerant and Li-Br is used as an absorbent, while in NH3-H2O system ammonia is used as an refrigerant and water is used as an absorbent, which served as standard for comparison in studying and developing new cycles and new absorbent/refrigerant pairs. Many researchers have studied the solar absorption refrigeration system in order to make it economically and technically available. But still, much more research in this area is needed. This paper will help many researchers working in this area and provide them with fundamental knowledge on absorption systems, and a detailed review on the past efforts in the field of solar absorption refrigeration systems with the absorption pair of ammonia and water. This knowledge will help them to start the parametric study in order to develop new refrigeration systems with the help of solar energy.

In view of shortage of energy production and fast increasing energy consumption, there is a need to minimize the use of energy and conserve it in all possible ways. In recent developments of Thermal Engineering the Refrigeration technologies play an important role in today's industrial applications [1, 15]. The present energy crisis has forced the scientists and engineers all over the world to adopt energy conservation measures in various industries. Reduction of the electric power and thermal energy consumption are not only desirable but unavoidable in view of fast and competitive industrial growth throughout the world. Refrigeration systems form a vital component for the industrial growth and affect the energy problems of the country at large [4, 11]. Therefore, it is desirable to provide a base for energy conservation and energy recovery from Vapour Absorption System. Mechanical Vapour Compression Refrigeration requires high grade energy for their operation. Apart from this, recent studies have shown that, conventional working fluids of vapour compression system are causing Ozone layer depletion and Green House Effects. However, Vapour Absorption Systems offer many advantages like it offers flexibility to utilize any sort of low grade, low cost heat energy available to produce cooling and thus giving a high savings in operating cost. It can operate on steam or any other waste heat source as the energy source instead of costly and unreliable electric power. No moving parts ensure noise less, vibration-less and trouble free operation. Moreover, maintenance costs are negligible as compared to power driven Mechanical Systems [2]. Vapour absorption refrigeration systems, the required input to absorption systems is in the form of heat. Hence these systems are also called as heat operated or thermal energy driven systems. Both vapour absorption and absorption refrigeration cycles accomplish the removal of heat through the evaporation of a refrigerant at a low pressure and the rejection of heat through the condensation of the refrigerant at a higher pressure. The basic difference is that, a vapour absorption system employs a mechanical compressor to create the pressure differences necessary to circulate the refrigerant whereas an absorption system uses heat source and the differences cause an absorption system to use little to no work input, but energy must be supplied in the form of heat. This makes the system very attractive when there is a cheap source of heat, such as solar heat or waste heat from electricity or heat generation [3,13]. The overall performance of the absorption cycle in terms of refrigerating effect per unit of energy input generally poor, however, waste heat such as, that rejected from a power can be used to achieve better overall energy utilization. Ammonia/water (NH3/H2O) systems are widely used where lower temperature is required. [10] However, water/lithium bromide (H2O/Li-Br) system are also widely used where moderate temperatures are required (e.g. air conditioning), and the latter system is more efficient than the former.

The main objective of this paper is to design an environment friendly vapour absorption refrigeration system by using solar power as a heat source instead of electricity. The result of this study can be used to develop new refrigeration system. This paper will help many researchers working in this area and provide them with fundamental knowledge on absorption systems, and a detailed review on the past efforts in the field of solar powered vapour absorption cooling systems.

Since the invention of absorption refrigeration system, NH3- Water has been widely used. Both NH3 (refrigerant) and water (absorbent) are highly stable for a wide range of operating temperature and pressure. NH3 has a high latent heat of vaporization, which is necessary for efficient performance of the system. It can be used for low temperature applications, as the freezing point of NH3 is - 77°C [12]. But, since both NH3 and water are volatile, the cycle requires a rectifier to strip away water that normally evaporates with NH3. Without a rectifier, the water would accumulate in the evaporator and offset the system performance. There are other disadvantages such as its high pressure, toxicity, and corrosive action to copper and copper alloy. Ammonia/Air mixtures are barely inflammable, but may be explosive in the case of high percentages of ammonia between 15.5 and 27% by volume [7].

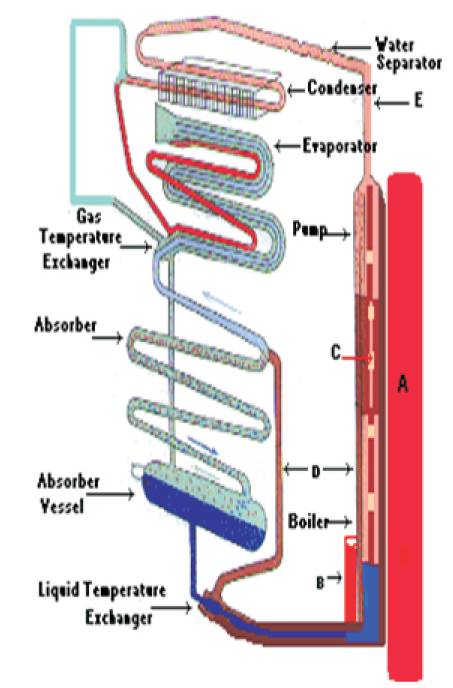

The Electrolux Refrigeration System is shown in Figure1.

Figure1. Electrolux Refrigeration System

The continuous absorption type of cooling unit is operated by the application of a limited amount of heat furnished by gas, electricity or kerosene. No moving parts are employed. The unit consists of four main parts- the boiler, condenser, evaporator, and absorber [4].

The unit can be run on electricity, kerosene or gas. When the unit operates on kerosene or gas, the heat is supplied by a burner which is fitted underneath the central tube (A) and when the unit operates on electricity, the heat is supplied by a heating element inserted in the pocket (B). The unit charge consists of a quantity of ammonia, water and hydrogen at a sufficient pressure to condense ammonia at the room temperature for which the unit is designed. When heat is supplied to the boiler system, bubbles of ammonia gas are produced which rise and carry with them quantities of weak ammonia solution through the siphon pump (C). This weak solution passes into the tube (D), whilst the ammonia vapor passes into the vapor pipe (E) and on to the water separator. Here, any water vapor is condensed and runs back into the boiler system leaving the dry ammonia vapor to pass to the condenser [11,12]. Air circulating over the fins of the condenser removes heat from the ammonia vapor to cause it to condense to liquid ammonia in which state it flows into the evaporator. The evaporator is supplied with hydrogen. The hydrogen passes across the surface of the ammonia and lowers the ammonia vapor pressure sufficiently to allow the liquid ammonia to evaporate. The evaporation of the ammonia extracts heat from the food storage space, as described above, thereby lowers the temperature inside the refrigerator. The mixture of ammonia and hydrogen vapor passes from the evaporator to the absorber. Entering the upper portion of the absorber is a continuous trickle of weak ammonia solution fed by gravity from the tube (D). This weak solution, flowing down through the absorber comes into contact with the mixed ammonia and hydrogen gases which readily absorbs the ammonia from the mixture, leaving the hydrogen free to rise through the absorber coil and to return to the evaporator. The hydrogen thus circulates continuously between the absorber and the evaporator [8]. The strong ammonia solution produced in the absorber flows down to the absorber vessel, and thence to the boiler system, thus completing the full cycle of operation. The liquid circulation of the unit is purely gravitational. Heat is generated in the absorber by the process of absorption. This heat must be dissipated into the surrounding air. Heat must also be dissipated from the condenser in order to cool the ammonia vapor sufficiently for it to liquefy. Free air circulation is therefore necessary over the absorber and condenser. The whole unit operates by the heat applied to the boiler system, and it is of paramount importance that this heat is kept within the necessary limits and is properly applied. A liquid seal is required at the end of the condenser to prevent the entry of hydrogen gas into the condenser. Additives are added to minimize corrosion and rust formation and also to improve absorption. Since there are no flared joints and if the quality of the welding is good, then these systems become extremely rugged and reliable. The refrigerant should have high heat of vaporization [5], [6] .

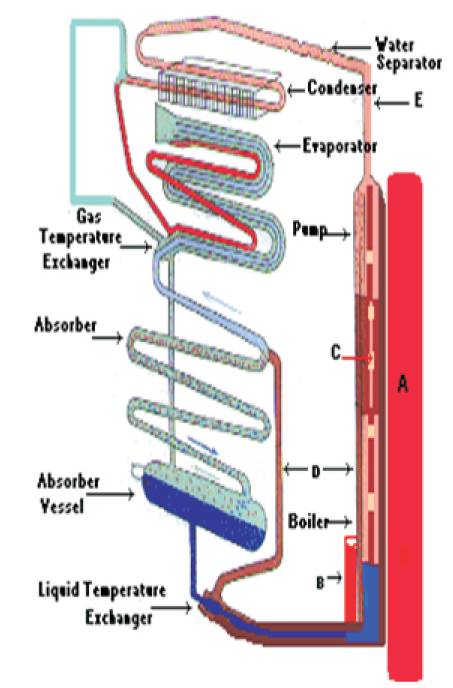

The use of LiBr-Water for absorption refrigeration systems began around 1930. Two outstanding features of LiBr-Water are non-volatility absorbent of LiBr (the need of a rectifier is eliminated) and extremely high heat of vaporization of water (refrigerant). However, using water as a refrigerant limits the low temperature application to that above 0°C. As water is the refrigerant, the system must be operated under vacuum conditions. The addition of the third component into the basic water-lithium bromide solution pushes the crystallization limit away from the normal operating zone. Hence the strong solution can be cooled in the heat exchanger to near absorber temperature without salt crystallization, thus improving the performance of the system. COP is high (0.7 to 0.9) as compared to (0.5 to 0.6) for Ammonia-Water systems[8],[9].

The schematic representation of the Lithium-Bromide Refrigeration System is shown in Figure 2.

Figure 2. Lithium-Bromide Refrigeration System

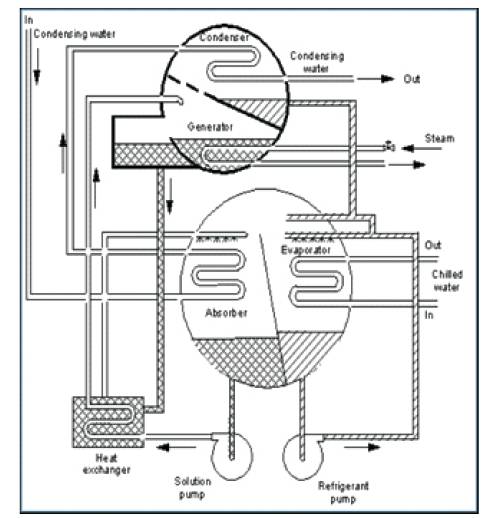

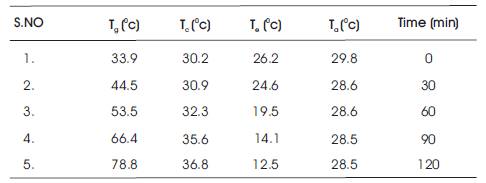

Before applying the solar water heating system, the values are taken by conducting an experiment on vapour absorption refrigeration system and the values are tabulated and calculated as follows, and the experimental values before applying the solar energy are tabulated in Table 1.

Table 1. Experimental Values Before Applying the Solar Energy

Where,

Tg = Generator temperature = 160oC

Tc = Condenser temperature = 40.8oC

Te = Evaporator temperature = -2.8oC

Ta = Ambient temperature = 28.4oC

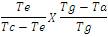

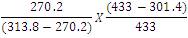

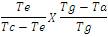

The Coefficient Of Performance (COP) of the system is: COP =

Where

Te = -2.8 +273 = 270.2 k

Tc = 40.8+273 = 313.8 k

Tg = 160 +273 = 433 k

Ta = 28.4 +273 = 301.4 k

COP =

There are two types of solar collectors for electricity generation:

1. Photo Voltaic

2. Parabolic through Solar power

Solar power is a conversion of sunlight into electricity either directly by using Photo Voltaic (PV) or indirectly by using Concentrated Solar Power (CSP). These converts light energy into electrical energy.

Heat collectors are of two types,

1. Flat plate collector

2. Evacuated tubes solar collector

Flat plate gives the maximum temperature of 40oC, which is not enough to supply to the generator, evacuated tubes gives very high temperature which is required at the generator.

The Evacuated tube solar water heating system is shown in Figure 3. The evacuated tube consists of a glass tube which is coated with copper, and this glass tube is surrounded by another glass tube. When the solar rays fall on the solar collector of the evacuated tubes, the copper coating absorbs the heat, and this heat is transfered to the water in the tube.

Figure 3. Evacuated Tube Solar Water Heating System

The connection from solar water tank to the Refrigerator is shown in Figure 4. Then by absorbing the heat, the cold water gets converts to hot water. This hot water has low density, hence it raises to the top of the tube and goes to the solar water tank. The cold water present in the water tank absorbs the heat from the hot water, then the whole water is converted to hot water. These evacuated tubes should be arranged at an angle of 27º on arranging in this way the evacuated tubes absorbs the heat even at low sun light. At the outlet of the storage tank, a control valve is arranged to control the flow of the water.

Figure 4. Connection from Solar Water Tank to the Refrigerator

The experimental setup for the development of solar powered Vapour Absorption Refrigeration System is shown in Figure 5.

Figure 5. Experimental Setup

By applying the solar water heating system the following values are taken for conducting an experiment on vapour absorption refrigeration system and these values are tabulated in Table 2 and COP is calculated.

Table 2. Experimental Values after applying the Solar Energy

Tg = Generator temperature = 78.8oC

Tc = Condenser temperature = 36.8oC

Te = Evaporator temperature = 12.5oC

Ta = Ambient temperature = 28.5oC

The Coefficient Of Performance (COP) of the system is:

COP =

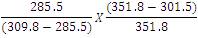

Te = 12.5 +273 = 285.5 k

Tc = 36.8+273 = 309.8k

Tg = 78.8+273 = 351.8 k

Ta = 28.5+273 = 301.5k

COP =

Solar-driven vapour absorption refrigeration has advantages in energy conservation. By applying solar energy the values are calculated and the values are tabulated. The COP of the refrigerator is 2.36 and there is saving of energy consumption of 220KJ. This result will help many researchers working in this area to provide them with fundamental knowledge on absorption systems, and a detailed review on the past efforts in the field of solar absorption cooling systems.