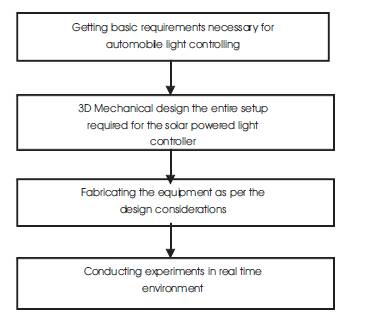

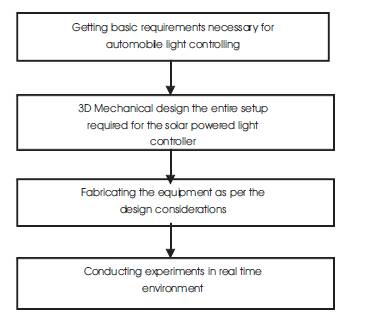

Figure 1. Flow of the work

In this paper, the authors have proposed a low cost solar powered automatic head light controller depending upon the traffic density on the roads. General automobiles have been provided with dual purpose headlights in the dark conditions where the scene is not visible. The low beam light and high beam light are used for different conditions or parameters which affect travelling on road. A 3D Mechanical Design has been done to check the feasibility of the solar panel, controller to accommodate on the stand, then fabricated the exact design with mild steel bars as a support in the form of a stand to the controller. With the help of LDR sensor circuit and dim and brightness controller unit they have successfully tested the unit. Even ultrasonic sensors are also used to detect the objects and activate the controller. At last the equipment is one of the low cost solar powered automatic controller.

Solar Photovoltaic provides clean energy and is environment-friendly. Photovoltaic represents one of the few energy generation options that do not create pollutants or hazardous wastes, in conventional energy resources. Due to the demand in solar cells, the manufacturing costs are also getting down, So the application is going in a wide range. In automobiles the light source is more important, maximum consumption is from battery source which is linked to the ignition of the engine. Here these can be replaced by solar panels, stores the energy which is collected from sun and transfers the energy to the battery then to the lights. This way of green way of energy production which provides free energy once an initial investment is made that too a low investment is to be made. In this paper, we propose a solar powered automatic light controller, which controls the brightness and dimness of the light depending on the visibility and traffic density on the road.

During night time driving, headlight glare from the vehicles traveling behind you can be blinding. Even after the source of the glare is removed, an after-image remains on the eye's retina that creates a blind spot, popularly known as the Troxler Effect; this phenomenon increases driver reaction time by up to 1.4 seconds. That means if driving at 60 mph, a motorist would travel 123 feet before reacting to a hazard. Normal reaction time to a change in driving conditions is 0.5 seconds and the distance traveled before applying the brakes is 41 feet when traveling at the same speed. Low visibility is a greater contributing factor to pedestrian deaths than drunk driving. Approximately, 42 percent of all crashes and 58 percent of fatal crashes in the United States occur at night or during other poor visibility conditions, according to statistics at the National Highway Traffic Safety Administration.

An effective system for detecting vehicles [1] in front of a camera-assisted vehicle (preceding vehicles traveling in the same direction and oncoming vehicles traveling in the opposite direction) during night-time driving conditions in order to automatically change vehicle head lights between low beams and high beams avoiding glares for the driver is essential.

Solar powered street lamp was used [2], Multi- sensor energy-saving control system distributes the reasonable lighting method based on the actual lighting requirement, realizes the automatic adjusting of lamp brightness, and achieves the target of energy-saving and working period extension. The application of this control system optimizes the distribution of battery energy, and reduces the dependence of solar street lamp on high-capacity battery, and improves the practical applicability and economy of solar street lamp. An automatic solar track system was used [3] with sun as a guiding source; its active sensor constantly monitors the sunlight and rotates the panel towards the direction where the intensity of sunlight is maximum. The light dependent resistors do the job of sensing the change in the position of the sun which is dealt by the respective change in the solar panel's position by switching ON and OFF the Geared Motor. The control circuit does the job of fetching the input from the sensor and gives command to the motor to run in order to tackle the change in the position of the sun. For reducing the cost of the solar panels, the authors have implemented the panels used for irrigation system water pump [4] with solar powered.

Vehicle detection on night based on tail-light detection has been proposed [5] using a camera. High beam light usage is warranted, in less than 25 percent of cases, the drivers actually use the high beam lights [6] because they are afraid to dazzle other drivers by mistake. An effective method for detecting vehicles in front of the cameraassisted [7] car during nighttime driving is Night time vehicle detection and they are based mainly in the detection of head lights and tail lights where some researchers are working on it [8]. A novel algorithm to detect and track by the location of tail lights which calculates the intensity of the diffused tail lights, then uses this information to find and track the location of the vehicle [9] has been proposed. Vehicle[10] detection system for identifying the moving vehicles at night, novel image processing system to detect and track long distance vehicle rear-lamp pairs in forward facing color video at dark night.

Assuming good driving conditions on an unlit road, the headlights of a typical car let you see for about 100 meters. Dipped lights will let you see for about 30 meters and a car travelling, rearview mirror is shining bright white reflecting headlights. It is good practise to use dipped headlights or dim/dip lights, which are fitted. In all of the vehicles today, they control the headlights by manual operation for dim / bright light. When you're going in highway each and every 5 seconds, there is a vehicle opposite to our vehicle. By manual operation it is difficult to the driver for operating manually, the driver strains a lot. Sometimes he may not be able to operate due to his negligence. Then automatically accidents are taken place during night times. A brief methodology has been discussed in Figure 1.

Figure 1. Flow of the work

For avoiding all this type of problems, the authors are doing a project in which the head lights are controlled automatically, whenever a vehicle comes in front of us. In this, they have used LDR sensor for sending signal to the control unit which controls the power supply to the headlights.

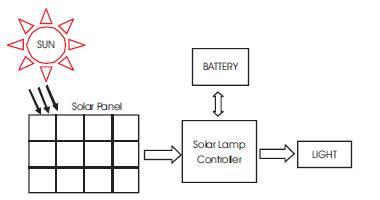

The sunlight delivers rays of photons (solar energy) which hits the solar panel (Photovoltaic module) as shown in Figure 2. The photons (energy) are absorbed by the PV and electrons are released. The electrons flow along the metal contact of the PV and form electricity. Energy is stored in the battery during daytime and operates according to the signal given by the controller depending on the surrounding environment. With the help of LDR sensor, it sends a signal for controlling the light.

Figure 2. Overview of Solar Lamp Controller

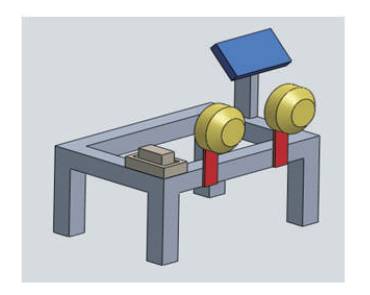

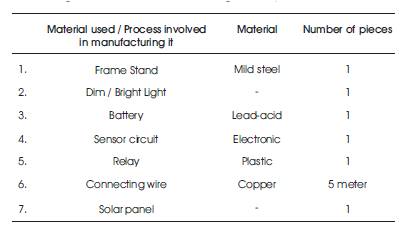

The required components were analyzed and a 3D Mechanical Design was designed using Mechanical Desktop Software. The components identified are PCB board enclosed in a box, PV solar panel. Two head lights (which took from the commercial vehicle), LDR sensor and mild steel bars are used for fabricating the frame. The 3D view of the model developed is shown in Figure 3. The controllers consist of the PCB, LDR sensor mounted on it with the connection of the battery. Table 1 shows the bill of materials used in manufacturing process.

Figure 3. 3D Mechanical Design of Proposed model

Table 1. Bill of materials

After getting all the parts, with the standard welding process mounted part by part and fabricated the equipment, it as shown in Figure 4.

Figure 4. Fabricated Solar powered automatic light controller

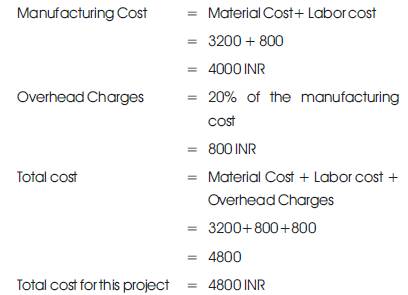

Normal cutting and arc welding process is used for fabrication of the equipment and some support hinges for holding the solar panels and the head light are clamped with the nuts and bolts. The total manufacturing cost in calculated in such a way that material and labor cost are also included in it. The overhead charge for the minor grinding operations which includes 20% of the manufacturing cost is also incurred here. The details cost estimation is listed below with the percentage of the charges incurred with respect to the material and manufacturing also.

The overhead charges are arrived by “Manufacturing cost”

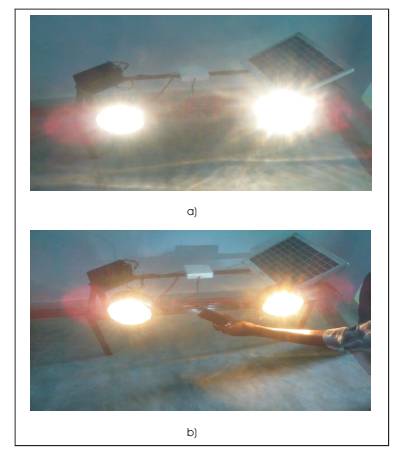

The brightness and dim condition of the light arrangement is clearly shown in Figure 5. It is not reliable to show results about distance detection, since the system is thought to detect head lights at far distances. Depending on changing the surroundings environment, it is clear that light change occurs.

Figure 5. a) Bright Condition b) Dim Condition

By implementing the proposed design where low cost automation equipment is manufactured, so it can reach each individual and the initial investment is also very low. This equipment can be further modified and the brightness controller has been adjusted depending on the environment conditions. With the implemention of such kind of solar energy equipments, the authors can protect the environment as the demand of the energy is increasing day by day and the diminution of fossil fuels. It is a known fact that the most unutilized source of energy is solar energy and efforts are on all over the world to increase its utilization. Everybody knows its importance but the authors created this project, and have tried to show the importance of getting the maximum energy out of this resource.