Figure 1. Bioreactor blade 1

The available fuel sources in the market are less than demand, therefore the alternative fuels are substitutes for different commercial and residential applications, such as diesel and petrol for automobiles. Currently, many countries need to import significant amount of crude oil and other petroleum products. Also the air pollution is another environmental problem caused by the pollutant emissions from the automobiles running on petroleum products. The biogas is a renewable clean fuel that can potentially replace the traditional petroleum fuels in the future. Biogas contains 55% CH4, 40.5% Co2, and 4.5% pollutants including H2, N2, H2S, and O2 to minimize the pollutant amount. Biogas can be processed by going through the enrichment system of scrubbing and bottling mechanisms to produce Bio-CNG gas for automobiles. Biogas can be widely utilized after performing purification process to remove pollutants. The pure Bio- Methane in this analysis is pressurized to 19.5 MPa to fill in CNG cylinder by compressor. The capacity of producing Biogas is about 148 m3 daily and Biogas production efficiency will rely on environment and other conditions. The design analysis of bio-reactor in this biomass system is accomplished by performing the mathematical modeling, computer aided simulation, and prototype experiment.

Biomass is the biological material processed from living or recently dead organisms which include the plants or plantrelated materials [1]. Biomass is an energy resource which can be either utilized directly by combustion to generate heat, or indirectly after being converted to other types of bio-fuel [2]. Conversion from biomass to bio-fuel can be done by different methodologies including thermal, chemical, and biochemical technologies [3, 4]. Currently the petrol and diesel are major fuels in commercial transportation systems and its demand is increasing gradually. Due to the shortage of natural petroleum resource, many petrol products required to be imported from other countries [5]. Also, there is importance of pollution control on automobile emission which drives to find alternate fuel resources. The natural gases including bio- fuel and biogas, wind power, geothermal, and solar energy are the alternative energy resources in commercial and residential applications [6]. Natural gas consists of methane, ethane, propane, butane and other gases, but biogas consists of about 70-74% enriched methane. It can potentially get pure methane from biogas by applying certain methodologies, such as utilizing scrubber [7]. Methane can be easily compressed after getting enriched methane from biogas, and so it can be potentially utilized as gas fuel for automobiles, cooking, and other applications [8]. Biomass source materials from organic wastes including sewage waste, community solid waste, and commercial waste can be utilized as the stock to produce biogas [9]. Biogas is one of the clean and renewable fuels and its waste coming from biogas production can be used for fertilizer products [10]. The source materials for biogas are commonly biodegradable wastes that can be easily found in all commercial and residential areas including human waste, green waste, paper waste, food waste, and many other organic wastes [11].

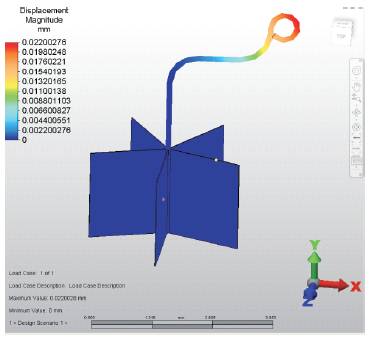

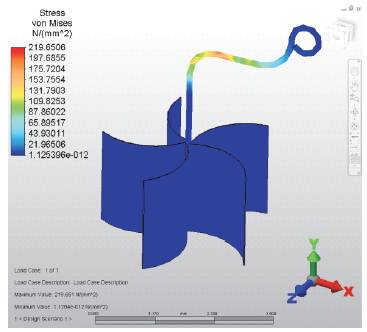

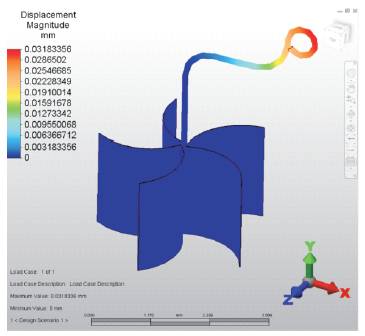

The computer-aided simulation has been applied to analyze and improve the functionality of biogas reactor in biomass well system. In biogas reactor, an external force is applied to rotate the biomass mixer to product the biogas. The raw feedstock material is steered rapidly and biogas is continuously produced in the biogas reactor. To optimize the reactor design, three different blade shapes shown in Figures 1 and 2 are investigated.

Figure 1. Bioreactor blade 1

Figure 2. Bioreactor blade 2

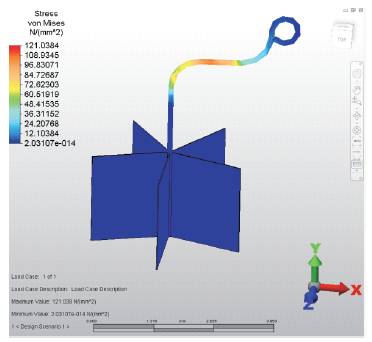

The computer aided simulation shows the stress profiles and deformation profiles of these three bioreactors in Figures 3-6.

As per Figures 3 -6, the maximum stress of 121.04 N/mm2 in blade 1 is less than 219.65 N/mm2 in blade 2 due to less force required to steer the blade with minimum flat surface.

Since the yield strength of mild steel is 250.28 N/mm2, the blade 1 design can function properly in biogas reactor. The maximum deformation of blade 1 is within the material’s allowable limit.

Figure 3. Stress profile in blade 1

Figure 4. Deformation profile in blade 1

Figure 5. Stress profile in blade 2

Figure 6. Deformation profile in blade 2

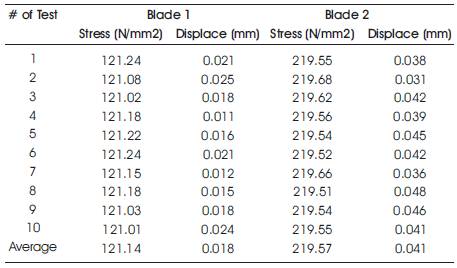

The prototype of biogas reactor has been built and tested to verify the design function and computer aided simulation. Table 1 presents the testing results of stress and deformation profiles in blades 1 and 2.

The maximum stress and deformation in Table 1 are 121.14 N/mm2 and 0.018 mm for blade 1, and 219.57 N/mm2 and 0.041 mm for blade 2 that are very close to computer aided simulation results with 121.04 N/mm2 and 0.022 mm for blade 1, and 219.65 N/mm2 and 0.032 mm for blade 2 respectively. This verifies the feasibility of the analytic methodology applied in this research.

Table 1. Testing results of stress and deformation profiles in blades 1 and 2

Both computational simulation and prototype experiment shows very close results, which demonstrate the proper functioning of this biogas reactor. The recommendation for future improvement will include: (1) optimizing the functionality via computer-aided analysis for high efficiency, (2) study of more reactor blades in different geometry for energy-saving, and (3) simplifying reactor design for cost-effectiveness.

Biogas is an environment-friendly fuel resource which can be widely used in commercial and residential applications with minimized pollution. The addition of this green and sustainable energy resource can potentially help current energy-shortage market. Its by-product out of the production will be utilized as fertilizer for farm and other industrial progress. The computer aided simulation and prototype testing on biogas reactor are described in this paper to optimally improve its functionality and process efficiency. Two different blade shapes are investigated and analyzed. Both computer aided simulation and prototype testing confirm that the flat blade shape has better performance in biogas reactor.