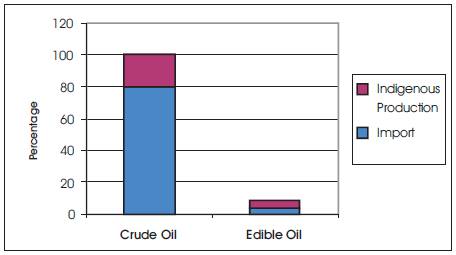

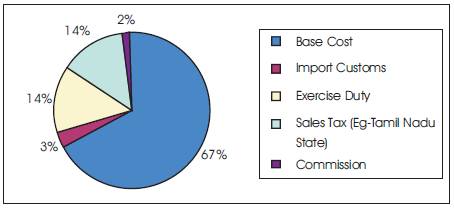

Figure 1. India's total crude and edible oil consumption

The use of vegetable oils as an alternative fuel for diesel engine is accelerated by the energy crisis due to depletion of resources and increased environmental problems. Biodiesel production is a very modern and technological area for researchers due to the relevance that it is winning everyday because of the increase in the petroleum price and the environmental advantages. It was reported that a diesel engine without any modification would run successfully on a blend of 20% vegetable oil and 80% diesel fuel without damage to engine parts. Edible and non-edible oils can be used for biodiesel production. As India is importing 44 percentage of its edible oil requirement and government policy of not to have edible oil for biodiesel production has led to the way for inedible oil research and development for biodiesel production in a massive way. The economics of existing oil price and different inedible feedstock sources for biodiesel production have been extensively investigated in this paper.

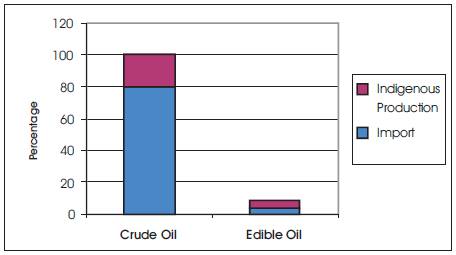

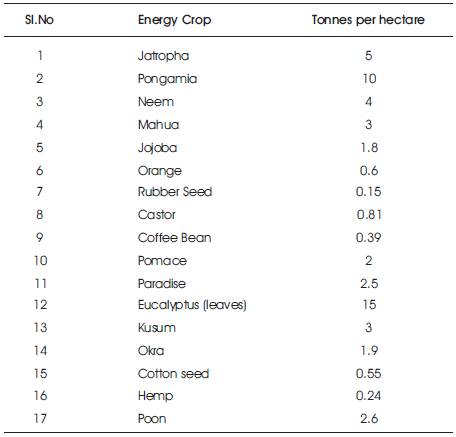

India's oil consumption is around 184 million tones [14]. Out of these 37 million tones are produced in the country itself from Figure 1. The reserves in the country were estimates around 775 million tonne as of now. India has wasteland of around 170 million hectares. This wasteland can be used for the plantation of biodiesel feedstock production. Many feedstock crops yield more than 1 tonne per hectare. If all wastelands were planted the yield will be more than India's requirement from Figure 2. By this way biodiesel can be substituted for conventional fossil fuel, which is going to be depleted, and along with its high emission problems. India's edible oil consumption is met by 44 percentages of imports. So the only option is going for inedible oil. Again lots of varieties of inedible oil crops are already available. They have to be exploited. And for further more usage, the wastelands can be utilized for the plantation of inedible crops. It is known that the remaining global oil resources appear to be insufficient to meet demand in the future. Therefore, there is a demand to develop alternative fuels motivated by the reduction of the dependency on fossil fuel due to the limited resources. Several oxygenated fuels are known to have the potential for use as the alternative gasoline and diesel fuel. The term ''biodiesel' commonly refers to an oxygenated diesel fuel made from various feedstock by conversion of the triglyceride fats to methyl or ethyl esters via trans esterification.

Figure 1. India's total crude and edible oil consumption

Figure 2. Demand for biodiesel

Many vegetable oils in some countries is edible and the same oil is inedible in other country. However, Balat [4] classified oilseeds and algae as vegetable oils and categorized the biodiesel feedstock into three groups: vegetable oils (edible or inedible oil), animal fat and used waste cooking oil. The different types of edible vegetable oils and biodiesels as substitutes for diesel fuels are considered in the different countries depending on the climate and soil conditions. Even though biodiesel production from vegetable oil has many advantages like ready availability, renewability, higher combustion efficiency, lower sulfur and aromatic content, higher cetane number and higher biodegradability for combustion in CI engines [4], important disadvantages of biodiesel include high feedstock cost, inferior storage and oxidative stability, lower heating value, inferior low temperature operability and higher NOx emissions compared to petrodiesel.

Knothe [16] discusses in a general and comparative fashion aspects such as fuel production and energy balance, fuel properties, environmental effects including exhaust emissions and co-products.

Singh and Singh [23] review the source of production and characterization of vegetable oils and their methyl ester as the substitute of the petroleum fuel and future possibilities of Biodiesel production.

About 7% of global vegetable oil supplies were used for biodiesel production in 2007 [4]. Extensive use of edible oils may cause other significant problems such as starvation in developing countries. The use of non-edible plant oils when compared with edible oils is very significant in developing countries because of the tremendous demand for edible oils as food, and they are far too expensive to be used as fuel at present. The production of biodiesel from different inedible oilseed crops has been extensively investigated over the last few years.

Biodiesel plantations can realize assimilation of atmospheric carbon, to the extent of approximately 10 tonnes CO2 per hectare. Under the Clean Development Mechanism (CDM), article 12 of Kyoto protocol specifies that developing countries can benefit from CDM projects resulting in "certified emission reductions" (CERs) and that industrialized countries may use CERs to comply with their quantified emission reduction commitments. This is an additional economic advantage favoring biodiesel usage. When burnt, biodiesel emits the same amount of CO2 as the plants absorb in growth and hence there will be no greenhouse effect and global warming.

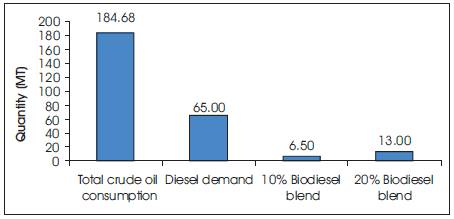

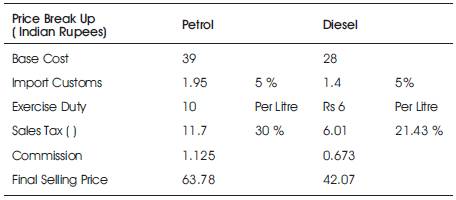

The selling price of petrol and diesel in India is almost 50 % higher than the base cost (Figure 3). Around fifty percentage of its cost goes for government taxes itself in various forms. First comes the import customs for all importing crude oil by the central government. Then the refining companies refine it and gives to oil marketing companies for selling. Again the central government put exercise duty for all the products coming out of the company for sale. Again the respective state governments put sales tax. Finally the oil marketing companies take a portion as commission. These are given in Table 1. As the total economy of the country depends on fuel, and hence its cost should be low as far as possible. So that other cost and inflation will be under control.

Figure 3. Diesel selling price breakup

Table 1. Price comparison of petrol and diesel in India [3,6,21]

India's four leading oil marketing companies financial data is given in Table 2. Out of these three are government owned and one private owned. The total employees expenses are around 2.8 billion dollars. The manpower estimated given by the government is around 0.13 million. Based on this per employee cost comes around 30,000 dollars per annum. Out of the total force around 41,387 are marketing persons. This salary is very high when compared with other sectors.

Reducing the manpower cost can reduce maximum cost of production. This is more particularly for Indian government owned companies. Likewise the subsidy cost should be totally avoided. Indian government is giving subsidy around 3.4 billion dollars on all petroleum products. The net profits of these companies are far more than the subsidy cost. The reserves of these companies are around more than 45 billion dollars. Total crude oil imports in the last year were around 85.31 billion dollars. Total exercise duty collected from the government for these petroleum products is 14.54 billion dollars and custom duty collected is 1.76 billion dollars.

Table 2. Financial Statement of Indian Oil Marketing Companies for the year 2009-2010 (Million Rupees) [25]

The inedible oils such as jatropha, karanja, neem, mauha, rubber, orange, eucalyptus, tall oil and micro algae are easily available in developing countries and are very economical comparable to edible oils. The oils from neem and rubber have high free fatty acid (FFA) content. FFAs easily react with alkaline catalysts to form soap that prohibits the separation of biodiesel and glycerol [24]. The soaps of FFAs also cause foaming in aqueous media. The resulting soaps also cause an increase in viscosity, formation of gels, and foams and make the separation of glycerol difficult. For karanja oil and neem oil the cetane number is more than diesel fuel. The various properties of the raw inedible oil are given in Table 3 [15].

The problem of high feedstock cost can be mitigated by the selection of inedible vegetable oil for the production of biodiesel because the cost of feedstocks accounts about 60–80% of the total cost of biodiesel production. It is clear from the recent review for the perspectives on biodiesel as a sustainable fuel that using low cost feed stocks is one of the key issues including improving efficiency of the production process, developing cost effective catalyst and managing agricultural land [16]. Development of low value alternative feed stocks for biodiesel production is, therefore, one of the important field of current and future research. The use of edible vegetable oil or biodiesel from it as substitutes to diesel fuels may lead to a problem of self-sufficiency in vegetable production. The use of inedible vegetable oils is of significance because of the great need for edible oil as food. In addition the selection of inedible vegetable oil can reduce the production cost of biodiesel due to the relatively high cost of edible vegetable oils. They emphasized that the major obstacle to widespread the use of biodiesel is the high cost (mainly due to high price of edible vegetable oils) relative to petroleum diesel even though biodiesels can be suitable fuels for CI engines.

Jatropha is being considered as one of the most promising potential oil source to produce biodiesel in Asia, Europe and Africa. Jatropha can grow under a wide variety of climatic conditions like severe heat, low rainfall, high rainfall and frost. Since Jatropha is water efficient and widely adaptable, large scale Jatropha plantations required for the biodiesel industry could lead to the regeneration of these wastelands. Jatropha is grown in marginal and wastelands with no possibility of land use competing with food production. The yield of Jatropha oil can be extracted from seeds starting from the second year. Jatropha biodiesel projects can also help in rural developments by introducing new employment opportunities in agricultural and small and medium industrial sectors [18]. Various parts of the plant have medicinal values. Apart from supplying oils for diesel replacement, the growing of the tree itself effectively reduces CO2 concentrations in the atmosphere [5].

It is a hardy tree of 12–15 m height, branches spread into hemispherical crown of dense green leaves and native to the Asian subcontinent. Pongamia can survive in adverse conditions like draught, heat, frost and salinity [17]. Most of the physical and chemical properties of the directly extracted oil are almost similar to those of the diesel, though ''conardson carbon” residue is higher in case of it and due to high viscosity preheating is necessary to start a diesel engine [22]. The toxic substances present in the oil limits its use as cooking oil. The seedcake after oil extraction can be utilized as nematicide.

Neem oil is Light to Dark Brown in color, bitter in taste and has a strong odor. Neem Oil can also be obtained from solvent extraction of the neem seed, fruit, oilcake or kernel. A large industry in India extracts the oil remaining in the seed cake using hexane. The neem tree is native to India and Burma and almost the whole tree is usable for various purposes such as medicines, pesticides and organic fertilizer. Neem can be grown on very marginal soils that may be very rocky, shallow, dry, or pan forming. Neem tree can tolerate some extreme conditions like temperature of 45C and rainfall less than 35 cm per year [20]. Azadirachtin is the main constituent of neem seed oil, which varies from 300 to 2500 ppm depending on the extraction technology and quality of the neem seeds crushed. The oil contains sulfurous compounds, which gives it a pungent odor and a less clean burn than other vegetable oils. It comprises of Triglyceride and Triterpenoid compounds. Neem Oil is Hydrophobic in nature and in order to emulsify it in water for application purpose [17].

Mahua oil is obtained from the kernel of mahua tree, which is a medium to large tree found in most parts of India. The unrefined but filtered crude mahua oil is greenish yellow in color [17]. Mahua has an estimated annual production potential of 181 thousand metric tones in India. It takes 8–15 years to mature fully and a mature tree can bear fruits up to 60 years. It is the native of tropical based deciduous forest of India. The fuel properties of mahua biodiesel were found to be comparable to those of diesel and conforming to both the American and European standards.

The use of jojoba oil for biodiesel is quite new. The plant is believed to be native to the desert areas of the southwestern North American continent, and it grows best in varying conditions of warm temperate deserts. Jojoba oil is not a triglyceride, but a mixture of long chain esters (97–98 wt.%) of fatty acids and fatty alcohols and therefore is more properly referred to as a wax. Jojoba oil is relatively easy to work with as it needs little refining, does not become rancid, and can withstand repeated heating and cooling cycles in excess of 250C [17].

Orange oil is a biomass derived fuel obtained from orange skin, which has 90% D-limonene and can be used for many applications. It may be used as an agent or a source in surface cleaners, hand cleaners, furniture polish, soaps and shampoo production. The orange oil was extracted from the peel of citrus at normal temperature, using the cold pressed oil technique, which uses D-limonene (C10H16) as the main ingredient. The distillation temperature for orange oil is 175° C and for gasoline is 45° C [19]. It was observed that 10% orange oil blended with gasoline does not change the distillation temperature and also has good startability, better acceleration and no vapor lock, which are desirable for spark ignition engines. The yield of the extracted orange oil is about 0.2–0.6% of the total weight of the citrus.

The rubber latex from the rubber tree is a prominent plantation crop of considerable significance to the Indian economy. The tree also provides a variety of ancillary products, prominent being rubber seed from which the oil can be extracted [17]. The oil content of the seed differs from place to place. However, the average oil yield comes to 40%. Except for some application in soap and lubricating oil industries, use of rubber seed oil is limited. The viscosity of neat rubber seed oil is 58.76 mm2/s at 400C. Its availability of 150 kg per hectare is lower compared to many prominent biodiesel sources like jatropha curcas. This is mainly due to its high demand for rain, humidity and bright sun light [11]. Rubber seed oils are reported to have 17–20% saturated fatty acids and 77–82% unsaturated fatty acids.

Castor oil is comprised almost entirely (ca. 90%) of triglycerides of ricinoleic acid (12-hydroxy-cisoctadec- 9enoic acid) in which the presence of a hydroxyl group at C-12 imparts several unique chemical and physical properties and thus, castor oil and its derivatives are completely soluble in alcohols and exhibit viscosities that are up to sevenfold higher than those of other vegetable oils [15]. Although castor has potential for very high oil yield, the fact that it is considered a weed by many agricultural producers certainly limits its viability as an option to produce significant amounts of biodiesel [17].

Brazil is the world's largest coffee producer. However, approximately 20% of the production in Latin America consists of defective beans, which greatly affect beverage quality. Studies revealed that the most attracted alternate use of these defective coffee beans is biodiesel production from the oil extracted from them. Spent coffee grounds contain between 11 and 20% oil by weight. Waste coffee grounds can be used as potential low cost environmental friendly source of biodiesel. Researchers in USA reported that the resulting, coffee based biodiesel is much more stable than traditional biodiesel because of coffee's high antioxidant content.

This oil was obtained from pomace, which is the waste of olive oil plants. Pomace is a kind of waste residue of olive oil plants that contains mainly crushed olive kernel, pulp, olive skin and olive stalks. Pomace oil has been extracted from pomace in the olive-pomace processes. Pomace has been collected to the pomace plant from olive oil plants. Pomace was obtained about 40% from olive [7]. Fresh pomace contains 6–9% oil, 42–54% kernel, 21–33% pulp and 10-11% skin. Optimum esterification producing conditions were determined experimentally. It releases fume and creates environmental pollution. Generally, it has been eliminated by means of burning. It has also been used widely in the soap manufacturing.

The Paradise tree is a multipurpose tree, capable of growing on degraded soils. It can adapt to a wide range of temperatures (30-45° C) and altitudes (up to 1000 m above sea level). The botanical name of paradise oil is simarouba glauca. Paradise oil, like Jatropha oil, is arousing great enthusiasm for its use in producing bio-diesel. The oil contains about 63% unsaturated fatty acids. This evergreen tree can check soil erosion and helps in wasteland reclamation [9]. As a long-term strategy, cultivation of paradise tree is advocated in the abundantly available marginal lands/wastelands, to overcome oil shortage and its implementation is economically viable and ecologically sustainable.

The eucalyptus tree grows in many parts of the world. Eucalyptus oil can be extracted from eucalyptus leaves, which are available abundantly throughout the year. Therefore, oil production is perennial and not seasonal [9]. Another added advantage of this oil is that, it can be directly blended with any oil without any modification to the oil.

The fruits are smooth, hard skin berries contains one or two irregularly ellipsoidal slightly compressed seeds. The brown seed coat is brittle and breaks at a slight pressure to expose a 'U' shape kernel. The oil content is 51-62% but the yields are 25-27% in village ghanis and about 36% oil in expellers. It contains only 3.6 to 3.9% of glycerin while normal vegetable oil contain 9-10% glycerin. FFA (free fatty acid) present in oil is 5-11%. Iodine value is 215-220 and total fatty acid content is 91.6%. The oil is bitter in taste thus it is not considered to be edible. In India, the oil is used generally for soap making [17].

It grows well under warm climatic conditions (temperature above 26° C). The seeds (500 g) of each batch of okra were crushed using a coffee grinder [2]. The extraction was done in n-hexane (0.8 L) on a water bath for 6 h, using the Soxhlet extractor. The solvent was distilled off at 45° C using a rotary evaporator. Okra seeds were found to contain 12% (w/w) oil, which is higher than that reported in the previous literature. The okra seed oil had an acid value of 3.4 mg KOH/g and required a slight acid pretreatment proceeding to base catalyzed transesterification.

Cotton, belonging to the Malvaceae family is an important crop that yields the natural fiber used by the textile industry. In some countries cottonseed oil is edible and in some countries like India it is inedible. It is one of the second best potential sources for plant proteins after soybean and the ninth best oil-producing crop [1]. Cottonseed oil is a relatively low cost feedstock for biodiesel production as cottonseeds are considered as by products or waste [12]. The oil is extracted from the seeds after removal of the cotton from them. Most of the physical and chemical properties of cottonseed oil resemble those of the major vegetable oils that also contain heterogeneous triglycerides.

Deccan hemp oil is obtained from the dried seeds of the Deccan hemp plant. It is an erect herbaceous annual with straight; slender glabrous or prickly stem plant. The plant is cultivated mainly as fibre crop substitute to jute. This is essentially a tropical crop, thriving best in humid climate with a temperature range of 20–35°C, during growing season [13]. Whole seeds after milling and pressing yields 13% odorless clear yellow fatty oil.

Poon tree can easily be raised from seeds and ripened cuttings; seedlings may be transplanted during the first rains, without much difficulty. In urban areas, plantation is ensured in parks, residential localities, streets, and road avenues and industrial sites as shelterbelts plantation. A shell and a thin 1–2 mm layer of pulp surround the single large seed. The fruit is at first white in color, later turning to black, and when ripe, to a shining blue black; the kernel is white in color. One hundred seeds weigh 200–250 g. The kernel of the seeds yields 50–55% of bland, light-yellow fatty oil [10]. The seed oil is suitable for culinary purposes but is mostly used as an illuminant; other likely uses are in the surface-coating industry and soap-making industry.

The yields of various inedible oil are given in Table 4 [4]. Any vegetable oil crops can grow under a wide variety of climatic conditions like severe heat, low rainfall, high rainfall and frost. Many crops no need water also; some crops will grow in desert also. So large-scale cultivation should be encouraged to produce the required biodiesel. This plantation could lead to the regeneration of these wastelands. Many crops will grow in marginal and wastelands with no possibility of land use competing with food production. The yield of oil varies depending upon the soil conditions and rainfall, and oil can be extracted from seeds starting from the second year. These plantations can also help in rural developments by introducing new employment opportunities in agricultural and small and medium industrial sectors.

Table 4. Comparison of Some Inedible Oil Feedstock Sources of Biodiesel

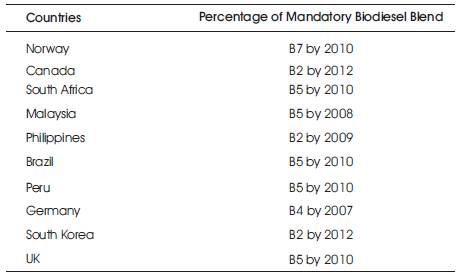

Many countries have formulated their own biodiesel policy Table 5. The Policy is to bring about accelerated development and promotion of the cultivation, production and use of biofuels to increasingly substitute petrol and diesel for transport and be used in stationary and other applications, while contributing to energy security [8], climate change mitigation, apart from creating new employment opportunities and leading to environmentally sustainable development [17]. Once this rule is made mandatory, everybody will think about this and work towards it, to attain this. Other countries are also framing policy for biodiesel blending with diesel. Similarly India should go for the mandatory blending of biodiesel with diesel step by step. India has very good potential to replace the fossil fuel completely in the future. Independent biodiesel producers should be motivated by many ways like giving loan, subsidy, tax benefits, procuring the produced biodiesel with fixing minimum purchase price and contract, etc. From this we can understand the huge potential of biodiesel to be produced to fulfill these policies in the future.

Table 5. Mandatory biodiesel blend percentage for different countries

Inedible oils selected in this article can be successfully applied in CI engine through fuel modifications and engine modifications. In this study, the different properties of the vegetable oils were included for discussion. Most of the studies concluded that a 20% blend of biodiesel with diesel works satisfactorily in the existing design of engine and parameters at which engines are operating. Hence inedible oil has to be planted in all the wasteland available in the country, and this has the potential to replace the existing fossil fuel fully. This has to be start with the government laying stringent blending policy for biodiesel with diesel. Many vegetable oil will grow in all type of climatic conditions, so that type of plants can be suitably planted for biodiesel generation. Further the government has to completely abolish all type of taxes associated with the fuel in any form and the employee cost to be reduced drastically for the benefit of 1.2 billion people.