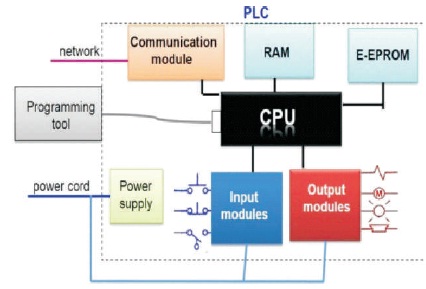

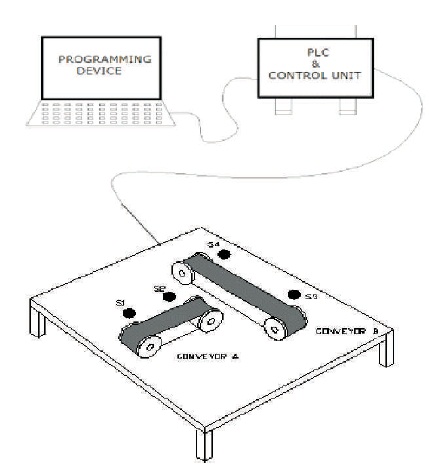

Figure 1. Architecture of PLC

In any Industrial Automation there are many instruments wired together during a network to make them function using Programmable Logic controllers (PLC). Programmable Logic Controllers are industry-based computers that monitor inputs and control the output, supported the logic state of the input. Sometimes the system is placed in remote locations to regulate the functions of such systems. SCADA may be a system that permits to regulate, monitor and coordinate devices and components in real-time from a foreign location with the acquisition of knowledge for analysis and planning from one central location. The conveyor hardware is connected to PLC via RS232 cable. The PLC provides instructions by software referred to as WPLSoft 2.47 which can be interfaced with laptop. The hardware will be controlled via SCADA software on the PC. During this application, conveyor A starts when the package is sensed by S1 and conveyor B starts when the package reaches S2. Thereafter conveyor B runs forward and reverse and unloads the packages as per the preset counts sensed by S3 and S4.

The PLC has its origin within the motor manufacturing industries. Manufacturing processes were partially automated by the utilization of rigid control circuits, electrical, hydraulic, and pneumatic. It has been found that whenever a change happens, the system has to be rewired or reconfigured. The changes in connection can be done by unplugging and changing the wiring of boards. With the event of microcomputers, it had been realized that if the PC could switch ON or OFF and answer a pattern of inputs, then the changes might be made by simply reprogramming the PC, then the PLC was born. PLC is an industrial computer system that continuously monitors the state of input devices and makes decisions based upon a custom program to regulate the state of output devices.

Almost any assembly line, machine function, or process are often greatly enhanced using this sort of system. However, the most important benefits of employing a PLC is its ability to vary and replicate the operation or process while collecting and communicating vital information. Another advantage of a PLC system is its modular. That is, you'll mix and match the various kinds of Input and Output devices to best fit your application.

The PLC hardware is digital electronic devices with memory which will be programmed to store commands or information and therefore the implementation of varied operations like logical operations, arithmetic, and timing. There are several devices like Siemens that produces SIMATIC 200, SIMATIC 300, and SIMATIC 400, Allen Bradley Inc., Mitsubishi, and lots of others. Each company has its software, but all accomplish the specified job of the PLC's.

The multi-level car parking system using PLC with sensors has been designed and developed (Albagul et al., 2013). The control system plays a vital role organizing the parking of vehicle for best utilization. Using sensors available vacancies are determined. With the elevators controlled by PLC, the cars can be shifted to these vacancy slots to regulate the entry and exit of parking lot.

Design and fabrication of an automated drilling Machine based on PLC is presented in Yousef et al. (2015). A prototype of the design is done to drill a small hole in wood piece. The performance of proposed design is validated by comparing with traditional manual method. The PLC based automation system increases efficiency and reduces the drilling time.

Design and fabrication of a small and simple conveyor belt system for packing industries using PLC is presented in Algitta et al. (2015). The process is carried at 2 stages such as carrying empty boxes and packing samples into boxes. Electrical DC motors as actuators are used to provide movement of conveyer belt. This movement is monitored by using PLC. Proposed design reduces packing time and increases production as compared to manual system.

As the technology is advancing people look for modern facilities both at work place as well as home. Industrial automation emerged in short span and increased the productivity with reduced process time. However, home automation is not advanced.

Home automation as proposed in Kumar et al. (2016) utilizes advanced technologies to ensure secured, comfortable and sophisticated facilities. This system greatly helps the senior people and physically differently abled people to improve their daily life styles.

Traditional medicine preparation is time consuming since the process involves boiling, filtering and mixing of medicinal herbs manually. By making use of automation using PLC as in Makade et al. (2016), reduction in the processing time as well continuous monitoring of process is possible. This involves hardware (mechanical and electrical components) and software (PLC).

Due to growing population across the world, space for utilization is becoming a major issue. As well as due to shift in paradigm, every individual likes to own 4-wheeler, which is another issue for parking space. In urban areas multi-level parking system is the only choice for best utilization of available space. This can be achieved by technology innovations.

PLC based design of conveyor belt system for carrying and packing the goods is presented in Kosare et al. (2018). The soft wiring feature of PLC makes easy changes in control system and are cheap. This reduces the complexity in the design and cost of the products.

Traditional methods existing for inspection and packing involves manpower, and the issues to be taken care are time, money involved and safety. PLC based design of controller for automatic inspection and packaging is proposed. Micro controller based Automation system are less flexible since most of the operations are fixed, whereas PLC's are programmable, any change can be easily incorporated without changing the hardware. PLC's are profitable for mass production compared to micro controllers.

In the recent times, the cranes are operated manually in the industry for the segregation and transportation of products in multiple conveyors. The process results in increased time delay for the products to reach the destination and also needs manpower to control the cranes. The operation of cranes and monitoring the status of the convey or belt are also tedious for the workers. The efficiency may also not be stable since it depends on the efficiency of the workers.

The paper by Murthy (2019) presented the design of controller for inspection and packaging using programmable logic controller. This will automate the process of inspection and packaging without any human intervention. This is a programming project with PLC for inspection, packing and automated storage of any manufactured component with Ladder logic. Traditional inspection, packaging and automatic storage requires lot of human intervention and money and safety will be the main problem. To overcome this problem the Programmable Logic Controller is introduced. Most of the companies are using micro controller-based automation.

From the literature, it is very clear that every process for its effective operation needs specific set of instructions and necessary infrastructure. The processes operated by human are non-automated and yield lesser productivity and may not be energy efficient. But such practices were inevitable till the advent of the concept automation. The Automation brought the revolution in every field of application to a greater extent incorporating technologies and machines to do activities in efficient manner by reducing human intervention.

The text by Shetty and Kolk (2011), blends the pertinent aspects of mechatronics-system modeling, simulation, sensors, actuation, real-time computer interfacing, and control into a single unified result suitable for use in the college-level mechatronic curriculum. Students are introduced to all the topics needed to develop a good understanding of the basic principles used in mechatronics technology through the use of examples, problems and case studies, all of which can be quickly and affordably assembled and investigated in laboratory settings.

The programmable logic controller is universally used for industrial applications. The programmable logic controller architecture is especially hooked in to three functional areas which contains processing, memor y and input/output. Depending upon the input instruction, the programming of PLC has been done. The output conditions are generated to drive the associated devices, and therefore the input/output actions are hooked in to the program which is stored within the memory. Figure 1 depicts the essential architecture of PLC which consists of input/output, communication modules and memory unit (Murthy, 2019; Shetty & Kolk, 2011).

Figure 1. Architecture of PLC

The input devices could be analog or digital devices that comprise sensors, limit switches, pushbuttons. Outputs are often analog or digital devices like relays, motors, and LED lights. Memory consists of ROM, RAM, and EEPROM. The communication module has Ethernet, PROFIBUS, and RS- 232.

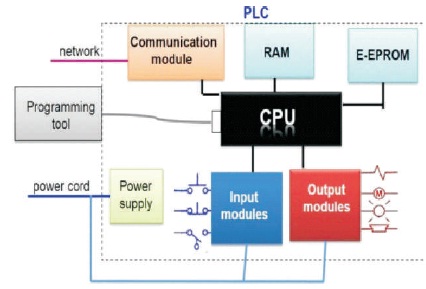

The Indra Logic PLC and its associated software IndraWorks is the heart of the work presented here. A variety of function modules (field bus interfaces and technology modules) are available to integrate the Indra Control into several heterogeneous control topologies. The modules use the high-speed system bus for communicating with the control processor ensuring high requirements of performance and functionality. Partial implementation of functions by the modules reduces the load on the controller CPU. Figure 2 depicts the Indra Logic L20 PLC module alongside its connectivity and interfaces.

Figure 2. Indra Control L20 Connectivity and Interfaces

The hardware is connected to PLC via RS-232 cable. The PLC provides instructions by a software referred to as WPLSoft 2.47 which can be interfaced with laptop. The hardware is controlled via SCADA software on the PC. During this application, conveyor A starts when the package is sensed by S1 and conveyor B starts when the package reaches S2. Thereafter conveyor B runs forward and reverse and unloads the packages as per the preset counts sensed by S3 and S4.

When the push button is pressed ON, the system gets ready/ turned ON, the conveyor-A belt starts moving by DC motor-1which carry and convey the objects when the object is detected by the proximity sensor S1. Once the object reaches proximity sensor S2, it'll activate and send signal back to the PLC to start the conveyor-B belt to move. At the same time when the system starts running, the green indicator lights turn ON, to tell the operator that the system started.

As the object reaches the specified location, the conveyor- A belt stops moving and then the conveyor-B belt starts moving after a particular predefined delay. Conveyor-B belt starts to bring the object one by one and drop them into the box. This operation runs until five samples, where the count is kept by the sensor S3. There is a time delay (predefined) after the five samples until subsequent sample is sensed by the sensor S1. This delay is for power conservation. After five samples, the conveyor-B belt starts occupying the other direction. This same operation runs for five samples. After the count of five samples. there is again a predefined delay for the conservation of power and the count is kept by the sensor S4.

If the sensor S1 doesn't sense any samples for a duration (predefined duration) of 5 minutes (in our case) or if there's a detection of two samples at an equivalent time, the whole system is going to be turned off for the detection of the error caused if any. The above process is controlled and monitored by the PLC and SCADA.

The modeling of an automatic packaging system using PLC and SCADA has been successfully designed, constructed and implemented. The elemental reason for PLC in automation is to regulate the whole system and therefore the major reason for utilizing SCADA is to watch, process and store data for future improvements. Moreover the program is developed within the PLC, so troubleshooting and making changes of program become very easy, due to the simplicity of the program.

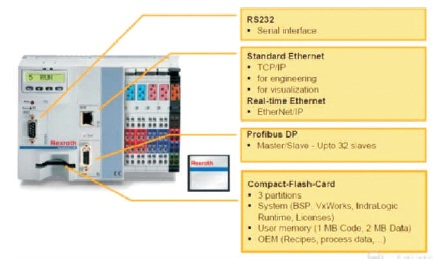

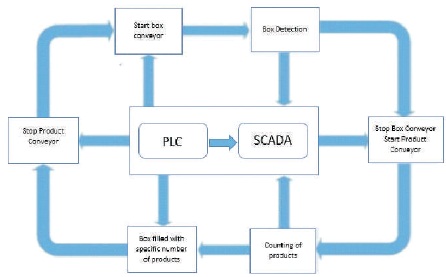

Figure 3. Block Diagram of Proposed Method

Figure 4. Connection Diagram

Figure 5. Working Model

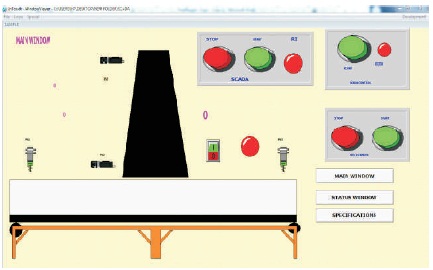

Figure 6 shows the main window of SCADA screen. The SCADA screen is made similar to the working model. When the object is placed on the conveyor, it is detected by the sensors and thereafter the object is graphically represented on the SCADA screen.

Figure 6. Main Window

The movement of the object on the conveyor is graphically shown. The SCADA screen consists of control switches and therefore the working model are often turned ON or OFF using these switches. It also consists of LED indicators that indicate the direction of the conveyor.

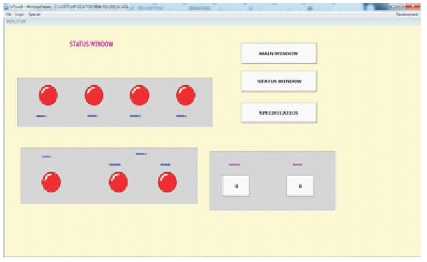

Figure 7 shows the status window where the software continuously monitors the quantity of objects and motor directions. This window also shows the sensors which detect the objects and monitors the movement of the objects on the conveyer belt.

Figure 7. Status Window

The modeling of an automatic packaging system using PLC and SCADA has been successfully designed, constructed and implemented. The elemental reason for PLC in automation is to regulate the whole system and therefore the major reason for utilizing SCADA is to watch, process and store data for future improvements. Moreover within the program developed on PLC, troubleshooting of program and making changes become, very easy due to the simplicity of the program. It are often concluded that any changes could also be made to the program in between the method then these are often downloaded into load memory of PLC with none inconvenience and without putting the PLC in stop mode. From this we conclude that, though the designed system is not cheap, it can effectively function for a long period. This in turn will prove profitable for future automated system in any industry.