Figure 1. Working of a Self-Driving Car

The development of control systems that operate independently without human intervention is a rapidly growing field in instrumentation and control engineering. These systems are designed to function autonomously, using Artificial Intelligence (AI) and Machine Learning (ML) techniques to make decisions and perform tasks. Applications of these systems can be found in a variety of fields, including autonomous vehicles, robotics, and industrial automation. The key benefits of these systems are their ability to perform tasks without human intervention, which can lead to increased efficiency and productivity. They also have the ability to operate in environments that may be too dangerous for humans, such as deep-sea exploration or space. Additionally, they are able to collect and process large amounts of data in realtime, which can be used to improve decision-making and control. This includes the use of machine learning and evolutionary algorithms to improve the ability of systems to adapt to changing conditions. This research is also focused on the integration of these systems with communication networks, such as the internet, to enable remote monitoring and control. With advancements in technology and increasing demand for automation, it is expected that autonomous systems will play an increasingly important role in various industries in the future.

The instrumentation and control engineering systems are designed to function autonomously, using artificial intelligence and machine learning techniques. The goal of this technology is to improve the efficiency and productivity of various industries by reducing the need for human intervention. In autonomous vehicles, for example, control systems that operate independently without human intervention are crucial for the safe and efficient operation of the vehicle, allowing it to navigate and make decisions without human input. Similarly, in industrial automation, these systems are used to perform tasks such as monitoring and controlling industrial processes in real time, reducing the need for human operators.

The advancement in technology and increasing demand for automation in various industries are driving the research and development of autonomous control systems. The research in this field is focused on developing new algorithms and control strategies to improve the performance of autonomous systems. This includes the use of machine learning and evolutionary algorithms to improve the ability of systems to adapt to changing conditions.

A literature review of the development of control systems that operate independently without human intervention would examine the current state of research in this field.

The literature would likely include studies and articles on the use of artificial intelligence and machine learning techniques in the design and implementation of these systems.

One area of focus in the literature would be the use of machine learning algorithms to improve the performance of autonomous systems. Studies have shown that the use of these algorithms, such as neural networks and genetic algorithms, can lead to improved decision-making and adaptability in autonomous systems. For example, a study by Yang et al. (2019) proposed a neural network-based control system for autonomous vehicles that was able to improve the vehicle's ability to navigate and make decisions in uncertain environments.

Another area of focus would be the integration of these systems with communication networks, such as the internet, to enable remote monitoring and control. Research in this area has shown that the use of these networks can lead to improved monitoring and control of autonomous systems, as well as the ability to access data from the systems in real-time. For example, a study by Yang et al. (2018) depicts a cloud-based remote monitoring system for industrial automation that was able to improve the efficiency and safety of the industrial process.

For example, analysis by Burton et al. (2020) examined the ethical and safety implications of autonomous systems and proposed a framework for the safe and ethical deployment of these systems.

Autonomous control of unmanned aerial vehicles by Becerra (2019) describes the use of autonomous control systems in Unmanned Aerial Vehicles (UAVs). The paper covers the advances in technology and control strategies that have enabled UAVs to operate independently without human intervention. The author also discussed the future developments and potential applications of UAVs in various fields, such as agriculture, surveillance, and search and rescue. The paper provides an overview of the current state of research on autonomous control of UAVs and the future directions of the field.

The paper "Autonomous Control Systems and Vehicles" by Nonami et al. (2013) presents an overview of the current state of research on autonomous control systems and vehicles. The authors discussed the various types of autonomous systems and their applications, such as Unmanned Aerial Vehicles (UAVs), Unmanned Ground Vehicles (UGVs), and autonomous ships. The authors also discussed the importance of sensor data fusion and control strategies such as trajectory planning for the development of autonomous systems and vehicles. This paper provides a comprehensive understanding of the field of autonomous control systems and vehicles and the state of the art of current research.

In summary, the literature on the development of control systems that operate independently without human intervention would examine the use of artificial intelligence and machine learning techniques, the integration of these systems with communication networks.

Control systems that operate independently without human intervention are systems that are able to perform tasks and make decisions without the need for direct human supervision or intervention. These systems use a variety of technologies, such as artificial intelligence and machine learning algorithms, to perform their tasks (Miller et al., 2007). Examples of control systems that operate independently without human intervention discussed as follows.

Autonomous Vehicles (AVs) are vehicles that are able to navigate and make decisions without the need for human input (Chen, 2021). These vehicles use a variety of technologies, such as sensors, cameras, lidar, and GPS, to gather information about their environment and to make decisions (Yurtsever et al., 2020). Autonomous vehicles can be classified into different categories based on the degree of autonomy they possess. Figure 1 shows the workings of a self-driving car. The Society of Automotive Engineers (SAE) International defines six levels of autonomy, ranging from Level 0 (no automation) to Level 5 (fully autonomous).

Figure 1. Working of a Self-Driving Car

Level 1 and 2 vehicles have some automation features, such as cruise control and lane keeping assistance, but the driver must remain in control at all times. Level 3 vehicles have some autonomy, but the driver must still be prepared to take over in an emergency. Level 4 and 5 vehicles are fully autonomous, meaning that the vehicle is capable of driving itself without human intervention. Aerial Vehicles (AVs) have the potential to improve safety, reduce traffic congestion, and increase mobility for people who are unable to drive. They also raise ethical and safety concerns, such as how to handle accidents and how to ensure the security and privacy of the data they collect. It is important to ensure that AV are designed, tested, and deployed in a safe and responsible manner. Now there are cars, drones, and robots that are able to navigate and make decisions without the need for human input.

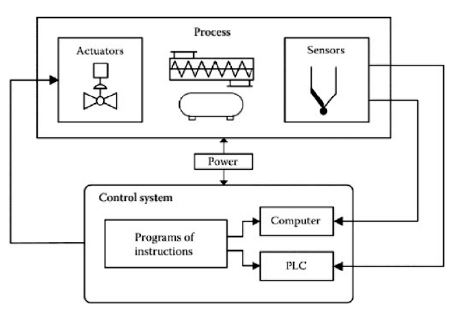

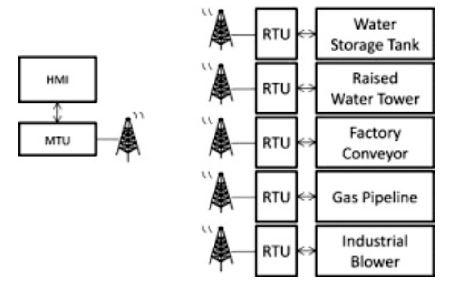

Industrial automation systems are control systems that are used to automate tasks in manufacturing and other industrial settings. These systems are designed to improve efficiency, productivity, and safety by performing tasks that would otherwise be done by humans (Thramboulidis, 2015). They can also be used to monitor and control various processes, such as production, quality, and energy management. The industrial automation system is shown in Figure 2.

Figure 2. Industrial Automation System

Industrial automation systems can be classified into different types based on the application and the level of automation. Some examples of industrial automation systems discussed as follows.

These are microprocessor-based systems that are used to control and monitor industrial processes. They are commonly used in manufacturing, packaging, and other industrial applications.

These systems are used to monitor and control largescale industrial processes, such as power generation, water treatment and, oil and gas production.

Robots are used in manufacturing, assembly, and other industrial applications to perform tasks that are dangerous or difficult for humans to do.

Machine vision systems are used to inspect and analyze images to ensure product quality and process efficiency.

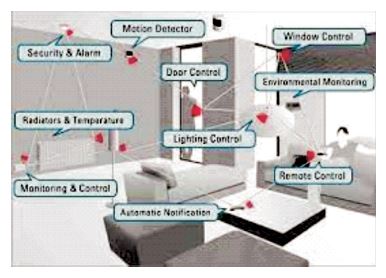

Building automation systems are used to control and monitor various building systems, such as Heating, Ventilation, And Air Conditioning (HVAC), lighting, and security. Figure 3 shows the building automation and control systems.

Figure 3. Building Automation Systems

Industrial automation systems have the potential to improve efficiency and productivity, but they also raise concerns about job displacement and the need for new skills for the workforce. It is important to ensure that these systems are designed and deployed in a way that benefits both the industry and the workforce.

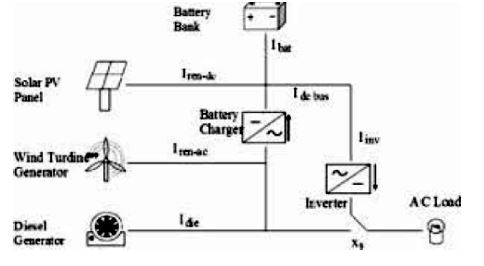

Control systems that are used to manage the generation, distribution, and consumption of electricity without human intervention (Mir & Senroy, 2019). An Autonomous Power System (APS) is a self-sufficient system that generates, distributes, and manages its own power without the need for a connection to a traditional power grid. The autonomous systems for various power systems is shown in Figure 4.

Figure 4. Autonomous Power Systems

APSs can be powered by a variety of energy sources, including solar, wind, hydro, and fossil fuels, and are typically used in remote locations where a connection to the grid is not feasible or cost-effective. APSs can be used for a wide range of applications, including powering homes, businesses, and infrastructure in remote areas providing backup power during power outages; and powering mobile or temporary structure.

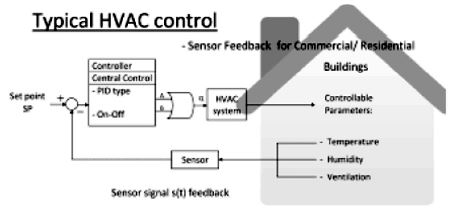

Control systems that are used to regulate temperature, humidity, and other environmental factors in a building without human intervention. Autonomous HVAC systems are self-regulating systems that control the temperature, ventilation, and air quality in a building without the need for manual intervention (Guo et al., 2020). Figure 5 shows the typical HVAC control system.

Figure 5. HVAC Control System

These systems use sensors and control algorithms to monitor and adjust the indoor environment in response to changes in temperature, humidity, and other factors. They can also be integrated with other building systems, such as lighting and security, to improve energy efficiency and comfort.

Some of the key features of autonomous HVAC systems as follows.

Adjusts the heating and cooling based on the space's actual occupancy and weather conditions.

It plans HVAC operations based on occupancy patterns and weather forecasts.

It continuously monitors the HVAC system for potential issues and alerts the building manager if a problem is detected. Autonomous HVAC systems can lead to energy savings and improved indoor air quality by providing precise temperature and humidity control, reducing energy consumption and maintenance costs, and creating a more comfortable indoor environment.

This allows for monitoring and control of the HVAC system through a web portal or mobile app.

Control systems are used to automate tasks in agriculture, such as planting, harvesting, and monitoring crop growth. The various autonomous control systems used in the agriculture sector are shown in Figure 6.

Figure 6. Autonomous Agricultural Systems

Autonomous Agricultural Systems (AAS) are self-sufficient systems that use advanced technology to automate various aspects of farming, including planting, harvesting, and crop management (Gil et al., 2017).

These systems rely on sensors, robotics, and artificial intelligence to monitor and control various aspects of the farming process with the goal of improving crop yields, reducing labor costs, and increasing efficiency. Some of the key features of autonomous agricultural systems as follows.

It uses GPS and other sensors to map the field, allowing for precise planting and harvesting.

Crop monitoring uses cameras, sensors, and other technologies to monitor crop growth, health, and yield.

It uses tractors, drones, and other vehicles that can operate without human input to plant, harvest, and spray crops.

Figure 7 shows the autonomous tractor used for agriculture.

Figure 7. Autonomous Tractor System

It uses weather forecasting to optimize the planting and harvesting schedule.

It uses machine learning algorithms to analyze data from sensors and cameras to make predictions and optimize crop yields.

AAS can improve crop yields, reduce labor costs, and increase efficiency by providing precise planting, harvesting, and crop management, which reduce human effort and increase the precision of farming practices. They are also able to operate 24/7, can work in harsh weather conditions, and can cover large areas.

The development of control systems that operate independently without human intervention typically involves the following steps.

It is necessary to define the goals and objectives of the control system, which involves identifying the tasks that it will need to perform, the environment in which it will operate, and the expected performance criteria. A dependable power supply, a strong communication network, precise sensors and actuators, a high performance controller, redundant backup systems, adequate security measures, a user-friendly interface for monitoring and maintenance, compliance with industry standards and regulations, flexibility for upgrades and modifications, and efficient data storage and retrieval systems are all required.

Develop mathematical models of the system and its environment and use simulation tools to test the system's. The development of mathematical models of the system and its environment, along with the use of simulation tools to test the system's performance and identify potential issues, is recommended.

The development of mathematical models of the system and its environment, along with the use of simulation tools to test the system's performance and identify potential issues, is recommended (Otter & Cellier, 2019). The important things that must be considered are mathematical modelling of system components and interactions, dynamic system analysis and simulation, model validation and verification, real-time system simulation, system optimization and control design, model-based control and estimation algorithms, hybrid simulation combining physical and virtual components, and system-level performance evaluation and testing.

The selection of appropriate sensors and actuators for the system involves taking into account several factors such as accuracy, range, and cost, based on the system requirements and specifications. Furthermore, performance criteria such as accuracy, precision, resolution, and response time, environmental conditions such as temperature, humidity, and electromagnetic interference, physical attributes such as size, weight, and durability, compatibility with other system components and communication protocols, cost-effectiveness and availability, calibration and maintenance requirements, reliability, and long-term stability are also considered.

It is necessary to develop control algorithms that consider the system requirements and the data collected by the sensors and actuators to control the system.

The control system should be implemented on the appropriate hardware platform, and the software needed to control the system must be developed.

To validate the performance of the system, it is necessary to test it in a laboratory or field environment, using the criteria established in the system requirements.

Once the system has been tested and validated, it can be deployed in the field. It is also essential to establish a maintenance plan to ensure that the system continues to operate correctly over time.

Continuously monitor and analyze the system. Continuous monitoring and analysis of the system performance is necessary, and the data obtained from this process should be used to improve the system over time. It is important to note that all of these steps are closely interrelated and require collaboration between engineers, scientists, and experts from various disciplines such as control theory, robotics, artificial intelligence, electrical, mechanical, and software engineering.

Experimental methods are used to develop and test control systems that operate independently without human intervention and can include a variety of techniques:

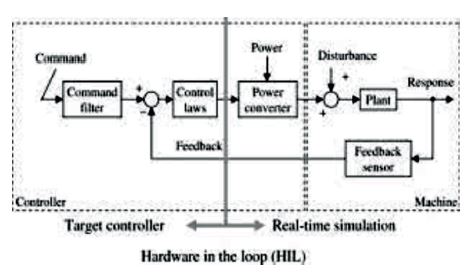

This method involves using a simulation of the system along with the actual hardware components to test the performance of the control algorithms. This allows for testing under realistic conditions and can be used to identify issues that may not be apparent in a purely simulated environment. Hardware in the loop process is shown in Figure 8.

Figure 8. Hardware in the Loop Process of Control System

It involves integrating physical hardware components with simulation software to create a realistic testing environment (Joshi, 2017). The HIL simulation allows developers to test control algorithms and systems under realistic conditions, improving system reliability and robustness. With HIL simulation, engineers can verify system functionality and performance before deployment, identify and resolve hardware-software interface issues, and reduce development time and costs. Additionally, the use of HIL simulation provides a safer testing environment, helping to better understand real-world system behavior and limitations. Overall, HIL simulation plays a critical role in the development of autonomous control systems.

This method involves using mathematical models of the system and its environment to design and test control algorithms and can be used to optimize the performance of the system.

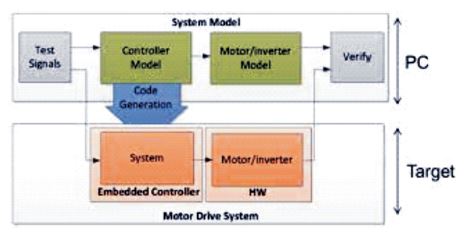

Model-Based Design (MBD) involves the use of mathematical models to represent system components and their interactions, providing a virtual representation of the system (Hartsell et al., 2019). This allows engineers to simulate and analyze the system's behavior and performance, including the effects of design changes, before building and testing physical prototypes. Figure 9 shows model-based design for advanced motor control system.

Figure 9. Model-Based Design for Advanced Motor Control System

MBD provides a number of advantages in the development of autonomous control systems, including improved design accuracy, faster development times, reduced design costs, and reduced testing and validation requirements. MBD also facilitates the integration of control algorithms and software with hardware components, helping to ensure the overall system design meets the necessary performance and reliability requirements. The use of MBD is becoming increasingly common in the development of control systems.

This method involves testing the control system in a realworld environment and can be used to validate the performance of the system under real-world conditions. Field testing is the process of evaluating a system's performance in real-world conditions, providing important information on the system's behavior and limitations. Field testing can be used to verify system functionality and performance, validate control algorithms and parameters, and identify any issues or limitations that may affect the system's performance (Almannaa et al., 2019). Field testing can also be used to refine system designs and improve system reliability, as well as to provide valuable data for training and refining machine learning algorithms. Field testing can be a complex and time-consuming process, but it is an essential step in the development of autonomous control systems. By providing real-world data, field testing helps ensure that control systems are robust and reliable, ready for deployment in real-world applications.

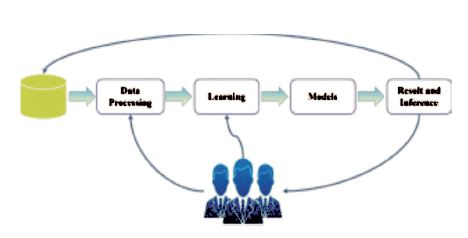

This method involves testing the control system with human users and evaluating the system's performance based on their feedback. This can be used to evaluate the system's usability and identify any issues that may not be apparent during testing with only simulated or real world environments. Human-in-the-Loop data processing is shown in Figure 10.

Figure 10. Human-in-the-Loop Data Processing Pipeline

User studies and Human-In-The-Loop (HITL) methods are important considerations in the development of control systems. User studies involve observing and evaluating the interaction between users and the system, providing valuable insight into the user experience and user acceptance of the system (Feng et al., 2016). This information can be used to improve the user interface and overall usability of the system. HITL methods, on the other hand, involve the integration of human decision-making into the control loop, allowing human operators to intervene and make decisions as necessary. This can be useful in situations where the autonomous control system may need to be overridden or when human intervention is required for safety reasons. User studies and HITL methods provide an important feedback mechanism in the development of autonomous control systems, ensuring that the system meets the needs of users and provides a safe and reliable user experience.

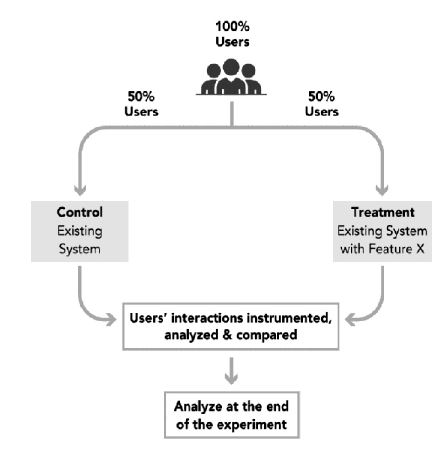

This method involves testing two different versions of the control system and comparing their performances to determine which version is more effective. A simple controlled A/B test is shown in Figure 11.

Figure 11. Simple Controlled A/B Test

A/B testing involves randomly dividing a sample of users or test subjects into two groups, group A and group B, and exposing each group to different versions of the control system. The performance of the two groups is then compared to determine which version of the system is more effective (Gardey & Garrido, 2020). A/B testing can be used to test and compare different control algorithms, user interfaces, or other system components. By comparing the performance of two different versions of the system, A/B testing provides valuable data that can be used to improve the design and performance of the control system. This type of testing is particularly useful in the development of autonomous control systems, as it provides data on the effectiveness and reliability of the control algorithms and system components.

Creating a physical test environment that mimics real world conditions as closely as possible to test and evaluate the control system under different scenarios. It is important to note that different experimental methods may be more appropriate for different stages of development and that a combination of methods can be used to comprehensively evaluate the system's performance (Becker et al., 2019). Figure 12 shows the control system test bed to validate critical infrastructure protection concepts.

Figure 12. Control System Test Bed to Validate Protection Concepts

Test beds are physical or virtual environments that simulate real-world conditions and allow developers to test and evaluate control systems under controlled conditions. Test beds can include hardware components, sensors, actuators, and software tools that are used to create a realistic testing environment (Ukwandu et al., 2020). The use of test beds allows developers to evaluate control algorithms and system behavior in a controlled environment, improving system reliability and reducing the risk of unexpected system behavior. Test beds also provide a platform for integrating and testing control algorithms with hardware components and for evaluating the performance and robustness of the system under a variety of conditions. It provides an environment for testing, validating, and refining control algorithms and system component.

The design of autonomous vehicles aims to improve safety by ensuring they follow traffic laws and regulations, thereby reducing the number of accidents caused by human error. Additionally, autonomous vehicles with increased efficiency can optimize their driving behavior and use advanced sensors to avoid traffic congestion, resulting in reduced travel time and fuel consumption. Autonomous vehicles can enhance mobility for the elderly and disabled by providing transportation options for individuals who are unable to drive. This can increase their independence and mobility. Autonomous vehicles can communicate with each other and make decisions in real-time to optimize traffic flow, reducing congestion and travel time increased productivity, and commuters can use their travel time more efficiently, such as working or relaxing, rather than having to focus on driving. Autonomous vehicles can decrease air pollution by being designed to be more energy-efficient, which reduces emissions and improves air quality. Additionally, the reduced number of accidents, fuel consumption, and maintenance requirements of autonomous vehicles can result in significant cost savings for both individuals and society. Improved road utilization by autonomous vehicles can make better use of existing road infrastructure, reducing the need for new roads and highways.

The development of autonomous vehicle control systems that operate independently without human intervention has been a rapidly growing field in recent years. The use of autonomous vehicles has the potential to revolutionize transportation and mobility, offering numerous benefits such as improved safety, increased efficiency, and reduced traffic congestion.

However, the widespread deployment of autonomous vehicles also raises several important challenges and concerns. One of the main challenges is the development of reliable and robust control systems that can ensure safe and efficient operation in a variety of driving scenarios. This requires significant advances in areas such as perception, decision-making, and control. Another important challenge is the integration of autonomous vehicles into existing transportation infrastructure, including the design of suitable road networks and communication systems. Furthermore, there are concerns about data privacy and cybersecurity, as well as the ethical implications of self-driving cars, such as liability in the event of an accident. Furthermore, the deployment of autonomous vehicles will also have significant societal and economic impacts, such as job losses in the traditional transportation sector and the need for new regulations and standards. Despite these challenges, the potential benefits of autonomous vehicles are significant, and the development of reliable and effective control systems is critical for their successful deployment. Further research and development in this field is needed to fully realize the potential of autonomous vehicles and to ensure their safe and efficient integration into society.

The future of autonomous vehicle control systems is bright and holds a lot of potential. Here are a few areas where technology is likely to see advancements and growth in the coming years.

The safe operation of autonomous vehicles relies heavily on improved perception, which is the ability to accurately perceive and interpret the environment. In the future, vehicles are likely to use more advanced sensors and algorithms to improve their perception capabilities, such as the integration of lidar, radar, and camera systems. Enhanced decision-making, or the development of advanced decision-making algorithms that can handle complex driving scenarios, will be critical for the safe operation of autonomous vehicles. In the future, vehicles are likely to use machine learning and artificial intelligence to make more informed decisions in realtime. The integration of autonomous vehicles with existing transportation infrastructure, such as smart roads, communication systems, and traffic management systems, will be essential for their safe and efficient operation. Regulation and standardization is the development of clear and consistent regulations and standards for the operation of autonomous vehicles will be critical for their safe deployment and widespread adoption. The future of autonomous vehicle control systems is promising, and continued advancements in technology, infrastructure, and regulations will be critical for their successful deployment and integration into society.

In conclusion, the development of control systems that operate independently without human intervention is a complex process that involves a combination of theoretical and experimental methods. These systems rely on advanced technologies such as sensors, robotics, and artificial intelligence to monitor and control various aspects of the system with the goal of improving performance and increasing efficiency. The process of developing such systems typically involves several steps, including identifying the system requirements, system modelling and simulation, sensor and actuator selection, control algorithm design, hardware and software implementation, testing and validation, deployment and maintenance, and continual improvement. Experimental methods play a crucial role in the development process, as they allow for testing and validating the performance of the system under realistic conditions. Hardware-in-the loop simulation, model-based design, field testing, user studies, A/B testing, and test-beds are all common experimental methods. Ultimately, the success of a control system that operates independently without human intervention depends on the ability of the development team to effectively integrate all of the theoretical and experimental methods throughout the development process.