Abstract

In our day to day life, the way we physically interact with electronic devices is changing through technological research. This change has led to recent techniques, including the development of touch screen technology. In touch screen technology, the operator is given an other method of how we can interact with a device. This technology already operates in three distinct ways: resistive systems, capacitive systems, and infrared systems. This paper propose, focus and compare these technologies with a new concept of touch screens which works using transistors, focusing on the differences in application.

Keywords:

- Capacitive;

- Infrared;

- Multi-Touch;

- Resistive;

- Transistor;

- Sustainability;

- Touch Screens.

Introduction

Human interaction with technology is changing. In touch screen technology, the user is able to manipulate a digital environment by only the touch of their finger, or another input device, on the screen. The invention of computers is a milestone in the research field of human beings. Though at first computers are used only for performing arithmetic operations in course of time it started dominating all other fields. At the beginning the human-machine interaction i.e. giving input and getting output was through punched cards, tapes etc. Then it was changed to keyboard and monitor in course of time. Only when monitors were introduced virtually icons too came along with it. Then virtual icons made interaction with machines more interesting and easy and this even made new users to operate computers easily. There virtual icons also made transparent touch screens popular. Initially the touch screen concept was revealed in 1970s, but at those days they were very costly and were used only in research sectors. Only during 1990s touch screens started appearing in consumer goods. Initially they were found in tabs, Ipads and Iphones Throughout this paper, the authors have discussed the various present age touch screen technology with transistor based touch screens and its working.

1.A history of Touch Screens

In the recent years the use of transparent touch screens have made our way of interacting with machines very easy and interesting. The first touch screen was invented by Mr. Sam Hurst in the year 1971 and he was sponsored by Siemens Corporation but it was non-transparent[1]. Then in the year 1974 he modified his design into transparent touch screen. Then in 1983 the next version of touch screens were revealed by Hewlett Packard (HP) enterprise in their HP-150 devices [5]. Then in 1993 Apple introduced its handwriting recognizing touch screens in its devices. After that in 1996 smart phones and PDAs were introduced using touch screens. By seeing the development and importance of touch screens, Microsoft revealed its tabs using touch screens in the year 2002. Then in 2004 Nokia designed its Symbian OS mobiles with resistance touch. Then in 2007 Apple designed its Iphones with multi touch capability projected capacitance touch screens. As Apple expected this capacitor touch screens increased their market. Then finally touch screens came into computers by Microsoft's PCs and tabs[2]

1.1 Resistive touch screens

Resistive touch screen systems are the most common type of touch screen technology in today's market. These devices are used in many applications, such as cell phones, handheld games, GPS navigation devices, and even some digital cameras[2]. The working of resistive touch screen is similar to that a strain gauge. It is basically a pressure sensor. The main difference is that in strain gauge the amount of pressure applied is sensed. In case of resistive touch screens the amount applied is same but the position where the pressure applied varies so this is taken into account either than the amount of pressure applied.

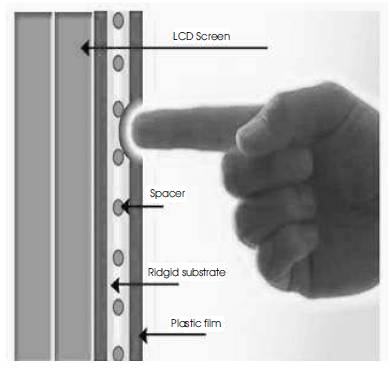

The resistive touch screen consist of two layers of Indium Tin Oxide (ITO) separated by a small air gap. Among the two layers base layer is non flexible and the top layer is flexible[3] as shown in Figure 1. The pressure applied on the top layer makes it to touch the bottom layers which produce the variation in the resistance. This variation in resistance is measured as voltage fluctuation and position is sensed by the drive. Basically four wire touch screens are used in most of the applications. Resistive touch screens typically have higher resolution (4096*4096 DPI or Higher), providing accurate touch control. Because the touch screens respond to pressure on its surface, contact can be made with the finger or any other pointing.

Figure 1. Resistive Touch Screen

1.2 Capacitive Touch Screens

Capacitive touch screens have their own role in touch screen industries. In fact they are the first invented touch screens, but were far behind of what we are using now. Capacitive touch screens are all glass touch screen with a transparent metallic conductive coating. In simple words, in capacitive touch screen, the first layer will be a ITO layer, next to that there will be glass screen which is insulated. When we touch the screen the static charges present in our finger acts as conductor. Thus these three layers i.e., ITO, glass and the finger act as a basic capacitor in which two metallic conductors are separated by an insulator. Initially these touch screens were not popular but the establishment of these touch screens in iphones and ipads in the year 2007 made it popular and common among everyone.

1.2.1 Projected capacitive touch screens

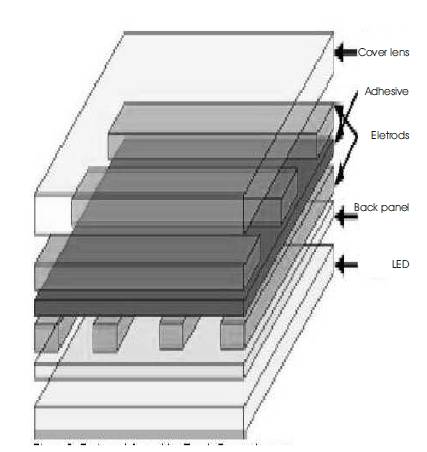

Projected capacitive touch screens are meaning most of these touch screens are made up of a matrix of rows and columns that are one by one to get a reading or count. To get an exact coordinate, the results from several row/column intersections are read and the counts are used to triangulate the exact touch location. The results are extremely precise and the resolution is usually 1024 by 1024(ten bit), as shown in Figure 2.

Figure 2. Projected Capacitive Touch Screen Layers

Scanning also has an advantage of being free of coordinate drift. This is possible because the rows and columns are physically capacitive touch screens that do not have to be calibrated by the end-user as long as the screen is mounted on the same place on the display. Typically, the only that occurs is that if the user draws very slowly across the screen, a tiny amount of stair stepping will be noted.

- Cover Glass

- Chemically strengthened with holes and slots cut into it, either 0.75mm or 1.1mm thick.

- Optical Bonding Adhesive Indium Tin Oxide(ITO)

- Deposited onto the top side of a piece of glass, with molybdenum signal lines at the edge

- Glass

- 0.55mm or 0.75mm

- Indium Tin Oxide Deposited onto bottom side of glass, with molybdenum signal lines at edge

1.2.2 Surface Capacitive Touch Screens

The surface capacitive touch screens provide a solution for customers seeking an alternative to the currently available capacitive options. The transparent protective coating makes the sensor resistant to scratches and abrasions. Touch performance is unaffected by everyday abuse and mishaps such as dirt, dust, condensation, liquid spills or cleaning solution. An electrode pattern printed along the edges distributes a low voltage field over the conductive layer, as shown in Figure 3. When a finger touches the screen, it draws minute amount of current to the point of contact, creating a voltage drop. The current flow from each corner is proportional to the distance to the touch point. Surface capacitive is another form of capacitive touch screen technology. The primary difference between surface capacitive and projected capacitive is that surface capacitive uses only one ITO surface[4]

Figure 3. Basic Surface Capacitive Touch Screen

2.Multi-touch Technology

Multi-touch is defined as the ability to recognize two or more Simultaneous touch points.

- Multi-touch touch was invented in 1982 at the University of Toronto (not by Apple in 2007)

- Pinching gestures were first defined in 1983 (not by Apple in 2007)

- Windows 7 (10/09) and Windows 8 (~10/12) both support multi-touch throughout the OS and is structured to support an number (~100) of simultaneous touch points

- Android, iOS and Linux currently support ~5 touches

An important feature of capacitive touch screens is their ability to recognize and calculate multiple touch points at one time, commonly called multi-touch. Multi-touch technology has been around since early research at the University of Toronto in 1982. The uses of this technology are very vast, allowing for greater human-computer interaction. This technology is traditionally associated with capacitive touch screens, but is not limited to this technology. It can also be found in infrared touch screens and is beginning to appear in resistive touch screens. Currently, multi-touch technology is being used with a purpose similar to the function keys (Control, Alt, Option, Command, etc.) on a standard keyboard. By adopting these functions, the user is able to complete the same tasks as before, but with one hand. With advances in hardware, multi touch will allow multiple users to access the same device simultaneously, like the Microsoft Surface's capability of 300 plus touches. While the hardware is available to create such devices, software implementation is holding back the growth of multi touch

3.Infrared touch screens

Infra red touch screens are highly accurate but they require large space. Dr. Andrew Hsu, an expert on touch screen technologies states that IR (infra red) screens are among the most durable surfaces and can handle hostile environments suited for military applications". They are most versatile and costly when compared with other type of touch screens.

3.1 Standard grid type

Normally standard grid type touch screen needs large space when compared with internal reflection type infra red touch screens, but their accuracy is very high. In this system IR transreceivers are mounting on the screens in matrix format, as shown in Figure 4. The IR transmitters keeps on generating IR rays but when these rays are disturbed by any substances like finger, styles etc. then the disturbed IR rays gets reflected back to the screen where they are absorbed by IR receivers. This is the basic principle of standard grid IR touch screens.

Figure 4. Standard Grid Touch Screen Infrared Emitters and Detectors

3.2 Internal reflection type

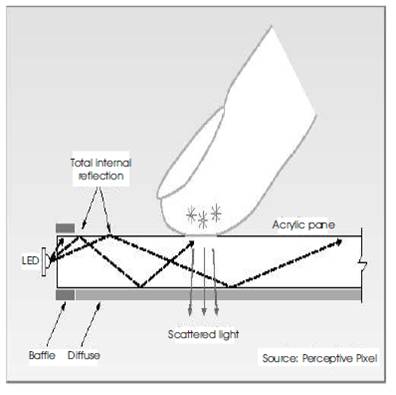

The first system is similar to resistive systems, which will be discussed later, in that it consists of a two dimensional grid of infrared light. In this technology, infrared LEDs (Light Emitting Diodes) are arranged on opposite sides of the unit underneath the glass, as shown in Figure 5. The diodes project infrared light into sensors located directly across from them. The sensors read the strength of the beams, and when a user makes contact with the screen, the system measures the drop in the sensor-output signal; this measurement allows the system to compute the location of the touch. This is to say that when the finger touches the screen, the infrared beams are obstructed by the user's finger; however, some light continues to pass to the sensor. The sensors send the measurements of light to the operating system, which analyzes the data and recognizes where the user touched. This technology has multi-touch capability because the beams of light are never fully obstructed by the user's touch. The second type of infrared system requires more space than the first. This system is based upon internal reflection; a beam of light is emitted from within the unit, hits the glass, and part of the beam exits through the lens while the other part goes back into the unit. Cameras are placed inside the unit and are calibrated to the standard reflection to the beams so that, when objects such as fingers touch the surface, the light diffuses at the contact point, causing the acrylic's internal-reflection pathways to change. A camera below the surface captures the diffusion and sends the information to image processing software, which can read multiple touches simultaneously and translate them into a command. In the example stated, the screen is an acrylic screen rather than standard glass, allowing for a thinner lens that is just as durable, cheaper, and more resilient. Advances are being made in internal reflection systems to make the instruments much smaller. One of these advancements, called Thin Sight, is a thin form-factor interactive surface technology based on optical sensors embedded inside a regular liquid crystal display. Thin Sight will allow a row of circuitry that possesses hundreds of small infrared LEDs, similar to the emitters and sensors, used in standard.

Figure 5. Internal Reflection Type

4.Touch Screens to Ordinary People

Though the touch screens had its existence from 1970s they are not available to ordinary human beings i.e., as consumer goods until 1990s. Only after 1990s they became familiar with common human beings. The main two pioneers in the field of touch screen industry who made the touch screen available to ordinary people are

4.1 Microsoft surface

As mentioned above, the Microsoft Surface is a great example of internal reflection infrared touch screens. In early 2001, Steve Bathiche of Microsoft Hardware and Andy Wilson of Microsoft Research began brainstorming concepts for an interactive table, beginning the development of the Surface. The process continued in development until 2003 when the idea was presented to Bill Gates, and 85 prototypes were created for developers on the Surface Computing group, a group created in 2004 to solely develop the surface. In 2005, various prototypes were created and analyzed, and eventually, in 2008, the Microsoft Surface was on sale to the public for $12,500 or $15,000.

The Surface's technology uses multiple image sensors around one side of the touch surface and IR backlights on the other side. When a user places his finger on the surface, intercepting the infrared beam, the device projects a shadow. Using multiple cameras, the unit converts this shadow into a touch point through Triangulation. As stated by Dr. Hsu, the Surface uses a system of cameras and IR LED's to capture the image of the object touching the surface. The surface took a step forward with their technology, developing a special motherboard to compute the data, transmitted at 100 megabytes per second, from the cameras. The board then divides the data into sections that decide what is relevant and what is not. Relevant data is considered to be any information from the cameras that has changed since the last transmission. An example of that is the shadow from the infrared light changing as someone touches the screen.

This software is also revolutionary in that it detects and distinguishes different types of touches. The Surface categorizes touches into three sets: finger, blob, and tagged objects. Fingers are given the ability to click on software application buttons, paint across the screen, and Further interact with the Surface. Blobs are generic objects that are given a circular or oval reading with a major and minor axis. Blobs include inanimate objects like paper or other pieces of technology like smart phones or cameras.

4.2 Apple

Apple Corporation is a pioneer in the field of consumer electronics. With their Innovative designs, Apple products have been setting new standards to which other technology is compared. In 2007, Apple revealed the iPhone, changing the face of telecommunications and touch screen technology. This device was revolutionary because it incorporated a cell phone, iPad, and Internet communications device, making it the only electronic device one may need. Apple also created a version of this device to be the next generation of iPod, called the iPod Touch or the iTouch. It is very similar to the iPhone, except for the difference that it does not have cell phone capabilities. For our purposes, these devices will be described as interchangeable, because they both rely on the same touch technology and the same user-interface.

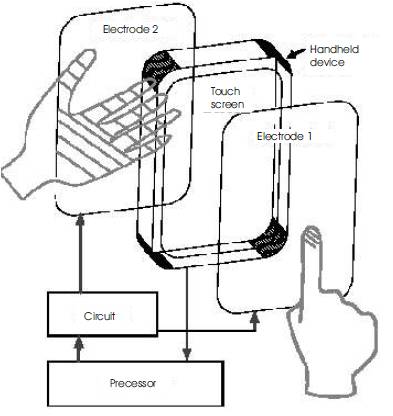

The iPhone and iTouch both use a projected capacitive touch screen, and are often used as examples in comparing projected capacitive technology to other touch screen technologies. The patent application for this system is where most of our knowledge of the screen is from. It describes two different types of touch technology; self-capacitance and mutual capacitance. Self capacitance is a simple passive array of 24×36 sensing electrodes in a single plane. Mutual capacitance, on the other hand, works much more like other capacitive touch screens. By setting two layers on top of each other, aligning the measuring strips perpendicular to each other, and calculating the touch point based on the X and Y coordinate of the touch, greater accuracy is achieved. Another technologically relevant aspect of the iPhone is its use of multi-touch input, which allows for 15 touches at a time. It is with this technology that the iPhone and iPod touch revolutionized the touch screen industry. These devices are important to the development of touch screen technology, because of their superior user interface (UI).

5.Transistor based touch screens

Finally we come to transistor based touch screens. We all knew that transistors are similar to a on/off switch, which operates based on the current/voltage supplied to the base of the transistor. Here current/voltage indicates nothing but the flow of charges/current. When these charges flow they generate electric current. This current is enough to trigger a transistor. Thus when we touch the screen the charges present in our finger moves towards the base and trigger it. Now the transistor acts as an ON switch. When we remove the finger from the screen then there will be no charges to trigger the transistor, so it acts as an OFF switch. Thus these transistors can be used as sensing element in touch screens. The sensed signal is digital, so it does not require an external analog to digital converter circuit. Apart from this, the authors use transistor as sensing element instead of resistors or IR transceivers which are all power dissipating elements, thus energy dissipation is also reduced. The construction of these transistor systems is similar to the construction of grid type IR system. Due to the grid of transistors, users do not need to press fully down on the screen putting less wear on screen increasing the life expectancy of the unit. The grid also increases the precision of the users touch. An important feature of this technology is its use and application of multi-touch gestures. This is because less force is required to maintain a touch point making dragging and zooming items much easier.

5.1 Comparisons with Transistor with IR system

The two types of infrared systems are internal reflection and infrared grid. Infrared grid systems are reliable and can be manufactured into appropriate sizes but they are more power consuming and costly when compared with these transistors.

Internal reflection systems are large systems because of the space required for cameras to accurately measure the shadow produced by the infrared LEDs. The large space required for larger instruments does make internal reflection devices the most accurate touch screen technology, but these transistors have the ability to provide multiple touches along with reduction in size.

5.2 Transistor with Resistor System

Resistive touch screen technology is the cheapest of the different types of touch screens; however, there are a few drawbacks. The first problem with this technology is the flexibility of the top layer of screen. This causes the ITO coating to crack due to the continual stretching and retracting of the flexible later. This wear also relates to the air gap between the ITO layers. This gap allows dirt and dust to collect between the two conductive surfaces, making the display appear dirty. Additionally, these devices are less than ideal for harsh environments,due to the fact that they are vulnerable to temperature and humidity changes, which would affect the accuracy of the touch screen. This is not to say that they do not perform consistently under standard conditions. Along with this these resistors dissipate a lot amount of power but transistors are only ON/OFF switch so they do not dissipate power. Thus the battery life can be extended. Apart from this a transistor will not depend upon the environment or surrounding temperature. As there are no flexible parts the fear of breakage is also rejected here. The main drawback of these resistors are that they require ITO (Indium Titanium Oxide), which is becoming very costlier nowadays i.e. the cost of 1kg ITO was 10$ before 6 years but now it costs 1000$,but we can replace this ITO with silicon and graphite which are naturally available in abundance. Since transistor devices do not need to be calibrated, they are more accurate than resistive devices after some wear. This difference between capacitive and resistive also increases because the ITO layers in resistive devices deteriorate over time. Transistor touch screens are therefore, more accurate and more durable than resistive touch screens.

5.3 Transistor with Capacitive System

Capacitive touch screens are very common in many Consumer devices. Although there are two different types of capacitive touch screens, their performance is very similar, with the exception that projected capacitive touch screens are a little more accurate than surface capacitive touch screens, but this difference is relatively negligible. However, a drawback of this technology is that these systems are severely affected by external noises. Another drawback is the cost of the screen. These screens are more expensive than resistive touch screens and the main difference between touch screen technologies are size and cost. Infrared touch screens are by far the biggest of the touch screen technologies. They are also more expensive than transistor touch screens, Infrared and transistor touch screens are best suited to devices like the Microsoft Surface, which require a very large touch screen, but transistors are cheaper. This is because transistor uses only transistor as sensors to detect the changes. Having a large capacitive or resistive system would require a large amount of wire throughout the screen; wires of that size would increase the chance for malfunction in detection, as well as wear and tear. Transistor touch screens are best suited for high end, portable electronic devices, and devices that need to perform consistently in many conditions. This is because of its durability, accuracy, multitouch support and ease, and its aesthetically pleasing appearance. Finally, transistor touch screens are also best suited for mobile applications, in which conditions will be consistent.

Conclusion

There are many complexities involved in the touch screen technology like software complexity, drive requirements, sensor fabrication, cost of saw materials etc. Among these the fabrication of sensing element plays a major role. In the present scenario ITO (Indium Tin Oxide) is the only transparent metal used by various screen manufacturers and it the only metal too. As its availability in nature is rare, this makes the cost of ITO to increase rapidly. According to an report the cost of that rare metal has raised from 100$ to 1000$ in the past six years. But by using these transistors as sensing element we can limit the use of ITO as these transistors can be fabricated by using silicon, graphite and carbon. Thus in future these transistor based touch screens will make touch screens cheaper, reliable and easier to use.