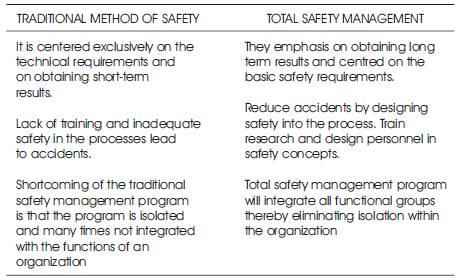

Figure 1. Traditional Focus of Safety Management (adapted from Rahimi, 1995).

This paper brings a whole new spectrum of light on Total Safety Management (TMS) philosophy and the evolution of TSM concept from a system perspective in an electronic components manufacturing industry. The traditional method of safety management employed in the industry was not productive in the context of organizational performance. In order to boost up the organizational performance, the establishment of TSM culture is viewed and focused. The functional content of the TSM model with its theoretical framework was discussed and the basic elemental features of TSM are highlighted in this paper. The components of TSM and the implementation steps are practically carried out, executed and fulfilled in the industry. Since the probability of occurrence of a fatal accidents are relatively less in this type of industries, TSM leadership communication and TSM training itself can influence the system to ensure the safety standards and keep down the incident rates thereby achieving the required safety performance. Finally, an impact study and evolution of TSM in the industry are discussed and recommendations/suggestions were given to the management safety professionals. The accident numbers are declining under the action of TSM in the industry.

Many Electronics based manufacturing industries, all over the globe have comprehensive safety plans, but the quality of the plan does not necessarily correlate to the Industrial safety performance [1]. Most current safety practices in the manufacturing sector are based on the normative approach which focus on measures to control hazards and predict unsafe conditions so that they comply with prescribed safety practices [2,3,4]. There are many forms of safety management in the industries. The types most commonly used are the traditional method of safety management and Total Safety Management [5,6]. Safety professionals from industries adhering to the traditional method of safety management direct and control workers so that they complete the expected industrial safety standards [7]. They also enforce laws and government regulations. They are devoted to impose regulations to their employees, carry out inspections, audit the system, direct investigations of accidents, and establish recommendations in order to prevent accidents in the future. The safety professionals try to modify the behavior of the worker, and use prizes and incentives to help them work in a safer way [8,[10]]. Although the concept of TSM is relatively new in the manufacturing industries, it is gaining popularity due to its ability to embrace various factors like psychological, managerial and behavioral [9, 12].

Total Safety Management is a performance-oriented approach which gives an organization a sustainable competitive advantage in the global marketplace by establishing a safe work environment that is consistent with peak per formance and encourage continual improvement [24]. TSM as a strategic and structured approach finds its roots from Total Quality Management (TQM) principles by reckoning customer satisfaction and continuous improvement as its two major guiding principles [[13],14]. The primary purpose of TSM is to provide excellence in safety through continuous improvements of products and processes by the total involvement and dedication of each individual who is in a part of that process/product [11]. The philosophy of TSM with its versatile applications gaining momentum in management are in the manufacturing industries. Safety leadership communication and safety training emphasized model can potentially influence the organizational performance [15].

The traditional safety management programs do not always improve the results of safety because they are centered exclusively on the technical requirements and on obtaining short-term results. Another shortcoming of the traditional safety management program is that the program is isolated and many times not integrated with the rest of the functions of an organization [16,17]. The responsibility of the safety program falls on the safety director, who occupies a position inside the organization of the company and, in many cases, does not have the authority to make change [20]. Because of such complex nature of traditional programs and the drawbacks are quite exposed, the challenges for researchers and practitioners is to develop total safety systems that are simultaneously highly productive and highly reliable [22]. It requires a treatment of safety from a total perspective taking into account the impact of safety on organizational work culture, production pressures and work procedures [21,23]. It is against this background that it becomes pertinent to explore and identify the influence of implemented total safety management model on organizational performance in the electronic components manufacturing industry [24].

Safety in any industry has always been measured by the level of implementation of safety rules and procedures. Recent advancements in industrial safety management such as the move towards safety culture have proven to generate better results. However, in the electronic components manufacturing industry, these approaches fail to acknowledge the essential objectives of safety as traditional methods of safety management have been employed. Therefore, from an industrial perspective, a change in mindset is needed from controlling the outcome (accidents) to a total measurement and improvement to address the system safety for which total safety management philosophy is introduced and recommended.

a) To introduce Total safety management concepts to top management.

b) To discard the old philosophy of accepting accidents and ensure long term benefits in safety aspects

c) To implement the TSM model in the industry.

d) To reduce/eliminate accidents in the wire harness division by motivating the workforce with effective safety leadership and training program.

Safety professionals from industries adhering to the traditional method of safety direct and control workers so that they complete the expected company safety standards and regulations. They also enforce laws and Government regulations. They are informed on new regulations, devoted to impose rules and regulations to their employees, carry out inspections, audit the system, direct investigations of accidents and injuries, and establish recommendations in order to prevent accidents and injuries in the future. For the safety professionals, adhering to this concept means modifying the behavior of the worker, motivating them, and using prizes and incentives to help them work in a safer way. Rewards are given only to those workers or departments that meet the preset safety objectives. The traditional model is shown in Figure 1.

Figure 1. Traditional Focus of Safety Management (adapted from Rahimi, 1995).

The difference between TMS and TSM is shown in Table 1.

Table 1. Difference Between TMS and TSM

A system that is centered on taking a proactive approach is more effective than the one that continually analyzes accidents after they happen in order to generate data on which to base improvements. Prevention is based on established rules, regulations, and safety instructions, but the mere publication of those rules and regulations in a safety manual is not enough for their effective implementation. Only when all personnel work in accordance with the safety norms and the established instructions will the company have safe practices [1,19,24].

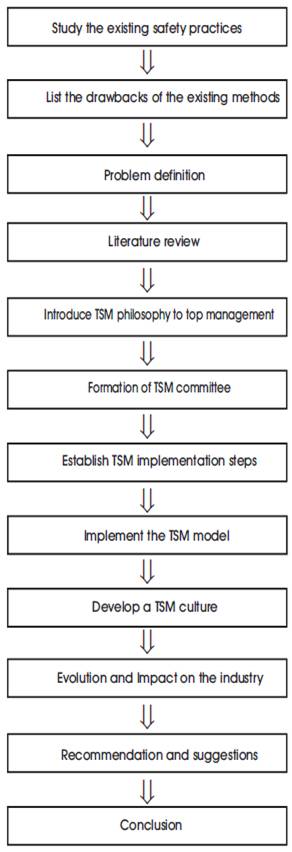

The flow chart for the proposed methodology is shown in Figure 2.

Figure 2. Proposed Methodology

Total Safety Management (TSM) is a performance-oriented approach to the safety management that involves the total organization in establishing and maintaining a safe and healthy work environment [24]. TSM includes various elements but these six basic elements were considered and adapted in the industry.

According to a Management expert, three components [19] are needed to take the TSM philosophy to practice:

(a) A TSM committee,

(b) Teams for improvement projects, and

(c) A facilitator

The fifteen steps involved in the implementation of any TSM model [19] are as follows:

(1) Gain executive-level commitment.

(2) Establish the TSM steering committee.

(3) Mold the steering committee into a team.

(4) Give the steering committee safety and health awareness training.

(5) Develop the organization's safety and health vision guiding principles.

(6) Develop the organization's safety and health mission and objectives.

(7) Communicate and inform Identification and measure.

(8) Identify the organization's safety and health strengths and weakness.

(9) Identify the defenders and opponents of safety and health.

(10) Benchmark initial employee perceptions concerning the work environment.

(11) Make it extensive to the organization.

(12) Identify specific improvement projects Execution /implementation.

(13) Create improvement project teams.

(14) Activate the feedback loop (new projects/new teams).

(15) Establish a TSM culture.

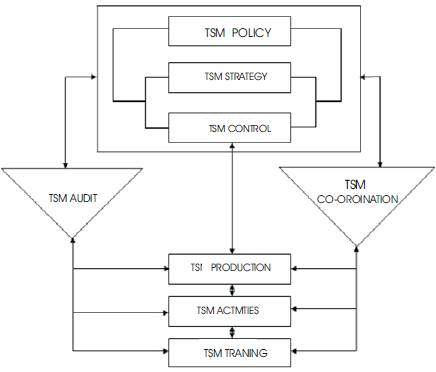

The constructed TSM model (Figure 3) shown interpreted from past studies depicts its functional content.

Figure 3. Total Safety Management Model (adopted from ZHI Xueyi, 2012)

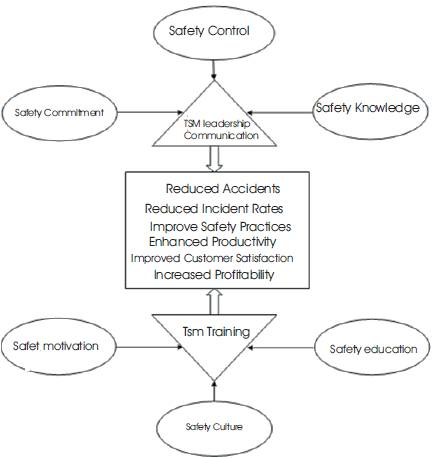

With the various information and interpretation postulated above, a new model is constructed according to the suitability and nature of the industry shown in Figure 4. Following are the theoretical framework of the functional content of the proposed model.

Figure 4. Proposed Model of TSM

Total Safety Management (TSM) concept can effectively be used as a strategic tool to boost up the organizational performance . It ensures a safe work environment that is consistent, efficient and structured. This model emphasis on TSM leadership communication and TSM training that positively influence the organizational performance that helps in reducing accidents and incident rates , improve safety practices and customer satisfaction, enhance productivity and profitability. TSM nurtures constructive safety leadership and safety training that resides in every function in an organization.

TSM leadership communication motivates team members to work harder, to work efficiently, and to take ownership of responsibility for safety performance. Operations under TSM are free of unrealistic numerical targets and are managed by facts and effective leadership that drives daily improvement to all processes at all levels. There is proactive safety leadership that interacts effectively with other functions. Developing and sustaining safety leadership communication is important to reduce accidents and to promote safety among managers and general employees. Three components namely safety commitment, safety control and safety culture provide adequate inputs for TSM leadership communication. TSM is a truly systemic approach in which effective safety commitment is enabled, with an effective communication system that enables the free communication of ideas for improvement. Safety knowledge comprises attitudes, behaviors, norms, values, personal responsibilities etc., must be transferred from leadership fraternity to the workforce. TSM favors a safety control system that does not rely on frequent safety inspection and audit. Instead , safety leadership communication influences the system. The increasing attention being paid to safety leadership in various industries is the evidence of the assumption that safety leadership will result in increased organizational safety effectiveness and performance.

TSM training is a fundamental safety practice emphasized by most central and state safety and health legislative bodies. Safety training produces the means for making accidents more predictable. There is considerable variation in the ways that safety training is designed and delivered. Three components namely safety education, safety motivation and safety participation gives more values for TSM training. Safety training works by increasing safety education ,safety motivation and involving safety participation in the workplace. Safety education is known to influence a number of employee behaviors which invariably have an impact on organizational performance by creating awareness among the workforce. Management commitment to safety motivation is a major factor influencing the success of an organization's safety programs which encourages the employees to opt for safe work procedures. Safety participation can manifest itself through job training programs, management participation in safety committees, consideration of safety in job design, and review of the pace of work. Most industries globally bank on safety training as a means to ensure better stability and organizational performance.

The study demonstrated that workplace safety is not simply an issue of doing the right thing or avoiding associated costs rather than establishing a safety culture thereby creating a safe environment. Analyzing the results of occupational safety and health in the industry, two of the phases were identified namely traditional method of safety management and total safety management. Since the probability of occurrence of fatal injuries is very less in the industry, TSM concepts were recommended. A proper integration of TSM into the system ensured stability in the context of workers safety. Also, TSM implementation results bolster the business case for safety. These findings offer good news for safety professionals because they add to the arsenal of arguments for investing in initiatives to improve safety environments and reduce accidents/injuries. As the accident/incident rates are in the downward trend under the action of TSM, there are positive outcomes to be gained in the form of safe work practices, safety culture, better organizational performance and improved customer satisfaction.

Arising from the findings of this paper, it is suggested that the management of the industry should take the following measures:

TSM brings about a new trend to safety management in the industry. It provides the industry with sustainable competitive advantage in the global marketplace. It helps boost up the organizational performance by involving workforce at all levels with effective leadership and training programs. The result witnessed that the accident numbers are declining after using the TSM model.