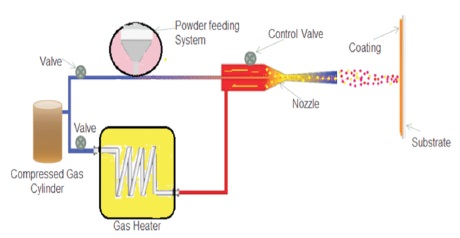

Figure 1. Schematics Diagram of CS Process

Gas dynamic cold spraying is a solid state powder spraying method with several different properties such as corrosion resistance, low oxidation, high strength, high hardness, high rate of coating deposition and allowing production of coatings from a broad range of materials. This review paper aims to provide an overview of the cold spray processes, coating materials, bonding mechanism and their development in trending applications. In particular, the revolutionary applications of gas dynamic cold spray in distinct sector such as energy sector, nuclear power plant, 3D printing, biomedical, wear and dimensional restoration, antimicrobial, electrical, catalysis and corrosion protection are discussed. The current state of coating material including high melting point metal and alloy and low melting point metal and alloy (tin, aluminum, zinc, copper) are presented. In addition, the comparison of gas dynamic cold spray with distinct thermal spray coating is briefly explained as a benchmark for future research and development.

Cold gas dynamic spraying is a relatively new coating method that utilizes converging-diverging nozzle at a very high velocity to accelerate distinct powders towards a base material where it permanently deforms on the base material, as a result of adhesion to the surface. A number of coating materials namely; metals, composites, polymers and ceramics can be used to improve the properties of base material. This technology was developed in the mid 1980s by a team headed by Alkhimov at the Institute of Theoretical and Applied Mechanics of the Siberian Branch of the Russian Academy of Sciences (ITAM of RAS) presently called as Khristianovich Institute of Theoretical and Applied Mechanics in Russia (Irissou et al., 2008). This process utilizes an extremely high Kinetic Energy (K.E.) of the carrier gas, in place of thermal energy to develop the coatings with the temperature completely low as compared to the melting temperature of feed stock material (Papyrin et al., 2006). The powder particles during this coating process, are not fully fused in the carrier gas (N ) flow and thus eliminate 2 various reactions. The high pressure gases such as helium, nitrogen or air is supplied through nozzle, which provides 300 m/s to 1200 m/s very high gas velocity (Sileo et al., 1996). The schematic representation of gas dynamic cold spray process is depicted in Figure 1.

The 1 U.S. patent on cold spray method has been published in 1994, which has been about feasibility of gas dynamic cold spray methods for a distinct range of applications (Irissou et al., 2008). After that the several other researchers patented the main design of distinct components of the cold spray system. A typical in house cold spray system comprises the following elements such as air compressor, nozzle (de Laval), spraying chamber, powder feeder, gas heater, regulating pressure and gas temperature. The temperature as well as pressure of air delivered by gas delivery system and electric heater is approximately 20 bar and 500 °C respectively. However, particle size of coating powder lies between 1 μm to 50 μm (Chavan et al., 2011; King et al., 2014).

Cold spray method has been extensively used in industry. It is classified into two groups called high and low pressure gas dynamic cold spray. In this spray method the propellant gas temperature lies between 20 to 650 °C. The maximum pressure generated for high pressure and low pressure gas dynamic gas spray is approximately 40 bar and 9 bars respectively (Oyinbo & Jen, 2019). The classification of distinct cold spray processes are shown in Figure 2.

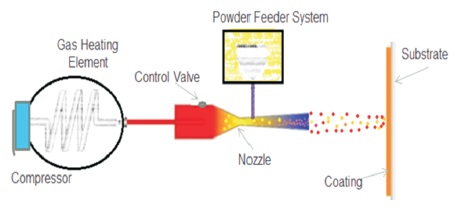

The high density particles in powder form such as alloy and pure metals are sprayed through the nozzle using a very high pressure gas supply. It utilizes lighter in weight gases namely nitrogen and hydrogen and approximate gas pressure, preheating temperature, particles velocity of 40 bar, 800 °C, and 1200 m/s respectively (Assadi et al., 2016). This process is known to make sure high particle velocities and bonding at the interface (Goyal et al., 2012). The micro-structures of high pressure gas dynamic cold spray system with Cu coating clearly indicate parachute shape of the Cu particles collected at 900–1000 m/s particle velocity and strain rate of 107–109 s-1 . The schematic diagram of HPCS system is shown in Figure 3.

Figure 3. Schematic Illustration of HPCS

In this type of spray process, the particles in the form of powder are injected through the nozzle using a low pressure gas supply. This spray system is considered as portable and compact. In this process, the gas (air) is supplied at 6 bar to 10 bar, temperature 650 ºC and particle velocities 350 m/s to 700 m/s which is very low (Koivuluoto & Vuoristo, 2014). The diagram of low pressure CS is illustrated in Figure 4.

Figure 4. Schematic Representation of Low Pressure CS

In this method submicron powder particles are used under partial vacuum. This method is suited for coating ceramic material in electronic industries (Assadi et al., 2016).

In this process laser heating is used along with cold spray either for surface preparation or to enhance bonding between the materials (Assadi et al., 2016).

In the system the idea is to utilize electrostatic field along with cold spray. By utilizing this method, the coating of the powder particles can be improved by electrostatic field, This concept is still under study. (Assadi et al., 2016).

It is highly simple, economical and novel method for depositing material on the surface of any reactivematerial at low temperature (Kumar et al., 2020).

Cold gas dynamic spraying can be utilized for repair, coating and 3D printing. CS method sprayed almost all metal ceramic composites and metallic materials to distinct thickness (> 50 mm) is technically achievable (Assadi et al., 2016; Bala et al., 2014; Champagne & Helfritch, 2014; Dong, 2010; Moridi et al., 2014). A broad range of coatings can enhance the wear resistance, corrosion and erosion of materials (Sharma et al., 2020). The current distinct materials and the field of applications are provided in Table 1.

Table 1. The Overview of Distinct Materials and their Applications in Cold Gas Dynamic Spraying (Assadi et al., 2016)

The classification of distinct material generally used in cold spray method is illustrated in Figure 5.

These materials can be easily sprayed on surface of base material by high and low pressure CS system for improving their ductility. Some of the commonly used low melting points coating materials are explained (Huang & Fukanuma, 2015; Kumar et al., 2019).

Zinc is mostly utilized for corrosion resistance of base material. Due to the better bonding strength of gas dynamic cold spray method, this material is effective to fabricate rotational sputtering target.

Due to the higher deposition efficiency (80%) of cold sprayed aluminum and its alloys, it is widely utilized for repair and to combat corrosion of substrate material.

Copper and its alloys are mainly utilized as coating material during CS due to their high ductility. These materials provide higher deposition efficiency (nearly 100%) (Kumar et al., 2018).

These materials can only be sprayed on a base material by using high pressure cold spray system. To produce plastic deformation of the coating material, greater particle velocity is required. In addition, the temperature produced during low pressure cold spray system is less (Kumar & Kumar, 2018). Some commonly used metals and alloys which have more melting point are given.

Using high melting point spray Fe and stainless steel with 90% high deposition efficiency. These coatings are uniform, denser and defect free.

With high melting point method, depositing nickel and its alloy with high deposition efficiency (> 90%) is possible. However, due to the high strength of Inconel 718, it is somewhat difficult to spray by cold spray method.

MCrAlY and its alloy are useful for corrosion protection of nozzle guide vanes and turbine blades. It can also be used as a bond coat to combat corrosion.

These materials can be sprayed with helium (He) gas owing the higher particle velocity accelerated by helium gas leading to high intensive permanent changes of the particle in the earlier spray coated layer.

The area wise uses of cold spray process are represented in Figure 6.

This process is most widely used in thermal power plant to provide safety of the boiler tubes from failure, as cold sprayed coating offers better resistance against high temperature oxidation, erosion and corrosion.

Due to the features of cold spray coatings such as high hardness value, adhesion strength, no Heat Affected Zone (HAZ), less surface preparation and retention in characteristics of feedstock powders, etc., these coatings are extensively utilized for nuclear power plants for repair purposes (Champagne & Helfritch, 2015).

Cold spray coating is mostly used in rapid prototyping, since the components created by this process has no residual stresses in tensile form (Řehořek et al., 2017).

Due to very low temperature produced during cold spraying, it is extremely used in preventing many crystalline transformations (Wang et al., 2014).

Cold spray method is very useful to improve hardness of the base material and thus enhance its resistance against wear (I25rissou et al., 2007; Sova et al., 2009, 2011; Wang et al., 2010, 2017).

This technology is effective to deposit hydroxyapatite coating for distinct biomedical application since it uses osteoconductive and bioactive material (Bedi et al., 2019; Gadow et al., 2010; Sidhu & Kumar, 2019).

Cold gas dynamic spray is an economic process to repair defective components. In aerospace industries lots of machine components are rejected, due to several defects during part manufacturing. Cold spray coating is a feasible solution to solve the problem (Kumar et al., 2019).

This process is highly effective method to prevent corrosion in the metals from environmental contact (da Silva et al., 2017; Kumar et al., 2019).

In foods processing industries and hospitals, bacterial growth on surfaces occurs because of their feasibility it improves risk of bacterial infection and cold spray prevents such risk (Page et al., 2009).

The application of cold spray on electrical appliances provide a very high thermal and electrical conductivity to the coatings, and hence it is used to improve the electrical and thermal properties of materials used in the electronics industry (Tazegul et al., 2016).

The effectiveness of cold spray process depends on the process parameters (Oyinbo & Jen, 2019). The summaries of parameters used by individual researchers to deposit varieties of coating material on different substrate are given in Table 2.

In addition, the merits and demerits of cold spray coatings are given in Table 3.

CS powder spraying is analogous with conventional thermal spray techniques such as plasma spray, D-Gun etc., at the same time the particles in powder form are present in solid phase with the metal substrate before their interaction. The cold spray offers less oxide coating, less porosity and higher hardness than the other thermal spray process (Kumar & Kumar, 2018; Kumar et al., 2018a, 2018b; Sharma et al., 2020; Vuoristo, 2014). The comparison of distinct thermal spray methods are represented in Figure 7.

Figure 7. Types of Thermal Spray Methods (Kumar et al, 2020)

Cold gas dynamic spraying may be considered as an accepted technique for coating and 3D printing. In terms of industrial uses, it provides several different advantages such as high hardness, low oxidation, low porosity, wear resistance, etc., which not achieved by any other powder spray technique. The surface coating not only decrease the cost of replacement but also boost the life of the component. The aim of surface technology is to generate functionally effective surfaces. The studies indicates that among all the spray coating processes, cold spray (CS) is functional and valid coating process to solve or determine several industrial applications. This study has been an attempt to give primary information regarding some of the major coatings materials and its use in various fields.

The metal powder and sprayed material in cold spray technique are mainly used in solid state. The advantages of CS deposits are quite different, and it useful for depositing a broad range of advanced and conventional materials on several categories of substrate materials, mostly in nonconventional utilizations where the process is temperature sensitive. There are a number of emerging initatives focusing on providing solutions for sensing, power grid, prognostics analysis in bridges, wind turbines, aircraft, automotive and construction equipments. Other possible opportunities for CS are 3D printing, fuel cells, laser surface modification, brazing and battery technology. The future for CS coatings are based on its ability to spray advanced materials on a variety of substrates with minimum thermal loss.

Authors are extremely thankful to the Research Innovation and Consultancy Department of Chandigarh University, Gharuan, Punjab, India, and Chandigarh Group of Colleges, Landran, Punjab, India, for offering the opportunity to carry out this research work.