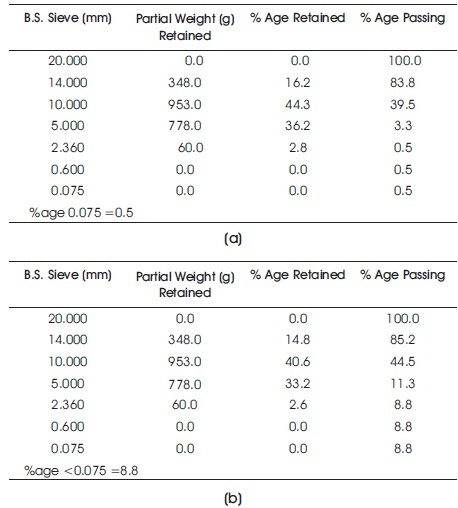

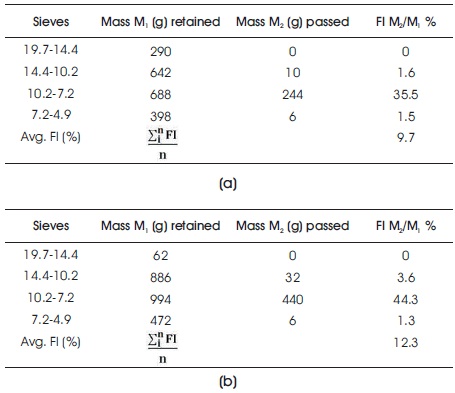

Table 1. Sieve Analysis for (a) Akia (b) Ngeta Rock Quarry Site Samples

The continued use of vast amounts of gravel in maintenance of low volume traffic roads does not only depletes it, but also is un-sustainable in the medium to long term run compared to bituminous sealing of them using low cost materials. One of the materials required to achieve the later are chippings. In Uganda, only few kilometers of these roads can be sealed in a financial year due to low indicative planning figures for road maintenance and this makes hand crushing of the chippings possible as only a small quantity will be required. This leads to employment creation and protecting the environment from noise and dust pollution caused by machine blasting. Haulage distances for these chippings from the quarries to sites of application also impact considerably the cost of these low cost sealing projects. It is against the above background that hand crushed samples from Akia and Ngeta quarries were taken and analyzed for their suitability as surfacing materials for single surface dressing of low volume traffic roads. All the parameters analyzed were within the permissible limits.

Road transport is the dominant mode of transport in Uganda, accounting for over 95% of volume of freight and human movement and it is the only means of access to the rural communities. Uganda has a total road network of 107,020 km made up of 20,563 km of national roads under Uganda National Roads Authority management; 1,207 km of roads under management of Kampala Capital City Authority; 30,000 km of district roads, managed by the Districts; 8,500 km of urban roads managed by town councils; 4,500 km of urban roads managed by Municipal Councils; and 42,250 km of Community Access Roads (CARs) managed by sub-counties (Uganda Road Fund Annual Report 2015-2016). According to Uganda Road Fund report, 2008, 100% of the CARs are un-paved with gravel or earth surface finish only. Although gravel roads are relatively cheap to construct, they are un-sustainable due to effect of rainfall, traffic, and other environmental factors. Between 12 to 15 mm of the gravel thickness is lost from the road annually (Paige-Green, Hongve, Sampson, & Cassiem, 2004), this causes an expensive burden of typically 3-5 year regravelling cycles in many countries (Cook, Petts, & O'Neil, 2008) Uganda inclusive. Many of these roads important as they are; carry low volume traffic and using the conventional pavement design and construction techniques cannot be economically justifiable. Economic justification is, however, subject to the use of innovative pavement designs and the use of appropriate surfacing types that reduce the overall construction, maintenance, rehabilitation costs of the project (Paige et al., 2004; Gourley, Toole, Morosiuk, & Hine, 2001). Done, Ford, and Edwards (2001) add that the provision of low cost waterproof surfacing on such gravel roads, which are under relatively low traffic, can be economically justifiable. It is within the policy framework of the government of Uganda to introduce low cost seal technology to road construction industry and it was proposed to have 300 km of District roads in 23 Districts with low volume traffic and 1,095 km gravel national roads promoted to low cost seal surface by 2014. This study focuses on single surface dressing, which is one of the low cost sealing options for low volume traffic roads. One of the key materials in this is the chippings. According to TRL and DFID (2000), the chippings to be used as a wearing surface in a single surface dressing for lightly trafficked roads (50-250 vehicles per lane per day) should have: the size between 10-14 mm, aggregate crushing value of 35%, flakiness index of 35%, water absorption of 1%, and application rate of 12 kg/m2. According to Department for International Development, DFID (2000), the binder spread rate should be 1.1 kg/m2 of the chipping surface. This study finds out whether the hand crushed chippings picked from Akia and Ngeta rock quarries meet the above standards. Lira-Soroti Road junction to Boroboro in Lira District, Uganda, East Africa was used as a case study.

Crushed chipping samples to be analyzed were collected from Ngeta and Akia rock quarries located in Lira District and analyzed at Makerere University soil laboratory in Kampala, Uganda. Traffic information on the case study road was picked from the office of the Lira District Engineer.

In determining the median sieve sizes of the chippings (i.e. sieve size allowing 50% of chippings samples to pass through), 2,150 g and 2,345 g of Akia and Ngeta Rock quarry samples, respectively were dry sieved through sieves with diameters of 20 mm, 14 mm, 10 mm, 5 mm, 2.36 mm, 0.6 mm, and 0.075 mm. Dry sieving was done because the aggregates did not have clay particles to cause agglomeration. The above was in accordance with British Standards Institution (1985). The results of sieving were tabulated from which the median sieves sizes were determined through interpolation.

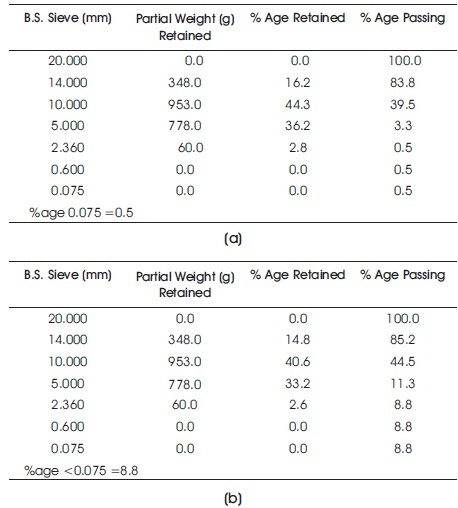

According to the Central Materials Laboratory (CML) testing manual (2000), Ministry of Works, United Republic of Tanzania, the ACV gives a relative measure of the resistance of an aggregate to crushing under gradually applied load. In determining it, 3000 g of samples from both sites were taken and analyzed as per British Standards Institution (1990) and results are tabulated. ACV was determined by dividing mass of the aggregate passing a separating sieve by the mass of aggregate retained on the separating sieve and mean ACV from averaging ACV for two tests for each of the samples.

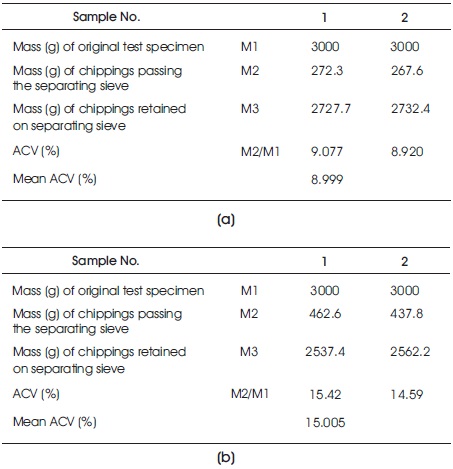

3508 g and 2542 g of chippings from Akia and Ngeta samples, respectively were taken and analyzed in accordance with BS 812: section 105.1:1989 in order to determine their FI. The FI (%) was calculated by dividing mass of materials retained in separating sieve by the mass passing the separating one, 4 tests were averaged to get the average FI.

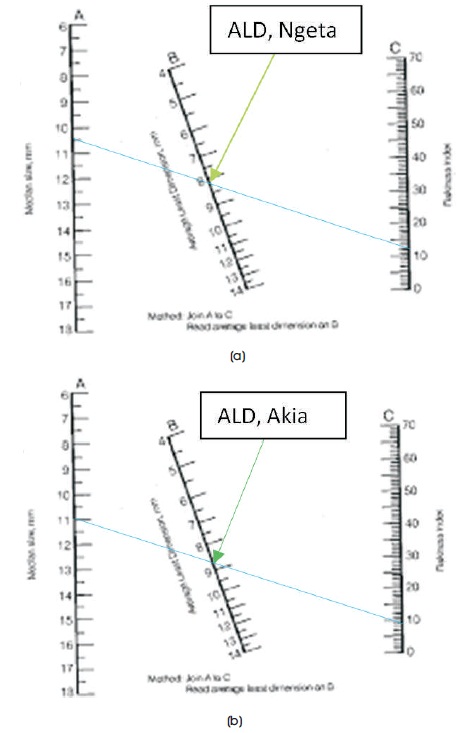

In the determination of ALD, the median sieve sizes and flakiness indices for the aggregates were used to determine the value of ALD from the Nomograph developed by Jackson (1963). This was in accordance with British Standards Institution (1985).

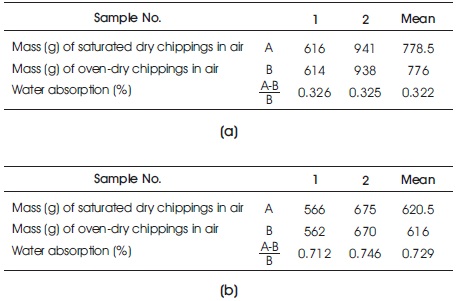

Since the chippings of interest in single surface dressing is the one that passes through the 14 mm sieve, but retained in 10 mm sieve, 4275 g of each sample from each quarry falling within the above sieve range were taken and analyzed in accordance with British Standards Institution (1975). Equation A-B/B ´ 100%, where A =the mass (g) of saturated surface dry aggregate in air and B=the mass (g) of oven dry aggregate in air, was used to calculate the water absorption of the chippings. This equation is adopted from Central Materials Laboratory Testing Manual, (2000), Ministry of Works, United Republic of Tanzania.

The equation R = K X ALD, where R=aggregate spread rate, K is a constant taken to be 1.364 kg/m2 (TRL and DFID, 2000), and ALD=Average Least Dimension of the chippings samples, was used to calculate the aggregate spread rate.

Equation R = K1 + K2 X F + (K 3+ K4 X F) X ALD, where, R=binder optimum spread rate (L/m2), K1 =a constant (0.625), K2 = a constant (0.023), K3 =a constant (0.0375), K4 =a constant (0.0011), and ALD = Average Least Dimension of chippings, was used to determine the binder (K1 -60) spread rate. This equation is adopted from TRL and DFID (2000).

Tables 1(a & b) - 4(a & b) presented show the results for sieve analysis from which the median sieve sizes were determined, ACV, FI, and water absorption for Akia and Ngeta Rock Quarry site samples, respectively, meanwhile Figures 1(a & b) are Nomographs from which the ALD for Ngeta and Akia Rock Quarry samples, respectively were determined. These tables and figures have been presented and discussed under the sub-headings presented below. Results for chipping and binder spread rates have also been presented and discussed under sub-headings 2.6 and 2.7, respectively.

Table 1. Sieve Analysis for (a) Akia (b) Ngeta Rock Quarry Site Samples

Table 2. ACV for (a) Akia (b) Ngeta Rock Quarry Site Samples

Table 3. FI for (a) Akia (b) Ngeta Rock Quarry Site Samples

Figure 1(a). Nomograph Showing ALD for Ngeta Rock Quarry Site Sample [Source: Jackson,1963] (b) Nomograph Showing ALD for Akia Rock Quarry Site Sample [Source: Shell, 1963].

Table 4. Results for Water Absorption of (a) Akia (b) Ngeta Rock Quarry Site Samples

By linear interpolation, the median sieve size is determined to be 10.9 mm and 10.5 mm for Akia and Ngeta Rock quarries samples, respectively.

According to TRL and DFID (2000), the allowable ACV for chippings to be used as a surfacing material for single surface dressing for a lightly trafficked road (50-250 vehicles/lane/day) is 35% and the mean ACVs of 9% and 15% for Ngeta and Akia rock quarries samples, respectively all fall within this allowable limit.

TRL and DFID (2000) allows a FI of 35% for chippings to be used in single surface dressings for lightly trafficked road.

All the mean flakiness indices for chipping samples from Akia and Ngeta rock quarry sites of 9.7% and 12.3%, respectively fall within the allowable limit.

Using median sieve sizes and flakiness indices of the two samples, the ALD was read by joining median sieve sizes on graph A to FI on graph C by the blue line and point of meeting graph C noted by green line taken as the ALD. From the Nomographs above, the ALD was determined to be 8.2 mm and 8.7 mm for Ngeta and Akia rock quarry samples, respectively.

The maximum allowable water absorption of chippings for single surface dressing is 1% and all the mean water absorptions for both sites are less than this value.

Using the equation R= K X ALD with K being a constant (1.364 kg/m2) and ALDs for Akia and Ngeta samples being 8.7 mm and 8.2 mm, respectively, the chipping spread rate were determined to be 11.87 kg/m2 and 11.18 kg/m2, respectively.

According to Department for International Development, DFID (2000), the spread rate of chippings for single surface dressing should be 12 kg/m2, of which the above results are approximate.

The daily traffic on the case study road was 215 vehicles/lane/day, existing surface untreated, the road is located within tropical-hot and wet region and the chippings were cubical for both quarry sites and basing on that, the total overall factor, F was calculated and found to be 8 and from, R = K1 + K2 X F + (K3 + K4 X F) X ALD with ALD for samples from Akia and Ngeta quarry sites being 8.7 mm and 8.2 mm, respectively and the constants as explained above, the binder spread rate was determined to be 1.21 kg/m2 and 1.19 kg/m2 for Akia and Ngeta quarry sites, respectively.

The results above is compared relatively to binder spread rate of 1.1 kg/m2 for single surface dressing as recommended by Department for International Development, DFID (2000).

Basing on the tests and analysis performed on the samples from both Akia and Ngeta rock quarry sites, the author concludes and recommends as follows:

The author acknowledges the time accorded to him by his wife Gloria Adongo (Mrs.) and his son Perez Agwe while he was executing this work and Irene Kabazira (Mrs.) for the Technical guidance accorded to him while he executed the task. The author is equally indebted to Mr. Enen Okello Richard for the necessary support accorded to him.