Figure 1. (a) Water Hyacinth Plant, (b) Dried Stem, (c) Needle Comb, (d) Water Hyacinth Fiber, (e) Hemp Plant, (f) Hemp Fiber [5]

For the past two decades researchers are working to identify and develop new natural textile fiber sources with eco-friendly manufacturing and sustainability processing. This study investigates the extraction of fibers from water hyacinth (Eichhornia crassipes) plants, its physical, mechanical, and structural properties. The water hyacinth fibers show good strength of about 220.5 g/tex and the fineness of 1.22 g/cm3 are prepared into nonwoven fabrics and their quality for textile applications is analyzed. Nonwoven fabrics are prepared by blending water hyacinth fibers with hemp fibers in three different ratios, such as 75:25, 50:50, and 25:75 for assessing their suitability. The prepared fabrics were analyzed with the effect of blend ratio of water hyacinth fibers for the physical and thermal insulation properties. The result shows that higher the proportion of water hyacinth fibers in the sample, higher the thickness and areal density, and lower the bulk density of the fabric. Further, the increase in the proportion of water hyacinth fibers decreases the thermal conductivity of the fabric and the good thermal resistivity was observed in the sample WH75/H25.

The textile market has the trend of manufacturing go green products; ultimately the consumers are also aware of buying eco-friendly fabrics [18,19] . Specifically, the present textile market is available with plenty of such products made of natural cellulosic fibers with top ranking fibers, such as organic cotton, hemp, jute, banana, and sisal [2]. But there is a possible risk of getting a plenty of resources for bulk and continuous production. Keeping such factors in mind, the new fiber sources are identified by the researchers and scientists [6].

There emerges a new fiber from water hyacinth plant, a free floating aquatic weed found abundant in water sources like pond, river, ocean, and dam [4]. Water hyacinth reproduces rapidly with the weight gain of 4.8% per day and double in every 11-15 days of field observation [20]. The water hyacinth plant are considered as a threat to bio-diversity, several steps has been adapted to control the growth of the weed and researches were carried out to destroy the weed completely [11].

On the other hand, water hyacinth plant is considered as a valuable resource due to some of their unique properties. Several researches have been done in the last decade to utilize this weed in an economical way to produce the products of different aspects [9]. Water hyacinth plant is rich in cellulose content which can be utilized by extracting the fibers from the stem part. The fiber has good absorbency and a sponge like texture that can be effectively used as an alternative fiber for textiles [16].

In this study, the comprehensive view of research related to water hyacinth fiber, a natural reinforcement of synthetics, and other commercial fibers for the utilization of thermal insulation materials are elaborated. Here the raw material, water hyacinth fibers are manufactured into needle punched nonwoven fabrics blended with Hemp fibers in different ratios. The nonwoven fabrics have the tailored characteristics, such as flexibility, low cost, lightweight, less process, high performance, and good degradability. The investigation aims to find the physical and insulation properties of the needle punch nonwoven fabrics made of water hyacinth fibers for the assessing the suitability of the product is analyzed and reported.

Water hyacinth (Eichhornia crassipes) is an aquatic plant found free floating on water sources like lake, pond, and rivers. This plant restricts the flow of water and thus reduces the oxygen level and considered as a serious threat to bio diversity [7]. Each plant can produce thousands of seed each year and these seeds can remain viable for more than 28 years.

In resource angle water hyacinth appears to be the valuable resources with several unique properties [14] . The result of various researches done in past decades has produced diversified uses of water hyacinth. The plant has been used for biogas or compost production [1]. The new technologies has now been developed to produce a decentralized waste water management system from the water hyacinth plant for the phytoremediation of metals like cadmium, chromium, and copper [12]. Water hyacinth is also used in the manufacture of fertilizers. In rural areas, handicrafts and furniture are developed using dried water hyacinth stalks. It is incredibly difficult to completely eradicate water hyacinth plants and the efforts made to remove them provide only a short-term benefit [11].

The stalks of water hyacinth (Eichhornia crassipes) are found to be alternative source for textile material, according to the Department of Science and Technology, Philippine Textile Research Institute (PTRI). Researchers at PTRI have produced the clothing using the water hyacinth fibers as raw material [15].

In textile industry, Nonwovens are one of the fastest growing sectors and constitutes one third of fiber industry Nonwoven has the highest advantages, such as simple production stages, efficient production, and low cost compared to conventional woven and knitted fabrics. The nonwovens technology helps to produce fabrics with good appearance, texture, and strength [10] . The properties of the nonwoven depend on the raw materials and methods of production. Therefore nonwovens are widely used for acoustics and thermal insulation materials [5].

The matured stalks produce good number of fibers than the younger ones [8]. The matured water hyacinth plants (Figure 1(a)) were collected from the Cauvery river side of Erode district, Tamilnadu, India. The stem of the plants are separated, washed, and dried in shade (Figure 1(b)).

Figure 1. (a) Water Hyacinth Plant, (b) Dried Stem, (c) Needle Comb, (d) Water Hyacinth Fiber, (e) Hemp Plant, (f) Hemp Fiber [5]

The needle comb (Figure 1(c)) with 0.2 mm gap was prepared to comb the stem, which helps in opening and separation of water hyacinth fibers. The thickness of the fibers obtained depends on the gap between the needles in comb. For finer fibers, a closely arranged needle comb may be used.

The dried Water hyacinth stems are opened into half in diameter by a knife and the fibers were extracted by the traditional scrapping method using the needles and tested for their qualities. Thus long strands of fibers (Figure 1(d)) are obtained and these fibers are used for further processes.

The hemp fibers are extracted from the matured hemp stalks (Figure 1(e)) by the process of water retting followed by decortication. The hemp fibers (Figure 1(f)) needed for the study was purchased from the local market of Erode district.

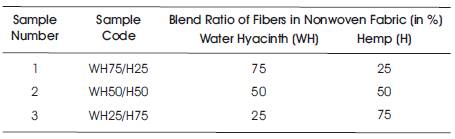

The characteristics of the fiber and the methods of manufacturing process influence the thermal properties of the nonwoven fabric. Since water hyacinth fiber is a hollow and shows good thermal conductivity the fiber is much suitable to produce the thermal insulation materials. Due to less cohesiveness, processing of 100% water hyacinth fibers is not practically possible. Hence the effect of water hyacinth fiber on the thermal insulation properties is thus analyzed by blending with hemp fibers, which also having good insulation properties analyzed in earlier researches ([3], [13]). The different proportions of water hyacinth with hemp fibers, such as 75:25, 50:50, and 25:75 are studied. The details of the nonwoven fabric construction and their nomenclature are given in Table 1.

Table 1. Nomenclature of Nonwoven Fabric [5]

The fibers were pre-cut to the staple length of 6–9 cm and manually opened to prevent from undesirable damages during the process. The fibers are then blended in the proposed ratios as given in Table 1. Mixing is done manually to ensure the homogenous web before feeding them into the Dilo nonwoven plant to produce the needle punched nonwovens. The machine consists of card, circular drum, and needle room. The fibers feed are carded, overlapped, and needle punched by the barbed needles. The Dilo nonwoven plant has the machine width of 100 cm where the working width is about 60 cm. The parallel laid web were produced from the carding and fed into the needle room with 30 laps overlaid. In the needle room the fabric is produced with the needle penetration depth of 12 mm with the punch density of 25 punch/cm2 using the 2500 needles placed as 2 needle boards with the needle motion of down strokes at the frequency of 225 strokes/min. Figures 2 (a), (b), (c) represent the WH75/H25, WH50/H50, and WH25/H75 nonwoven fabric, respectively.

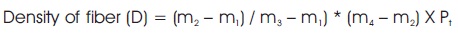

The extracted water hyacinth and hemp fibers are analyzed for the length using a metal scale by stretching on the flat table. Since the natural fibers are brittle, it is not possible to analyze the length using advanced instruments. The length of the fibers are obtained from the average of 20 samples and expressed in cm. The average diameter of the fibers is analyzed using a photograph of Scanning Electron Microscope (SEM) of individual fiber taken along the longitudinal direction by analyzing the ten different areas. The fineness of the fibers is analyzed according to ASTM D 1577 test method. The density of the fibers is carried out using the standard procedure. About 1 gm of oven dried staple fiber is taken in a standardized measuring glass and weighted in a weighing balance. The beaker with 50 ml of water is weighed separately and noted. Then the weighted dry sample and water is mixed well without any air bubbles and the weight is taken. Then the density of the fiber is calculated using the formula 1 and is expressed in g/cm3.

where, m1 – Mass of empty standard measuring glass (gm), m2 – Mass of standard measuring glass with staple fibers (gm), m3 – Mass of 50 ml water in the standard measuring glass (gm), m4 – Mass of standard measuring glass with staple fibers and water (gm), and Pt – Density of water (g/cm3).

The mechanical properties of the fiber, such as tensile strength and elongation influence the fabric properties. Hence the tensile strength and elongation of the extracted fibers were studied using the standard procedures. Single fiber strength of the fiber was determined using the INSTRON – 5500R universal testing machine with the aid of 1 kN load cell to compute the maximum strength as per the ASTM D 3822 standard. The test was performed at a room temperature of 21 oC with a relative humidity of 65%. Twenty single fibers were investigated at a crosshead speed of 5 mm/min for 100 mm gauge length. Thus the average value of the strength and elongations were obtained using the statistical methods.

Morphological characterization of the fibers provide the information regarding the fiber features, such as fiber size, shape, diameter, structures, and so on. In this study, the morphology of the extracted fibers is analyzed using the Scanning Electron Microscopy. The surface of the fiber is coated with thin layer of gold using Edward Sputter Coater Apparatus and then observed in a vacuum mode with secondary electron detector and an accelerating potential voltage between 5 and 10 kV with working distance of 15 mm.

The needle punched nonwoven fabrics were tested for the physical and thermal insulation properties are as follows.

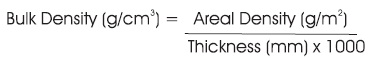

The physical properties, such as Thickness (ASTM D 5729 – 97), Areal Density (ASTM D 6242 – 98), and Air Permeability (ASTM D 737 – 96) of the water hyacinth/hemp needle punched nonwoven fabrics were tested according to the standard ASTM test procedures. The Bulk Density of the needle punched nonwoven fabric is calculated using the following equation,

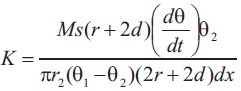

The thermal behavior of the prepared needle punched nonwoven fabrics was tested using Lee's disc method. The specimen to be tested is precut to thin disc of 11 inch diameter. The thickness of the fabric is measured at different places of the specimen using the screw gauge and the diameter of the specimen is measured using a millimeter scale, and mean value of thickness and diameter was calculated [17].

The specimen was mounted on the steam chest brass cylinder with thick brass base (B) of same diameter of the sample. The thermometers were inserted to both steam chest and metallic disc. The steam chest was connected to a boiler and the steak was allowed to pass through. When the steady state temperature was attained, the readings θ1 and θ2 of both the thermometers T1 and T2 , respectively were noted. The specimen is then removed from the disc. Place the chamber to contact the disc directly. The disc gets heated more rapidly. Remove the steam chamber when the temperature raises 7-8 oC above the steady state temperature (θ2). Now, allow the disc to cool and start a stop clock when the temperature falls exactly to 5 oC above θ2. The temperature is noted for every 30 s till it reaches 5 oC below θ2. The thermal conductivity of the nonwoven fabric is calculated using equation (3).

where,

K – Thermal conductivity (W/mK)

M – Mass of metal disc

s – Specific heat capacity of the metal disc

D - Thickness of the bad conductor

r – Radius of the metallic disc

d – Thickness of the disc

θ1 – Steady temperature of steam chamber

θ2 - Steady temperature of metallic disc

(dθ/dt) – Rate of cooling at θ2.

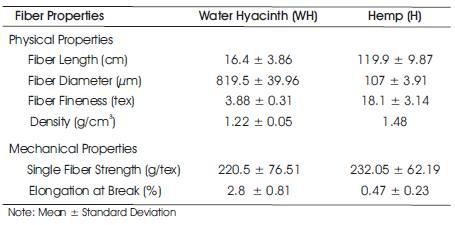

The physical properties of the water hyacinth and hemp fibers are given in Table 2. The length of the water hyacinth fiber is found to be 16.4 cm and for hemp is 119.9 cm which are in the range of other bast fibers. The diameter of the water hyacinth and hemp fibers obtained using SEM analysis is 819.5 μm and 107 μm, respectively. The result describes that water hyacinth fibers are thicker and hemp is fine compared to that of other bast fibers, such as Sisal and Banana. The fineness of the water hyacinth is 3.88 tex and hemp is 18.1 tex determines the coarse and fine nature of the respective fibers. The density of the water hyacinth is 1.22 g/cm3 and hemp is 1.48 g/cm3 shows both the fibers are in the range of other bast fibers.

Table 2. Fiber Properties

The mechanical properties of the water hyacinth and hemp fibers are given in Table 2. The single fiber strength of the water hyacinth and hemp fibers are 220.5 g/tex and 232.05 g/tex, respectively. Both the fibers show the similar strength characteristics which are suitable to produce the nonwoven fabrics. The elongation of the water hyacinth and hemp fibers are 2.8% and 0.47%, respectively describes that the water hyacinth fibers are flexible and able to produce the nonwoven fabrics.

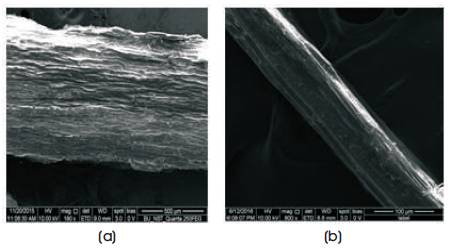

The morphology of the fibers analyzed using Scanning Electron Microscope (SEM) is shown in Figure 3. The result shows that the water hyacinth fibers (Figure 3(a)) have rough surface with bark-like stripes with higher amount of wax and fatty substances. The outer surface also exhibits the layer of lignin tends to the floating behavior of the fiber. The result of hemp fibers (Figure 3(b)) shows that the fiber has smooth surface with wax, small amount of lignin, and fatty substances. Thus the fiber is much suitable for entangling during nonwoven preparation.

Figure 3. SEM Image (a) Water Hyacinth Fiber – 180x (b) Hemp Fiber – 800x

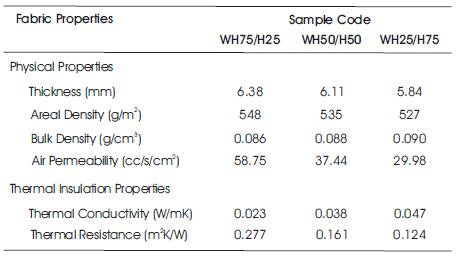

The physical and thermal insulation properties of needle punched nonwoven fabrics of water hyacinth/hemp blends were shown in Table 3. From the table, it is observed that the properties, such as thickness, areal density, bulk density, air permeability, and thermal conductivity of the nonwoven fabrics are significantly influenced by the blend proportion of water hyacinth fibers.

Table 3. Nonwoven Fabric Properties

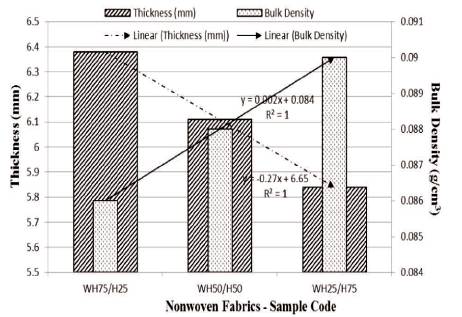

Figure 4 shows the influence of blend proportion of water hyacinth fibers on thickness and bulk density of the nonwoven fabrics. From Figure 4, it is clear that the increase in the blend proportion of water hyacinth fiber tends to increase the thickness of the fabric. The hollow nature and cell structure of water hyacinth fibers prevents compact packing of fibers during needle punching that leads to the increase in the thickness of the fabric. Thus increase in the thickness leads to the decrease in the bulk density and increase in the areal density. The result depicts that the porous structure of the fabric increases with the increase in the water hyacinth fiber proportions.

Figure 4. Effect of Blend Proportion of Water Hyacinth Fiber on Thickness and Bulk Density

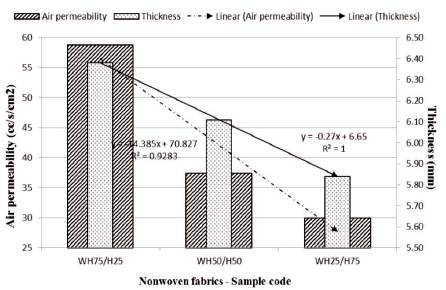

Figure 5 shows the influence of blend proportion of water hyacinth fibers on air permeability and thickness of the nonwoven fabrics. From Figure 5, it is clear that the increase in the blend proportion of water hyacinth fiber tends to increase the air permeability of the fabric with increase in the thickness of the fabric.

Figure 5. Effect of Blend Proportion of Water Hyacinth Fiber on Air Permeability

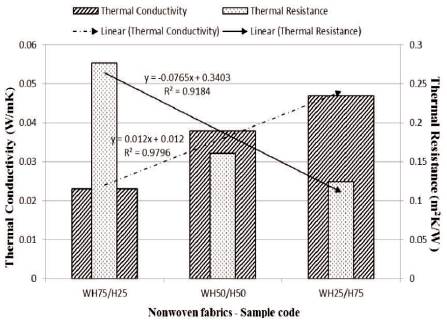

Figure 6 shows the influence of blend proportion of water hyacinth fibers on thermal conductivity and thermal resistivity of the nonwoven fabrics. The thermal conductivity of the nonwoven fabric decreases with the increase in the blend proportion of water hyacinth fiber and also due to increase in thickness of the fabric. The thermal resistance of the nonwoven fabric has the positive correlation with the thickness of the fabric. The result shows that the increase in the blend proportion of water hyacinth fiber tends to increase the thermal resistance of the nonwoven fabric.

Figure 6. Effect of Blend Proportion of Water Hyacinth Fiber on Thermal Insulation Properties

The fibers extracted from the stem of water hyacinth plant shows good characteristics and can be effectively used as an alternative fiber for textile industry. The morphology of the fiber obtained from SEM depicts that the fiber has hollow structure with wax and lignin content on the surface similar to other bast fibers and are suitable to produce nonwovens. The needle punched nonwoven are prepared with altering the blend proportion of the water hyacinth fibers with hemp and analyzed for the thermal insulation properties. Thermal conductivity is one of the important properties of textiles helps to analyze the heat transferred by convention and radiation through open spaces in the fabric. The sample WH75/H25 shows the good thermal resistivity compared to that of other nonwoven samples. The increase in the proportion of water hyacinth fibers in the sample increases the thickness as well as areal density and decreases the bulk density of the fabric. Thus the nonwoven fabric made of water hyacinth fibers can be effectively used for the insulation materials in the interiors of the constructions. Since the needle punched nonwoven fabric made of water hyacinth fiber has the void structure, the acoustic properties of this material for sound reduction in room interiors, and for automobile interiors is under study.

The thermal insulation properties can also be obtained for the multiple layers of nonwoven fabric. The water hyacinth fiber can be combined with other fibers and its properties may be analysed for thermal insulation characteristics. The acoustical behavior of the water hyacinth nonwovens can be studied.