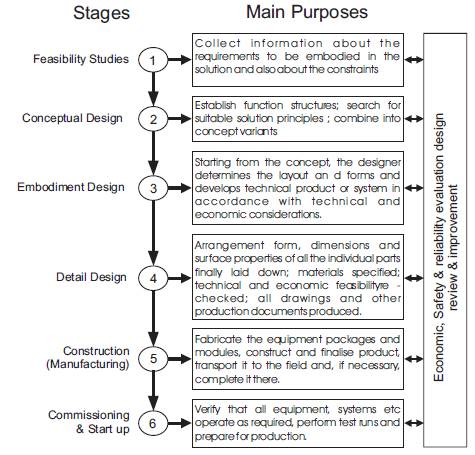

Figure 1: A generic engineering product development process

It has been noted that the stages do not necessarily follow rigidly one after the other. They are often carried out iteratively returning to preceding ones, thus achieving a step-by-step optimisation (An, et al., 2001b; Ertas and Jones, 1996). There are several reasons for this interest in developing new design procedures. One is the increasing complexity of modern design. A great variety of new demands are increasingly being made on the designers, such as the new materials and devices that become available and the new problems that are presented to the designers. The other one is that growing technical complexity and engineering change (Wright, 2000) of large engineering products and the public concern regarding their safety, reliability and economic have aroused great interest in the development and application of safety and reliability assessment procedures. Additionally, as well as being more complex, modern design work often has very high risks and costs associated with it. Therefore, the design must be absolutely right before it goes to production. This means that decision making of any new product must have been through a careful process of design. For example, an engineering product has to have a very rigorous design process to ensure their safe operation and avoid the catastrophic consequences of failure. Therefore a new, systematic approach is needed. However, safety, cost and reliability analysis is involved in all design stages.

When designing an engineering product, uncertainties are involved in all design stages, in particular, at the initial design stage where there is a lack of safety, cost and reliability data and information for use in the traditional methods based decision making (An, et al., 1999; Karwowski, et al., 1986; Wang et al., 1996). In many circumstances, there are usually several design options produced for selection at the initial design stage. The information available for making decisions on which design option to be selected at this stage may be incomplete. As the design proceeds, more and more information becomes available. As a design proceeds to a more detailed stage, the selection of design options at lower levels is required and again the similar process for selecting a particular design option is required. It should be noted that the decision making process at all levels may involve the uncertain or incomplete information. This is particular true when the safety, cost and reliability aspects are taken into account. Therefore, the decisions made at the early design stages probably have a more significant impact on the performance of an engineering product than those at any other stages in its life cycle. Because the process of safety, cost and reliability analysis in such a stage are very complex and the data available at the very initial stage may not be complete for decision making due to the great uncertainty involved. Fuzzy reasoning analysis which usually involves fuzzy set theory, may be more appropriate to analyse the safety, cost and reliability with incomplete information (Klir and Yuan, 1995; Mamdani and Gaines, 1987, An et al, 2005b). This paper presents the development of a fuzzy-based intelligent decision making support system for modelling various design variables for making design decisions at the design stage based on safety, cost and reliability assessment.

2. A Framework For Making Design Decision

The objective of the studies at the feasibility design stage is to evaluate whether or not further development of an engineering product is technically feasible and commercially favourable (An et al, 2000a; Ertas and Jones, 1996). The safety, cost and reliability evaluation at this stage usually plays a relatively subordinate role regarding whether to develop this engineering product or not. Therefore, the risk estimation will be aimed at comparing different factors with respect to safety, cost and reliability. Safety, cost and reliability analysis will identify areas of uncertainties where detailed studies may need to be carried out later. Estimates of probabilities and consequences should be used in order to compare different types of product designs. In general, safety, cost and reliability analysis at the feasibility design stage is aimed at specifying one or more design alternatives for engineering products.

The objective of safety, cost and reliability analysis during the conceptual design stage of an engineering product is to provide safety-cost-reliability related input in the process of developing and selecting an engineering product. The conceptual design shall satisfy the public requirements for a safe, reliable and economically attractive solution, together with the requirements given by the regulations (Ertas and Jones, 1996). The acceptability of the conceptual design shall be documented through a safety and reliability evaluation of Safety Case which will accompany the product development plan.

Both the feasibility and conceptual design stages usually form the initial design stage in the design process of an engineering product. It has be noted, at such stages, that incomplete data and high level of uncertainty may not allow tradition methods to be effectively and efficiently applied to model safety, cost and reliability for decision making (Wang et al., 1996).

An analysis at the initial design stages will deal with large uncertainties because the available information is limited, and many assumptions must be made. However, since safety, cost and reliability factors have significant influence on the future design, uncertainties associated with these factors need to be addressed properly. On the other hand, conservative estimates cannot solve the problems, because such estimates would lead to a design basis that could never be used in practical design due to enormous economical implications. It is necessary to evaluate the various design options that need to be considered at the feasibility and conceptual selection stages of an engineering product. Uncertainties may have three types:

- Uncertainties due to the lack of detailed design information,

- Uncertainties due to insufficient existing database, and

- Uncertainties due to the analytical methods.

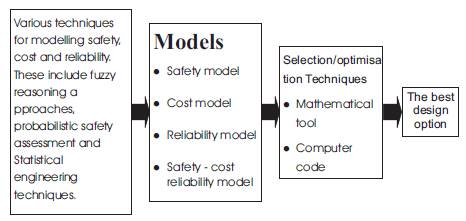

Design for safety and reliability is a process of identifying hazards, estimating the risks associated with those hazards and finally evaluating them in terms of two basic parameters, namely the occurrence probability of each hazard and the magnitude of possible consequences (An, 2005a). However, it is important for safety, cost and reliability to be considered in an integrated manner in the design process of an engineering product. Therefore, it is essential to develop an analytical methodology with incomplete information. A fuzzy reasoning approach provides a useful tool to deal with such uncertainties for decision making purposes, thus allowing safety, cost and reliability analysis with linguistic terms to represent safety, cost and reliability levels. In other words, one or more control functions and objective functions are required to be formulated and then processed to derive the best design option using optimisation techniques. This includes obtaining the fundamental safety, cost and reliability information (basic problem analysis), formulating the mathematical models (mathematical modelling) and finally processing them (An et al, 2000a and b; Pilly and Wang, 2003; Sii et al., 2001). Figure 2 shows a framework for making design decisions. The combination of safety, cost and reliability model is so called safety-cost-reliability model.

Figure 2: A framework for making design decision

In this framework, various techniques need to be employed to produce information for building up mathematical models that includes fuzzy reasoning approaches, probabilistic safety assessment and statistical engineering techniques. A design is gradually developed during the design stages of an engineering product. It should be noted that a design is usually an iterative process and the initial estimates made may be inadequate. Each estimate reacts on other features of the design. Therefore, safety, cost and reliability analysis may need to be carried out in an integrated manner. An engineering product can be efficiently and effectively analysed by this framework which may provide a designer with a method and tool to make safety, cost and reliability based design decisions. A new fuzzy-based intelligent decision making support system using fuzzy reasoning approach is described in Section 3.

3. A New Fuzzy-Based Intelligent Decision Making Support System

Many typical safety, cost and reliability assessment approaches may have some problems in situations where there is a lack of confidence in safety, cost and reliability assessment or the novelty of design is too high resulting in the lack of reliable data and information (An, 1998). In many circumstances, a designer may have to describe a design in terms of vague and imprecise descriptors such as "good" and "poor". Such judgements are obviously subjective. Fuzzy reasoning approaches may provide a solution. In this method:

- a membership function is regarded as a possibility distribution based on the proposed theory and

- an apparent possibility distribution expressed by fuzzy set theory is transferred into a possibility measure distribution.

- Both of these processes result in a set of probability distributions which can be used to safety, cost and reliability.

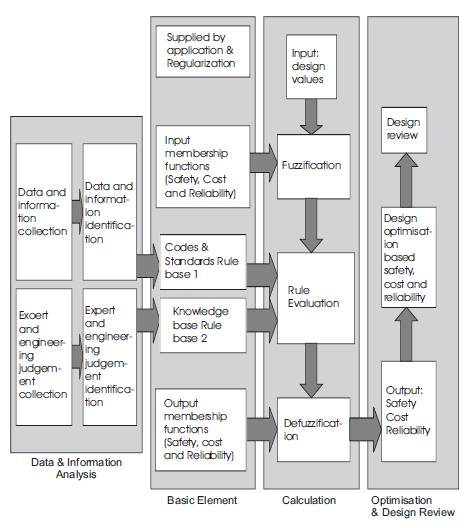

A fuzzy reasoning approach is a computer-based approach system that emulates the reasoning process of human expert within a specific domain of knowledge and also includes codes and standards based on the regulations and company policy. Therefore, it is primarily built for the purpose of making the experience, understanding, and problem-solving capabilities in a particular subject area available to the decision making in this area (Karwowski and Mital, 1986; Klir and Yuan, 1995; Mamdani and Gains, 1987). A fuzzy reasoning approach can be employed to produce design rules that can be used to build a design support system. An overview of the fuzzy based intelligent decision making support system is shown in

Figure 3: An overview of the intelligent system using approximate logic approaches for making design decisions

3. This intelligent system consists of four components: data and information analysis, basic element, calculation, and optimisation & design review.

3.1 Data And Information Analysis

Data and information need to be collected from various sources, for example, previous accidents and incident reports from classification societies, insurance companies and industries etc. As described earlier, it is obvious that an analysis involves uncertainties at the initial design stage of an engineering product. Therefore, both expert and engineering judgements have to be used to describe judgements from human experts with good knowledge of engineering products. The main difference is that the engineering judgement follows a rather unstructured approach without proper documentation and explanation. A well structured and documented process, however, can be obtained by expert judgements. The following is the data and information identification. In this system, safety, cost and reliability are identified as failure probability, failure severity and failure consequence probability. These data and information are then used to produce a knowledge base and a specific domain of code and standards base based on the guidelines and company policy. In the fuzzy reasoning methodology, the knowledge is usually represented by a set of fuzzy production rules, which connect antecedents with consequences, premises with conclusions, or conditions with actions (An et al., 2000b; Boules and Pelaez, 1995; Wang et al., 1996).

3.2 Basic Elements

Basic element is composed of input membership functions, codes and standards (Rule base 1), knowledge base (Rule base 2) and output membership functions

The input membership functions use linguistic variables to describe the failure probability, failure severity and failure consequence probability that are developed based on fuzzy set theory via data collection analysis, expert and engineering judgements. These inputs are then "fuzzified" to determine the membership degrees in each input class (An et al., 2005b). The responses yielded categories that are synonymous with the following levels for each factors (3-5):

Failure probability defines the likelihood of failure of an event. 7 levels of linguistic variables in the failure probability, i.e., "Very low", "Low", "Reasonably Low", "Average", "Reasonably frequent", "Frequent" and "Highly frequent".

Failure severity describes the magnitude of possible consequences. 5 levels of linguistic variables may often use to describes failure severity, i.e., "Negligible", "Marginal", "Moderate", "Critical" and "Catastrophic".

Failure consequence probability defines the probability that the effects will happen given the occurrence of the failure. 7 levels of linguistic variables would be useful for the failure consequence probability, i.e., "Definite", "Highly likely", "Reasonably likely", "Likely", "Reasonably unlikely", "Unlikely" and "Highly unlikely".

For many practical situations, several approaches can be used to gather information and knowledge required in deriving fuzzy rules. Three of the most commonly used techniques are:

- statistical data and information analysis,

- domain human expert experience and engineering knowledge analysis, and

- concept mapping.

These techniques are not mutually exclusive and a combination of them is often the most effective way to create rules for the rule base. The developed fuzzy based intelligent decision making support system has a knowledge base (also called a long-term memory) and a data and information base (also called a short-term memory). The knowledge base contains general knowledge pertaining to problem domain. The knowledge is usually represented by a set of fuzzy production rules, which connect antecedents with consequences, premises with conclusions, or conditions with actions. They most commonly have the form "IF A, THEN B," where A and B are fuzzy sets (Klir and Yuan, 1995). The purpose of the data and information base is to store, for instance, codes and standards, for each specific task of the fuzzy reasoning analysis. The data and information may be obtained through a dialog between the fuzzy reasoning analysis and the user. Typically, such data are parameters of the problem or other relevant facts. Additionally, the knowledge base and data and information base are usually needed to update through interaction with relevant human experts, company's policy and guidelines. The capability allows the system to expand or modify its knowledge base or data and information base through feedback during designing.

Output membership functions are a graphical representation of the safety, cost and reliability expressions (An et al., 2001a; Sii et al., 2001). It is commonly understood that safety, cost and reliability can be expressed by degrees to which it belongs with such linguistic variables, "Poor", "Fair", "Average" and "Good" that are referred to as safety, cost and reliability expressions. To evaluate the degree of safety, cost and reliability in terms of those expressions, it is necessary to characterize them using membership degrees with respect to the same categories used to design the obtained subjective safety, cost and reliability descriptions back to the output expressions.

3.3 Calculation

When a designer inputs the design values of failure probability, failure severity and failure consequence probability, these inputs are evaluated using the linguistic rules and fuzzy reasoning expressions. The results are then evaluated terms of the output expressions. The defuzzification process creates a crisp ranking from the fuzzy conclusion set to express the safety, cost and reliability of the design so that corrective actions and design revisions can be prioritized

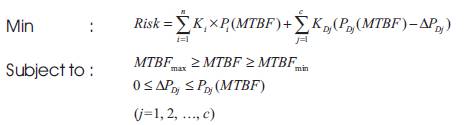

3.4 Optimisation And Design Review

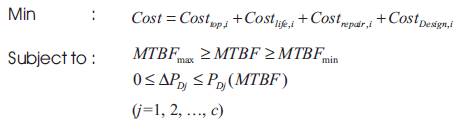

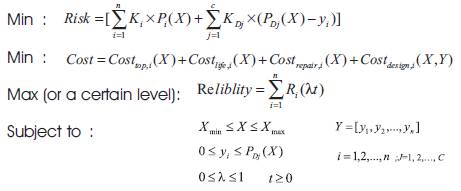

After defuzzification, the information of safety, cost and reliability produced in capculation component are then transferred into optimisation process for decision making. The safety and reliability of an engineering product can be improved by minimising the risks and increasing safety and reliability while reducing cost. The risk function can be expressed in terms of the occurrence probabilities of top events (an engineering product failure event) with each top event being weighted on the basis of the severity of its possible consequences. Suppose MTBF represents Mean Time Between Failure and there are n product failure top events. represents the probability of occurrence of the top event and c cut sets are taken into account for reduction or elimination regarding all the top events. Let represents the original probability of occurrence of the jth cut set before a design review action is taken and represents the probability reduction of occurrence of this cut set as a result of a design review action. and can be obtained by using statistical engineering techniques. Suppose Risk represents such a function. The safety model can be generally represented as follows:

Where is the weighting factor representing the severity of the top events; is the largest MTBF value used in the safety analysis, is smallest MTBF value used in the safety analysis and if the jth cut set is associated with top event.

This safety model implies that the design actions should be implemented efficiently to minimise the risk of the design (An et al., 1999; Wang et al., 1996).

The safety and reliability-related life cycle cost of an engineering product may be modelled by taking into account the top event-caused consequence cost, repair cost, maintenance cost and design review cost. It can be generally represented as follows:

where is cost directly caused by the occurrence of the product failure top event. is maintenance cost which includes cost of labour, cost of parts and lost income during the period of maintenance activities. is repair cost which includes cost of labour, cost of parts and lost income due to repair. is design review cost which includes the cost incurred in the reduction or elimination of c cut set in the design review process.

The first three terms of the cost model deal with the maintenance policies and the last term takes into account both the maintenance policies and design review actions. This model implies that the design should be implemented efficiently to minimise the safety and reliability-related life cycle cost (An et al., 1999; Wang et al., 1996).

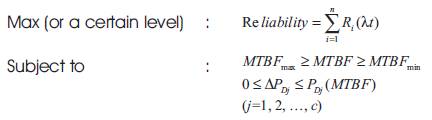

Reliability function can be expressed as when a system is subject only to failure which occur at random intervals, and the expected number of failures is the same for equally long operating period. It can be generally represented as follows:

where is failure rate that is defined as for a stated period in the life of an product, the ratio of the total number of failure to the observed mean time to fail .

A safety-cost-reliability model is proposed which combines the safety model, cost model with reliability model. Let , (j=1, 2, …c) and . Since , and are functions of , and is a function of and , such a safety-cost-reliability model is given by:

where X and Y are design variables which need to be determined to attain the risk, cost and reliability objectives as closely as possible.

The above model implies that the design actions should be implemented efficiently to minimise the potential the risks and maximise reliability and safety of an engineering product design and minimise safety and safety-related life cycle cost. Risk, Cost and Reliability are three competing objectives. The purpose of design synthesis is therefore to evolve compromise design solutions by balancing and effectively utilising resources so that these three objectives can be simultaneously attained as closely as possible. Traditional cost benefit analysis cannot be applied to process the above model which involves multiple design variables and objectives and a set of constraints. However, formal multiple objective decision making techniques can be used to process the safety-cost-reliability model to obtain the efficient designs. This will be demonstrated by an example in Section 4.

4. An Example

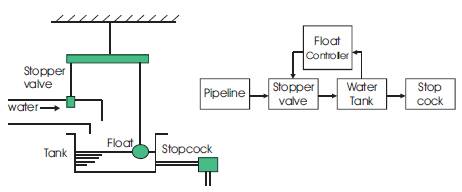

To illustrate the application of the proposed fuzzy based intelligent decision making support system we consider an evaluation of the stopper valve on the water tank leveling system as shown in Figure 4 (Boules and Pelaez, 1995). As is evident from the diagram rising water lifts the float which, through the cord and system of pulleys, causes the stopper valve to shut off the flow of incoming water. The system top events and their possible consequences are identified as follows:

T-E1: Fails close (Tank overfills and water level overflows of the system).

T-E2: Fails open (Water does not turn on and no water in tank of the system).

T-E3: Leaks through valve (Tank eventually overflows and water level overflows of the system).

Figure 4: A water tank leveling system

The probabilities of occurrence of the identified top events are estimated based on Mean Time Between Failure (MTBF). Suppose there are four design options in hand. Those options are:

Design Option 1: Eliminating no failure modes in the design review process.

Design Option 2: Eliminating failure modes "open failure" and "close failure" associated with the stopper valve.

Design Option 3: Eliminating the failure modes involving "leaks through valve" and "tank eventually overflows and water level overflows of the system".

Design Option 4: Eliminating the two failure modes associated with the stopper valve in design options 2 and 3.

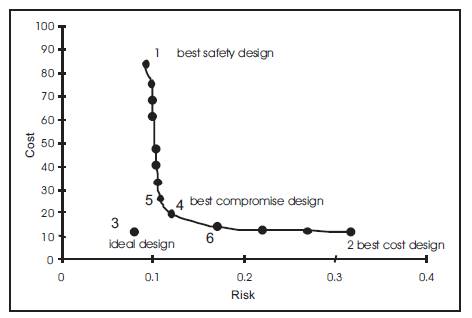

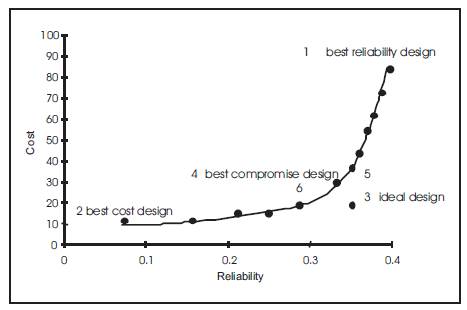

The costs included the top event-caused consequences, repair cost, maintenance cost and design review cost. The developed fuzzy based intelligent decision making support system can take into account safety and cost together with reliability to obtain the utility function associated with each option for ranking the design options in hand, once all preference degrees of all design options in hand are produced, the best option can be chosen. The optimisation results based the decision making system are shown in Figures 5 and 6. The ideal design is located at point 3 where both the cost and risk objectives are simultaneously minimised and reliability is maximised. However, such a design is not feasible, therefore, only compromise designs can be obtained. The best compromise design is located at a point in the frontier, which is nearest to the ideal design point. Therefore, a practical efficient design can be at some point in the section between points 5 and 6, depending on the particular requirements on cost, safety and reliability to be considered. The result in this case, design option 1 is ranked first. The ranking of the four design options is as follows:

It can be noted that the ranking of design options varies with the relative importance of cost factor against safety and reliability factors shown in Figures 5 and 6. For example, when the cost factor is considered to be ten times as important as the safety factor, then the ranking of the four design options is Option 4, Option 3, Option 2 and Option 1. Additionally, as can been seen from Figures 5 and 6, Cost is significantly reduced with slight increase of Risk and a slight decrease of Reliability from point 1 to point 5 in the efficient frontier, and Risk and Reliability are significantly reduced with a slight increase of Cost from point 2 to point 6. These sections should obviously be avoided in the design

Figure 5: Risk against cost

Figure 6: Reliability against cost

From the above analysis, it is obvious that the optimisation results can assist the designer in understanding the problem and making a decision as to what risk reduction measures should be taken.

5. Conclusions

A safety-cost-reliability modeling methodology is proposed in this paper to incorporate safety, cost and reliability into the design process from the initial design stages and to make design decisions. This gives a higher level of confidence that all product top events and the associated cut sets are identified. The developed fuzzy based intelligent decision making support system provides design engineers with a useful tool to make full use of the information produced in safety, cost and reliability analysis and to take into consideration design aspects simultaneously. Great benefit may be received by using the proposed safety-cost reliability modeling methodology at engineering design stages so that design can be made more economically with out increasing risks. The intelligent decision making support system can be used throughout the design process of performing a safety, cost and reliability on an engineering product design and prioritizing the failures for the corrective actions.

From the illustrative example, it is noted that there exist three competing demands of safety, cost and reliability. The decision as to which one is to be stressed may dependent on the particular situation in hand. The proposed fuzzy based intelligent decision making support system can be used to assist designers in understanding the interaction between safety, cost and reliability considerations, so as to balance the best utilizes resources for design of an engineering product.