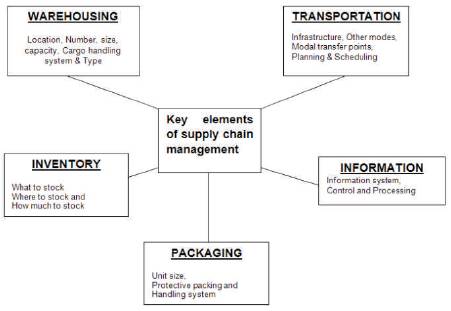

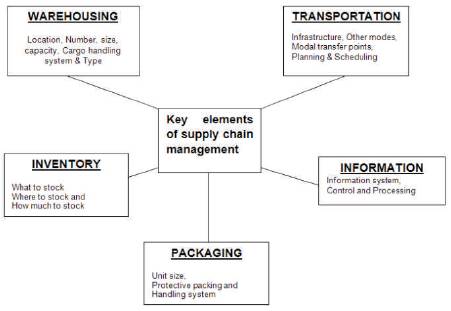

Figure 1. Key elements of Supply chain [6, 7]

Supply chain is an integrated area providing scope for enormous development and improvement in any business network. The paper discusses issues related to supply chain network in the context of Indian Railways (IR). A relationship of the existing supply chain network in India and USA has been attempted in brief. The key issues have been identified, segregated area wise and some potential solutions to these supply chain issues in the Indian context have been attempted and discussed. The methodology adopted in the present analysis was through carrying out an extensive literature survey, including study on the reports published by the Indian Railways and discussion with various stakeholders of the IR freight business. Some feedbacks were taken from the grass root levels through interactions with the railway workers in the ambala zone. The proposed solutions reflect the need to understand the key issues that can eventually lead to an active interest among the researcher community. Its active considerations by the IR can provide some cost cutting and esteemed benefits to its customers and stake holders.

The practice of supply chain management is guided by some basic concepts that have not changed much over the decades. Hundreds of years back, Napoleon remarked, “An army marches on its stomach”. A master strategist and an expert general through such a remark showed that he knows the importance an efficient supply chain system. The term “supply chain management” came in the late 1980's and got into widespread use in the 1990's. Much before this, instead, the terms used were “logistics” and “operations management”. The supply chain has been defined with different terminologies by various researchers (Islam et al., 2012) [1]. Douglas et al.,1998 [2] have said, supply chain brings firms together, which brings products or services to market; while Chopra et al, 2001 [3] have said, it consists of all the stages involved, directly or indirectly, in satisfying customer's request. It includes not only the manufacturer and suppliers, but also warehouses, retailers, transporters, and customers themselves. Ganeshan et al.,1995 [4] have defined supply chain as a network of facilities and distribution options which performs the functions of materials procurement, transformation of these materials into semi-finished and finished products and further distribution of these finished products to respective customers. Mentzer et al., 2001 [5] have termed supply chain as the systemic and strategic coordination of the traditional business functions and skills across the business functions within a particular company and across businesses within the supply chain, with the purposes of improving the long-term performance of the individual companies and the supply chain as a whole.

In simple terms, supply chain is inputs we put in, in-order to influence the behaviour so that we get the required output. It has 5 drivers i.e. Production, inventory, location, transportation and information, which makes it a perfect blend of efficiency and responsiveness. The key elements of supply chain management system are shown in Figure1, which acknowledges all of the traditional logistics and includes activities such as marketing, finance, new product development and customer service. In the wider aspect of supply chain thinking, these additional activities are now seen as an integral part of the work needed to satisfy customer requests. It brings a systems approach to understanding and managing the different activities needed to coordinate the flow of products and services to best serve the final customer. This systems approach provides the basic essential structure, which responds best to business requirements that otherwise would seem to be in contrary with each other. Efficient supply chain management needs continuous improvements in both internal operating efficiencies of the companies and the customer service levels in the supply chain.

Each level of customer has specific sets of requirement. The supply chains that meet different markets require responding effectively to such needs. Some of the supply chains demand for high levels of responsiveness and also pay for it; however, others require them to focus more on efficiency. How well the supply chain serves its market and how profitable it is for the participants in that supply chain is a result of the overall decisions the company makes regarding its each drivers.

Supply chain Management have applications in vast ranges and can be implemented in any type of industries, be it a small enterprise or a big, whether you are producer, supplier or a service provider. Some of the sectors where it has been in widespread use are automotive, manufacturing, garment, logistics etc. Esposito et al., 2009 [8] suggests that the growth of supply chain from the conventional supplying phase to the strategic alliance phase and then finally to the globalisation phase implies that these are no longer exclusively product-oriented activities but have risen to become a service-oriented activity. In building an efficient supply chain, it requires a longer development period but with the rising pressures of competition, it can make the large customer firms follow a short-period strategy based on cost factors, without taking into account the relevant strategic factors such as technological capability, financial robustness, quality etc. This strategy undermines the development of a supply chain and its own long term competitiveness. Supply chain has in particularly have a great impact on logistics business and railways is one of the major aspect of logistics ( Coyle J. et al., 1996[9] ) which cannot be overlooked and Indian railways freight business is the main snippet which can be concentrated to build more efficient and responsive railway. Lumsden et al., 2006 [10] suggests transport network (links in supply chains) and transport infrastructure (nodes in the supply chains) as the important elements in efficient logistic system; hence supply chain has in particularly a great impact on logistics business and railways.

Figure 1. Key elements of Supply chain [6, 7]

Indian Railways (IR) is the state-owned railway company of India having a complete monopoly over the country's rail transport. It has one of the largest and busiest rail networks in the world with over 350 million tonnes of freight turnovers annually. Railways are among safest transportation systems when compared with other means of transport [11]. Railway transportation is capable of high levels of cargo utilization and energy efficiency, but is often less flexible and more capital intensive than of the highway transportation, when lower traffic levels are considered. Freight revenue may be sold per container slot or for a whole train. At times, the shipper owns only the cars or rents the haulage. Indian Railways makes 70% of its revenues and most of its profit from the freight sector and uses these profits as the cross-subsidies for the loss-making passenger sector[12] ; however, competition from trucks which offer cheaper rates has seen decrease in freight traffic in the recent years. The course of the next half decade is obviously unclear, but prospects in railways seem favourable, especially in the view of its relatively low environmental impact.

Indian Railways is plagued by inefficiencies resulting from the lack of infrastructure and equipment, high handling costs, theft and damage. The costs to end users are higher as compared with other countries with equivalent logistics infrastructure. The detailed analysis suggests losses in logistics business in India from inefficiencies amounting to around 45 billion US $ in 2007 [13] and railway is one of its major contributor. Since 1990's, Indian Railways has moved on from small consignments to larger container movement which has helped in increasing efficiency by speeding up its operations. Most of its freight earnings are from such rakes carrying bulk goods such as cement, food, coal, grains and iron ore. The railway management has been providing many services and facilities to the freight customers. On one hand the IR's improve their profits through customer satisfaction and continuing business, while on the other hand; the customers are faced with many problems in their freight traffic. The customers are not satisfied with the services provided by the railways and they are bound to switch over to other modes of transport, hence it is in their deep interest to identify the problems faced and their expectations towards the railways service provider. Indian Railway is very much ambitious to grow to the largest rail network in the world in a decade or so and these ambitious goals of growth cannot be achieved without creating adequate capacity in the IR's network and providing better supply chain solutions.

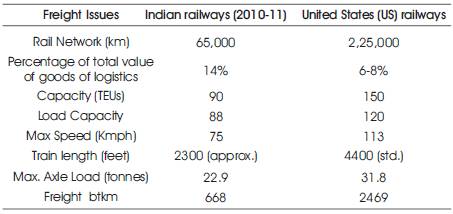

Indian Railways (IR) had lost its market share in high rated freight commodities especially cement, Petroleum Oil and Lubricants (POL), and iron and steel. IR was missing an overall strategy for freight business, which was overcharged without sensitivity to competition. Over time, other transport modes, especially road (and pipeline in case of POL) has captured a very significant share of freight due to their faster and door-to-door deliveries[14]. India's logistic cost is one of the highest in the world. Low rolling stock, less axle capacity, no availability of high speed freight corridor, inadequate warehousing facility near rail terminals which increase handling cost and transportation cost and no web based management system are few of the listed problems which are acting as a constraint in IR's growth and these problem are needed to be solved for the growth of IR as due to these inadequacies railways are losing significant revenues. Some of the key issues are illustrated in Table 1 and are benchmarked with USA.

Table 1. Comparison between Indian Railways and USA Railways [15, 16]

Indian railways are facing the same problem as those faced by many other countries. A loss of monopoly position and with it, need to adapt to a competitive environment. IR has been losing market share to road transport in both passenger and freight services. Unless it improves its commercial orientation, IR's position in freight will further degraded as India upgrades its highway networks. The only unique aspect of Indian Railways is its vast size ( in terms of working force) and its scale of operations.; these make IR's adaptation more difficult, but not less urgent. In comparison, railway in other countries has also been confronted with the similar changing environment, but has begun its process of change to meet the challenges, with measurable initial results. To realize IR's full potential contribution to India's transport system and economic growth, substantial investment will be required to fund capacity expansion, track modernization and safety enhancement. The IR needs to be undertaken in conjunction with pragmatic actions by the government and also needs to address its institutional performance issues. The Government Of India (GOI) needs to signal its strategy for IR. Several of the changes are necessary to allow IR to compete effectively in the transport market and to fulfil the railway's potential, which are outside the direct control of railway management and requires strategic policy direction from GOI. Some of these changes include the phasing out of cross-subsidies between freight and passengers and between the core commercial railway and the network of non-commercial lines and services. Right sizing of the labour force and de-politicization of investments will also require a clear expression of political will by GOI. The GOI has to decide that it desires IR to function as a commercial entity. In particular, the Government, as Owner, needs to:

These developments can strengthen the role of operational railway system as well as in the project based suppliers in railway projects [17].

The key issues relating to the existing problems in the IR and its probable solutions[18-21] are being presented in Table 2.

Freight transport is a key source of revenue for Indian Railways (IR), which makes the major percentage of the total revenue and is growing rapidly. The railways face supply disruptions on an on-going basis; however, there is a limited research in the area of supply chain management especially in the Indian context. The employees of IR and their stake holders have shown keen interest to work with their developmental projects. IR is confident that their test systems will help them in increasing the freight payload capacity. The high payloads and the extensive tests RDSO (Research Design and Standard Organization of ministry of Railways) requirements are quite impressive and show the further movement of railways. The IR has recently provided an electric actuation for tilt control on high-speed trains such as the “Shinkansen” in Japan.

This study describes the problems in Indian railways and the mitigation practices followed by them. The study further suggests remedial measures that could be used by the Indian Railways. The key recommendations from this study reveal the following aspects: