Application Of Statistical Analysis System For Explosives Effects Of Camouflet Deep-Hole Charges

U.F. Nasirov * Sayavur I. Bakhtiyarov **

* Mining Department, Navoi State Mining Institute, Navoi, South Str, Uzbekistan.

** New Mexico Institute of Mining and Technology, 801 Leroy Place, Socorro, USA.

Abstract

In this paper the authors present the results of the experimental study of the radius change of explosive effect and the depths of ground compaction at the blast of camouflet deep-hole charges depending on their mass and depth of their lay, besides their compaction level and types of SAS solution at different levels of flowing ground compaction. Additionally, for the calculation of radius change of explosive effect for camouflet deep-hole charges, they have developed a special engineering technique as well as for the depth of flowing ground compaction while using different types of SAS solution.

Keywords :

- Condensation,

- Dredging,

- Trenched Charge of Burst,

- Camouflet Charge,

- Lateral Chinks

Introduction

Strengthening the economical potential of the Republic of Uzbekistan promotes all possible development of mining-metallurgical manufacture. For achievement of this purpose the main role belongs to explosive works [1].

Development of the open mining works is connected, first of all, with fulfillment of huge quantity of volume of excavation-loading works in various conditions. A wide experience of conducting open-cast mining by using the energy of explosion has shown that the explosive methods are technologically simple and economically profitable [2 – 4]. Accordingly, the special actuality emerges on the elaborating technologies in formation of lengthened excavation for flowing ground by the way of trench charge outburst. For achievement of the purpose it is necessary to solve one of the main tasks – to study of the radius change of explosive effect of camouflet deephole charges and the depths of flowing ground compaction at the use of various types of SAS (surfaceactive substances) solution [5].

At present, different technologies based on the mechanical, physical and chemical, thermal and other influences are being used for surface treatment of rock mass. The explosion method refers to one of the most progressive and intensive trends of ground work. This method has advantageous over others while conducting the process in ground mass with unstable structural connections, where the usage of traditional mechanical means are both difficult and unavailable.

1. Objectives

The objectives of this work is an experimental study of the the radius change of explosive effect and the depth of ground compaction at explosion of camouflet deephole charges depending on their mass and depth of lay, and also compaction level of SAS solution at different levels of flowing ground compaction. Experimental study carried out for growth of the efficiency in the energy use of trench charge outburst show that in the terms of subterranean lay close to surface, the technology of excavation depth was considered to be the least effective. It was caused relatively, by a huge ground flow which flows back initially upwards along the axe of trench. The study proposed that while forming specific excavation of flowing ground by the explosion of trench charge outburst to have been observed their flowing back. The main reason of this process is the destruction of flowing ground under the explosion of energy motion and its transition into the dilution state.

Accordingly, one of the actual problems of impregnation methods in forming depth extraction excavation with precompaction of edge and bottom of the cast is the study of radius of explosive effect of camouflet deep-hole charges and the depth of flowing ground compaction in the process of different SAS usage.

2. Methods and Materials

The study is carried out with the use of complex methods including theoretical and experimental investigating in the laboratory and industry conditions with the use of mathematical and physical modeling on identifying the dimensions of depth extraction excavation of flowing ground by explosive way of trench charge outburst. Additionally, such methods as mathematical programming and statistics, correlation analyze of industrial experiments research with the use of computer technology were involved.

The study was conducted in accordance with the thematic plan on State Grant of Science and Technology Center at the Cabinet of the Ministry of Uzbekistan Republic of applied scientific research No. P 6.2.5 – “Survey and Exploitation of New Methods in Forming Depth Extraction Excavation of Flowing Ground by Exploration of Trench Charge Outburst” and 5-038- “Exploitation of Ground Compaction Technology in Forming Depth Extraction Excavation by the Exploration of Trench Charge Outburst”.

3. Results

The experimental study proposes the change of radius of explosive effect and ground compaction depth while explosive works of borehole charges depending on their mass and depth of deposit, and also their compaction level of flowing ground. The results are given in Figures 1 to 3. As for SAS solutions other emulsifying agents CF-8901, FF/4 and aluminum hydro-oxide were used.

In Figures 1 to 3 there are examples of changes of contour interval depth of camouflet deep-hole charges, according to their mass and ground compaction level while using of different types of SAS solution.

The obtained parabolic relations show that the most compaction effect is achieved at the mass of the charge which closes to the effect of maximal camouflet. At this stage a greater part of energy consumption is directed to the destruction of flowing ground.

According to the experiment of comouflet explosion, the maximal explosion is achieved at the depth of charge is up to 6 meters and mass of camouflet deep-hole charge is up to 6 kg. The least depth of deposit charge causes ground loosen, forming outburst crater which is not acceptable at the compaction of flowing ground. If depth increases the lay of charge of extra maximal camouflet causes the decrease of possibility for ground destruction which results in growing of compressing pressure in soil skeleton under the influence of its mass, in comparison with its effecting load at explosion.

It is studied generalized parabolic law of radius change of explosion effect and the depth of flowing ground compaction depending on charge mass and its deposit depth which supplies maximal comouflet of explosion and compaction effect.

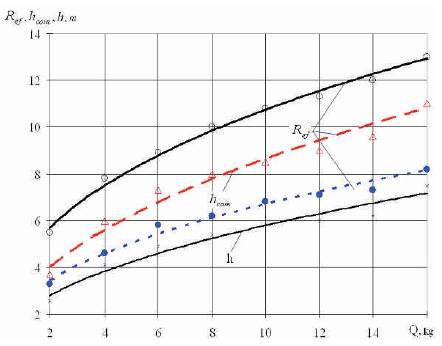

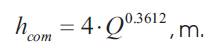

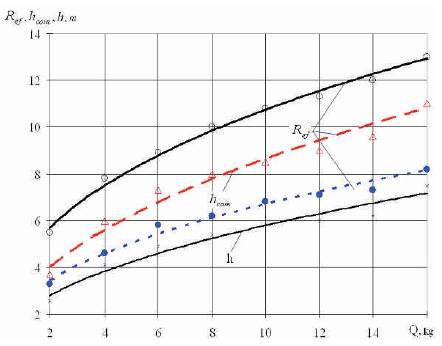

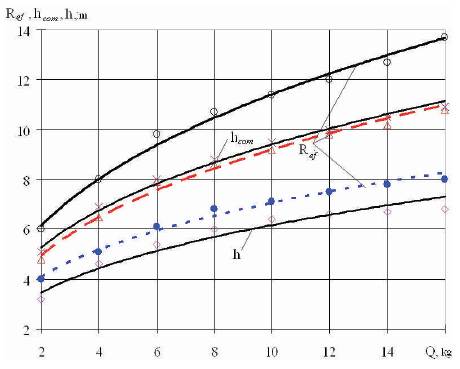

The obtained results, given in Figure 1, shows the more growth of the charge mass from 2 to 16 kg while using aluminum hydro-oxide solution, the more effective radius of explosive effect becomes. Consequently, at the level of compaction from 3.5 to 8.1 m, at the level of compaction of 0-0.2 from 4 to 11 m, at the compaction level of 0.3-0.4.

Figure 1. The radius change of explosive effect for camouflet deephole charges and the depth of flowing ground compaction while using aluminum hydro-oxide: ○ – at the level of ground compaction 0-0.2; Δ – at the level of ground compaction 0.2-0.3; ● – at the level of ground compaction 0.3-0.4.

The study also considered the following: according to mass growing of camouflet deep-hole charge from 2 to 16 kg, the depth of flowing ground compaction changes, consequently from 4 to 11 meters.

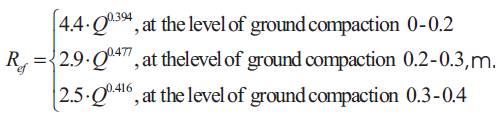

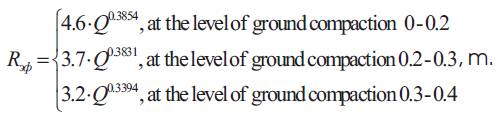

According to statistical analysis of the results, the radius of explosive effect of comouflet borehole charges and the depth of flowing ground compaction under the influence of aluminum hydro-oxide depend on the charge mass and ground compaction level, which characterized relatively, by the following empirical equations:

The correlation coefficient for the given equation is 0.88±0.017.

The correlation coefficient for the given equation is 0.92±0.015.

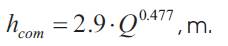

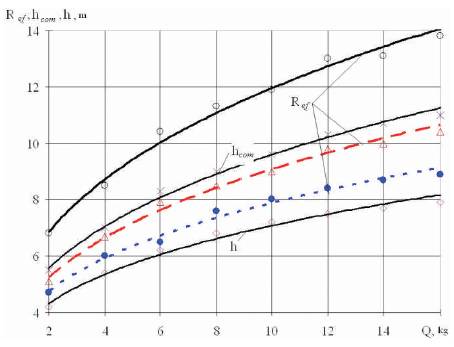

When using FF/4 emulsifying solution the growth of the charge mass from 2 to 16 kg causes the growing of radius of explosive effect from 4 to 8 m at the level of ground compaction 0-0.2; from 4.8 to 10.8 m at the level of ground compaction 0.2-0.3 and from 6 to 13,8 m at the level of ground compaction 0.3-0.4 Figure 2.

Figure 2. The radius change of explosive effect for camouflet deephole charges and the depth of flowing ground compaction while using FF/4 emulsifying solution: ○ – at the level of ground compaction 0-0.2; Δ – at the level of ground compaction 0.2-0.3; ● – at the level of ground compaction 0.3-0.4.

It is estimated, the more is the mass of comouflet deephole charge from 2 to 16 kg the more changeable is the depth of flowing ground compaction, accordingly from 5.1 to 10.9 m.

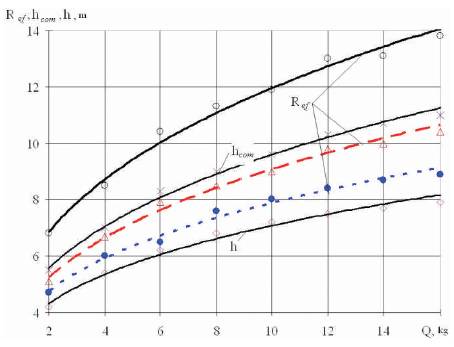

A statistical analysis of the results defines that the radius change of explosive effect for borehole charge camouflet and the depth of flowing ground compaction while using FF/4 emulsifying solution and the ground compaction which is characterized, accordingly by the following empirical equation:

The correlation coefficient for the given equation is 0.90±0.013.

The correlation coefficient for the given equation is 0.89±0.016.

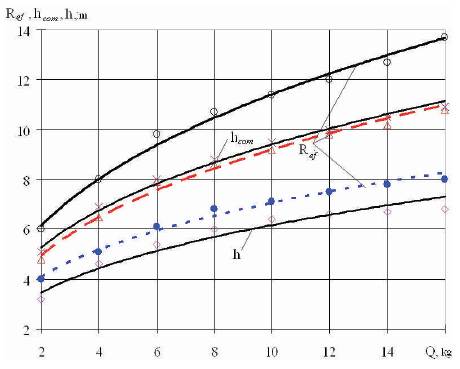

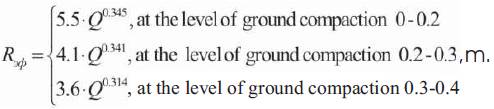

The obtained results in Figure 3 show that the more is the growth of the charge mass from 2 to 16 kg while using CF- 8901 emulsifying solution, the more changeable is the radius of explosive effect, accordingly from 4.8 to 9 m at the level of ground compaction 0.2-0.3 and from 6.8 to 13.9 m at the level of ground compaction 0.3-0.4.

Figure 3. The radius change of explosive effect for camouflet deephole charges and the depth of flowing ground compaction while using CF-8901 emulsifying solution: ○ – at the level of ground compaction 0-0.2; Δ – at the level of ground compaction 0.2-0.3; ● – at the level of ground compaction 0.3-0.4.

According to the mass growth of the borehole charge camouflet from 2 to 16 kg the depth of flowing ground compaction changes from 5.5 to 11 м.

Statistical analyze of the results defines that the radius change of explosive effect for deep-hole charge camouflet and the depth of flowing ground compaction while using CF-8901 emulsifying solution and the ground compaction which is characterized, accordingly by the following empirical equations:

The correlation coefficient for the given equation is 0.86±0.015.

The correlation coefficient for the given equation is 0.88±0.012.

By this way the change of the radius of explosive effect and the depth of ground compaction at the blasting of borehole charges depending on their mass and depth of lay and also at the compaction level and types of SAS solution at the various levels of ground compaction were found out.

4. Discussions

According to the results of experiments in the industrial conditions and to the statistical treatment of the results, which are given in Figures 1 to 3, the method of engineering calculation for change of radius of explosive effect and the depth of ground compaction at explosion of camouflet deep-hole charges depending on their mass and depth of lay, and also compaction level and types of SAS solutions at different flowing ground compaction were worked out.

1. The depth of camouflet deep-hole charges lay with the use of different SAS types is determined by the following formula:

k – coefficient, defining the type of fastening SAS solution: for aluminum hydro-oxide solution k=1.8; for CF-8901 emulsifying solution k=2.1; for FF/4 emulsifying solution k=2.9.

2. The depth of flowing ground compaction at the blast of camouflet deep-hole charges with the use of different types of SAS solution is defined by the following formula:

For aluminum hydro-oxide k=3.5; for CF-8901 emulsifying solution k=4.4; for FF/4 emulsifying solution k=3.8.

3. The radius of explosive effect of camouflet deep-hole charges while using different types of SAS solution is determined by the following formula:

k1 – is a coefficient, defining the compaction level of exploring ground. Using aluminum for fine grain with compaction level 0-0.2 k1 =4.5; for fine grain ground with compaction level 0.2-0.3 k1 =3.2; for middle grain ground with compaction level 0.3-0.4 k1 =2.5. Using CF 8901 emulsifying solution: for fine grain ground with compaction level 0-0.2 k1 =4.1; for fine grain ground with compaction level 0.2-0.3 k1 =2.9; for middle grain ground with compaction level 0.3-0.4 k1 =2.3. Using FF/4 emulsifying solution: for fine grain ground with compaction level 0-0.2 k1 =5.1; for fine grain ground with compaction level 0.2-0.3 k1 =3.4; for middle grain ground with compaction level 0.3-0.4 k1 =3.1.

Conclusions

The study surveyed the radius change of explosive effect and the depth of ground compaction at explosion of camouflet deep-hole charges depending on their mass and depth of lay, and also compaction level of SAS solution at different levels of flowing ground compaction. The obtained parabolic dependence directs to the following: the most effect of compaction is achieved at the mass of the charge, which is close to the effect of maximal camouflet, besides the most part of its energy is consumed to the destruction of the flowing ground.

Moreover, the method of engineering calculation on radius of explosive effect for camouflet borehole charges and the depth of ground compaction taking into account the usage of different types of solution were worked out. On the base of this method a Borland Delphi 7.0 computer program was developed. The novelty of this program is defended by the patent of the Republic of Uzbekistan.

References

[1]. Hall, C. E. (1962). “Compacting a Dam Foundation Blasting”, Journal of the Soil Mechanics and Foundation Division, 88(3), pp. 79-100.

[2]. Prugh, B. I. (1963). “Densification of Soils by Explosive Vibrations”, Proc. of the ASCE, 89(1), pp. 79-100.

[3]. Ivanov, P. L. (1983). “Compaction of Grounds with Explosion Operation”, Moscow, “Nedra”.

[4]. Vovk, A. A., Kravetz, V. G., & Luchko, I. A. (1981). “Geodynamics of Explosion Operations”, Kiev, “Naukova Dumka”.

[5]. Kravetz, V. G. (1979). “Dynamics of Ground Compaction with Explosion Operations”, Kiev, “Naukova Dumka”.