Table 1. VR-based Interaction Mechanisms, Advantages, and Disadvantages

Conventional Computer-Aided Design (CCAD) systems assist the creation, modification, analysis, and optimization of a detailed design. Designer requires extensive geometric modeling and engineering analysis to enhance designer productivity, quality of design, design documentation, and to create manufacturing database. However, these highly precise and sophisticated software tools cannot help in conceptual design phase because the artistic activities involved during the detailed design phase are less formulaic during conceptual designing. In the initial phase of product design, the specifications cannot be thoroughly recognized and recommended. The designer needs to modify product specifications to study the product behavior regarding different design attributes like shape, strength, surface roughness, ergonomics, and many other aspects. Hence, the industrial designers continue to explore new tools, which can provide the designer more freedom to modify product design artistically and technically. Virtual Reality (VR) and haptics technology provide the opportunity to collaborate the artistic phase of design with the conceptual design phase. The visualization of the model with material properties will be easy to interpret. The collision detection can automatically report the geometric contact when it occurs or about to occur. The physics-based modeling will help to measure the deformation during the collision. In the present paper, the authors have presented effective and efficient tools for the conceptual design in virtual reality environment.

For efficient and effective product designing, CCAD plays a valuable role. However, the use of CCAD is mainly restricted to embodiment design and detailed design phase. CCAD system is not much appropriate to support conceptual design activities because the activities associated with developing such modules are less formulaic in the available software. For the productive designing of the system, one should require a natural way of human-computer interaction tool that can help in the conceptual design phase. To interact with the CCAD systems mostly the designers are still using twodimensional monitor screens, mouse, keyboard, and joystick. The use of these computer input devices provides a constraint on the designer during the three-dimensional modeling for visualization. The performance of designer would be better when there was an exact dimensional homogeneity between the input devices used and the task performed by the user (Zhai & Milgram, 1998). Modern designers use interfaces involving both twodimensional and three-dimensional interactions. Hence, the contemporary computers should have a perfect data input devices for two-dimensional and three-dimensional input capabilities. The designers who lack in threedimensional geometrical modeling try to proficient themselves in CCAD systems; often conduct conceptual design. Frequently the use of such techniques makes the designer arduous to communicate conceptions with the others and consequently lengthens the conceptual design phase. For the support of conceptual designing, human-computer interfaces for the CAD system is evidently created and deployed. Also, the use of CAD in conceptual design phase should authorize the designers to concentrate on the original conceptual aspects rather than applying themselves the interaction constraints. Virtual reality environment and haptics provide new and better mode of human-computer interaction to overcome communication drawbacks. Virtual reality and haptic technology also prevail over in CCAD systems to support the concept generation and evaluation. Once the virtual object is created, the user gets real-time visual and forces feedback while interacting with the virtual model. For the visualization of tool and model, haptic rendering system is used. Haptics allows the user to benefit in the natural way of working with the model, without the constraints imposed by commercially available CAD/CAM software. The collision detection system informs regarding the collision between the tool and the model and the tool penetration. This collision detection algorithm provides the information to the physics-based system. The physics-based system uses this information to measure the deformation of the model, and reactive forces fed back to the user. This paper elaborates the various effective tools and techniques for conceptual designing. The focus of this article is in virtual reality, haptics technology, collision detection, and deformation modeling. Colliding all these technologies can extend the work to effective conceptual product designing naturally and intuitively. The paper is structured subsequently. Section 1 of this article describes virtual reality, virtual reality bottlenecks, and its application in CAD. Section 2 describes the haptics technology to interact with the virtual objects. Section 3 covers the various virtual reality-based conceptual design components like haptic rendering system, collision detection system; physics-based modeling, and scope and significance. Finally, conceptual design using virtual reality is explained in Section 4 and conclusions are enlisted in the last section.

Virtual reality is a computer-generated environment with some computer software package and assigned the user just to accept it as an authentic environment suggested by different authors ( Flanagan & Earnshaw, 1997; Holloway & Lastra, 1995; Magnenat-thalmann & Egges, 2006). Authors showed that the virtual reality technology is characterized owing to its real-time illustration of 3D real space known as virtual area and virtual world generation that reacts to the action of the user. The virtual reality is a technology that is commonly considered a natural extension to three dimensional computer graphics with advanced input-output devices (Pan & Marchese, 2004). Three different types of VR systems named Desktop VR, Video Mapping VR, and Immersive VR are in existence. However, Immersive VR is most typical in use. The basis of VR technology emerges within the 1960's in simulators that help in training to fly planes, drive tanks, and other applications ( Gobbetti & Scateni, 1998). VR has the potential for use in several fields like entertainment, medication, biotechnology, engineering, design, and marketing. Virtual reality pioneers Ivan Sutherland, Myron Krueger, and Archangel Noll gave an appreciated contribution to the creation of 'Modern-Day' virtual reality. Therefore, virtual reality thought can be applied to a broad variety of technologies, but as per literature owing to the ambiguous nature, not accepted by researcher community ( del Rio, Bartz, Jager, Gurvit, & Freudenstein, 2003; Koschan, 1993). Kunz and Spagno gave a definition that was broadly welcomed and recommended by Sutherland in his famed 'Ultimate Display' (Kunz & Spagno, 2002). By using ultimate display, the user cannot judge that the imaginary world, which the designer is using, is not real. It is crucial for an individual to manage the knowledge perceived by senses for participating in an artificial world. The idea was to create a portable virtually created world using two small television sets; each one contributed for each eye. A Head-Mounted Display (HMD) was designed for realization. Although this invention worked and created a sort of a virtual world, the images were fundamental and rough. Virtual reality is an environment that gives the user a sense of reality through the immersive environment.

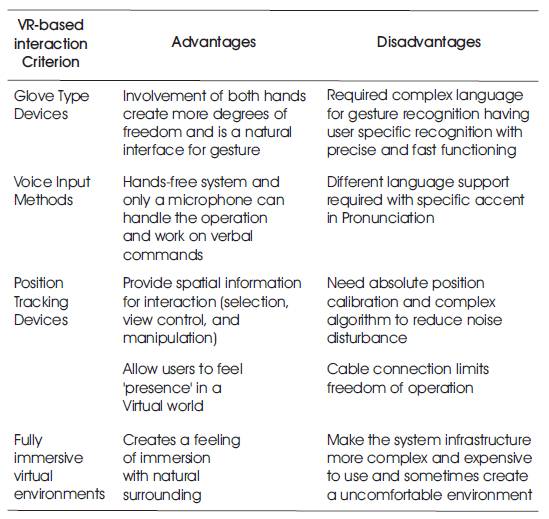

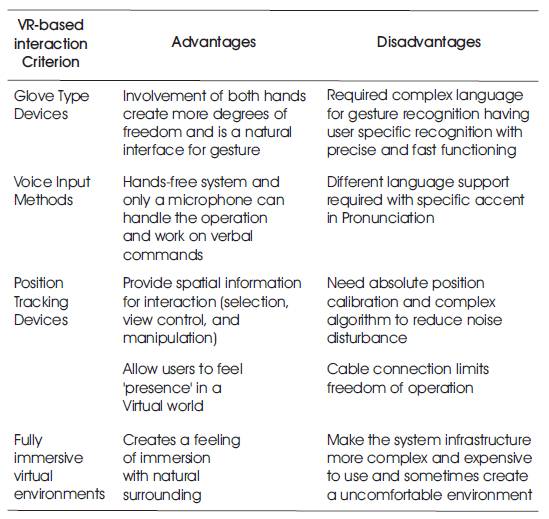

VR technology supports the virtual prototype implementation. Virtual reality technology supports the implementation of effective virtual prototypes by which the user can touch, sense, move, manipulate, and operate the virtual prototypes of products with the best degree of realism. For such interaction with virtual prototypes, it must be multi-sensory, multimodal, and often based on the combination of haptic, visual, and auditory modalities. Goodson was the first person who introduced the virtual reality in CAD. Virtual reality gives the user a sensation of a presence in the simulated environment. The presence sense gives the user a fantasy of being physically present in a virtual environment and interaction with a chance to modify it. Schuemie et al., generalized two different technological factors that distinguish virtual reality in CAD/CAM as presence and interaction in the visual interface (Schuemie, van der Straaten, Krijn, & van der Mast, 2001). Most of the CAD systems are feature-based and constraint-based. Feature-based design means that product is firstly designed using simple extrusion or revolution and then modified by adding features. For the feature-based system, the immersive interface of the virtual reality offers three significant benefits over the traditional twodimensional interfaces. Working with immersive interface simplifies the design process, implicitly enforces the accessibility of feature constraints and help process planner for feature sequencing (Trika, Banerjeet, & Kashyap, 1997). Various studies distinguished between immersion and presence; even both are connected. Using immersion, the sensation of reality in a virtual environment can be judged ( Capin, Noser, Thalmann, Pandzic, & Thalmann, 1997). If a user has not the ability to differentiate between the real and virtual then the one that is generated by the computer, is immersion. These factors should be refined in such a manner for each design such that the designer can feel more comfort ability with the virtual reality system. As virtual environments are becoming user-friendly, the designer will be able to interact more comfortably. Consequently, the user present in a virtual environment perform activities and interact using hardware devices. Mine worked on the ways of interacting with a virtual environment (M.R. Mine, 1995). Author categorized the interactions as physical control, virtual control and direct user interface control. Some of the VR based interaction mechanisms with their advantages and disadvantages are shown in Table 1.

Table 1. VR-based Interaction Mechanisms, Advantages, and Disadvantages

Using these tabulated interaction tools, VR technology provides a real-time interaction with the virtual world. VR can enhance the creativity and productivity of the designer. Hence, VR environment is especially suitable for the designing the shape of freeform objects, but some bottlenecks of the VR are kept in consideration during its applications in design.

However, VR technology is growing very fast in every field of technology; still, it has some bottlenecks in its implementations. The very first bottleneck in VR is the quality of the graphics. For complex models, the real-time rendering is not much satisfactory during simulation. The implementation of collision detection algorithm in VR is the second bottleneck due to its limited applications. For rigid bodies, various algorithms are available, but these algorithms cannot be applied to deformable objects due to the complex behavior of deformable objects during real-time interactions. To simulate the exact behavior of the real model, some physical properties should be assigned to the virtual model. The assigning of physical characteristics to the virtual object is the third bottleneck.

Currently, one of the biggest factors for limited immersion of virtual reality is the low resolution of Head Mounted Displays (HMD). The low resolution of the HMD can irritate, induce nausea for some user, makes hard to read the small text, and, therefore, limit certain applications of VR. However, the low resolution has to fix because the increase in the resolution means the high burden on the CPU (Central Processing Unit) and GPU (Graphical Processing Unit), which can cause performance loss. Because a high FPS (Frame per second) is necessary for an immersive experience and one cannot sacrifice performance for a higher resolution. Other bottlenecks are a low performance for complex models, lack of realism, the poor behavior of complex surfaces, and in existent link to the related database. Hence, the difficulties mentioned above are due to the diversity of CAD and VR models. The CAD model generation demands high details for the execution process and does not consider the real-time visualization effects. When virtual reality established in the design, then it is necessary to verify its applications in manufacturing. The integration of VR with available CAD/CAM system can assure a very effective and efficient way to exploit designer creativity.

Initially, the product models were created in existing CAD systems and suitably translated into VR environment as in Virtual Design II (Astheimer, Dai, Felger, Göbel, & Haase, 1995) and ISAAC (M. R. Mine, 1997). These systems are only used for the visualization and analysis of CAD objects in three-dimensional virtual reality environment. The Conceptual VIRtual Design System (COVIRDS) developed by Dani and Gadh overwhelmed the limitations of conventional CAD systems by providing VR-based CAD modeling environment. The system allowed the rapid shape creation in three dimensions using a bi-modal voice and gesture-based interface ( Dani & Gadh, 1997). COVIRDS provides parametric and free-form design modes. The two-dimensional input devices (Mouse/ Keyboard) are replaced with voice recognition and three dimensional interaction systems. However, this system has some limitations like recognition capability and complex commands.

Different techniques are available for real-time interaction with the virtual objects. However, for design applications, every VR based interaction technique has some benefits and limitations. To create a realistic environment, fully immersive design system is used, but it makes the system some cumbersome regarding visualization and computationally expensive. There are many research groups ( Dani & Gadh, 1997; DiGironimo, Lanzotti, & Vanacore, 2006; Harish Pungotra, 2012; Ye, Campbell, Page, & Badni, 2006) using virtual reality for conceptual design. When the object is created in VR environment then there is a need for visualization and interaction with the virtually created object. In the next section, haptics technology is explained which can help in interfacing between real and virtual.

The word “haptics” originated from Greek 'haptikos' means the ability to grasp or perceive. Haptics is a sensation to touch. Haptics technology allows the user to interface between real and virtual environment using the haptic device. The user feels the sense of touch through the application of force, vibrations, motion, and resistance via a haptic device. Haptics has applications in the field of medical science (training for laparoscopic surgery), games, art, shape design, and user training. Haptic interfaces are the positioning devices like joysticks that can provide force feedback. The haptic device can be used to feel the physical objects. The haptic system came into existence in teleoperation (Sheridan, 1997) and further developed regarding design and control ( Burdea, 1999). With the advancement in computing, haptics devices became popular in the field of virtual reality (Massie & Salisbury, 1994). The haptic system ties the virtual model with the haptic device so the user can have the sense to feel or touch the virtual model. Burdea showed that haptics allows the users to feel the sensation of touch and physical properties while interacting with the virtual objects in the virtual environment ( Burdea, 1999). Virtual objects exert a force in reaction to user's haptic action. Haptic devices can be categorized as force feedback devices and tactile devices. Srinivasan and Basdogan gave a detailed review of the haptic literature.

From last many years, it has been seen a significant increase in force feedback systems; an overview of stateof- the-art haptic devices, recent advancements of haptics and its applications are shown by various authors (Bordegoni & Cugini, 2005; Laycock & Day, 2003; Srinivasan & Basdogan, 1997). The authors considered some dimensional and nondimensional haptic performance indicators. The indicators are working space, positioning resolution, stiffness, nominal forces, and tip inertia ( Hayward, Astley, Cruz-Hernandez, Grant, & Robles-De-La-Torre, 2004). PHANTOM is the first commercial haptic product and still the most popular tool provided by SensAble Technologies. Many point-based haptic devices are having a degree of freedom from 3 to 6. The working space and the maximum feedback force is somewhat limited. For realistic force feedback, Massie and Salisbury showed that the force signal must be updated at least at a rate of 1000 Hz or more to reduce haptic sensation deterioration. In the virtual haptic system, the force computation derived from the solid modeling system must be less than 1ms. There are mainly two tasks in the haptic interface: collision detection and extent of collision computation. The collision detection is used to determine the force feedback using some physics-based modeling like the spring-mass system, Finite Element Method (FEM), and Finite Difference Method (FDM). Computing extent of collision is a complicated and timeconsuming task to meet the 1ms time limit. Most of the haptic devices can model a shape like a point and a curve. Full three-dimensional interference detection is yet under search (Massie & Salisbury, 1994). Various studies (Sener, Wormald, & Campbell, 2002; Ye, 2005) suggested that a haptics-based interactive design system is well suited to exploit the creativity of an industrial designer or engineer. It would make it possible to modify the product design artistically and quickly to evaluate different concepts.

University of Tsukuba and Immersion Corporation developed some comparable devices like Haptic Master device actuating three fingers. These class of devices includes exoskeletons, like Sarcos Dextrous ArmMaster, PERCRO device, and actuated gloves. Such devices are complex, difficult to wear and operate, less practical and rarely used in industrial applications. Iwata et al., gave an impressive technology for intellectual prototypes based haptic windows and tactile devices (Iwata, Yano, Nakaizumi, & Kawamura, 2001). There are some critical issues for the addition of a haptic interface in the CAD models designing. Virtual Design Works adopted the world's first COM-based haptic model that proves significant benefits as compared to the traditional haptic models. Using haptic devices, Virtual Design Works allows the designer to touch directly, sense and deform a B-Rep CAD model by push/pull/drag the surfaces in a natural three-dimensional computer-generated virtual space. Force feedback provides the designer a great flexibility and haptics gives a perspective to become a critical interface for design applications (Liu, Dodds, McCartney, & Hinds, 2005).

Bloomenthal and Shoemaker proposed the implicit geometry techniques for clay like objects (Bloomenthal, 1997). Pungotra et al., used B-spline surfaces for modeling of free-form objects in VR environment for the exchange of data with existing CAD software (Harish Pungotra, Knopf, & Canas, 2009). When the model is created in the VR environment, virtual sculpting is done. Virtual sculpting is used for dynamically manipulating the virtual objects for generating different shapes. The three-dimensional input device controls a sculpting tool, and voxel data represent the material. Various researchers are in continuous search of tools and techniques for improving the computation efficiency. Multiresolution technique is proposed by Gao and Gibson ( Gao & Gibson, 2006) for haptic interaction to minimize the computational cost, but feedback to the designer in the form of haptic force is not realistic. For the VR based conceptual designing, required components are explained in the next section.

For VR based conceptual design module, three components, viz., haptic rendering, collision detection, and physics-based system are used. The haptic rendering system is used to visualize the virtual model and the tool. The collision detection system helps in providing the information regarding the tool and model contact including penetration depth. The physics-based system uses the feedback given by collision detection algorithm to measure model deformation, and reactive forces are fed back to the designer.

The haptic rendering system is preferred for the visualization of the virtual model and the tool. The system includes graphics animation and haptic feedback. Using haptic rendering, the user/designer can feel and manipulate a virtual object with the haptic device. Hence, the haptic rendering sub-system is used for creative design regarding tactile and visual interaction to interact with virtual objects and tools. The haptic rendering system is used to produce forces when the system is attached to a user's hand/arm to create a contacting sense between virtual model and tool. Direct parametric tracing provisions haptic rendering of NURBS (Non-uniform Rational Basis Spline) surfaces and allow the fast-tracking on the sculptured surface. The rendering of the parametric surface had compact representation and used for rendering complex models, thus improves the quality of tracking (Thompson, Johnson, & Cohen, 1997). Some haptic rendering algorithm for interaction between surgical instruments with soft tissues is developed in the laparoscopic surgery simulation. The techniques are helpful in simulating some procedures like touch and feel the soft tissues and simulate the behavior of elastically deformable objects in virtual environments ( C. Bosdogan, C. Ho, & Dawson, 1998). The reliability of haptic rendering depends expressively on the contact space modeling. However, contact space modeling does not allow a realistic rendering in physical phenomena like a slip and sticks effects. Duriez et al., used contact law and Coulomb's friction law as a computer haptics basis for the real-time performance with linearization behavior in the contact space ( Duriez, Dubois, Kheddar, & Andriot, 2006). Galoppo et al., proposed an efficient haptic rendering algorithm for deformable bodies with highly detailed surface geometry using a fast contact-handling algorithm ( Galoppo, Tekin, Otaduy, Gross, & Lin 2007).

Collision detection is one of the significant bottlenecks of real-time virtual reality applications from last thirty years. To enhance the computational power of collision detection algorithms, researchers focus on the development of new and friendly hardware architecture. Recent studies came into sight for speeding up the collision detection like the use of multi-cores and graphical processing unit (Hermann, Raffin, & Faure, 2009; Kim, Heo, & Yoon, 2009; Tang, Manocha, & Tong, 2009). Collision detection algorithms are dependent on the formulation of geometric model like polygonal, Constructive Solid Geometry (CSG), implicit or parametric functions. All of these problems expose the range of this field of study (Jiménez, Thomas, & Torras, 2001; Kockara, Halic, Iqbal, Bayrak, & Rowe, 2007; Teschner et al., 2005). Collision detection enables simulation-based interactive designing, animations, engineering analysis, assembly, motion planning, and medical training. However, collision detection is considered a significant major computational bottleneck in these applications. Various authors proposed different collision detection algorithms. JimEnez (Jiménez et al., 2001), concentrated on the model representation that leads to different collision detection algorithms. Collision detection system is significantly affected by many factors like representation of objects, the number of objects, and collision type. However, polygonal representation and polygonal soup are most generic due to the unordered collection of polygons without any connectivity information. Such description helps in checking the interior of an object. The information can be useful for testing the edge and vertices connectivity and check whether the object is convex, concave or closed solid. Polygonal representation of objects may be implicit (sphere, cone, cylinder, and ellipsoids) or explicit (vertices, edges, and faces). However implicit objects’ collision detection is easy, quick and economical as they are represented using a mathematical equation. Hence, this work leads to culling operation. The kind of collision includes three conditions intersecting, touching, and not colliding. In the case of an intersecting object, one may need to find the value of penetration depth whereas in the case of touching contact point's calculation is a problem. Penetration depth in two intersecting objects is the minimum perpendicular distance required to bring the intersecting objects in touching contact condition. When 'n' objects are colliding, there is a need to perform the collision between all objects. The time complexity and cost of collision test also increases even for a small value 2 of 'n' as O(n ) pairwise test is required. The collision handling should be divided into broad phase and narrow phase to economize the collision tests. Surveys (Kockara et al., 2007; Teschner et al., 2005) help the reader to study the topic more deeply. Hubbard (Hubbard, 1993) also suggested the collision detection in two phases as the broad phase and the narrow phase. Narrow phase composed of pairwise collision test within a particular subgroup. However, broad phase collision test can work on narrowphase, reduces the work by using divide, and conquer rule. Collision detection based on triangletriangle intersection test was used for the best of the parametric representation of the surface (Harish Pungotra, Knopf, & Canas, 2008). Authors proposed an algorithm for triangle-triangle intersection test that uses the parametric representation of the surface.

Physics-based deformation modeling techniques offer more opportunities to use different material properties during the interactive design phase and authenticate product models to the designer in real-time applications. Study of deformable objects is of great importance in computer graphics ( Cotin et al., 1996; Lin, Baxter, Foskey, Otaduy, & Scheib, 2002; Nedel & Thalmann, 1998). The principal physics-based methods used are amass-spring method, finite element method, and continuum method. In finite element method, the calculations are extremely slow and do not make the system very likable in real-time applications. FEM system requires a significant preprocessing time for numerically integrating distributed forces over the entire volume at each time step. Finite element methods are often considered less efficient than spring-mass models. However, FEM is a common and accurate approach to solve continuum-mechanical boundary-value problems (Zienkiewicz, Taylor, & Zhu, 2013). FEM provides more physically realistic simulation than a mass-spring system with fewer nodes. The object deformation system is a function of the forces acting on the model and its material properties. Mass-spring systems are simple to use. In the physically based massspring- damper models, the elastic model is prepared by adding mass at each mesh node, and these nodes are connected through springs. During the real-time interaction, spring and damper provide a reasonable accuracy and deformation speed. Pungotra et al. represented B-spline surface using blending matrices, integrated collision detection and mass-spring system for the merging B-spline surfaces (H. Pungotra, Knopf, & Canas, 2010).

Physics-based deformation system can simulate the deformation of any product regarding reasonable accuracy and real-time interaction. Knopf and Sangole investigated Self-Organization Feature Map (SOFM) and extended its use for geometric parameterization (G.K. Knopf, Sangole, & Igwe, 2003), surface fitting (G. K. Knopf & Sangole, 2004) and visual exploration of numerical data (G. Knopf & Pungotra, 2007). The extended version of Self-Organization Feature Map (SOFM) is Volumetric Self- Organization Feature Map (VSOFM) (Igwe, Knopf, & Canas, 2008), which is a practical skeletal framework for modeling realistic objects that change their shape with time dynamically. The deformable VSOFM provides a flexible mesh for the representation of a virtual lump of clay that changes shape dynamically under the influence of external forces. The lattice structure confirms a closed geometry without any gaps or breaks in the surface. This technique is used to generate a hexahedral mass-spring mesh for the physics-based modeling. The hexahedral mesh of the object is constructed using deformable VSOFM with a three-dimensional lattice of uniformly distributed nodes or weight points. The point cloud generated on the B-spline surface encloses a three dimensional lattice of deformable VSOFM. The VSOFM have required number of nodes represented as masses, and these nodes are connected through springs and dampers. The lattice is then allowed to expand, and the three dimensional VSOFM maintains its connectivity between the neighboring nodes in the mesh as the mesh gets geometrically deformed into the B-spline surface model. These surface nodes are in interconnection with the neighboring surface nodes as well as the interior nodes that are directly below. Connectivity and topology of the developed mesh are registered to prevent unstable dynamic behavior during modeling. Hence, the points generated on the B-spline surface are assigned as exterior nodes of the mass-spring-damper mesh representation. The number of nodes in the 3D lattice limits the density of the hexahedral element in the final physics-based deformable model. The collision detection algorithm determines the region of tool and model interaction and the information is fed to map the haptic forces.

For the conceptual product design, the designers continue to explore new tools and techniques that can provide freedom to modify product design artistically as well as technically. The virtual reality environment provides the designer a facility to create and amend the complex CAD models during concept generation and hence economise the cost of the conceptual design phase. Haptics allows the users to experience the sensation of touch and feels the physical properties while interaction and helps in combining physical aspects of product design and development. Various collision detection algorithms are available for geometrical contact when it occurs or likely to occur. Different techniques are reported in the paper to find deformation of a virtual object. These include FEM, FDM, Continuum method, and mass-springdamper system for physics-based deformation. However, the mass-spring-damper technique can be used with reasonable accuracy and speed. Hence, the combination of virtual reality, haptic technology, collision detection, and physics-based deformation is significant for effective conceptual product designing. The combination of above-said tools will help the designer to modify product design naturally and intuitively.

During the concept generation phase, a rough conception of background research, from precedent design is extended into several alternative solutions. Alternative design solutions of physical product prototype designs may require major investment and can lead to paramount financial implicative insinuations. The prototype created may or may not have the event of the explanation not meeting design requisites or designations. However, these risks can be eliminated to some extent by developing and testing incipient solutions at the conceptual designing stage of product design. The conceptual product ideas can be evaluated easily depending upon the design considerations and customer requirements. As per today's quality plan, an industrial designer first considers the requisites of the customer. The conceptual designing process commences by defining the user groups and final product concept. As per the user and product concept, the designer sets out a hypothetical user activity and commence engendering more comprehensive solutions for the products to fortify this activity. This process involves a description of the rudimental functions, design designation requisites, functional requisites, ergonomic shape features, constraints, and other paramount technical attributes. The conceptual design process requires ingeniousness and liberation to innovate and explore alternative solutions (Morris, 2009).

Evaluation of product concept solutions is the most critical step in the concept development. The main goal of product concept evaluation is to decide whether to start the concept utilization, iterate the concept further, or concept discontinuation. A paramount goal is to identify the acceptance of early product concepts among the intended target user group. Another goal is the evaluation of the design from a human factors perspective. The user evaluation is predicted by feedback given by user according to the concept of user-centered design and used for iteratively refining of the designs. The modeling techniques developed should be such that which helps the industrial designer to sculpt and validate the conceptual product design in the VR environment authentically. A group of users who are the fair representatives of the proposed user's segment may evaluate the concept in VR environment. Different sets of users may guide further design modifications. These various sets of the user may be predicted according to culture, geography, medical conditions or age group. All these amendments will deal with a variety of needs that can be consummated utilizing innovative, but merely implemented changes to the surviving generic model.

The various tools and techniques for conceptual design are introduced in this article. The product designer requires conceptual designing and graphical visualization tools and techniques that can be helpful in shape modification, style, and functionality of conceptual design of the product.

Virtual reality technology plays a major role in creative and artistic conceptual product designing. VR technology gives the designer an ability for creation and manipulation the complex shaped CAD models during concept generation. For detailed specifications of product design, several concepts are evaluated. In some cases, prototypes are required to be built for conceptualization and initial validation, which adds up time and cost of conceptual design.

Haptic technology provides an innovative approach for combining physical aspects of product design and development. During the interaction, the haptics allows the users to experience the touch sensation and feel the physical properties while interacting with the virtual objects.

Product designer needs conceptual design and perfect graphical visualization tools that can modify the product shape, structure and product functioning as per the customer demand. Hence, for the conceptual designing, a fast, reliable and accurate visualization tool is required to the product designer.

Many techniques to find deformation of a virtual object have been reported these include FEM, FDM, Continuum method, and mass-spring method. However, mass-spring damper technique can be used with reasonable accuracy and speed.

During Product designing, several methods have been developed to fulfill the product requirements and for supporting design activities. Computer Aided Design (CAD) systems support the precise and detailed specifications of the geometry of the product. However, before finalizing the detailed and accurate specification of the product, several conceptual ideas are developed. These concepts must be tested using virtual reality, haptics, collision detection, and deformation modeling.

The authors would like to express sincere thanks to IKG Punjab Technical University, Kapurthala and Beant College of Engineering and Technology, Gurdaspur for supporting this research work.