Table 1. Mass Fraction of FAME of different biodiesel Fuels

Biodiesel is a name applied to fuels produced by the transesterification of vegetable oils. Biodiesel fuels are generally classified as Fatty Acid Methyl Esters (FAME). As the use of biodiesel becomes more widespread, the researchers have shown a strong interest in modeling the engine combustion processes to understand the basic characteristics of the combustion of biodiesel. Density and surface tension of a fuel are the main contributing factors for the combustion process in a diesel engine. The objective of the present work is to theoretically predict the surface tension of different biodiesel from their density using a regression model. The density and surface tension of different biodiesels were taken from the available published data. A linear regression model was developed to predict the surface tension of different biodiesels and compared with the reported data. The predicted results showed that the error was less than 2 % compared to available published data.

Carbon dioxide (CO2) emissions have risen over the last two decades, reaching an atmospheric content of 360 ppm, estimating the world CO2 emissions at about 26 billion metric ton per year, 80 percent of which comes from the combustion of fossil combustibles such as coal, petroleum and natural gas [9]. Research on alternative fuels is being extensively carried out [6,8]. Vegetable oil based biodiesel fuels have been shown to be an emerging alternative to conventional diesel fuel. Since they are renewable, and reduce net production of CO2, biodiesel has gained a considerable attention in the past few years. Organic seed oils such as soybean, sunflower, peanut, cottonseed, rapeseed, coconut, jojoba, jatropha, palm oil and their esters are considered as viable alternative types of fuels because they are renewable, non-toxic and biodegradable and produce lower emissions [7]. Biodiesel is obtained when a vegetable oil is chemically reacted with an alcohol to produce monoalkyl esters [4]. Biodiesel fuels are generally classified as fatty acid methyl esters and those are derived from transesterification of vegetable oils [1]. The properties of various individual fatty esters those form a biodiesel determine the overall fuel properties of biodiesel. The fatty acids vary in their carbon chain length and in the number of double bonds [2]. The increasing interest in biodiesel fuels has also led to numerical studies of combustion and emission of biodiesel in diesel engines. For these numerical studies, physical properties, such as viscosity, density, vapor pressure, latent heat of vaporization and surface tension are required.

Atomization is the breakup of bulk liquid jets into small droplets by using an atomizer [5]. An increase in fuel density adversely affects atomization, whereas higher fuel surface tension opposes the formation of droplets from the liquid fuel [5]. The objective of the current work is to theoretically predict surface tension of different biodiesel fuels from their density using regression model. The density and surface tension of different biodiesels were taken from the available published data [8]. The importance of the present work is to predict the surface tension of any given fuel from density, so that there may be no need for testing programmes to determine the surface tension.

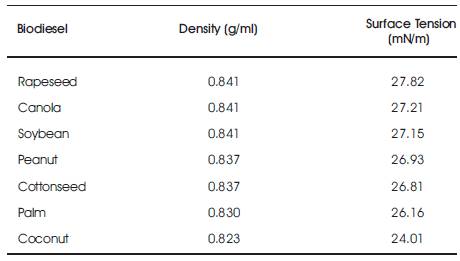

The mass fraction of FAME of different biodiesel fuels are listed in Table 1 [5]. The density and surface tension of different biodiesel fuels are listed in Table 2 [5].

Table 2. Density and Surface Tension of different biodiesel Fuels

To evaluate the degree of linear association between the surface tension and density, correlation analysis was done.

It is a measure of the degree of linear relationship between two variables. The correlation coefficient lies between (-) 1 and +1. If one variable tends to increase as the other decreases, the correlation coefficient is negative. Conversely, if two variables tend to increase together the correlation coefficient is positive [3].

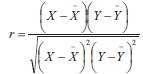

Where,

X = density of biodiesel fuels &

Y = surface tension of biodiesel fuels.

Taking density and surface tension values from Table 2 and by substituting in equation (1), Pearson correlation coefficient was calculated between surface tension and density. It was found to be 0.9566.

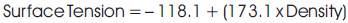

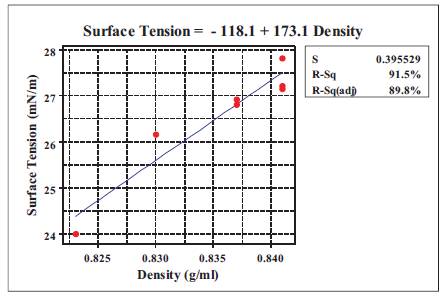

After evaluating the Pearson correlation coefficient, a regression model was developed to predict the surface tension of biodiesel fuels. The following regression model was developed to predict the surface tension of biodiesel fuels. Fitted regression line plot is shown in Figure 1. Taking density as 'X' variable and surface tension as 'Y' variable (values were taken from Table 2), the regression equation (2) was developed.

r2 = 0.915, adj.r2 = 0.898, Standard Deviation (S) = 0.3955.

Figure 1. Fitted regression line plot

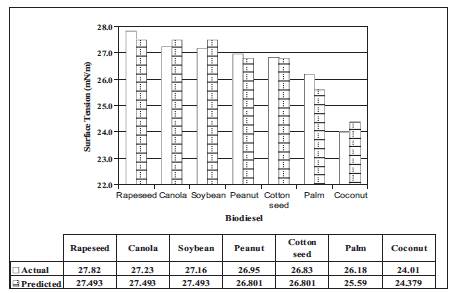

From the correlation analysis, it was observed that the surface tension has a high degree of positive correlation with density (correlation coefficient is 0.95666). In other words, surface tension increases with increase in density of biodiesel fuels. The relationship between density and unsaturation was investigated. From Tables 1 and 2, it can be observed that the density increases with increase in weight percentage of unsaturated FAMEs. It can also be observed that the surface tension increases with increase in unsaturation. In other words, both density and surface tension increases with increase in number of carbon double bonds. To validate the regression equation (2), another set of values were taken from [8] and shown in Table 3. Substituting these density values in equation (2), the surface tension of different biodiesel fuels were predicted and listed against the actual value in Table 4. It can be observed that the maximum error is 1.5 %. The actual and predicted values are compared in Figure 2.

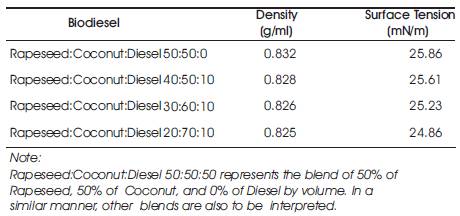

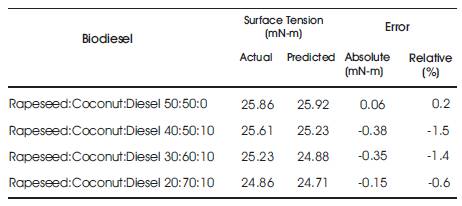

Table 3. Density and surface tension of different biodiesel fuels used to validate the equation (2)

Table 4 Actual and predicted Values of surface Tension of different biodiesel fuels

Figure 2. Actual and predicted values of surface tension of different biodiesel fuels

The density and surface tension of biodiesel fuels obtained in the present work are in agreement with the data given in the literature. The surface tension of a given biodiesel can be calculated using density of that particular biodiesel. The applicability of regression has been investigated for surface tension of biodiesel fuels. To develop the regression model, density and surface tension of biodiesels were taken as inputs. The regression 2 model has yielded R value as 0.915. The surface tension calculated with equation (2) showed a maximum error of 1.5 % only. The predicted results are within the acceptable limits. Therefore, equation (2) is recommended to predict the surface tension of biodiesel fuels instead of undertaking expensive and time-consuming experimental studies.

C8:0 - Caprylic

C10:0 – Capric

C12:0 – Lauric

C14:0 - Myristic

C16:0 - Palmitic

C16:0 - Stearic

C18:1 - Oleic

C18:2 - Linoleic

C18:3 - Linolenic

FAME - Fatty Acid Methyl Ester

r2 - Coefficient of correlation for regression model

S - Saturated acids

US - Unsaturated acids