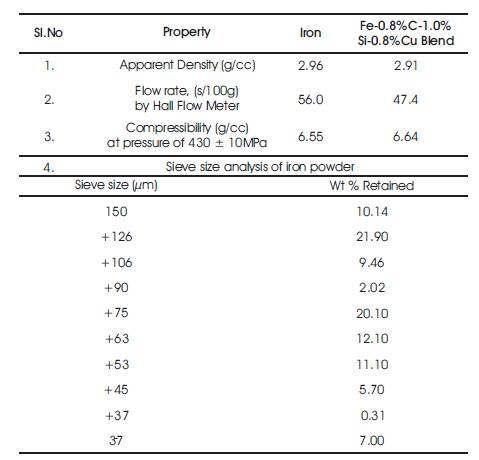

Table 1. Characterization of iron powder and Fe-0.8%C-1.0%Si-0.8%Cu blend

Cold upsetting experiments were carried out on sintered Fe-0.8%C-1.0%Si-0.8%Cu steel preforms in order to evaluate stress – strain, stress – densification and work hardening characteristics. Powder preforms of 86% theoretical density and 0.40 of initial aspect ratio were prepared using a suitable die – set assembly on a 1MN capacity hydraulic press. Sintering was carried out in an electric muffle furnace for a period of 90 minutes at 1150o C. Each sintered compact was subjected to incremental compressive loading of 0.04MN under two different lubricating constraints namely nil/no and graphite lubricant till fracture appears at free surfaces. The behavior of applied stresses with strain and densification exhibits a continuous enhancement but with three different modes of responses. The first and third stage offers high resistance to deformation, whereas the second stage shows virtually steady state, deformation needed gradual increase in applied stresses but with high rate of densifcation. The instantaneous strain hardening exponent ni and strength co-efficient Ki of the aforementioned steel preforms were calculated and found to enhance continuously with the continuous enhancement of deformation and densification.

Powder Metallurgy (P/M) processes provide techno – economic benefits over ingot metallurgy processes; the distinctive features that possess by P/M processes being cost reduction, improvement in performance, tailor made design and the production of unique materials. The manufacturing processes of P/M parts can broadly be divided into two different deformation processes [1]; the powder production, compaction and sintering are termed as primary deformation processes. The parts produced by aforementioned route can also be addressed as conventional P/M processing technique, which are used in applications requiring low mechanical property levels. Since, the presence of substantial amount of porosity content in conventional P/M parts will act as stress riser when it is subjected to mechanical application, which restricts the usage in structural and high strength application. As an alternative, secondary deformation [2] such as pressing or repressing, powder extrusion, powder rolling and infiltration etc., can be used to eliminate the porosity and subsequently increased density of the parts, which in turn improve the mechanical properties. The maximum density attained and the mode through which maximum density being attained play an effective role in determining the product properties [3], [4]. The secondary deformation process takes importance only when full density being a requirement, since the attraction and interest in net shape and near net shape (full density) find P/M route to be a competitive method of manufacturing particular parts such as in the mass production of machine tool components [5].

Powder preform forging involves the fabrication of a preform by the conventional P/M processing technique, followed by the conventional forging of the preform to its final shape with substantial densification [6]. Basically, two distinct modes of powder preform forging are carried out. One involves compression without giving any room for inducing any change in the cross section called as the repressive mode and the other one involving compression of relatively simple shaped preforms into a complex product addresses as true forging. The former part of the argument involves densification with no lateral deformation while the later part of the argument involves densification as well as the shape change occurring simultaneously through large degree of plastic deformations couples with an extended level of lateral flow of material [7], [8]. The plastic deformation of porous material is similar to that of pore free materials, but is complicated by the effect of substantial volume fraction of voids in the material. Although different theories and methods of analysis have been developed for analyzing problems in conventional metal forming processes, they cannot be applied as it is to P/M working. Since, change of volume and yielding of porous metals are not completely insensitive to the hydrostatic stress imposed. In fact, the mode of deformation is quite different in porous preform materials in comparison to wrought materials and is a function of both density and the hydrostatic stress, which have been promoted due to induced strain during powder preform forging [9].

It has been reported [10] that as the attained density increases, the imposed stress subsequently increases. Similarly, increase of friction condition at die contact surface during deformation substantially increases the stresses [11]. With the application of axial compressive stress, the pores will collapse and ultimately closes, at the same time density also enhances, whilst with application of axial tensile stress the pores will grow and densification will decrease. Even pure hydrostatic stress can cause a metal powder preform to yield as the yield surface is closed on the stress axis, which is not true in the pore free metal [12]. Apart from the regular enhancement of densification and stress due to induced strain during forging, usually porous material would also experience matrix strain hardening characteristics as well as geometrical work hardening characteristics [13]. This in fact, reveals the means for the increase of compressive axial stress as the amount of axial strain increases. However, the rate of increase in the stress value w.r.t. strain is greater than that would be observed in a pore free material of the same composition under identical testing conditions, as the continued reduction in the porosity level during upsetting increases the load bearing cross sectional area. This in turn increases the stress required for further deformation, resulting in matrix and geometric work hardening behaviour. Thus total work hardening behaviour of porous preform is due to the combined effects of induced densification and induced strain during cold forging [14], [15].

Thus, present investigation is aimed to investigate and to establish the technical relationship that existing between the resistance to deformation against induced height strain and the attained densification as well as to evaluate the strain hardening behavior during cold deformation of sintered Fe-0.8%C-1.0%Si-0.8%Cu preforms of constant initial aspect ratio and theoretical density under the influence of two different lubricating constraints.

Atomized iron powder of -150μm size was obtained from M/S. The Sundaram Fasteners Limited, Hyderabad, India. Silicon and copper powder of -37μm size of each was obtained from M/S. The Metal Powder Company, Thirumangalam, Madurai, Tamil Nadu, India, whereas graphite powder of 2-3μm size was supplied by M/S. The Ashbury Graphite Mills Inc., Ashbury Warren County, New Jersey, USA. Analysis indicated that the purity of iron, copper and silicon powders were 99.7%, 99.93% and 99.90% respectively and the rest were insoluble impurities. The characteristic of iron powder and Fe-0.8%C-1.0%Si- 0.8%Cu blend are shown in Table. 1.

Table 1. Characterization of iron powder and Fe-0.8%C-1.0%Si-0.8%Cu blend

The required amount of powder corresponding to aforementioned system were measured and blended in a pot mill along with porcelain balls of ratio 1:1 by weight for a period of 20 hours in order to obtain homogeneous mix. This powder blend was compacted on a 1.0MN hydraulic press in the pressure range of 430±10MPa to obtain an initial theoretical density of 0.86±0.01. These green compacts were sintered in an electric muffle furnace at 1150o ±10o C for 90 minutes. In order to avoid oxidation during sintering, the compacts were ceramic coated. These sintered preforms were furnace cooled.

Sintered and furnace cooled preforms were machined to yield constant height – to – diameter ratio of 0.40 and were compressively deformed between a flat die set in the incremental loading step of 0.04MN under two different frictional constraints, namely, nil/no lubricants and graphite lubricant using 1MN capacity hydraulic press. Dimensional measurements such as deformed height, deformed diameters (including bulged and contact) were carried out after every step of deformation and the density measurements being carried out using the Archimedes principle [16]. Experimental results were used to calculate the engineering stress, true stress, true height strain, percentage theoretical density and instantaneous strength coefficient (Ki ) and Strain hardening exponent (ni ).

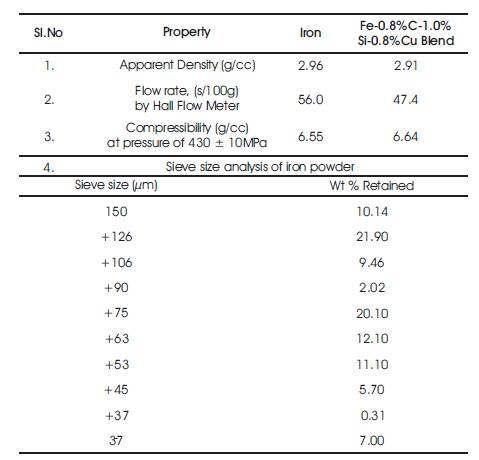

To assess the mechanical behavior of any material when it is subjected to any form of external loading condition, stress – strain analysis is considered to be the fundamental, since stress that determines the internal resistance of a material against the external disturbance on a particular area of cross section exposed to deformation. Strain normally deals with the deformation of the body. When the applied incremental load is directly considered for original area of cross section Do i.e., before deformation is termed as engineering stress, whereas the same applied incremental load is considered for instantaneous deformed diameter Df , which is termed as true stress. Since, both the stresses are the causes of the applied load, these can be addressed as applied stresses, which were drawn against true height strain to assess the resistance to deformation for the induced height strain during cold axial forging and is shown in Figure 1.

Figure 1. Influence of lubricants on the relationship between applied stresses and true height strain

The general observations of curves reveal that with the increasing height strain, stresses are also continuously increasing. The extensiveness of resistance to deformation is highly apparent during first stage (up to the value of 0.05 height strain) and little apparent during last stage (after approximately the value of 0.6 height strain), however intermediate stage exhibits relatively a steady and constant increment of stress values. This reveals the fact that the presence of 14% of porosity in the preform at initial stage cannot be deformed by initial application of incremental loading, however these loading would stimulate the kinetics of particle; both voids and materials. But, the fact was different in last stage because the presence of porosity percentage is less, approximately 4 to 5% (refer Figure 2) or otherwise the preforms are considerably densified. In addition, extensive induced strain made a preform to harden more, by and large the presence of very little amount of pores would expect to behave as a second phase particle during deformation as it was in fully dense material and so more than height reduction, the lateral deformation is pronounced. This is the cause for true stress values dropped down in comparison with engineering stress values and the same reason is applicable for vanishing out the last stage in case of true stress against true strain. Technically, the lateral spread is distinct after 0.1 height strain value which can be observed in Figure 1. In other wards, the height strain is substantially high and the diameter strain is practically negligible up to the value of 0.1 height strain i.e., during the initial stage of deformation. The intermediate or second stage, where induced strain is contributed to raise the kinetics of particles that contributed to reduce the slope of applied stress curves and so the resistance offered is considerably diminished in comparison to first and last stages. This behavior is true irrespective of lubricant employed during deformation.

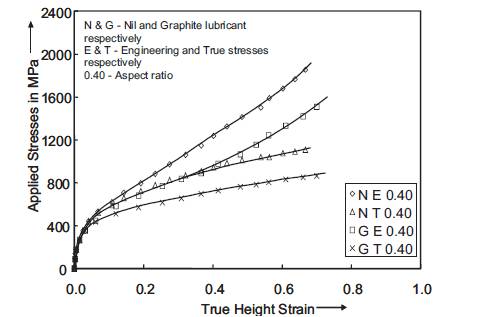

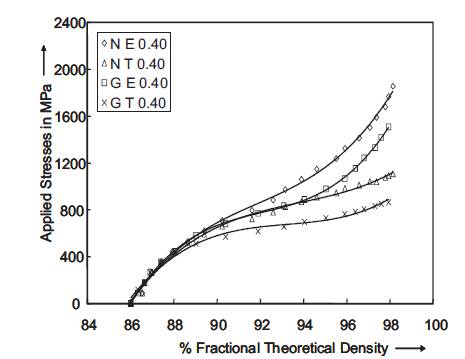

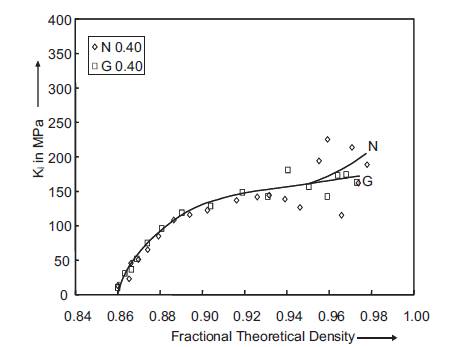

It is well established [9], [10] that densification can enhance appreciably with the application of one or more deformation processes, therefore, densification is a function of induced strain. Similarly, the strength and other mechanical properties are very much dependent on the maximum density that possessed by the P/M preform and of course, the mode by which the full densification is attained. In broad prospect, strength can be expressed as the resistance against deformation up to its fracture. Therefore, the strength can also be the function of attained density. In this view, the experimental results have been utilized to find out the relationship exist between applied stresses and the density attained continuously during cold forging. The corresponding plot is shown in Figure 2.

Figure 2. Influence of lubricants on the relationship between the applied stresses and percentage fractional theoretical density

The characteristics nature of the curves is following similar in trend. Further these curves are following more so three different stages, also the existence of third stage for true stress against densification is little evident which was not true against height strain. At initial stages (from initial pack density to 88% theoretical density), the application of load is not sufficient to deform the preform and so there is a little rise in stress values, but this is no longer valid. Further application of continuous load collapses bigger pores followed by smaller pores and pore beds. This induces better densification in the preform, which in turn raises the applied stress values. However, the slope of second stage is relatively low in comparison to its previous stage which confirms that kinetics or mobility of particles is highly evident. The critical observation of Figure 2 expresses that the divergence between engineering and true stresses irrespective of lubricants employed, virtually starts at the end of first stage. Meaning thereby until the first stage, specimen height reduction is high but the lateral expansion is very less. As soon as 88 to 89 percent theoretical density achieved, deformation in both linear and lateral direction is appreciable. This effect was little pronounced at last stage with considerable enhancement in densification i.e., after 95% of theoretical density and up to the maximum densification that can be achieved. The reason for higher slope obtained at last stage especially for engineering stress values is that the material are expected to strain harden due to the induced strain while cold forging, however the presence of voids and its deformation along with material in the lateral direction made to lower down the true stress values in order to bear the applied load. Further at any values of attained densification, it is observed that preform deformed under dry friction are preceded in the amount of enhancement of stress values over the preform deformed under graphite employed friction condition. This indicates a concrete justification that graphite employed preform facilitated lateral deformation along with low enhancement of densification in comparison with dry friction condition. Since, friction at die contact surfaces induces a transverse pressure, which reinforces vertical forming pressure and thus enhances the densification of material. The magnitude of lateral pressure increases with increasing friction conditions.

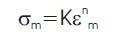

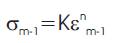

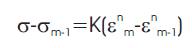

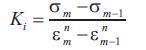

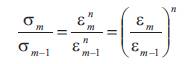

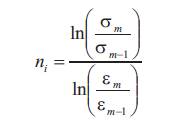

Based on the nature of curve that follows for applied stresses against induced strain and densification, it cannot be claimed scientifically that strength was also highly induced in a preform while cold deformation. Though, the stress rise is substantially pronounced for engineering stress against densification attained by the preform, this is not conveying a true behaviour. Therefore, an attempt was made to use plastic flow (Ludwik) equation σ = Kεn , with little modification for P/M preforms to determine the instantaneous strength (Ki ) and instantaneous strain hardening (ni ), where σ is true stress; ε is true strain; K is strength co-efficient and n is strain hardening exponent. The theoretical description follows:

Assuming consecutive applied load on the preform were specified as 1, 2, 3, . . ., (m-1) and m. Now the plastic flow equation can be written as follows:

Subtracting Eqs. (1) and (2), the following expression can be obtained

The Eq. (3) can further deduce into

Now, dividing the Eq. (1) by Eq. (2), the following expression is obtained

Taking natural logarithm on both sides of Eq. (5), it follows

Eq. (6) can further simplify into

Eqs. (4) and (7) can be utilized for determining the instantaneous strength coefficient and instantaneous strain hardening exponent from the experimental data corresponding to stress and strain.

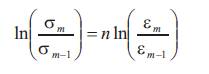

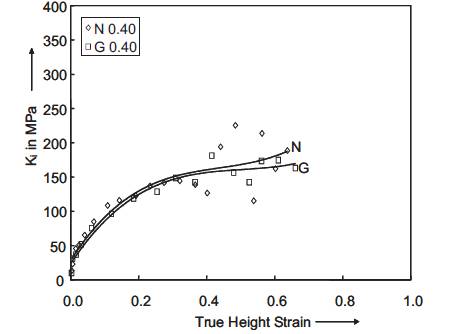

Figures 3 and 4 were drawn between instantaneous strength coefficients (Ki ) against true height strain and percentage fractional theoretical density respectively. It can be observed that in the range of 35 – 40% of height strain and/or up to 94% of theoretical densifcation, strength values are falling almost on a same frequency; thereafter fluctuation of points was observed. Particularly, this fluctuation is more when lubricant is not employed during deformation. In general, it is observed that as induced height strain and densification is increased, the instantaneous strength coefficients were also increased; this phenomenon can also ascertain from the Figures 1 and 2 respectively, since the applied stress values are continuously increasing with respect to height strain and attained densification. However, the reason for fluctuation is that the deformation induced in the preform was not homogeneous or else the load distribution is not homogenous during deformation and this phenomenon is highly pronounced at later stages of deformation. Thus, it can be concluded that the increase of friction constraint at die contact surface will increase the fluctuation of strength coefficient. However, an approximate trend curve have been drawn using Microsoft excel, which exhibits nil lubricant curve topped the position, followed by graphite lubricant respectively. Further, it can be concluded from the trend line that irrespective of lubricants employed, strength can continuously enhanced with continuous cold deformation and densification. However, maximum strength can be induced in the preform deformed under nil lubricant condition in comparison with graphite employed lubricant condition.

Figure 3. The relationship between Ki and true height strain with the influence of frictional conditions

Figure 4. The relationship between Ki and percentage fractional theoretical density with the influence of frictional conditions

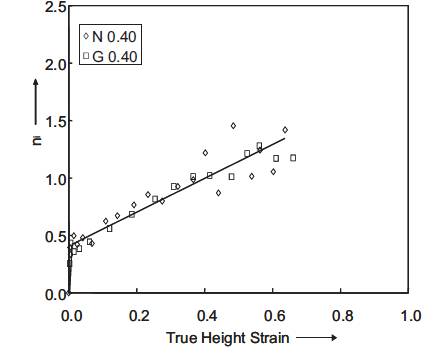

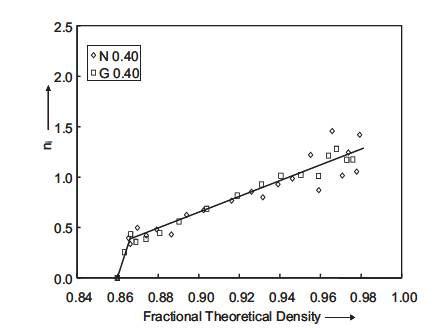

Figures 5 and 6 were drawn between instantaneous strain hardening exponent (ni ) with the true height strain and the percentage fractional theoretical density respectively. Observation of both the figures uniquely expresses that strain hardening is enhanced continuously for each incremental of deformation. Preform deformed under nil lubrication is subjected to strain harden little faster, whereas preform deformed under lubricating condition extended the deformation little more and then it gets strain harden. This can be understood from Figures 5 & 6, that fluctuation of points are originated much quicker in dry friction condition and the same is little delayed for graphite lubricant condition, which is the index of proof that as soon as the kinetics of densification slow down because of the mobility of particles are arrested that ultimately promotes work hardening effect. It is noted that all the preforms were deformed until the crack appear at the free end and is suggested that proper identification of fracture appearance point can be utilized to introduce circumferential constraint to arrest cracks. This would yield material with pore free and enhanced property.

Figure 5. The relationship between ni and true height strain with the influence of frictional conditions

Figure 6. The relationship between ni and percentage fractional theoretical density with the influence of frictional conditions

The major conclusions have been drawn from the present investigations that are as follows.