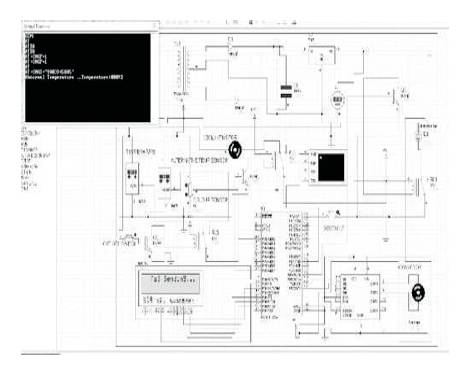

Figure 1. Simulation Diagram

An industrial beverage processing plant generally consisting of nonlinear dynamics which requires temperature, colour, pressure, and PH level controllers to be nonlinear. So the automation requires systematic process for getting accuracy and efficient output. Even though the control of nonlinear parameters is automated, it requires skilled professionals in case of emergency conditions, when the hardware fails. The aim of this paper is to provide an Advanced Food Handling Method (AFHM) which combines Unified Modeling Language (UML) and Aspect-Oriented Software Development (AOSD) to design real-time and embedded automation systems. The proposed technique contains a notification mechanism, and facilities alternate to hardware support system. Proper management of quality is especially important in the beverage plant because the drinks which are easily perishable, are in great demand and relies on a quick response and on a fast supply chain. The notification mechanism can ensures the quality of the beverage by informing staff when variations occur. With the introduction of AFHM, the food Industry can utilize inventory information and manage the food handling process more effectively.

Like all other processing industries, the food industry is striving to economically and efficiently produce high quality products. To reduce some of these negative effects, modern automation and control systems include complex embedded systems, comprising hardware and software components can be employed. These devices are able to execute autonomously and support fully decentralized decision making therefore dramatically changing the architectures (usually centred on Programmable Logic Controllers (PLC)) adopted in the industrial automation field.

Usually, these systems must respect real-time constraints and perform many distinct tasks, which are traditionally partitioned between the system's hardware and software components. Tasks may also be deployed into distinct processing units and need to cooperate to deliver the expected services. Thus, engineers must deal not only with the design of software and hardware in the same project, but also with their interaction which is generally implemented via industrial communication protocols [1, 3]. In this sense, it is important to minimize (or even avoid) inconsistencies in system specification, i.e., software and hardware teams must follow the same consistent system specification basis. Furthermore, embedded systems of industrial automation applications have requirements of distinct natures, such as functional and non-functional. Functional requirements specify the expected services to be delivered by the system, whereas non-functional requirements describe the system's properties and constraints [6], e.g., real-time, concurrency, scheduling, and safety.

Normally, non-functional requirements are addressed within the functional requirements' handling, leading to a scattered and tangled handling. This modularization problem hinders the modifications of the created artifacts (e.g., models or source code), restricting their reuse in other projects. Such issues lead to a large increase in design complexity, directly affecting the duration and cost of the design and deployment phase. One approach is to raise the abstraction level during design to cope with the increased complexity. In this sense, model-driven engineering (MDE) [13] can be seen as a trend in designing embedded systems for automation applications, since many approaches have been proposed in the last years [2, 4, 5]. MDE advocates that engineers must put more effort into creating system specifications [2] using models that allow automatic code generation for the system's components, rather than writing this code manually [1].

One widely known and accepted modeling language is the Unified Modeling Language (UML), which was initially proposed to specify only IT systems' software [16]. However, in recent literature, there is a growing interest in applying UML in other application domains (e.g., automation systems), especially in approaches that deal with the code sign of software and hardware components [4, 8, 15]. Although raising the abstraction level is a good approach to manage complexity, the problems related to non-functional requirements' crosscutting concerns still affect traditional design approaches such as functional or Object-Oriented (OO) paradigms. To cope with these issues, approaches such as subject-oriented programming [11] and aspect-oriented programming [9] propose units of modularization called, respectively, subjects and aspects. Scattering [12] and tangling problems are usually addressed at the level of the system's source code. However, crosscutting concerns are not exclusively found in source code. They also appear in requirements documents and design models. Hence, it is also interesting to apply the same principles in earlier phases, as in Early Aspects [10]. This work addresses the mentioned problems by proposing a MDE approach called Aspect-oriented Model Driven Engineering for Real-Time systems (AMoDE-RT). It combines UML with concepts of aspect-oriented software development (AOSD) [7], Platform-based Design [14], and code generation techniques in a consistent set of activities and tools. AMoDE-RT allows progress from requirements engineering to the system's implementation (using different target platforms) in a straightforward manner. AMoDE-RT increases the reuse of artifacts produced during design, as it allows for a better separation of concerns in requirements handling [13].

The main objective of this study is that it is a basic process and the different ways, a particular type of food can be handled is easily understood by normal people. Also that, the different types of procedures performed step by step are also explained.

The first step is to measure the temperature value. There is no problem if normal temparature value is obtained. Otherwise, abnormal condition occurs and a message will be sent to the control system. The control system than controls the value. After which, the colour value is also to be checked by the control system.

Figure 1 shows the overall construction of the simulation work. In this simulation, temperature sensor, Colour sensor, Voltage sensor, and Object sensor are used for sensing the temperature, Colour, System voltage, and object in the system, respectively with the help of ATmega16 microcontroller. An LCD display is used to display the condition of the system it should be in normal or abnormal condition with the help of proteus software.

Figure 1. Simulation Diagram

The working of above mentioned sensors under normal and abnormal conditions is shown in the following snapshots.

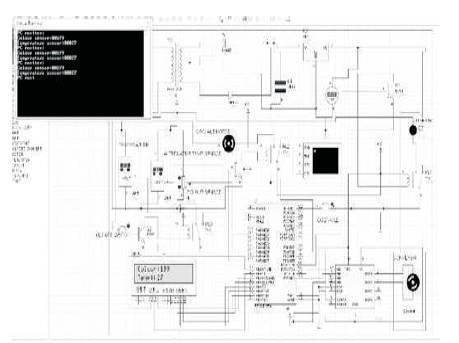

Figure 2 shows the normal temperature operation of the system. In this period of time, the sensor senses the system temperature to maintain a healthy operation in the industry.

Figure 2. Normal Temperture

Figure 3 shows the abnormal temperature caused in the system. In this period of time, the sensor is activated to avoid excessive temperature. At the same time, the system displays a reporting message in the monitor.

Figure 3. Abnormal Temperature

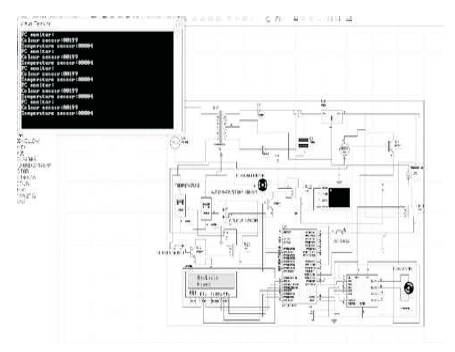

After the activation of temperature sensor, a message sent to reduce the temperature is shown in Figure 4. At this stage, excessive temperature can be identified. If the ideal temperature sensor fails, the alternative temperature sensor is turned on and continues the work of an ideal temperature sensor. The alternative temperature sensor is shown in Figure 5.

Figure 4. Message Sending to Reduce Abnormal Temperature

Figure 5. Alternative Temperature Sensor

Figure 6 shows the normal colour maintained in the system. In this period of time, the sensor predicts the product colour to maintain a healthy operation in the industry. Figure 7 shows that the colour value changes in the product of the system. In this period of time, the sensor is activated to avoid further problem. The colour sensor is activated to identify the colour change and a message is sent as shown in Figure 8. Figure 9 shows the normal operation of object sensor. In this stage, the sensor views the overall system, whether any object is found in the system. When it is turns on, and if any object is identified in the network, it sends a message as shown in Figure 10.

Figure 6. Normal Colour Operation

Figure 7. Colour Value Changed

Figure 8. Message Sending after Colour Change

Figure 9. Normal Operation of Object Sensor

Figure 10. Message Sending after Object Identification

The paper has described about the advanced food handling technique which can control the industrial food beverage processing plant more efficiently. The AMoDERT approach to design real-time and embedded systems for food beverage automation applications has been proposed here. It covers activities from earlier phases up to system implementation using a given target platform. These activities are supported by several tools. AMoDE-RT combines a widely accepted modeling language (i.e., UML) with concepts of AOSD to cope with specific nonfunctional requirements. Through the use of DERAF, AMoDE-RT improves the encapsulation of non-functional requirements handling, avoiding scattering, and tangling of crosscutting concerns.

The AMoDE-RT has been successfully applied to real-world examples of automation systems. Considering the calculated metrics, it can be observed that the AMoDE-RT approach can positively impact the design of real-time and embedded systems for automation applications. Considering code generation, GenERTiCA's approach is different from the majority of code generation tools available. It allows the separation of concerns in describing mapping rules by using short scripts which are responsible for generating source code fragments for well-defined structural and/or behavioral elements. It can be stated empirically that this approach improves cohesion and reinforces the engineers' focus on individual elements instead of the whole model. This work demonstrates that GenERTiCA can generate a great amount of source code using platforms targeted to automation systems. GenERTiCA is able to generate not only the classes' structure (with their attributes and methods declarations), but also the code for the system's behavior. Additionally, GenERTiCA weaves aspects' code into the generated code fragments, since their adaptations use the target platform services described within scripts. The use of an AMoDE-RT as described in this paper is one that can be implemented in hardware on basic microcontroller with an insignificant cost but with a tremendous cost saving for a food processing plant.