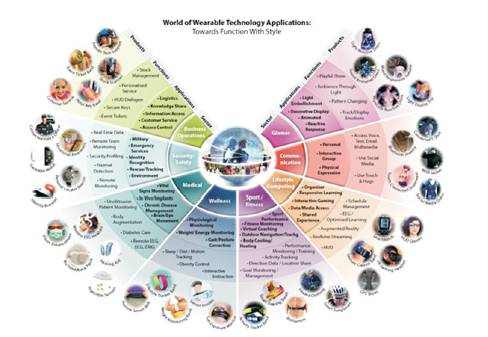

Figure 1. Applications of wearable technology (Anon, 2014)

This paper aims to investigate into the applications and technology behind embedded electronics within wearable textiles in order to determine what direction it should take in order to thrive in the future. Wearable technology is a term that is highly ill-defined whose name and meaning has continued to evolve since the first abacus necklace in the early 1600's. A literature review will be used to analyse trends within wearable technology from its origin to its current state of the art. The comparing and contrasting of different papers will allow the current key technological barriers that could affect the future growth of electronic textiles within clothing to be identified, to aid the prediction of its future.

As a result of the rapid growth of the internet of things, it will be found that wireless communication technology within electronics textiles is a fundamental piece of technology that will determine how e-textiles could expand in the future. Further interviews with experts and analysis of wearable antenna case studies will highlight the key technical challenges that are currently faced and a prediction will be made regarding whether wireless communications within electronic wearable textiles should develop to allow it to thrive in the future.

The results show that within the next decade, wireless electronic wearable textile devices will not breach into mass production, will be used as an attachable accessory rather than being combined on a fibre level and will have to be used only on rigid thick items of clothing. This is due to limitations in washing electronics, under-researched mass manufacturing processes and a lack of a solution to a large reduction in wireless signal strength due to close proximity with the human body.

Identify limitations and future trends within wearable technology to predict progress in this field over the next decade.

Objective 1: Define wearable technology

Objective 2: Investigate the history of wearable technology

Objective 3: Understand trends in the applications of wearables and smart textiles.

Objective 4: What are smart textiles or electronics embedded into clothing?

Objective 5: Understand recent advances in wireless communications within smart textile technology and its limitations.

What is wearable technology?

What is the current state of the art in electronic wearable textiles?

What are the limitations of wireless communication technology within electronic wearable textiles?

What is the potential future of electronic wearable textiles?

Despite being heavily used across the design and technology sectors over the past couple of years, the term wearable technology is still rather broad and ill-defined. The Chambers dictionary describes wearable technology as; ‘Wearable - something that is capable of being worn or good for wearing’ (Anon, 2011)and ‘Technology – the practical use of scientific knowledge in industry and everyday life’ (Anon, 2011). Clearly as science has developed over time, people’s perception of wearable technology has diversified significantly. This has led to a widespread set of applications ranging from a basic smart watch to enhance the user experience of using a mobile phone, through to medical skin worn sensors that monitor our biological conditions. Figure 1 describes the diverse range of market sectors that wearable technology is used in today along with its applications.

Figure 1. Applications of wearable technology (Anon, 2014)

Hosun(2010) described wearables as a physical computer contained within users’ personal space which is always accessible and can be directly interacted with. With the rising developments of cloud computing, computing processes are increasingly being performed away from the user which would argue with both Mann and Yeo’s claims of a need for a physical computer to be worn on the user. As will be discussed further on, some recent smart textiles can automatically adapt their behaviour with regard to the environment with no direct interaction from the user. This also challenges the above claims.This study focus on the incorporation of technology within textiles or the body that has the means to communicate with or without interaction from the user and or become a tool more powerful than the standard item of clothing.

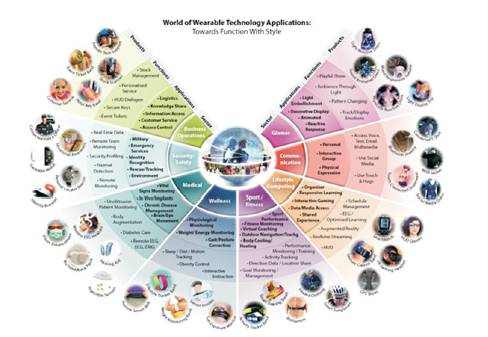

In the mid 1200's the invention of eye glasses would have been seen as cutting edge wearable technology where now it is rather basic. As a result of the varying perceptions of the terms wearable and technology throughout history, there is little literature that has been able to precisely pinpoint its origin (Castano, 2014). Manyview Edward O. Thorps computerised roulette cheating timing device concealed within a shoe as the first piece of wearable technology, where others turn towards Breguets invention of the first ever timepiece in 1810. (Ryan,2006) However, traces could be argued to date back to the early 1600's with the first ever abacus necklace in Figure 2. (Anon, 2002).

Figure 2. First abacus necklace (Anon, 2002)

The 20th century referred to wearable technology as the wearable computer. It saw existing devices being made portable and attachable to the user such as the wristwatch and the algebraic calculator watch. The main development focus was on making the technology portable as opposed to developing any user interaction to make it a useful tool as it is today. (Anon, 2002).

Large advances in ICT in the mid 1990's resulted in an increase in research into wearables, including the creation of Edgar Matias' wrist computer, Steve Manns wireless webcam and DARPA's portable wearable computer. (Hosun, 2010). This is somewhat similar to the google glass and the smart watch that many believe wearable technology to be today. Wearable technology was still copying existing ideas and making it portable instead of becoming a unique product in its own right.

The fashion industry started research into wearable electronics in the early 2000's. Figure 3 shows Levi's collaborated with Philips to create an 'ICD+ jacket'. A mobile workplace for the busy professional within a jacket that featured an interconnected mobile phone, MP3 player and speakers within the hood. Whilst this hadn't fused electronics together with fibres yet, it sparked the idea of a potential future of a collaboration between fashion and wearable technology.

Having seen industries' attempts to make technology more accessible and seamlessly integrated into consumers' everyday lives, the next natural progression would be to attempt to embed bespoke electronics directly within clothing rather than just placing it within compartments of clothes. Initial attempts predictably started as somewhat of a gimmick with the integration of electronics onto clothing to create illumination for aesthetic purposes only as illustrated in Figure 4. This was a result of companies racing to release a product to prove themselves to be at the cutting edge of technology rather than aiming to develop a meaningful useful product.

Figure 3. Philips ICD + jacket

Figure 4. Illuminated fashion clothing (Anon, n.d.)

More recent technological developments have started to see electronics integrated within textiles to create an array of applications which make wearable technology innovative and a standalone product in its own right rather than developing the portability of what already exists.

Having established the potential of embedding electronics within clothing. Some scientists including Warwick and Lieber deemed the next natural progression was to incorporate electronics under the skin within the human body. (Warwick, 2011)

This theory had only been previously explored in films such as 'Total Recall' and 'Tron.' Here ideas of placing electronics under the skin to create aesthetically personalised illuminated tattoos, Figure 5, as well as more impressively embedding a mobile phone device into the palm of an actors' hand, Figure 6. Here a keypad screen interface would not only illuminate through the skin to make phone calls, but also has the ability to turn any glass surface into an interface to see the person you are.

Figure 5. Total Recall, Electronic Illuminated Tattoos (Hurst, 2012)

Figure 6. Total Recall - phone under the skin (Anon, 2012)

Many scientists were known to possible ideas of human embedded electronics yet few had investigated into it amid fears of developing a generation of computer controlled human cyborgs. Charles Lieber attempted to embed a 'three-dimensional network of functional biocompatible, nanoscale wires into engineered human tissue' to monitor the activity of cells without causing damage. (Warwick, 2011).

Figure 7. Total Recall - phone glass interface (Warwick, 2013)

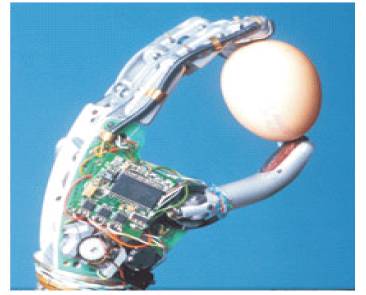

Kevin Warwick, also known as 'Captain Cyborg' took the technology to its furthest progression to date by controversially implanting sensors and a microchip into the nerves of his arm. This allowed him to control an electric wheelchair and an intelligent artificial hand through his nervous system just by thinking about it, Figure 8.

Figure 8. Electronic artificial nervous controlled hand (Warwick, 2013)

Despite revolutionising the technological boundaries of wearables, the ethics of Warwick’s research was challenged by many who claimed he was creating human cyborgs and turning people into machines. (Mizrach, n.d.)

Therefore, it would seem unlikely that technology interconnected with our bodies under the skin will be incorporated into mass consumer goods in the near future for the above reason. Clearly ethics and moral issues of developing wearable technology is a factor which will inevitably influence its future even if technical challenges are overcome. However, it breaches the remits of this paper and so will not be looked into further.

Now that the past and present trends of wearables and electro-textiles have been identified, it is necessary to explore deeper into finer details behind embedded electronics within textiles.

As was demonstrated by the wide array of applications for embedding electronics into fabrics, the smart textile industry is incredibly broad. It ranges from fashion clothing being able to detect changes in the environment, to very smart materials that incorporate shape memory alloys to change their own shape with respect to external stimuli. (Ritter, 2007) Essentially they are ‘fabrics that enable digital components to be embedded in or attached to them’ (Anwar, 2013)

From researching a variety of Journals and sources, smart textiles being developed currently commonly fall into three main categories: passive smart textiles; active smart textiles; and very smart textiles.

These materials are effectively sensors that have the ability to detect changes in the environment.

These are both sensors and actuators, they have the ability to sense the environment and produce a reaction to respond to their environment or a stimulus. (Henock,D, 2010).

These can sense and respond to changes in the environment as well as having the ability to change their shape according to the environmental conditions. (Henock,D, 2010).

Various types of electronic smart clothing solutions are being developed for the sports industry. Athletes wear various watches and straps to gather data about their performance such as heart rate and pace and temperature. (Hosun, 2010). Such data could be gathered automatically through the integration of passive smart textiles within clothing, this would avoid having to use a range of separate devices.

Adidas have developed smart textiles within clothing, which monitor the temperature at different parts of the body. The clothing automatically changes colour to inform the user of how they are using their muscles during activity. This is an example of active smart textiles that senses and responds to its environment.

The use of smart textiles and wearable technology is an essential tool for the military. DARPA has developed smart textiles which monitor the health of soldiers on the front line in extreme environments (Hosun, 2010) as well as developing active smart textiles that change the colour of clothing to match the environment within an active camouflage.

It is necessary to discover what the current state of the art of embedded electronics is within textiles to identify its main limitations which could restrict its development in the future.

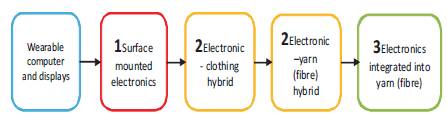

Wearable electronic textiles can be split into three main categories as shown in Figure 9: (Anwar, 2013)

Figure 9. E-textile development (Anwar, 2013)

Standard electronic devices placed into clothing

Hybrid electronic fibres.

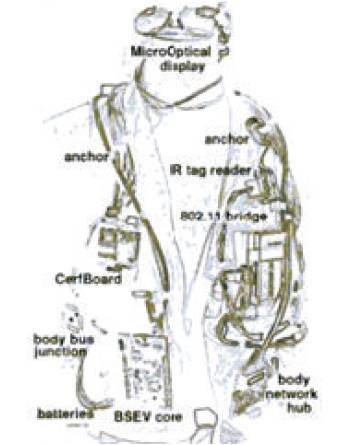

This is the most basic form of electronic textiles where electronic circuitry is placed within the garment as opposed to within the textile. This could be placed inside a clothing’s compartment where it can be removed such as in the MIT media Labs Mithril project in Figure 10. (Anwar, 2013)

Figure 10. Surface mounted electronics (MIT Mithril Project) (Anwar, 2013)

Arduinos Lillypad microcontroller range goes further by allowing consumers to create their own computerised clothing by sewing sensors and components onto their own wearable electronic clothing projects, Figure 11. (Anon, 2015) Arduino perceive these to be an example of wearable technology. However they still use rigid PCB’s as a microcontroller, with the conductive fibres connecting components together being the only fact that links them to actual wearable technology. Therefore, one would argue that since they should not be considered wearables, but standard electronic components that can simulate the user experience of wearable technology within clothing.

Figure 11. arduino Lillypad(Anon, n.d.)

The attempt to integrate prototype surface mounted electronics within the basic Arduino range demonstrates that surface mounted electronics is becoming more commonplace within the industry and can therefore no longer be categorised as state of the art.

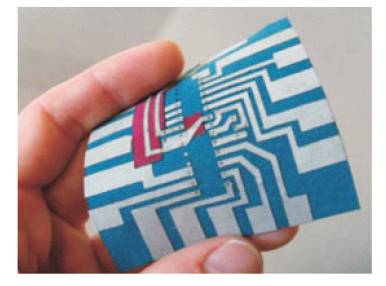

Buechley describes her hybrid system of being able to sew electronic buttons and LED’s etc onto clothing using conductive yarn to create personalised fabric PCB circuits as shown in Figure 12 and Figure 13. (Buechley, 2007)

Figure 12. Fabric sewn PCB (Buechley, 2007)

Figure 13. Hybrid microcontroller button and LED circuit (Buechley, 2007)

This takes the Arduino Lillypad to another level by replacing the PCB with textile tracks that a microcontroller can be attached to and thus is a better representation of the current state of electronic textiles. This method is effective in combining the flexible nature of textiles with the high conductivity of copper, both of which are essential within e-textiles. However, the labour intensive manufacturing process involved, limits its suitability for mass future use. A better method of combining the natural fibre and copper together during the fibres’ manufacture may be required if the technology is to be suitable for mass manufacture.

Purohit and Raval also describe a textile patch antenna as a piece of hybrid e-textile technology as in Figure 14. A metallic signal radiating patch is combined on top of a dielectric substrate that allows radio signals to be sent wirelessly between wearable devices.(Kumar,1999)

Figure 14. Hybrid Textile Patch Antenna (Purohit, 2013)

These patches are designed to be placed within pockets of clothing and then removed when the garment is due to be washed. As will be discussed later on, the wash-ability of electronic textiles is a major limitation within the industry. Ideally these patches would be incorporated directly into clothing however current technology forces them to be removed when due to come into contact with water.

However, this also solves an issue of user customisation. Since there are thousands of different jumpers on the market it would be impractical to embed electronics into every item, and consumers are likely to not be prepared to purchase a particular colour/ brand/ item of clothing to gain access to an antenna. Making the technology removable allows a user to purchase one antenna separately and transfer it to a variety of clothing items that they own.

This would seem a practical short term solution for the electronic textile industry as a whole until manufacturing processes are developed enough to be cost effective as existing standalone natural fibres, and until conductive fibres are developed whose properties are maintained after being in contact with water.

As a result of the recent growth of the internet of things, one would argue that this is a fundamental piece of wearable technology for the future. While it may be adequate to develop electronic methods of sensing or gathering data about the environment, if the wearables are fully reliant on wiring and have no reliable method of wirelessly communicating data with each other or external systems then the true value of the electronic wearable textile is lost. Therefore the wireless connectivity of electronic wearable textile needs to be established in order for the technology to thrive in the future.

Many regard the most advanced method of embedding electronics into textiles is to weave it directly into the fibres at a yarn level. Figure 15 shows conductive copper foil being wrapped around standard silk thread to make it conductive to form wearable circuits. This can be connected to external electrical devices such as phones or MP3 players to transmit power and data.

Figure 15. Hybrid yarn

A limitation of wearable technologies is how they are to be disposed of at the end of their life. At present, clothes are made from a single material which can easily be recycled. However, by weaving fine electrical circuits into clothing, it becomes almost impossible to separate the different components into their separate materials so that they can be recycled. (Kohler, 2008) This would impact the feasibility of the introduction of electrical circuits into clothing on a mass scale due to the negative environmental effects given the large volume of clothes that are disposed of.

To combat this, Antalis are researching in trying to construct textiles from paper and conductive polymer in order to make wearable electronics biodegradable and more sustainable. However in its current state, conductive polymers have a far poorer conductivity than metals for it to be useful.

Cost was also found to be a limitation in wearable technologies. Current clothing is very simple in terms of its composition and manufacture. However, when technical electronic circuitry is woven into clothing, its composition becomes far more complex and thus more expensive. The moral and economic issues of increasing the consumer costs of clothing was found to be a potential limitation within current literature.

Both of these factors would suggest that the future of electronics textiles would be the integration of textiles via a hybrid method where electronic components are made as separate parts that can be integrated into a range of items.

The opposite mechanical nature of electronic circuitry and textiles is a major challenge in its development. It is essential that textiles are highly flexible and can move freely around the body to be comfortable. Standard electronic components are inherently fragile and excessive movements could cause a breakage and failure in the circuit. To solve this, Minyoung describes how electronics are integrated within clothing by weaving metallic conductive material into textiles to create a hybrid conductive fibre. The more metallic the fibre compound is, the better the circuit will perform. However, a low textile to metal ratio will result in a stiff compound that is uncomfortable to wear, therefore a compromise is required. Minyoung, (2010).

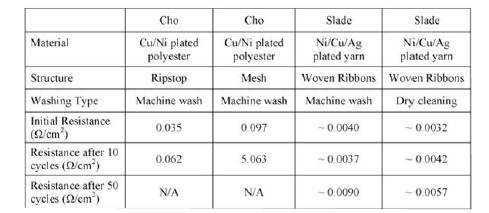

The interaction between smart clothing and water is another issue. Clearly failure occurs if water comes into contact with an electrical circuit, therefore cleaning items of clothing is a major limitation. Minyoung's table below describes how the resistance of an electrical fibre increases significantly after just ten wash cycles (Minyoung, 2010). This would suggest a large limitation for the application of technology within clothing. Therefore, based on current technologies, electronics may not be able to be integrated into mass market clothing and may be restricted to either disposable uses or more high tech specialised applications or on items where less frequent washing is required. Table 1shows an analysis of textile fibre washability (Minyoung, 2010).

Table 1. Textile fibre washability analysis (Minyoung, 2010).

While rapid developments have been seen in wearable textile technology over recent years, the same cannot be said for the lithium rechargeable battery sources that power them and thus remains a limitation in the growth of the technology according to Stoppa and Chiolerio. (Stoppa, 2014)

Previously, wearable textile devices required separate external rechargeable lithium battery attached to the clothing. These batteries are often bulky, heavy devices that are difficult to integrate seamlessly within a wearable product. They are normally positioned on the waist or near the ankles where the user is less likely to notice them, however this makes cabling an issue by connecting it to components that could be on the head or the other side of the body.

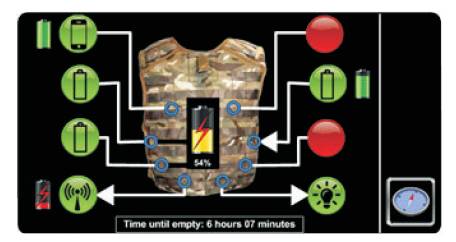

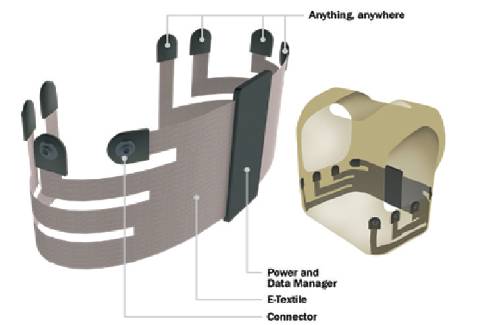

Figures 16-18 shows a wearable military power system branded ‘broadsword’ developed by BAE systems. It consists of a flexible waist worn device that supplies power and data connectivity from a central energy storage unit to an array of electronic devices. This is useful on long missions where recharging a series of individual devices may not be possible. It features an inductive charging system that can be charged automatically from a vehicles’ seat when travelling to a location. (Anon, 2014)

While this is adequate for military use, walking around with a lithium battery strapped to the back is clearly not feasible for public use unless its size is miniaturised significantly. In order to be integrated into mass consumer goods, engineers face the challenge of making a battery that is lightweight, has a decent battery life, performance and price as well as being small enough to be worn without inhibiting the overall design. The latest battery developments have progressed in two main directions: Super capacitors and textile energy generation from the body (renewable energy)

Figure 16. Military power system (Anon, 2014)

Figure 17. Military charging system (Anon, 2014)

Figure 18. Lithium inductive seat charger (Anon, 2014)

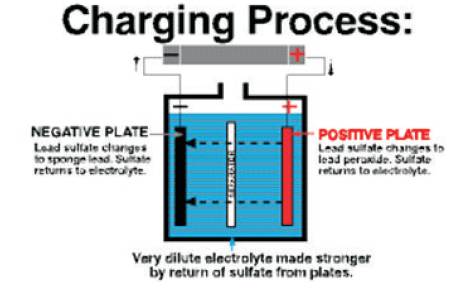

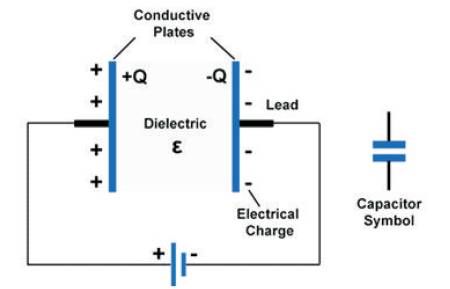

Where batteries work by using chemicals to store energy (Figure 19), capacitors use two conducting metal plates surrounding a dielectric insulator (Figure 20). Early capacitors could not store minimal quantities of charge compared to batteries and so were only used for rapid charging and discharging purposes. However more recent super capacitor technologies use much large plates with a reduced distance between the plates. This allows a far greater amount of charge to be stored, however their in-flexibility and bulky size suits them better towards electric and hybrid automotive vehicles.

Figure 19. how a battery works (Anon, 2014)

Figure 20. Capacitor diagram

Batteries have the ability to store large amounts of energy but have a low power density as they cannot discharge it quickly, where capacitors have a lower energy density but can deliver energy rapidly when needed. When incorporated into electronic textile fibres, the super capacitor has a far greater surface area to store charge creating the potential to exceed that of the lithium battery. (Casey, 2014)

Yuan Chen at the Nanyang Technological University combined a network of graphene and single-walled carbon nanotubes to produce a hybrid flexible fibre super capacitor up to 50m in length that can be woven into clothing, (Figure 21). It has huge amounts of accessible surface area – 396m2 per gram of fibre to store charge and even maintains its performance when flexed, making it perfect for flexible textiles. Despite being initially directed towards being woven into clothing for biomedical monitoring devices, the technology is being developed for low-cost, commercialize-able mass produced products. (Dingshan, 2013)

Figure 21. textile super capacitor(Bae, 2011)

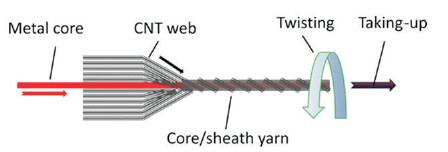

This is backed up by Zhang and Miaos’ work, who describe the main challenges for the future of the technology concerning its suitability for manufacture. The length of the super capacitors fibres need to be elongated and viable production technology developed to produce molecularly repeatable fibres on a mass scale. A proposed manufacturing method is described in Figure 22, however further research is required to scale it up to become commercially viable. (Daohong, 2014)

Figure 22. super capacitor manufacture (Daohong, 2014)

This technology shows huge potential for solving the power issue within current wearable textiles, although it won’t be ready to be incorporated within products for a good while yet.

While the successful development of fabric supercapacitors would revolutionize the e-textile industry, it would still require the user to charge them regularly. An ideal scenario would be for the textiles’ electronics to be able to charge itself from renewable sources of energy loss such as the users’ movements using piezoelectric materials, heat radiation and the environment. This is another field currently being researched into to power electronic textiles in a sustainable manner. (Stoppa, 2014)

The future applications of wearable technology is likely to be determined by science and technological developments as well as people’s views on wearable technology. As mentioned previously, the term wearable technology is highly ill-defined and has different meanings to different people. Therefore, there is little existing research which fully understands people’s views and expectations on wearable technology. Thus later primary research should be used to determine this.

The literature review has been extremely effective in answering the first two research questions by uncovering information about what wearable technology is as well as highlighting key applications in order to identify trends in its development from its origin to the present day. The review of numerous papers allowed conflicting views to be analysed to identify the current state of the art of electronic textiles along with its limitations to form insights on where the possible future may reside.

However, gaps in knowledge regarding the limitation and the future of wearable antennas were discovered. It has been established that as a result of the recent growth of the internet of things, the technology behind the wireless communication of electronic wearable textiles between each other and external systems is fundamental in enabling it to reach its full potential in the future. Therefore, further empirical research with relevant experts in the field is necessary to fill the gaps to make an informed and justified conclusion regarding the potential future of electronic wearable textiles.

Questionnaires are useful for gathering large amounts of quantitative data from a range of demographics based on a fixed set of questions.

Enables the collection of large amounts of quantitative data in order to gather large amounts of expert views to rank the severity of certain limitations.

Allows data to be collected and analysed quickly.

High efficiency as data can be collected whilst performing other tasks.

Low flexibility, unable to alter questions on the spot.New unconsidered issues may be brought up by the experts that were not previously considered prior to the questionnaire. An in-ability to adapt and adjust the line of questioning on the go could result in valuable information being missed.(Kumar,1999)

People may not take the questionnaire seriously and could fill it out quickly resulting in less reliable results. The limitations of wireless communications technology within wearable textiles could be quite broad. A questionnaire asks fixed questions and gives little opportunity to elaborate on answers or provide extra opinions.

The wearable technology experts answering the questionnaire are likely to have similar backgrounds and knowledge given that they work in similar areas, therefore, it is unlikely that a wide spread of data will be achieved and so a questionnaire may be inappropriate.

Kumar describes a semi or unstructured interview as one which allows the interviewer to come up with a basic framework or guide and then is able to formulate spontaneous questions during the interview.(Kumar,1999)

Useful to gain in-depth knowledge about the interviewers experiences with understanding the limitations of the wireless communications of wearable textile technology. Though not asking pre-determined questions, the expert is encouraged to elaborate on ideas.

Only using a limited number of pre-set questions allows the interviewer to respond to previous answers and ask user specific spontaneous questions to gain more indepth knowledge.

Time consuming having to visit experts in the field.

Experts may be difficult to get hold of who would be willing to have an interview.

Results gained are only representative of the individual rather than a population and so could be less reliable. A reduced number of responses will be gained from interviews compared to questionnaires which will reduce the reliability of the results, however selecting reputable experts to interview should eliminate this issue. The unstructured format of the questions could make comparability of subjects’ answers an issue. However, there is likely to be a minimal amount of quantitative data being required when investigating the research questions and so a huge amount of comparability will not be necessary.

A case study is the observation and analysis of an individual example of an experts work from their point of view. Instead of asking the expert direct questions which could potentially be misleading, the expert leads by explaining a project which is later questioned and analysed.

Avoids potentially misleading the expert by asking leading questions within a questionnaire or an interview to obtain more natural responses from their point of view.

Incredibly useful to examine key wearable textile projects that the expert has worked on that are directly linked to the research questions.

Observations of a project from an external position allow insights and limitations to be obtained that the expert may not have been aware of.

Limited comparability. Despite being on a similar topic, each project will be individual to each expert and so results may not be able to be compared.(Kumar,1999)

Blaxter(2006) refers to a possible difficulty in analysing results if the project within the case study is of a high complexity given that the researcher is not highly experienced within the field.(Blaxter,2006)

Both semi-structured interviews and case studies will be required to complete the empirical research in this study. Questionnaires are not necessary in this study as more indepth knowledge is required as opposed to gathering large amounts of basic quantitative data.

A semi-structured interview with an expert in wearable antennas will provide in-depth knowledge about its limitations in order to generate informed predictions about where the future of the industry lies. The semistructured nature facilitates the adaptation of questions on the go so that the interview can be tailored to the experts’ answers to gather an in-depth understanding of a somewhat complicated field.

Following the interview, case studies of projects involving wearable antennas will be invaluable to gain first-hand experience on current state of the art projects and build on knowledge from the interview. By understanding what is possible now, it will be easier to make a more informed prediction about what scientists should be able to achieve with the technology in the near future.

The Literature review established that wearable antennae is a key part of wearable electronics within textiles. The following research consists of interviews with expert researchers in wearable antennas including Dr Robert Edwards from Loughborough University and case studies on current state of the art wearable antenna projects being undertaken. It aims to discover the main limitations of wireless communication technology within electronic wearable textiles in order to make an informed prediction about where the technology is likely to progress.

One primary piece of technology within a vast amount of wearable electronics is the wearable antenna.

An antenna is a conductor that is able to send and receive signals in order to communicate from one device or system to another, such as a smart watch connecting to a phone via Bluetooth or google glass using wifi and GPS antennas to gauge the users’ location and gather data about their immediate environment. Dr Robert Edwards described that while this technology has been implemented successfully on rigid housed products outside the body, challenges arise when it is placed close to the body within flexible textiles as follows. Recent applications of wearable technology are dependent on gathering data from external sources, therefore making this technology reliable within textiles could be key to evaluating its future direction.

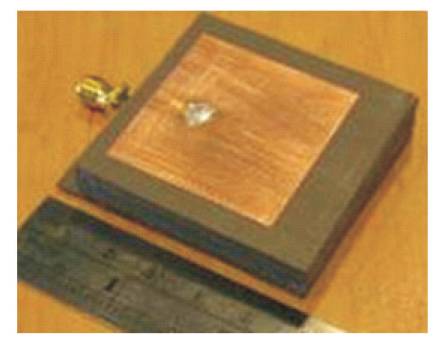

Figure 23 shows a copper impregnated textile patch antenna created by a Phd student at Loughborough University to investigate into the potential of wearable antennas. It consists of a layer of copper etched onto a layer of felt and dialetric substrate with an antenna connection breaching the top. The following findings were based on this case study combined with an interview with Dr Robert Edwards.

Figure 23. Textile patch antenna (Dr Robert Edwards)

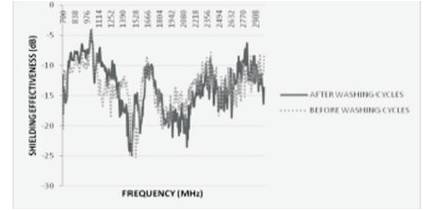

The antenna functioned well when placed on housed devices outside the body such as smart watches. However, when placed on or near the human body, the signal is damaged by an increased S11 return signal loss, as shown in Figure 24 which often reduces the strength by around 40 – 60%. (Zhang, 2014)

Figure 24. IPO antenna diagram

As referred to later in Figure 25, when antennas transmit between two different mediums, the resonant frequency of the signal changes thus varying its' efficiency. Wearing an antenna creates a large difference in dielectric properties between the human tissue and the outside air that the signal must transmit through. This cause of discontinuity causes variances in the resonant frequency resulting in a large signal reflection.

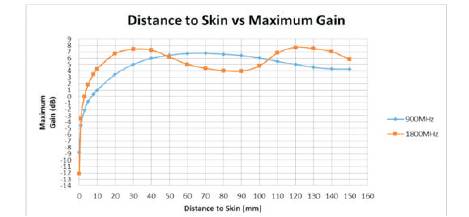

Figure 25. Wearable signal vs distance to the body graph (Russel, 2012)

This is supported by Russel who investigated into the gain of an antenna against various' distances to the skin at two resonant frequencies. Here the recommended offset of an antenna to the human skin is at least 10mm with an optimal signal gain at 20-40mm offset. This problem has been researched into for several years however limited progress has been made. This suggests that with the current technology, it would be advised that a future wearable e-textile should be placed away from the body on a thick coat rather than on a t-shirt for it to be able to transmit a reliable wireless signal.

This limitation greatly narrows the possible future applications of wearable textiles.

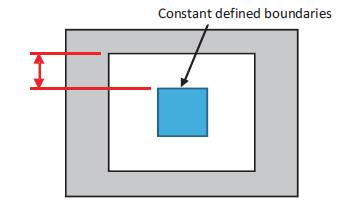

The shape and rigidity of a material is another factor which affected the performance of the wearable antenna. Antennas work by radiating a signal from a precise gap, x, between two conducting layers.

As Figures 26-27 show, metals are very stiff and have defined edges which allow distance x to be controlled. Where textile edges are inherently flexible and tiny changes of shape, even by a single strand of fibre, can have a large effect on its conductive properties and the strength of the signal it radiates.

Figure 26. metallic wearable antenna

Figure 27. Fabric wearable antenna

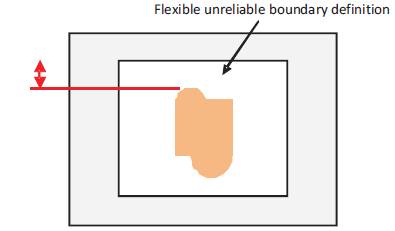

In Figure 28, Purohit and Raval back this up further by showing the effect that this un-constrainable shape boundaries has on the resonant frequency and signal loss of an antenna. In order to maximise efficiency, an antenna should be tuned to its resonant frequency, point A. With current technology, it is difficult to precisely maintain this within textiles as slight changes in the shape of the material cause the frequency to fluctuate resulting in signal loss, point B. (Purohit, 2013)

Figure 28. Effect of shape of a textile antenna on its resonant frequency and signal loss (Purohit, 2013)

Today a challenge is faced to find a compromise between maximising the flexibility of a textile antenna whilst maintaining an appropriate output signal. As was found previously, this limits its use to be placed on rigid items of outer clothing such as military jackets where a suitable stiffness level can be achieved.

While metallic fibres can maintain their dielectric properties over time, fabrics are found to deteriorate and lose conductivity when washed.

In an interview Edwards described how the effectiveness of a textile antenna is proportional to its size in comparison to the resonant frequency of the material. When common textile materials such as wool or cotton are washed, they shrink in size as the fibres contract and lose conductivity. This limits its future applications to rare extreme situations as opposed to daily mass consumer use.

When washed the chemical properties of a textile also change over time which affects its conductivity. When purchased wool contains lots of oils present from its manufacture. When repeatedly washed these oils are released from the fabric thus changing its dielectric properties. This makes it highly difficult to engineer the optimal resonant frequency of an antenna to maximise the signal output.

Over time the loose fibres on the surface of a fabric can become entangled in a process called pilling as shown in Figure 29. Despite only being a big problem on loose textiles such as wool, Pilling can have a large effect on the capacitance and inductance of a materials surface.

Figure 29. Pilling (Hariey, 2012)

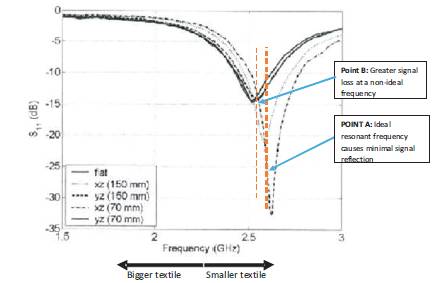

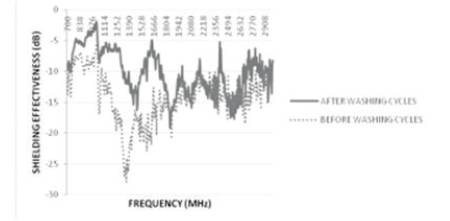

Kayacan work also backed up the knowledge presented by Edwards’ interview. He investigates into the effect of washing on conductivity, or shielding effectiveness, of both loose and interlocked fabrics due to pilling. Figures 30-31 clearly show a change in the shielding effectiveness of both single jersey and interlocked fabrics.

Figure 30. EMSE of interlocked fabrics (Kayacan, 2014)

The shielding effectiveness difference is clearly greater in the loose fabric in Figure 31, especially around the 800 – 1700MHz frequency range. This demonstrates that the pilling and surface degradation of fabrics due to washing would be a major concern for the future of embedding electronics within mass market goods. (Kayacan, 2014)

Figure 31. EMSE of single jersey loose fabrics (Kayacan, 2014)

Therefore, a wearable textile needs to be developed that can maintain its geometric profile when washed if it is to be viable for the future. It would seem more likely however for electronics to be removable from clothes prior to washing. Another solution would be to only use the technology within items of clothing that require minimal washing such as jackets.

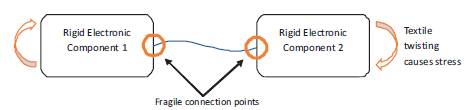

Edwards also described a common problem with wiring between components which is also an issue within wearable electronics. Physical electronic components such as PCB’s and sensors etc are highly rigid and solid, while textiles are highly flexible. When electronic components are wired together on a flexible surface, movements in the fabric are likely to cause wiring failures and breakages at the fragile end points as highlighted in Figure 32.

Figure 32. fragile wiring issue

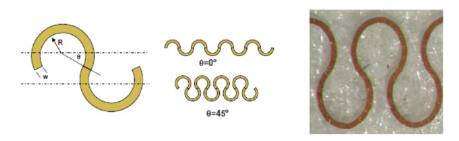

A way of combatting this is to create a stretchable interconnected wiring structure between components as shown in Figure 33. Here a series of horseshoe shapes formed by the wiring connections enable them to stretch and deform as the textile moves, thus reducing the chances of failure.

Figure 33. stretchable interconnected wiring structure (Stoppa, 2014)

While this does reduce the severity of the problem, connection failures do still occur. Connection failures in a future consumer product would clearly not be acceptable, and thus highlights the need to perfect the wearable antenna technology to allow data to be communicated wirelessly rather than through wires if it is to be successful.

Edwards described another problem regarding the need to maintain the consistency of the textiles materials' weaved fibre structure during manufacture. If the conductivity properties of textiles is to be controlled in manufacture, each unit needs to have an identical substructure. While this is easily achieved in other metal and polymer processes such as injection moulding and casting, the same is not true for textiles.

Without embedded electronics, repeatability was not previously a concern within textiles. As long as each unit was about the same size and felt roughly the same to the customer it would sell. Therefore, the poor repeatability of natural fibre material was not a concern. Felt material is often used in pool tables as well as wearable antennas due to manufacturing processes being able to produce repeatable samples on a micro level. However, felt is not a desirable material for clothing.

This reflects the minimal research taken into developing manufacturing processes that produce repeatable textiles on a molecular level. Therefore, the future of wearable textiles either requires the development of better repeatable manufacturing processes for natural fibres, or the invention of a new material that is as repeatable as felt, with current manufacturing processes yet mirrors the desirability and comfort of natural fibres.

The drape-ability of a textile is defined as the ‘ability of a fabric to conform to a complex surface’ (Gurit, 2015). Clearly this is an important characteristic of a wearable textile. The more drape-able a material is, the more comfortable it will feel, but the worse it will perform as an antenna also. Therefore, further research is required to either develop a new material or establish an acceptable compromise between conductivity and comfort.

The aim of this study was to research into wearable technology to identify its limitations and trends in order to predict its potential future development. The literature review was successful in defining what wearable technology is within textiles, identifying its trends to the present state of the art and exploring its technological limitations. A future need for a focus on the wireless communication of wearable electronic textile devices was established. Further antenna patch case studies combined with a semi-structured interview with wearable antenna experts was key to narrowing down the main challenges that the technology faces, to suggest a recommended future development direction.

Justified predicted future direction of electronic wearable textiles were,

1. Electronic wearable textiles will be placed on rarely washed rigid items of clothing such as jackets that are not worn close to the body.

Dr Robert Edwards' wearable patch antenna case study highlighted a problem of the absorption of an antenna signal when within 10mm of the body. This has been researched into for many years and still isn't resolved and so is unlikely to be solved in the near future.

The resonant frequency of a textile wearable antenna changes, as the shape is flexed. Therefore, the rigidity of the medium it is placed upon, should be maximised to optimise its performance.

The largest problem highlighted in the literature review and interviews was the detrimental effect washing electronic textiles has on its surface quality and conductivity. Current trends indicate that a washable electronic fibre is not going to be developed in the near future and so placing attaching electronics to rarely washed items of clothing is essential to maintain performance.

2. Electronic wearable devices will be worn as an accessory and will not be integrated directly into clothes.

In mass or batch manufacture the consistence of the conductivity of a hybrid textile is partly determined by the consistency of its microstructure. At present manufacturing processes are not developed enough to produce natural/ metal hybrid fibres that are repeatable and thus will display great ranges in performance. Little research has been put into developing repeatable mass manufacturing processes to date and thus can only be integrated as a hybrid accessory in order to ensure consistent performance between units.

User needs for clothing customisation has resulted in a great range of clothes on the market. It would be a waste of money and resources to incorporate the technology into all items of clothing and consumers probably wouldn't like to be restricted to a single style of jacket in order to access its embedded electronics. Therefore, the evidence suggests that the attachment of external electronic wearables such as Buechleys hybrid fibres and the wearable patch antenna to clothing is the only future option.

3. Electronic wearable textiles will not make its way into mass consumer goods in the near future but will remain specialised in the military and emergency services.

Justified through above user customisation and limitations in mass manufacturing technologies.

This paper has paid particular focus on the technological aspects which could influence the future development of wearable textiles. Despite being briefly touched upon in the literature review, other factors such as ethics, morals, economic, sustainable and user needs could be researched into, to establish how much of an impact they have on the future of wearable electronic textiles.

This paper has also paid little attention to the effect of using different metallic materials combined with different types of fibres on the conductivity and performance of an electro-textile. Research could determine whether different materials has implications on the feasibility of different technologies which could affect its future.