Figure 1. Line Follower Robot

Agriculture plays a very important role in human survival. Now - a - days, the availability of manual power has gradually reduced. In order to reduce the manual work power in the field of agriculture, the authors have proposed a model of multi-purpose agricultural robot to perform dropping seeds, monitoring crops, de-weeding, irrigation and pesticide supply. To provide a proper monitoring, the authors have used a technique of the line following robots. This will involve efficient utilization of water resources, intensive plant and soil monitoring, condition based use of fertilizers and the ability to work in unstructured environments.

Automation in any working field will make the humans to work comfortably. In recent years, the industrial automation is growing very rapidly, but the automation in the field of agriculture has not developed much. Due to increasing growth of population, the necessity of food also will increase simultaneously. In future, it is going to be a big challenge for providing nutritious, safe and healthy food for such population. The productivity is reducing due to some drawbacks, such as wastage of water and seeds, improper spraying of pesticide by the traditional methods. To make the agriculture more modern automation can be used for all these operations and through this humans can be prevented from harmful pesticides. The robot will do pesticide spraying, dropping of seeds and water supply more accurately and automatically. The power is obtained from a solar panel. The operations of the robot using a solar panel is obtained from the sun energy. So this robot will be eco-friendly [8,9] .

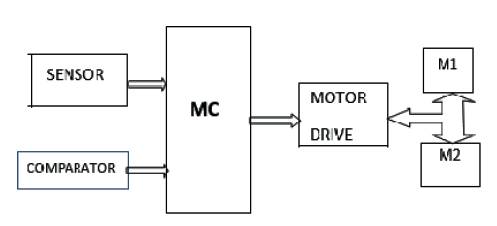

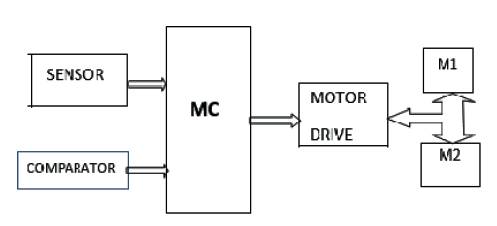

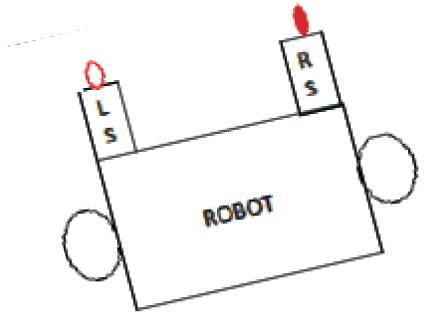

Line Follower Robot methodology is used in the agriculture field for tracking purposes. Block diagram for Line Follower Robot is shown in Figure 1.The robot circuit consists of sensor circuit, comparator, microcontroller and motor drive.

Figure 1. Line Follower Robot

Sensor circuit used in the system for tracking purpose detects the obstacles present in its path [1-5].

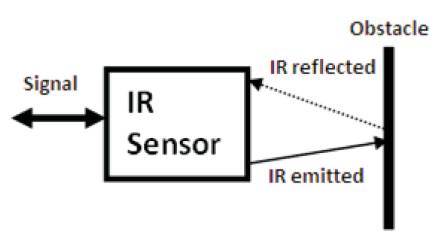

The IR sensor circuit consist of a transmitter and a receiver. For the transmission purpose, an IR LED is used, which reflects its light on either white line or soil. Here in agriculture field, the soil is considered as a dark surface because of its brown colour in nature [6]. The white line is used in the field for tracking when emitting a light towards, it. IR Sensor is shown in Figure 2.

Figure 2. IR Sensor

The surface of white line will be a good reflector so that, more light will fall on the photo diode. Because of the bad reflection of the photo diode, output voltage of white surface will be more than the soil surface.

Comparator used here is a simple LM358 IC, which will compare the output voltage of white surface and the soil surface with the reference voltage. So it will be set like, the reference voltage will be greater than soil colour voltage and less than white line voltage.

The output of the comparator is given to the microcontroller (89c51), which will take the control action according to the comparator output. The action of microcontroller can be explained in three different conditions.

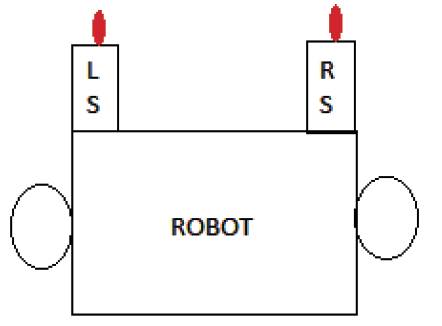

At this condition, both the Motors M1 and M2 will be ON. Due to this condition, the robot will follow the straight white line path and it is shown in Figure 3.

Figure 3. Moving Straight

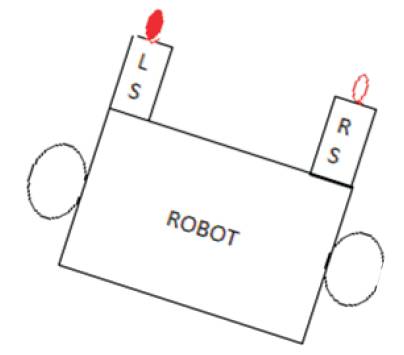

In this situation, the left sensor detects the soil colour voltage where the right sensor is on white track. To take right turns, the right motor will go to the OFF condition and the left sensor will sense to detect the soil colour voltage. Still the left motor will be in ON condition, which forces the robot to move in a right side. Once it moves in right side, the robot can find the white line path and now the right motor will also get ON. So the normal operation will continue. The operation is shown in Figure 4.

Figure 4. Bending Right

To perform the action of taking left, the right sensor detects the soil colour voltage, still the left sensor is on White track. To take the left turn, the left motor will go to OFF condition. And the right motor is still ON condition, which forces the robot to move in, the left direction. Once it moves in, the left direction, the robot finds the white line path, and the left motor gets ON. And the normal operation will continue. The operation is shown in Figure 5.

Figure 5. Bending Left

So, the tracking concept of the robot is done using a line follower robot. Functioning and application of the robot, while the robot is on white track is to provide the delay the function in the farm at equal distance.

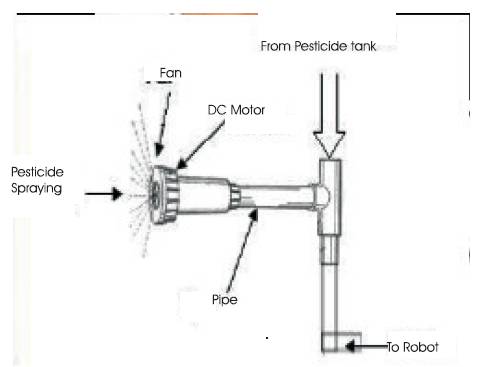

The pesticide from the tank is pumped through the rubber tube to the fan blade at the shaft of the DC motor, which revolves at the delay time of the robot or in front of the crop. Because of the revolution, the liquid pesticide gets sprayed on the crop. The standard time delay is maintained in the robot for spraying pesticide or the amount of time for which the robot need to stand in front of the crop [9]. Pesticide Spraying is shown in Figure 6.

Figure 6. Pesticide Spraying

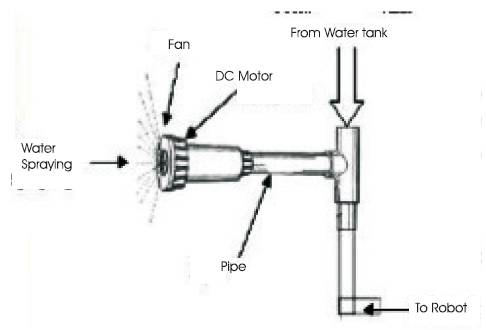

The water source is the most important source in the field of agriculture field. This system will avoid the wastage of water. The rubber pipe will carry the water from the tank, the water is taken to the fan blade, which is attached with a DC motor. During the rotation of the DC motor, the water will sprinkle in front of the crop alone. By keeping the delay time, the actual amount of water needed for the crop can be decided. It will provide a sufficient amount of water to the crop, so it minimizes the wastage of water. It also overcomes the requirement of sprinkle and drip irrigation system, and is less costly and easy for construction [9].

The mechanism of stepper motor is used for dropping seeds. A special mechanical head is located at the shaft of the stepper motor for this purpose. Water supply is shown in Figure 7.

Figure 7. Water Spraying Mechanism

When the robot reaches the location for dropping the seed, the stepper motor moves in a clockwise direction. The tip of the stationary as well as the rotator container gets matched due to the clock wise rotation of the stepper motor. Once the tips meet , the seeds gets path to drop in the farm. After a very small delay time, the stepper motor is programmed to move in the anticlockwise direction with same angle and again, the tips gets closed. In this way, the controlling action of motor takes place at equal distance of farm, and it also measures the dropped quantity of seeds in the field.

The supply for the robot is obtained from the solar panel, which can produce electricity from sun energy. Due to the implementation using solar energy, this robot is eco- friendly and more useful for the farmers, because the sun energy is a standard source available by nature as we can obtain electricity regularly. In case of rainy season, the battery in the robot will store the electricity during the time when the sunlight is available, and that can be utilised for the later use.

This can be easily achieved by attaching the rotavator behind the robot. For this application, the authors are supposed to give a good mechanical strength to the robot, because it is quite heavy and when it is placed on soil for ploughing purpose, it requires an extra force to move forward. This is the initial operation in the farm. So this application does not require no time delays. Once it is placed on the farm, it continuously tracks the white line on the farm and do ploughing through the rotavator.

From this project, the authors conclude that by implementing this robot helps human to perform major works in the field of agriculture automatically and accurately. This robot is more useful in the fruit cropping field of agriculture. Spraying pesticide prevents exposure to humans from the harmful pesticides and the accurate amount of pesticide needed by the plant is sprayed, which gives a healthy fruit and the spraying of accurate amount of water reduces the wastage of water and this improves the growth of the fruit. So if this method is implemented is the field of agriculture, it can improve the quality of productions as well as yields a healthy fruit [7].